height DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 128 of 513

CHASSIS

Ii

t

L

1

J

rJ

I

e

i

L

rubber

parts

und

alcohol

long

than

30

seconds

After

the

parts

are

cleaned

dry

them

with

com

pressed

air

Check

the

cylinder

and

piston

for

damage

and

uneven

wear

on

the

sliding

surface

and

for

other

defective

conditions

Replace

as

required

2

Replace

if

the

cylinder

and

piston

clearance

is

more

than

0

15

mm

0

006

in

3

In

principle

replace

the

piston

cup

packing

and

valves

with

new

ones

whenever

the

master

cylinder

is

disassembled

Be

sure

to

replace

if

damaged

worn

weakened

or

expanded

4

Check

the

return

springs

for

wear

damage

and

other

defective

conditions

and

replace

as

required

5

Replace

others

if

deformed

damaged

or

defective

Reassembly

Assemble

the

master

cylinder

in

reverse

sequence

of

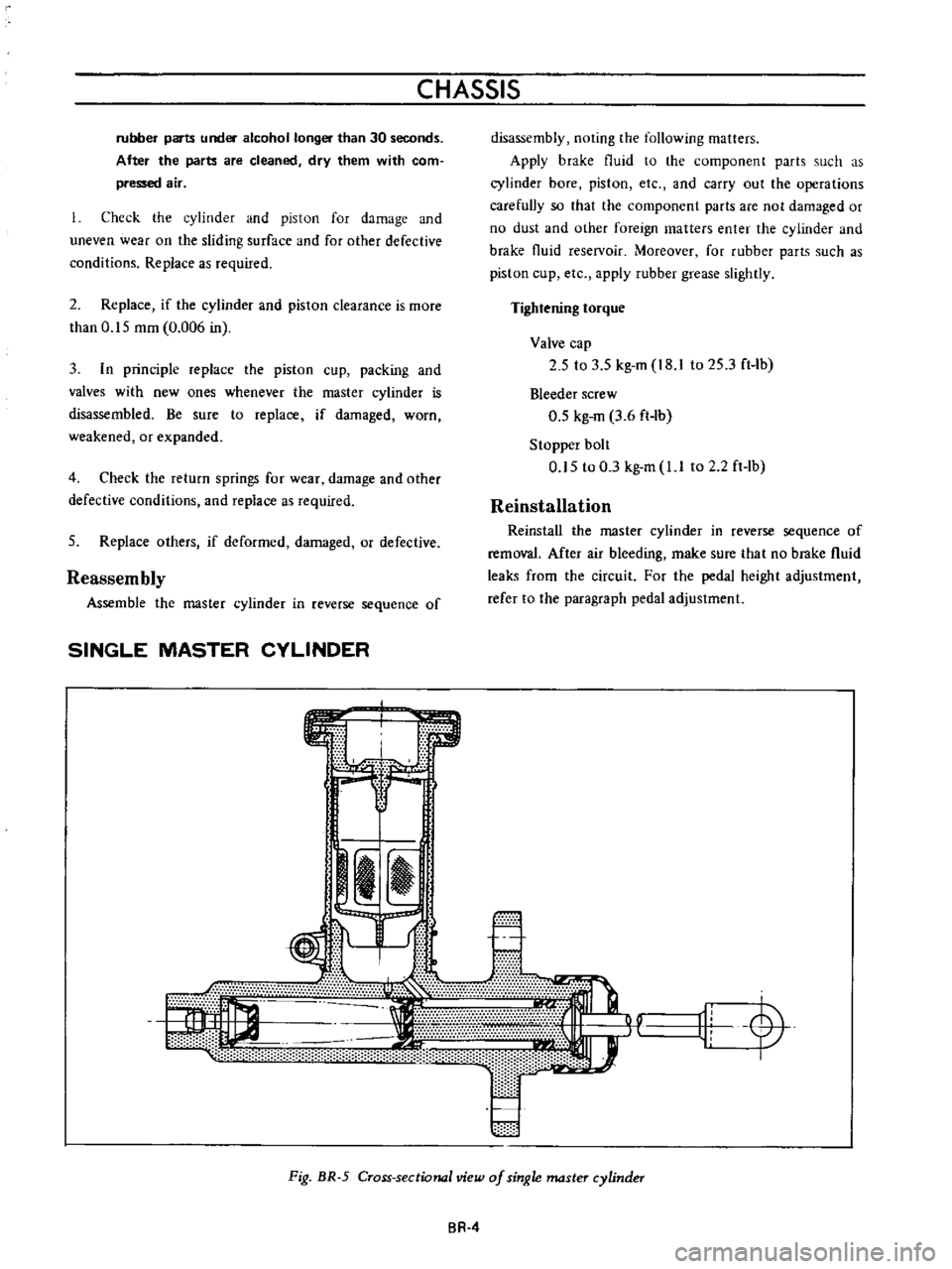

SINGLE

MASTER

CYLINDER

s

m

e

disassembly

noting

the

following

matters

Apply

brake

fluid

to

the

component

parts

such

as

cylinder

bore

piston

etc

and

carry

out

the

operations

carefully

so

that

the

component

parts

are

not

damaged

or

no

dust

and

other

foreign

matters

enter

the

cylinder

and

brake

fluid

reselVoir

Moreover

for

rubber

parts

such

as

piston

cup

etc

apply

rubber

grease

slightly

Tightening

torque

Valve

cap

2

5

to

3

5

kg

m

I8

to

25

3

ft

Ib

Bleeder

screw

0

5

kg

m

3

6

ft

lb

Stopper

bolt

0

5

to

0

3

kg

m

l

I

to

2

2ft

lb

Reinstallation

Reinstall

the

master

cylinder

in

reverse

sequence

of

removal

After

air

bleeding

make

sure

that

no

brake

fluid

leaks

from

the

circuit

For

the

pedal

height

adjustment

refer

to

lhe

paragraph

pedal

adjustment

r

11L

y

Fig

BR

5

Cross

sectional

view

of

single

master

cylinder

BR

4

Page 145 of 513

BRAKE

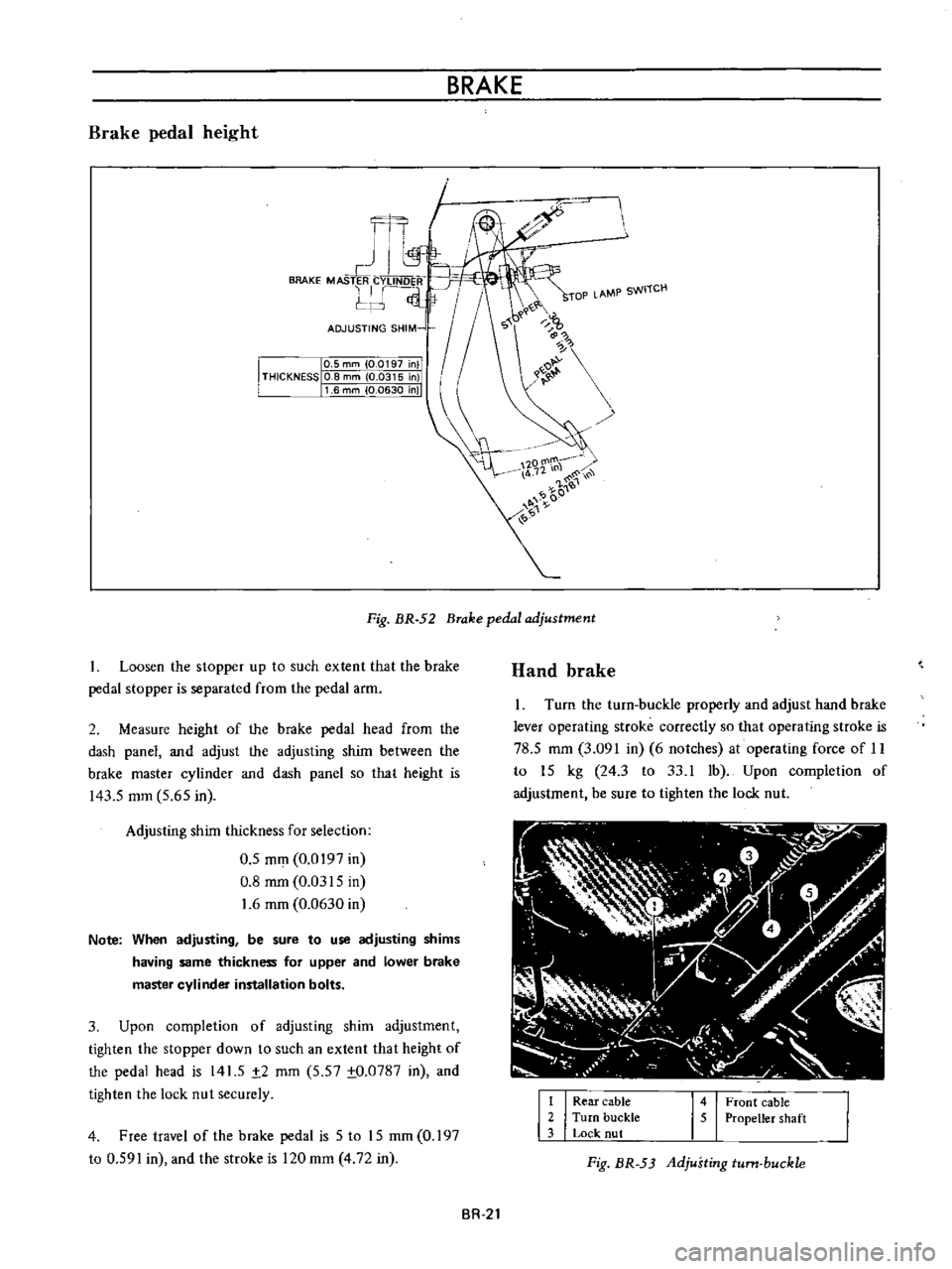

Brake

pedal

height

I

Fl

I

Jl

BRAKE

MASTER

CYllN

ADJU

SHI

1

I

195mm

001971011

THICKNESSIO

8

mm

00315

Inl

116mm

00630In

TOP

LAMP

SWrTCH

r

b

O

ZOlTlI

I

A

12

n

Y

