height DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 329 of 513

ENGINE

3

Connect

a

3

way

connector

a

manometer

and

a

cock

or

an

equivalent

3

way

change

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

the

pressure

becomes

368

mm

Aq

14

5

in

Aq

5

Shut

the

cock

completely

and

leave

it

that

way

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

within

254

mmAq

1

0

in

Aq

8

When

the

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

If

the

height

does

not

drop

to

zero

in

a

short

time

when

the

filler

cap

is

removed

it

is

the

cause

of

the

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thus

causing

insufficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

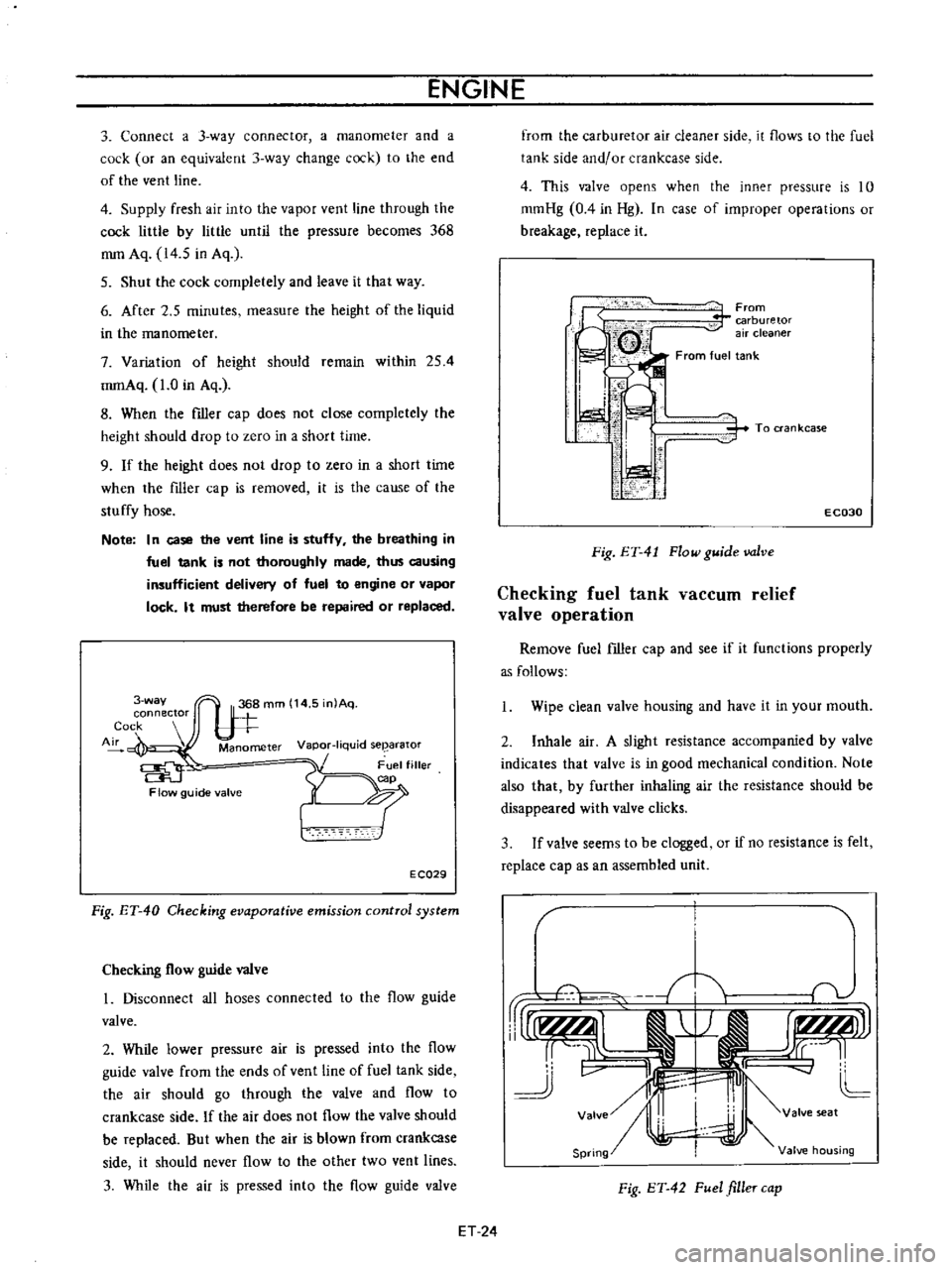

3

way

connector

Cock

Air

Manometer

Vapor

liquid

seearator

Flow

guide

valve

E

CQ29

Fig

ET

40

Checking

evaporative

emission

control

system

Checking

flow

guide

valve

I

Disconnect

all

hoses

connected

to

the

flow

guide

valve

2

While

lower

pressure

air

is

pressed

into

the

flow

guide

valve

from

the

ends

of

vent

line

of

fuel

tank

side

the

air

should

go

through

the

valve

and

flow

to

crankcase

side

If

the

air

does

not

flow

the

valve

should

be

replaced

But

when

the

air

is

blown

from

crankcase

side

it

should

never

flow

to

the

other

two

vent

lines

3

While

the

air

is

pressed

into

the

flow

guide

valve

from

the

carburetor

air

cleaner

side

it

flows

to

the

fuel

tank

side

and

or

crankcase

side

4

This

valve

opens

when

the

inner

pressure

is

10

mmHg

0

4

in

Hg

In

case

of

improper

operations

or

breakage

replace

it

From

carburetor

air

cleaner

From

fuel

tank

i

I

I

ti

i

i

1

1

i

To

ran

kcase

E

C030

Fig

ET

41

Flow

guide

valve

Checking

fuel

tank

vaCCUID

relief

valve

operation

Remove

fuel

filler

cap

and

see

if

it

functions

properly

as

follows

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

accompanied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

seems

to

be

clogged

or

if

no

resistance

is

felt

replace

cap

as

an

assembled

unit

T

1i

v

rUr1f

AlI

j

r

I

r

tLMJJl

rr

L

cc

11

J

v

II

4J

L

Valve

I

valve

seat

Spring

Valve

housing

Fig

ET

42

Fuel

filler

cap

ET

24

Page 355 of 513

ENGINE

MECHANICAL

Bendin9

limit

0

05mm

0

0020

in

Standard

0

of5mm

0

0006

in

or

less

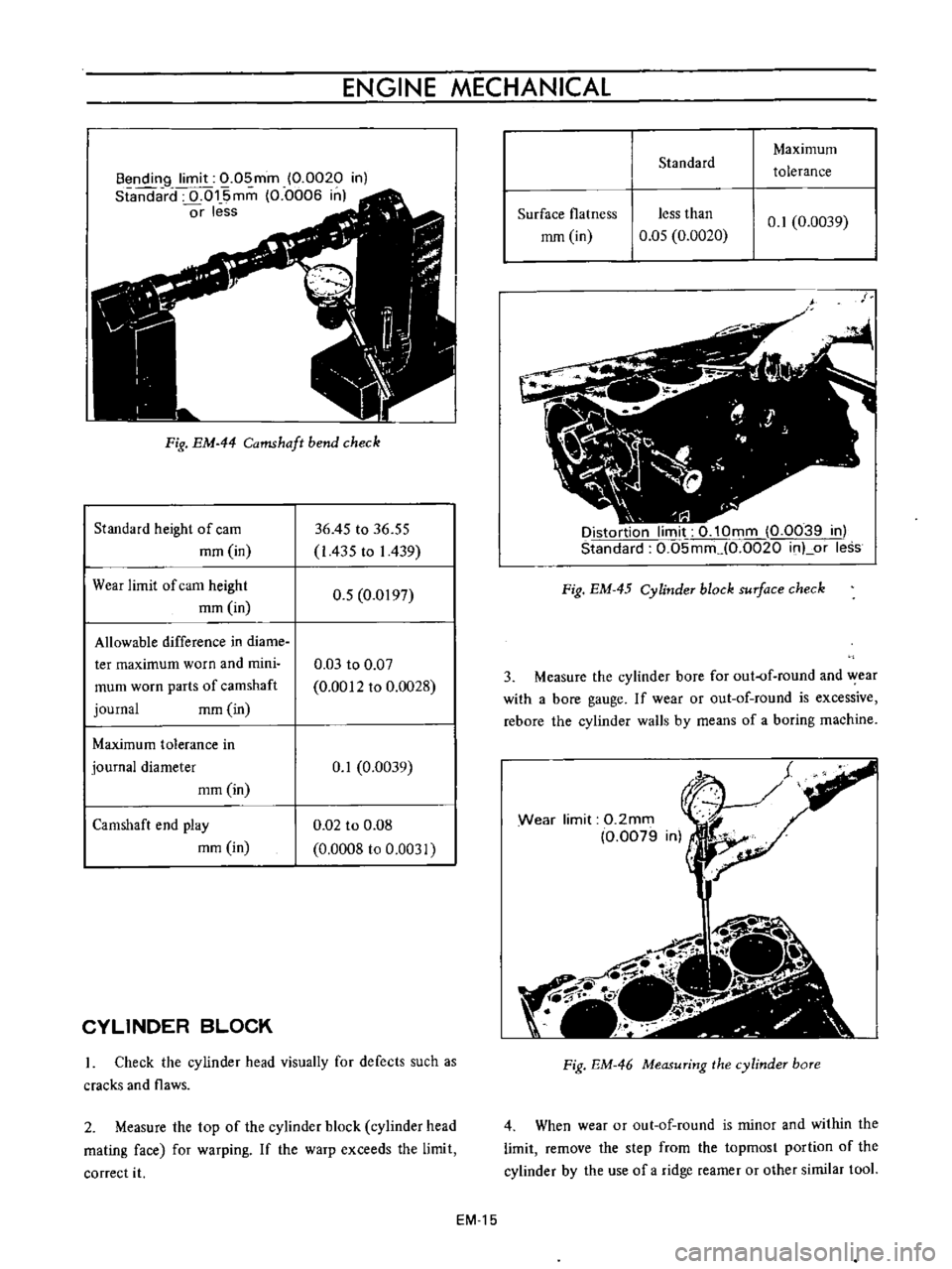

Fig

EM

44

Camshaft

bend

check

Standard

height

of

cam

mm

in

36

45

to

36

55

I

435

to

I

439

Wear

limit

of

cam

height

mm

in

0

5

0

0197

Allowable

difference

in

diame

ter

maximum

worn

and

mini

mum

worn

parts

of

camshaft

journal

mm

in

0

03

to

0

07

0

0012

to

0

0028

Maximum

tolerance

in

journal

diameter

mm

in

0

1

0

0039

Camshaft

end

play

mm

in

0

02

to

0

08

0

0008

to

0

0031

CYLINDER

BLOCK

Check

the

cylinder

head

visually

for

defects

such

as

cracks

and

flaws

2

Measure

the

top

of

the

cylinder

block

cylinder

head

mating

face

for

warping

If

the

warp

exceeds

the

limit

correct

it

EM

15

Standard

Maximum

tolerance

Surface

flatness

less

than

mm

in

0

05

0

0020

0

1

0

0039