1

O

09

ttr

i

l

Fig

BR

52

Brake

pedal

adjustment

1

Loosen

the

stopper

up

to

such

extent

that

the

brake

pedal

stopper

is

separated

from

the

pedal

arm

2

Measure

height

of

the

brake

pedal

head

from

the

dash

panel

and

adjust

the

adjusting

shim

between

the

brake

master

cylinder

and

dash

panel

so

that

height

is

143

5

mm

5

65

in

Adjusting

shim

thickness

for

selection

0

5

mm

0

0197

in

0

8

mm

0

0315

in

1

6

mm

0

0630

in

Note

When

adjusting

be

sure

to

use

adjusting

shims

having

same

thickness

for

upper

and

lower

brake

master

cylinder

installation

bolts

3

Upon

completion

of

adjusting

shim

adjustment

tighten

the

stopper

down

to

such

an

extent

that

height

of

the

pedal

head

is

141

5

t2

mm

5

57

to

0787

in

and

tighten

the

lock

nut

securely

4

Free

travel

of

the

brake

pedal

is

5

to

15

mm

0

197

to

0

591

in

and

the

stroke

is

120

mm

4

72

in

Hand

brake

Turn

the

turn

buckle

properly

and

adjust

hand

brake

lever

operating

stroke

correctly

so

that

operating

stroke

is

78

5

mm

3

091

in

6

notches

at

operating

force

of

11

to

15

kg

24

3

to

33

1

1b

Upon

completion

of

adjustment

be

sure

to

tighten

the

lock

nut

I

I

Rear

cable

2

Turn

buckle

3

Lock

nut

1451

Front

cable

Propeller

shaft

Fig

BR

53

Adjusting

turn

buckle

BR

21

Page 146 of 513

CHASSIS

2

Upon

completion

of

the

adjustment

release

the

hand

brake

lever

and

make

sure

that

the

rear

wheels

are

not

braked

Normal

stroke

78

5

mm

3

091

in

6

notches

Limited

stroke

136

0

mm

5

35

in

10

notches

The

term

Stroke

means

height

from

the

standard

position

220

mm

8

7

in

above

the

hand

brake

lever

fulcrum

Note

Readjust

hand

brake

stroke

when

it

reaches

the

limited

stroke

136

mm

5

35

inl

10

notches

Bleeding

hydraulic

system

Bleeding

the

hydraulic

brake

system

deserves

much

attention

as

it

is

an

essential

factor

for

regular

service

brake

operation

As

a

matter

of

fact

during

the

brake

service

air

is

likely

to

creep

into

the

circuit

with

the

result

that

the

fluid

action

is

altered

and

the

brake

pedal

becomes

spongy

at

the

travel

end

Bleeding

should

be

carried

out

at

first

with

the

masler

cylinder

then

from

the

longest

line

from

the

master

cylinder

and

then

finish

up

with

the

shortest

Note

Always

clear

away

any

dirt

around

master

cylinder

reservoir

cover

before

removing

cover

for

any

reason

Never

depress

pedal

while

brake

drums

are

removed

unless

bleeder

valve

is

open

Top

up

the

reservoir

master

cylinder

with

fluid

of

the

recommended

type

2

Thoroughly

wipe

the

bleeder

screw

and

from

any

mud

or

dust

present

so

that

the

outlet

hole

is

free

from

foreign

matter

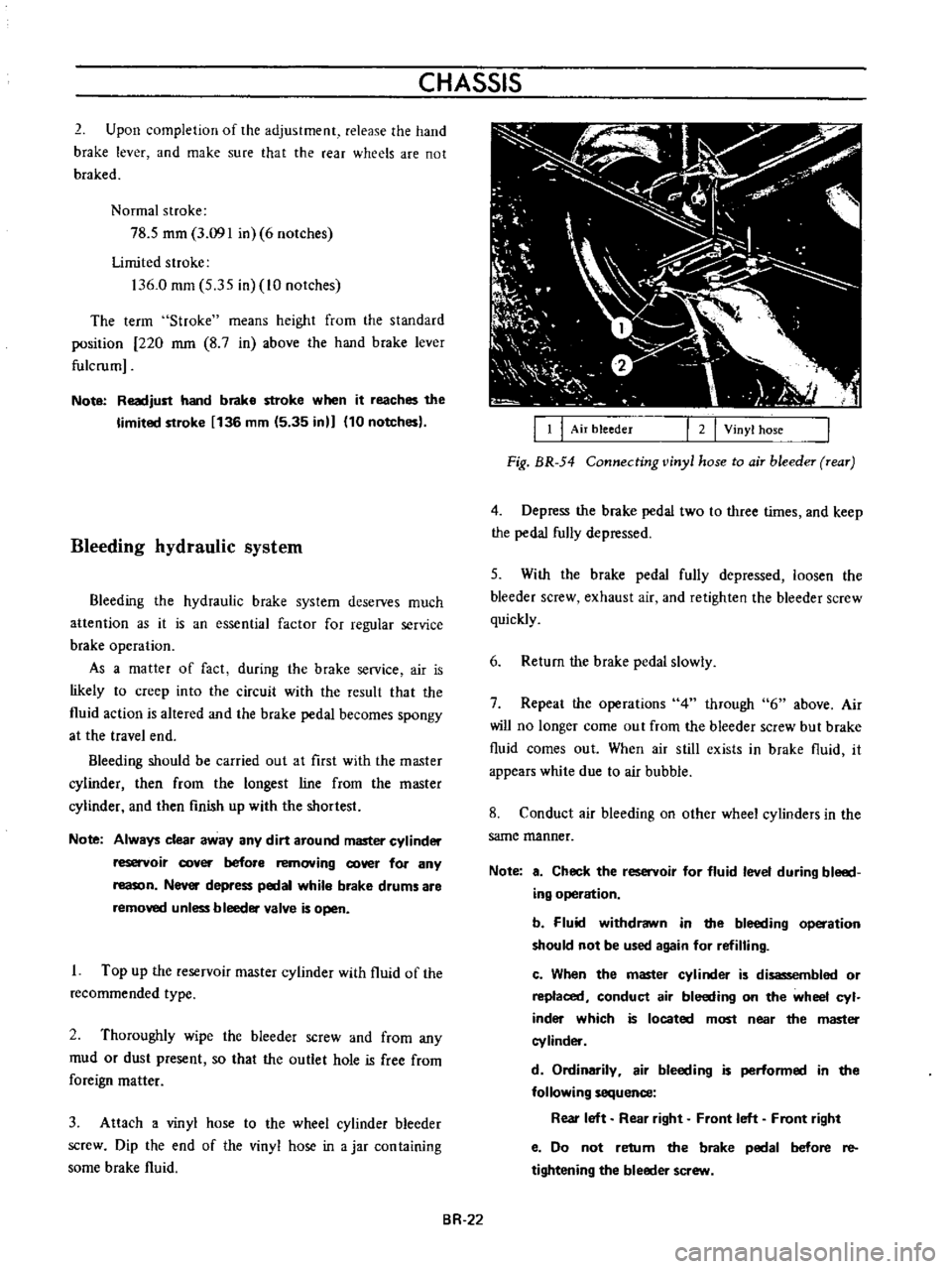

3

Attach

a

vinyl

hose

to

the

wheel

cylinder

bleeder

screw

Dip

the

end

of

the

vinyl

hose

in

a

jar

con

taining

some

brake

fluid

BR

22

I

I

I

Air

bleeder

I

2

I

Vinyl

hose

Fig

BR

54

Connecting

vinyl

hose

to

air

bleeder

rear

4

Depress

the

brake

pedal

two

to

three

times

and

keep

the

pedal

fully

depressed

5

With

the

brake

pedal

fully

depressed

loosen

the

bleeder

screw

exhaust

air

and

retighten

the

bleeder

screw

quickly

6

Return

the

brake

pedal

slowly

7

Repeat

the

operations

4

through

6

above

Air

will

no

longer

come

out

from

the

bleeder

screw

but

brake

fluid

comes

out

When

air

still

exists

in

brake

fluid

it

appears

white

due

to

air

bubble

8

Conduct

air

bleeding

on

other

wheel

cylinders

in

the

same

manner

Note

a

Check

the

reservoir

for

fluid

level

during

bleed

ing

operation

b

Fluid

withdrawn

in

the

bleeding

operation

should

not

be

used

again

for

refilling

c

When

the

master

cylinder

is

disassembled

or

replaced

conduct

air

bleeding

on

the

wheel

cyl

inder

which

is

located

most

near

the

master

cylinder

d

Ordinarily

air

bleeding

is

performed

in

the

following

sequence

Rear

left

Rear

right

Front

left

Front

right

e

Do

not

retum

the

brake

pedal

before

re

tightening

the

bleeder