Distortion

limit

0

10mm

0

0039

in

Standard

0

05mm

0

0020

inLor

less

Fig

EM

45

Cylinder

block

surface

check

3

Measure

the

cylinder

bore

for

out

of

round

and

wear

with

a

bore

gauge

If

wear

or

out

of

round

is

excessive

rebore

the

cylinder

walls

by

means

of

a

boring

machine

Wear

limit

0

2mm

0

0079

Fig

EM

46

Measuring

the

cylinder

bore

4

When

wear

or

out

of

round

is

minor

and

within

the

limit

remove

the

step

from

the

topmost

portion

of

the

cylinder

by

the

use

of

a

ridge

reamer

or

other

similar

tooL

Page 368 of 513

ENGINE

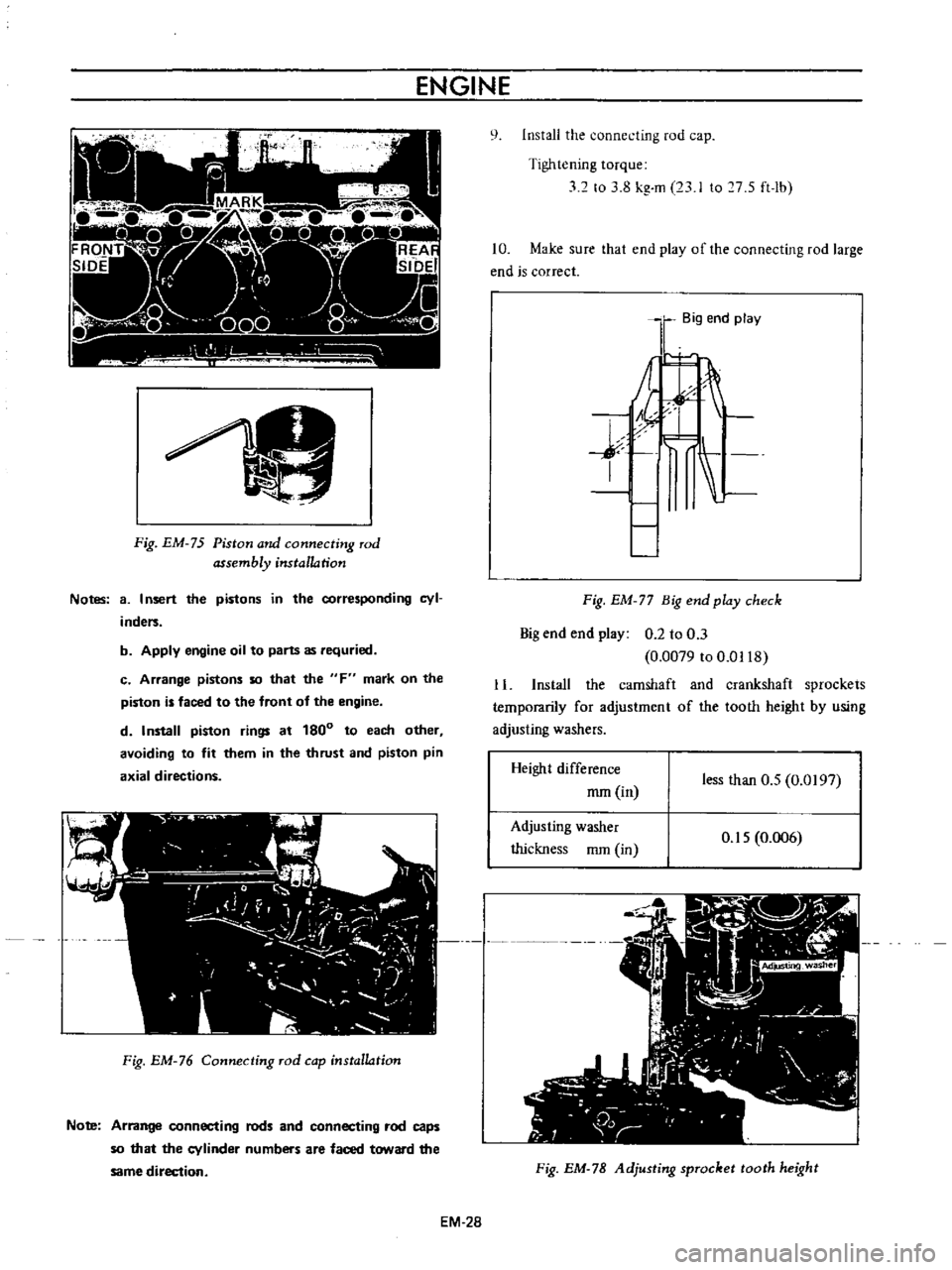

Fig

EM

75

Piston

and

connecting

rod

assembly

installation

Notes

8

I

nsert

the

pistons

in

the

corresponding

cyl

inders

b

Apply

engine

oil

to

parts

as

requried

c

Arrange

pistons

so

that

the

F

mark

on

the

piston

is

faced

to

the

front

of

the

engine

d

Install

piston

rings

at

180

to

each

other

avoiding

to

fit

them

in

the

thrust

and

piston

pin

axial

directions

Fig

EM

76

Connecting

rod

cap

installation

Note

Arrange

connecting

rods

and

connecting

rod

caps

so

that

the

cylinder

numbers

are

faced

toward

the

same

direction

EM

28

q

Install

the

connecting

rod

cap

Tightening

torque

32

to

3

8

kg

m

23

I

to

7

S

ft

lb

10

Make

sure

that

end

play

of

the

connecting

rod

large

end

is

correct

Big

end

play

j

I

Fig

EM

77

Big

end

play

check

Big

end

end

play

0

2

to

0

3

0

0079

to

0

0118

11

Install

the

camshaft

and

crankshaft

sprockets

temporarily

for

adjustment

of

the

tooth

height

by

using

adjusting

washers

Height

difference

mm

in

less

than

O

S

0

0197

Adjusting

washer

thickness

mm

in

O

IS

0

006

Fig

EM

78

Adjusting

sprocket

tooth

height

Page 374 of 513

ENGINE

SPECIFICATION

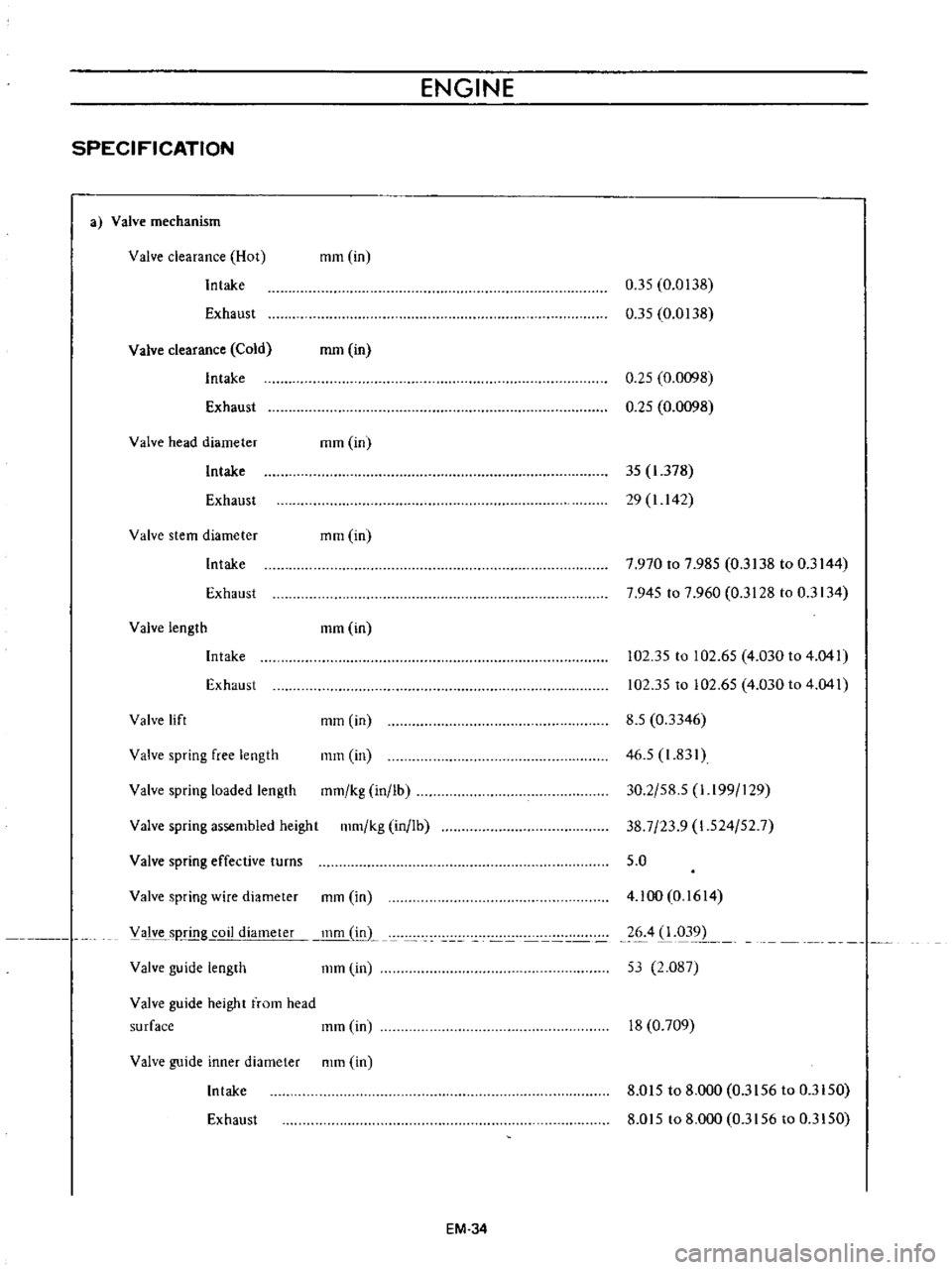

a

Valve

mechanism

Valve

clearance

Hot

Intake

mm

in

Exhaust

0

35

0

0138

0

35

0

0138

Valve

clearance

Cold

Intake

Exhaust

mm

in

0

25

0

0098

0

25

0

0098

Valve

head

diameter

mm

in

Intake

35

1

378

29

1

142

Exhaust

Valve

stem

diameter

mm

in