screw

Page 147 of 513

BRAKE

SERVICE

DATA

AND

SPECIFICATIONS

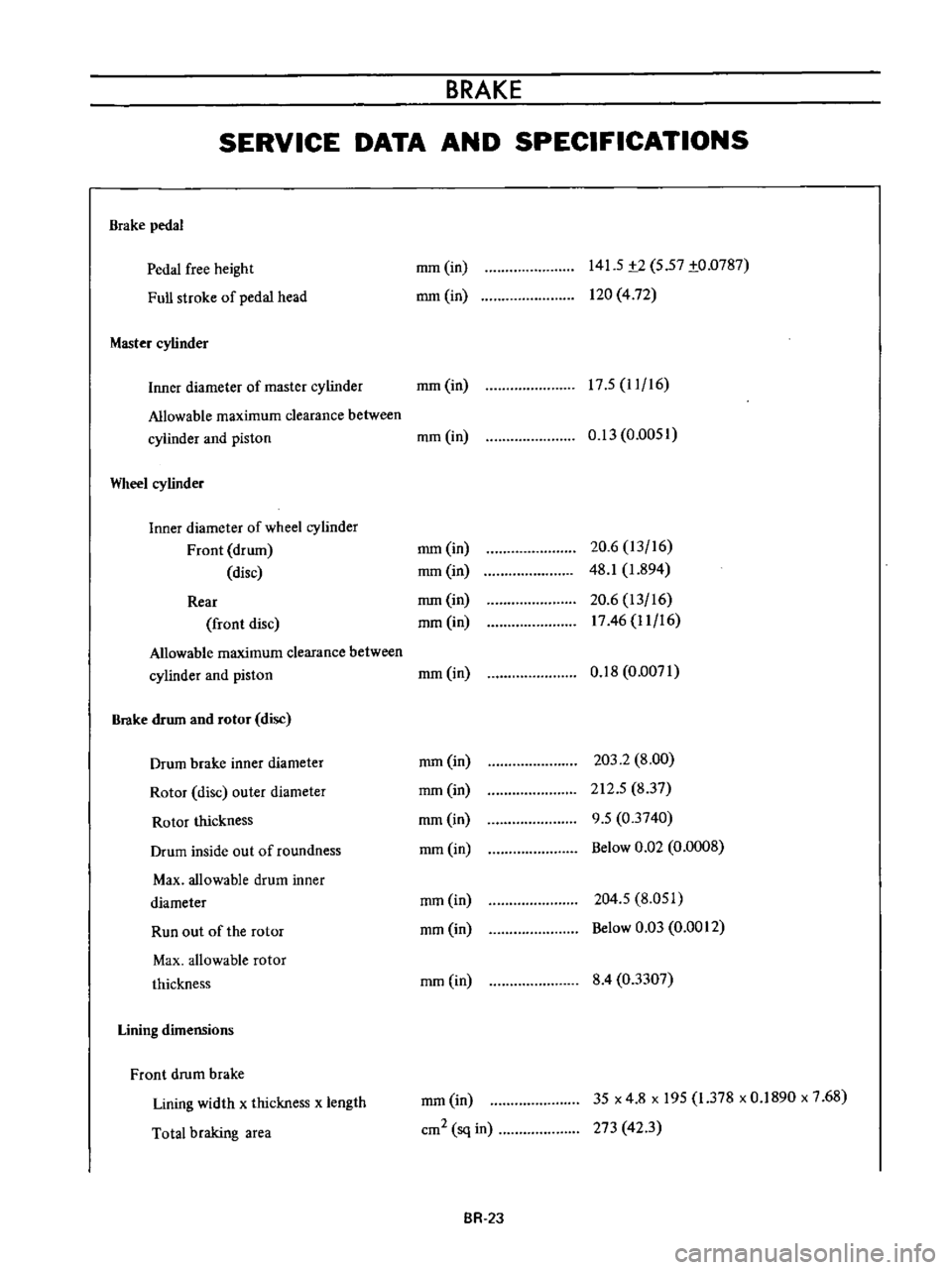

Brake

pedal

Pedal

free

height

Full

stroke

of

pedal

head

Master

cylinder

mm

in

mm

in

141

5

t2

5

57

to

0787

120

4

72

17

5

11

16

Inner

diameter

of

master

cylinder

mm

in

Allowable

maximum

clearance

between

cylinder

and

piston

mm

in

Wheel

cylinder

Inner

diameter

of

wheel

cylinder

Front

drum

disc

Rear

front

disc

Allowable

maximum

clearance

between

cylinder

and

piston

Brake

drum

and

rotor

disc

Drum

brake

inner

diameter

Rotor

disc

outer

diameter

Rotor

thickness

Drum

inside

out

of

roundness

Max

allowable

drum

inner

diameter

Run

out

of

the

rotor

Max

allowable

rotor

thickness

Lining

dimensions

Front

drum

brake

Lining

width

x

thickness

x

length

Total

braking

area

0

13

0

0051

mm

in

mm

in

mm

in

mm

in

20

6

13

16

48

1

1

894

20

6

13

16

1746

11

16

mm

in

0

18

0

0071

mm

in

mm

in

mm

in

mm

in

203

2

8

00

212

5

837

9

5

03740

Below

0

Q2

0

0008

mm

in

mm

in

204

5

8

051

Below

0

03

0

0012

mm

in

8

4

03307

mm

in

cm2

sq

in

35

x

4

8

x

195

1

378

x

0

1890

x

7

68

273

423

BR

2J

Page 149 of 513

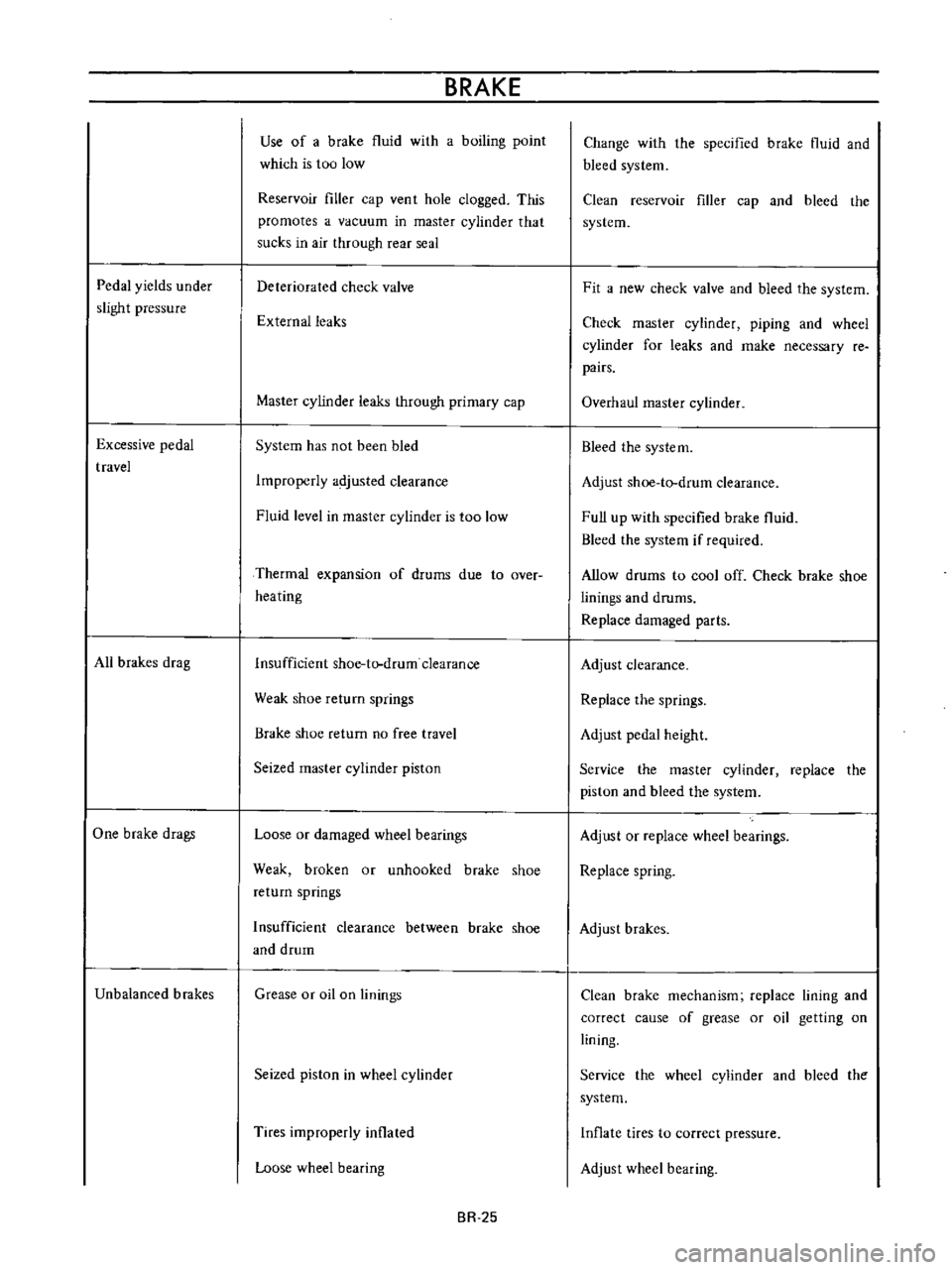

Pedal

yields

under

slight

pressure

Excessive

pedal

travel

All

brakes

drag

One

brake

drags

Unbalanced

brakes

BRAKE

Use

of

a

brake

fluid

with

a

boiling

point

which

is

too

low

Reservoir

filler

cap

ven

t

hole

clogged

This

promotes

a

vacuum

in

master

cylinder

that

sucks

in

air

through

rear

seal

Deteriorated

check

valve

External

leaks

Master

cylinder

leaks

through

primary

cap

System

has

not

been

bled

Improperly

adjusted

clearance

Fluid

level

in

master

cylinder

is

too

low

Thermal

expansion

of

drums

due

to

over

heating

Insufficient

shoe

tlrdrum

clearance

Weak

shoe

return

springs

Brake

shoe

return

no

free

travel

Seized

master

cylinder

piston

Loose

or

damaged

wheel

bearings

Weak

broken

or

unhooked

brake

shoe

return

springs

Insufficient

clearance

between

brake

shoe

and

drum

Grease

or

oil

on

linings

Seized

piston

in

wheel

cylinder

Tires

improperly

inflated

Loose

wheel

bearing

BR

25

Change

with

the

specified

brake

fluid

and

bleed

system

Clean

reservoir

filler

cap

and

bleed

the

system

Fit

a

new

check

valve

and

bleed

the

system

Check

master

cylinder

piping

and

wheel

cylinder

for

leaks

and

make

necessary

re

pairs

Overhaul

master

cylinder

Bleed

the

system

Adjust

shoe

to

drum

clearance

Full

up

with

specified

brake

fluid

Bleed

the

system

if

required

Allow

drums

to

cool

off

Check

brake

shoe

linings

and

drums

Replace

damaged

parts

Adjust

clearance

Replace

the

springs

Adjust

pedal

height

Service

the

master

cylinder

replace

the

piston

and

bleed

the

system

Adjust

or

replace

wheel

bearings

Replace

spring

Adjust

brakes

Clean

brake

mechanism

replace

lining

and

correct

cause

of

grease

or

oil

getting

on

lining

Service

the

wheel

cylinder

and

bleed

the

system

Inflate

tires

to

correct

pressure

Adjust

wheel

bearing

Page 181 of 513

CHASSIS

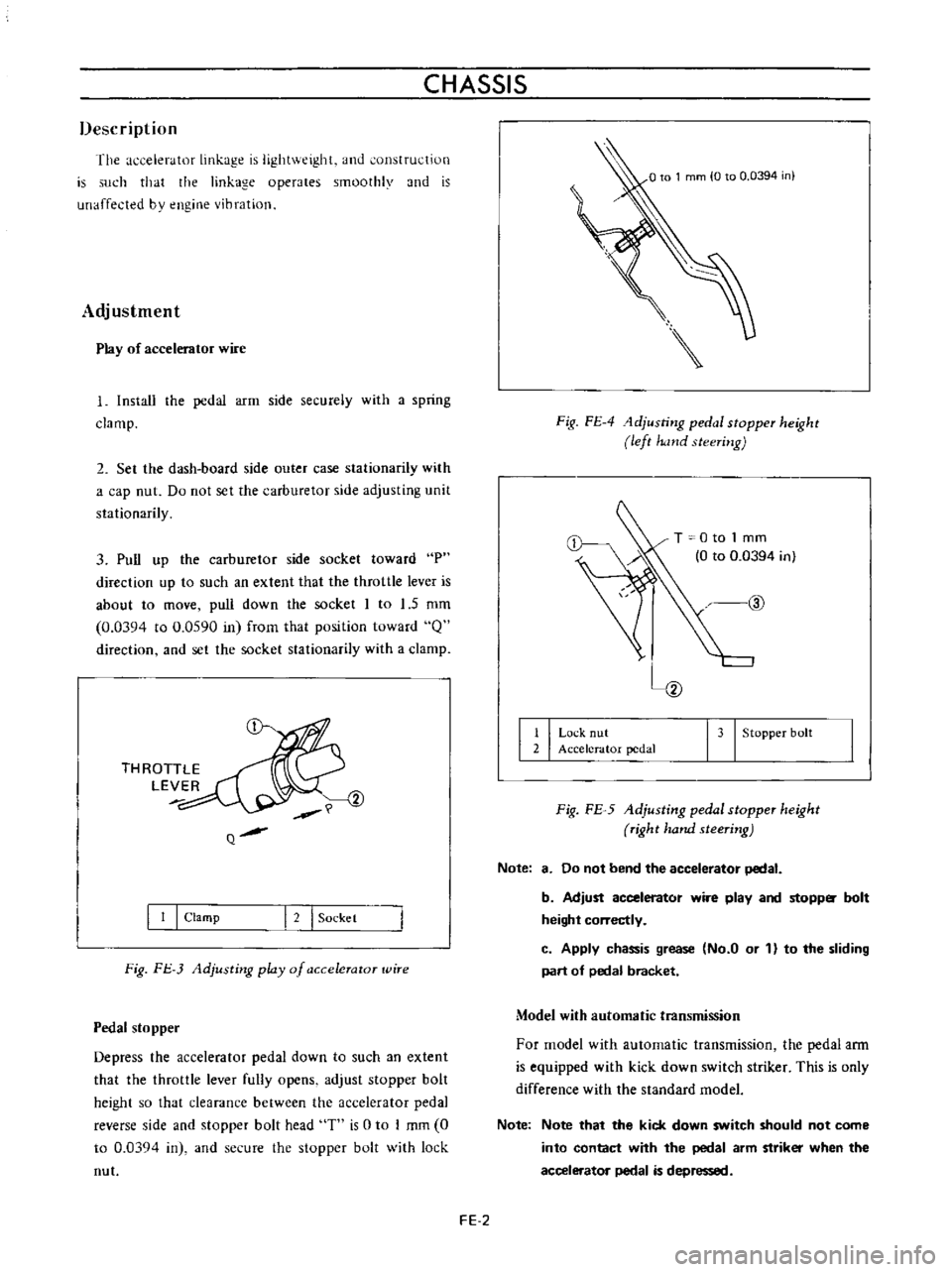

Description

The

accelerator

linkage

is

lightv

eighL

and

onstfuction

is

such

that

the

linkage

operates

smoothly

and

is

unaffected

bv

engine

vibration

Adjustment

Play

of

accelerator

wire

I

Install

the

pedal

arm

side

securely

with

a

spring

clamp

2

Set

the

dash

board

side

Quter

case

stationarily

with

a

cap

nut

Do

not

set

the

carburetor

side

adjusting

unit

stationarily

3

Pull

up

the

carburetor

side

socket

toward

P

direction

up

to

such

an

extent

that

the

throttle

lever

is

about

to

move

pull

down

the

socket

I

to

1

5

mm

0

0394

to

0

0590

in

frorn

that

position

toward

Q

direction

and

set

the

socket

stationarily

with

a

clamp

THROTTLE

LEVER

Q

I

I

I

Clamp

I

2

I

Sockel

Fig

FJ

3

Adjusting

play

of

a

ccelerator

wire

Pedal

stopper

Depress

the

accelerator

pedal

down

to

such

an

extent

that

the

throttle

lever

fully

opens

adjust

stopper

bolt

height

so

that

clearance

between