Intake

7

970

to

7

985

0

3138

to

0

3144

7

945

to

7

960

0

3128

to

0

3134

Exhaust

Valve

length

mm

in

Intake

Exhaust

102

35

to

102

65

4

030

to

4

041

102

35

to

102

65

4

030

to

4

041

Valve

spring

assembled

height

111m

kg

in

lb

8

5

0

3346

46

5

1

831

30

2

58

5

1

I99

129

38

7

23

9

1

524

52

7

5

0

Valve

lift

mm

in

Valve

spring

free

length

mm

in

Valve

spring

loaded

length

mm

kg

in

lb

Valve

spring

effective

turns

Valve

guide

length

111m

in

4

100

0

1614

26

4

1

031

1

53

2

087

Valve

spring

wire

diameter

mm

in

V

alve

sp

g

coil

diameter

inm

L

Valve

guide

height

from

head

surface

111m

in

18

0

709

Valve

guide

inner

diameter

mm

in

Intake

8

015

to

8

000

0

3156

to

0

3150

Exhaust

8

015

to

8

000

0

3156

to

0

3150

EM

34

Page 377 of 513

ENGINE

MECHANICAL

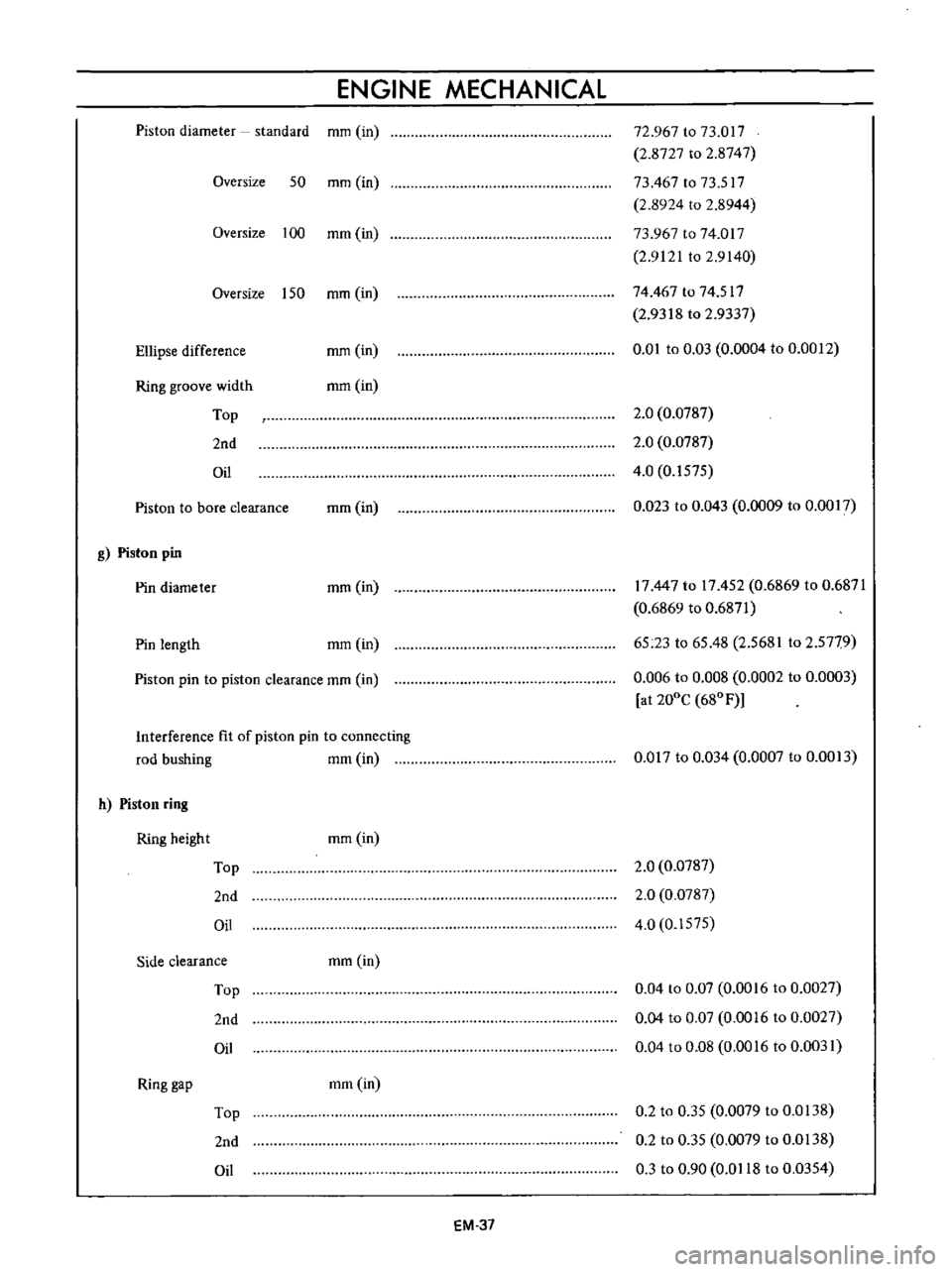

Piston

diameter

standard

mm

in

Oversize

50

mm

in

Oversize

100

mm

in

Oversize

150

mm

in

Ellipse

difference

mm

in

Ring

groove

width

Top

2nd

Oil