the

accelerator

pedal

reverse

side

and

stopper

bolt

head

T

is

0

to

I

mm

0

to

0

03Q4

in

and

secure

the

stopper

bolt

with

lock

nut

Fig

FE

4

1djusting

pedal

stopper

height

left

hand

steering

T

0

to

1

mm

0

to

0

0394

in

@

I

I

Lo

k

nut

2

Accelerator

pedal

I

3

I

Stopper

bolt

Fig

FE

5

Adjusting

pedal

stopper

height

right

hand

steering

Note

8

Do

not

bend

the

accelerator

pedal

b

Adjust

accelerator

wire

play

and

stopp

bolt

height

correctly

c

Apply

chassis

grease

No

a

or

1

to

the

sliding

part

of

pedal

bracket

Model

with

automatic

transmission

For

model

with

automatic

transmission

the

pedal

ann

is

equipped

with

kick

down

switch

striker

This

is

only

difference

with

the

standard

model

Note

Note

that

the

kick

down

switch

should

not

come

into

contact

with

the

pedal

arm

striker

when

the

accelerator

pedal

is

depressed

FE

2

Page 199 of 513

BODY

UNDERBODY

ALIGNMENT

CONTENTS

UNDERBODY

GENERAL

SERVICE

INFORMATION

ALIGNMENT

CHECKING

PROCEDURE

BF

9

BF

9

UNDERBODY

GENERAL

SERVICE

INFORMATION

Since

each

underbody

component

directly

affects

the

overall

strength

of

the

body

it

is

essential

that

proper

welding

sealing

and

rust

proofing

techniques

be

observed

during

service

operations

Whenever

the

body

is

repaired

be

sure

to

provide

the

repaired

body

parts

with

rust

proof

In

the

case

of

a

rust

proofmg

critical

underbody

component

it

is

essential

that

a

good

quality

type

air

dry

primer

such

as

corrosion

resistant

zinc

chromate

be

used

Do

not

use

combination

type

primer

surfacers

ALIGNMENT

CHECKING

PROCEDURE

Misalignment

in

the

underbody

affects

the

front

fender

door

trunk

lid

and

window

alignments

and

also

the

tail

gate

and

rear

body

opening

alignments

in

the

case

of

a

station

wagon

or

van

Underbody

misalignment

particularly

affects

the

suspension

system

thereby

causing

various

problems

that

arise

from

suspension

misalignment

It

is

essential

that

underbody

components

be

aligned

within

the

specified

dimensions

given

in

Figures

BF

13

14

and

IS

In

the

event

of

collision

damage

it

is

important

that

underbody

a1ignrnent

be

thoroughly

checked

and

if

necessary

realigned

to

the

specified

dirnensions

There

are

many

tools

that

may

be

ernployed

to

correct

collision

damage

such

as

frame

straightening

machines

external

pulling

equipment

other

standard

body

jacks

PRINCIPLES

OF

TRAMMING

CAR

PREPARATION

TRAMMING

SEQUENCE

BF

9

BF

10

BF

10

To

assist

in

checking

alignment

of

the

underbody

components

repairing

minor

underbody

damage

or

locating

replacement

parts

the

following

underbody

dimensions

and

alignment

checking

information

are

presented

PRINCIPLES

OF

TRAMMING

All

reference

locations

shown

in

Figure

BF

13

14

and

15

are

symmetrical

at

the

centerline

of

the

vehicle

For

example

wheo

performing

a

crosHheck

of

the

body

floor

panel

dimensions

Figures

BF

I3

14

and

IS

the

diagonal

measurement

should

be

the

same

in

boflii

directions

Cross

checking

operations

are

used

to

deter

mine

the

relationship

between

two

locations

on

the

underbody

To

measure

the

distance

between

any

two

reference

points

on

the

underbody

accurately

two

specifications

are

required

I

The

horizontal

dimension

between

the

two

points

to

be

measured

2

The

vertical

dimension

from

the

datum

line

to

the

points

to

be

measured

For

an

example

the

diagonal

measurement

calculated

on

a

horizontal

plane

between

reference

points

of

dimension

line

L

shown

in

Figure

BF

I3

is

631

3

mm

24

8

in

The

specifications

from

the

datum

line

have

a

vertical

height

difference

of

11

6

mm

0

456

in

between

the

forward

location

of

dimension

L

at

vertical

dimension

80

0

mm

3

150

in

and

the

rearward

location

of

dimension

L

at

vertical

dimension

91

6

mm

3

606

in

The

vertical

pointer

used

at

the

forward

location

should

be

positioned

so

as

to

extend

11

6

mm

0

456

in

further

from

the

tram

bar

than

the

BF

9

Page 276 of 513