mm

in

Piston

to

bore

clearance

mm

in

g

Piston

pin

Pin

diameter

mm

in

Pin

length

mm

in

Piston

pin

to

piston

clearance

mm

in

Interference

fit

of

piston

pin

to

connecting

rod

bushing

mm

in

h

Piston

ring

Ring

height

Top

2nd

Oil

mm

in

Side

clearance

mm

in

Top

2nd

Oil

Ring

gap

mm

in

Top

2nd

Oil

EM

37

72

967

to

73

017

2

8727

to

2

8747

73

467

to

73

517

2

8924

to

2

8944

73

967

to

74

017

2

9121

to

2

9140

74

467

to

74

517

2

9318

to

2

9337

0

01

to

0

03

0

0004

to

0

0012

2

0

0

0787

2

0

0

0787

4

0

0

1575

0

023

to

0

043

0

0009

to

0

0017

17

447

to

17

452

0

6869

to

0

6871

0

6869

to

0

6871

65

23

to

65

48

2

5681

to

2

5779

0

006

to

0

008

0

0002

to

0

0003

at

200e

680

F

0

017

to

0

034

0

0007

to

0

0013

2

0

0

0787

2

0

0

0787

4

0

0

1575

0

04

to

0

07

0

0016

to

0

0027

0

04

to

0

07

0

0016

to

0

0027

0

04

to

0

08

0

0016

to

0

0031

0

2

to

0

35

0

0079

to

0

0138

0

2

to

0

35

0

0079

to

0

0138

0

3

to