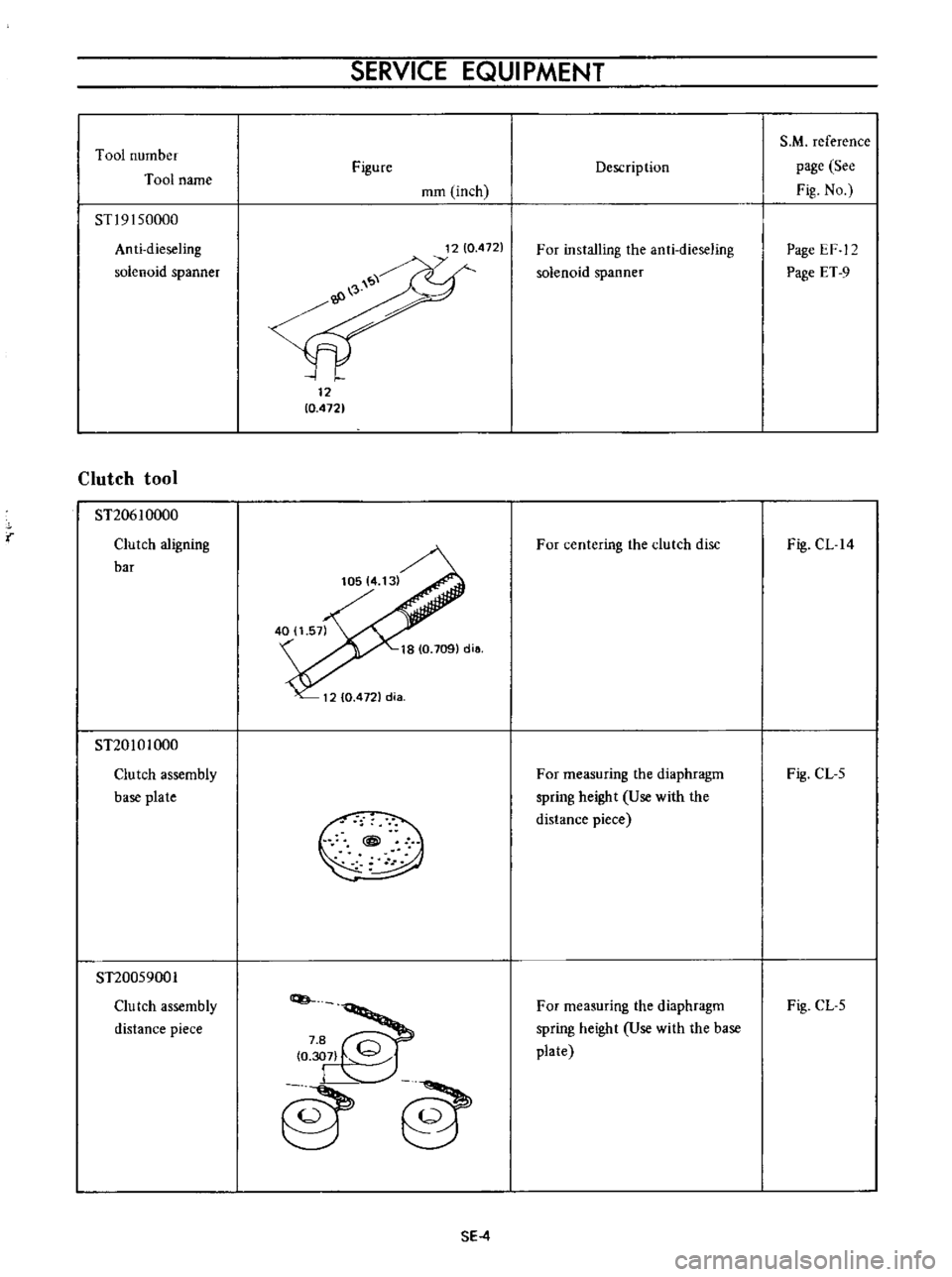

Tool

number

Tool

name

STl9

I

50000

Anti

dieseling

solenoid

spanner

Clutch

tool

ST20610000

Clutch

aligning

bar

ST20101000

Clutch

assembly

base

plate

ST20059001

Clu

tch

assembly

distance

piece

SERVICE

EQUI

PMENT

Figure

mm

inch

12

10

4721

0

o

8

C

307

l

j

@@

SE

4

Description

For

installing

the

anti

dieseling

solenoid

spanner

For

centering

the

clutch

disc

For

measuring

the

diaphragm

spring

height

Use

with

the

distance

piece

For

measuring

the

diaphragm

spring

height

Use

with

the

base

plate

S

M

reference

page

See

Fig

No

Page

EF

12

Page

ET

9

Fig

CL

14

Fig

CL

5

Fig

CL

5

Page 277 of 513

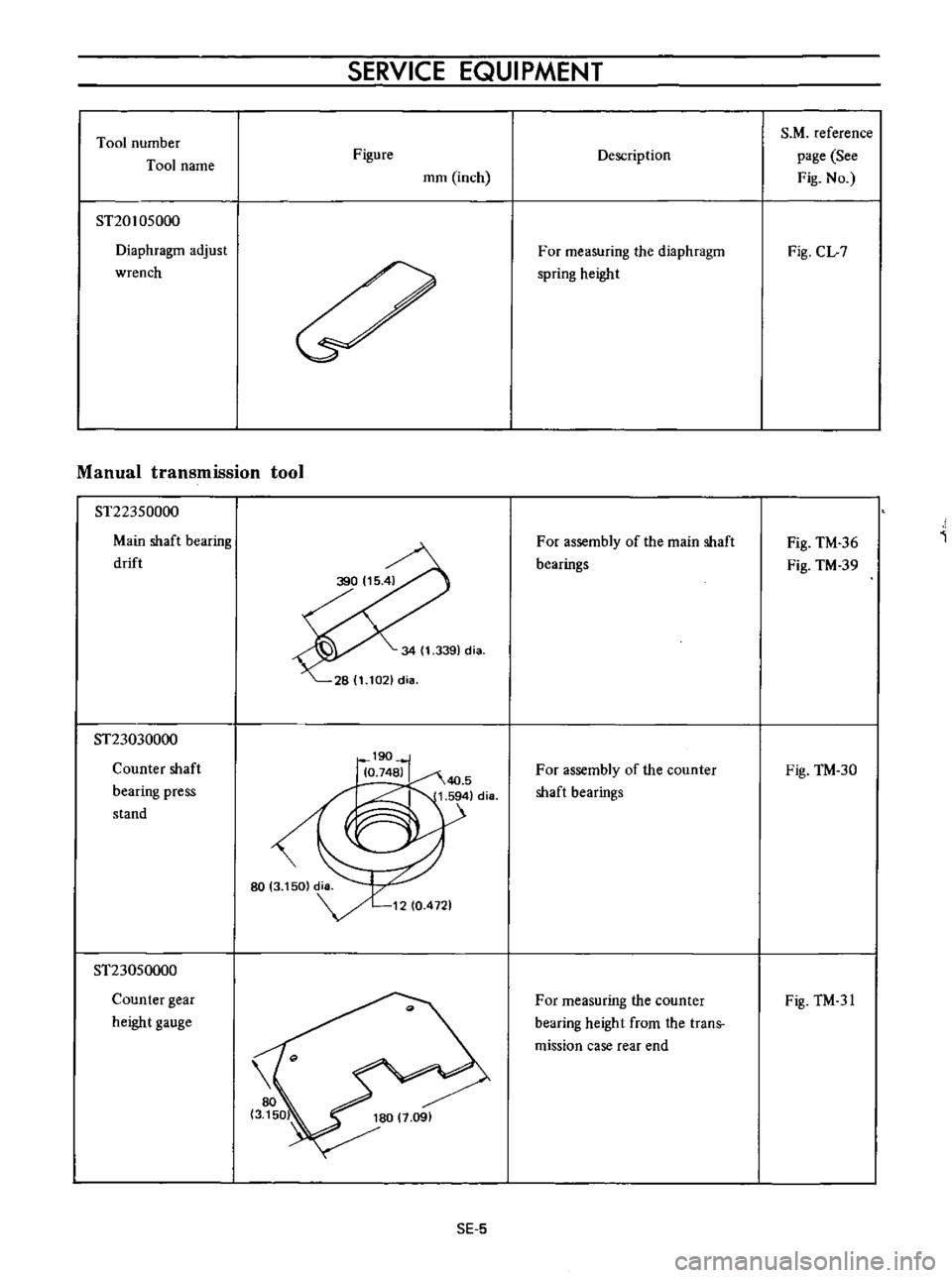

Tool

number

Tool

name

ST20105000

Diaphragm

adjust

wrench

SERVICE

EQUIPMENT

Figure

mm

inch

Manual

transmission

tool

ST22350000

Main

shaft

bearing

drift

ST23030000

Counter

shaft

bearing

press

stand

ST23050000

Counter

gear

height

gauge

SE

5

Description

For

measuring

the

diaphragm

spring

height

For

assembly

of

the

main

shaft

bearings

For

assembly

of

the

counter

shaft

bearings

For

measuring

the

counter

bearing

height

from

the

trans

mission

case

rear

end

S

M

reference

page

See

Fig

No

Fig

CL

7

Fig

TM

36

Fig

TM

39

Fig

TM

30

Fig

TM

31

Page 282 of 513

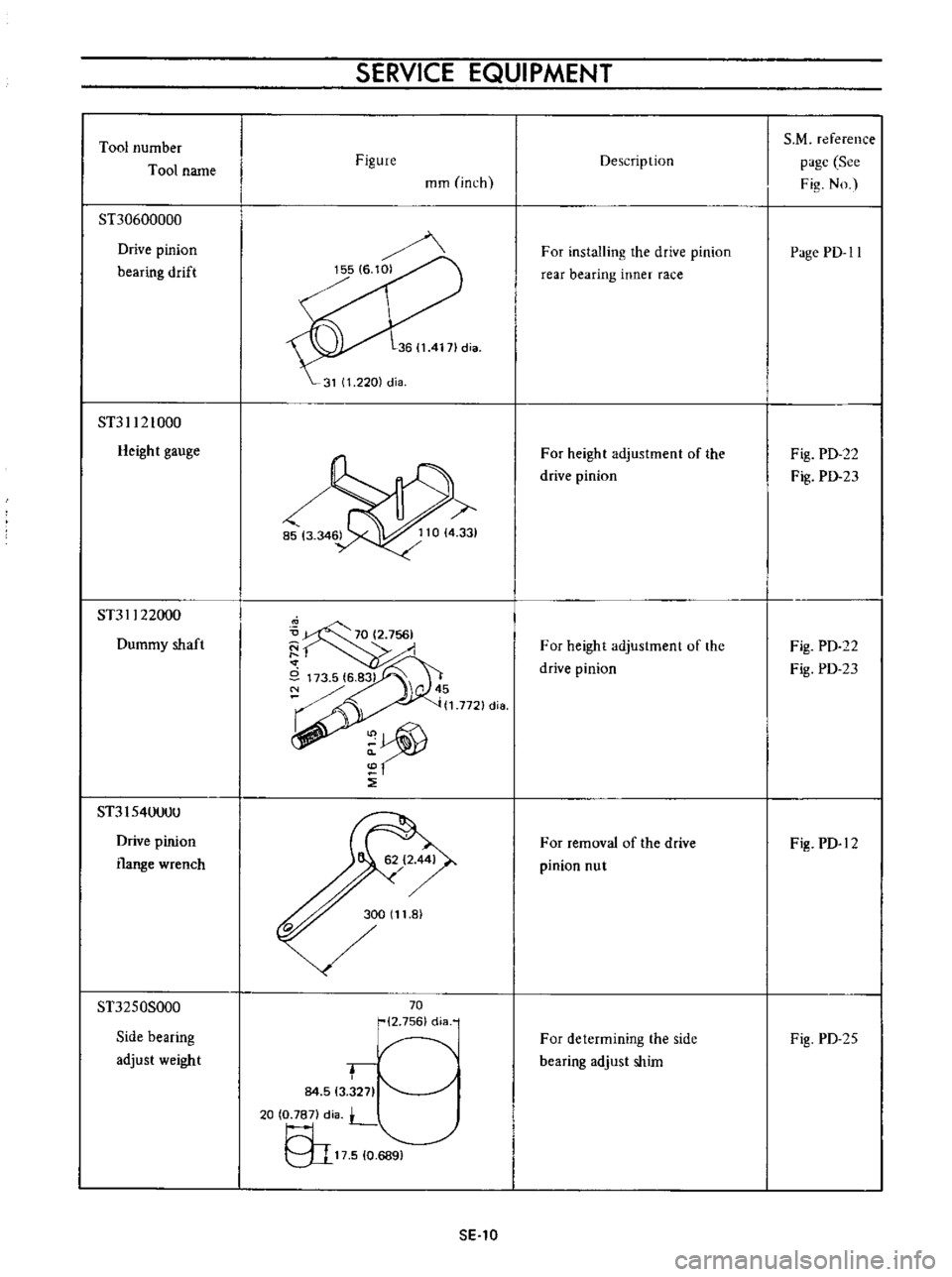

Tool

number

Tool

name

ST30600000

Drive

pinion

bearing

drift

ST31121000

Heigh

t

gauge

ST31122000

Dummy

shaft

ST3154llllUll

Drive

pinion

flange

wrench

ST3250S000

Side

bearing

adjust

weight

SERVICE

EQUIPMENT

Figure

mm

inch

15516

101

36114171dia

31

1

220

dia

70

2

756

cHa

r

84

513

271

20

O

Je7l

diil

L

9I17510Y

sE

lO

Description

For

installing

the

drive

pinion

rear

bearing

inner

race

For

height

adjustment

of

the

drive

pinion

For

height

adjustment

of

the

drive

pinion

For

removal

of

the

dri

ve

pinion

nut

For

determining

the

side

bearing

adjust

shim

S

M

reference

page

See

Fig

No

Page

PD

II

Fig

PD

22

Fig

PD

23

Fig

PD

22

Fig

PD

23

Fig

PD

12

Fig

PD

25