0

90

0

0118

to

0

0354

Page 390 of 513

ENGINE

SPECIFICATIONS

Dimensions

of

radiator

core

Height

x

Width

x

Thickness

mm

in

330

x

344

x

32

13

0

x

13

5

x

1

26

Type

Corrugate

fin

type

Radiator

fin

spacing

mm

in

2

5

0

098

Radiator

capacity

K

cal

hoC

335

Water

capacity

with

heater

kg

em

lb

sq

in

t

US

qt

Imp

qt

0

9IO

l

13II4

4

9

5

I

4

X

Cap

working

pressure

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

CQ

4

Page 417 of 513

ENGINE

ffi68

mmAq

14

5

mAq

3

way

connector

Cock

II

M

nam

e

Flow

guide

valve

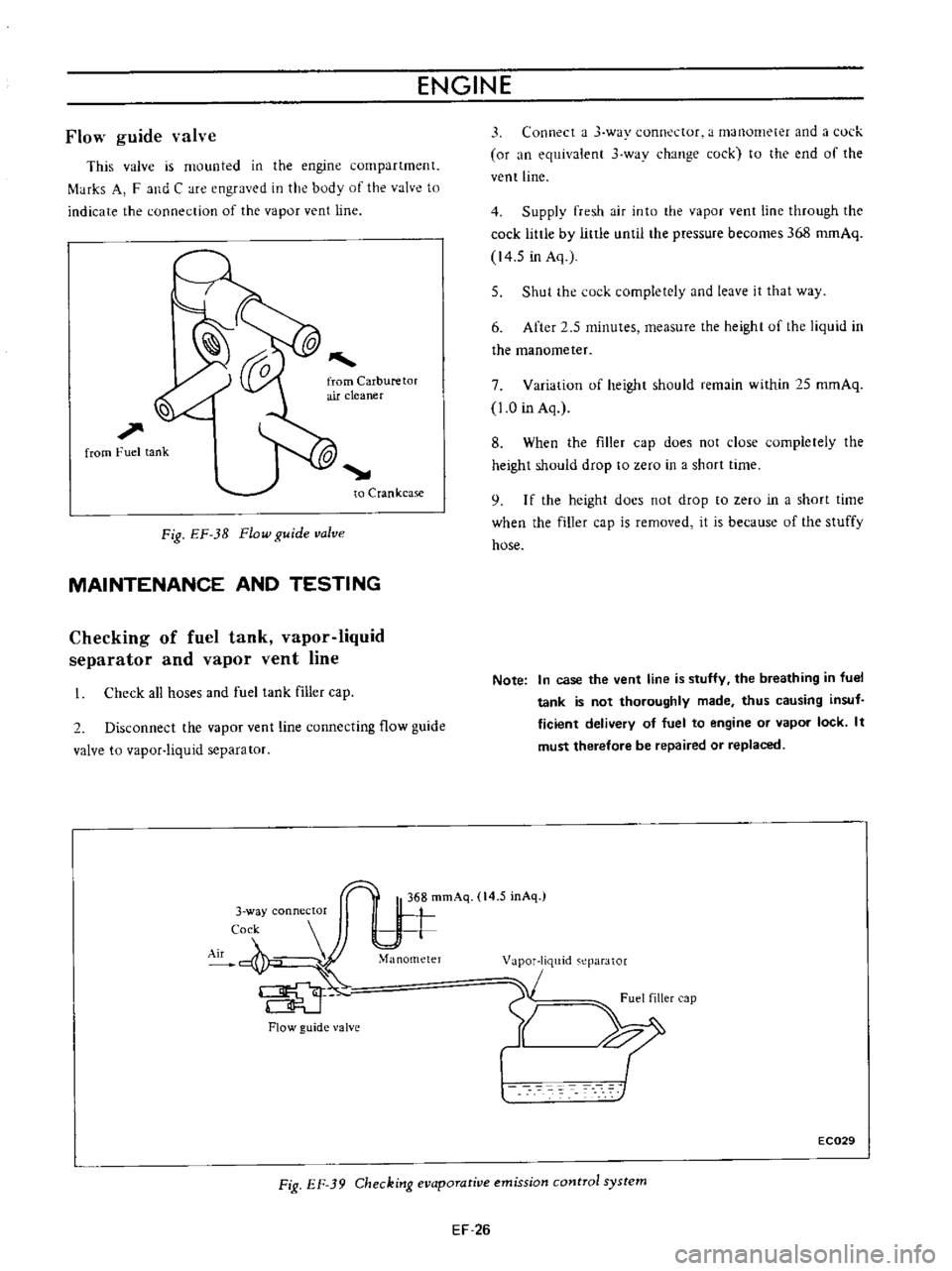

This

valve

is

mounted

in

the

engine

compartment

f

tHks

A

F

and

C

are

engraved

in

the

body

of

the

valve

to

indicate

the

connection

of

the

vapor

vent

line

l

l

1

from

Fuel

tank

to

Crankcase

Fig

EF

3B

Flow

guide

valve

MAINTENANCE

AND

TESTING

Checking

of

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

Check

all

hoses

and

fuel

tank

filler

cap

2

Disconnect

the

vapor

vent

line

connecting

flow

guide

valve

to

vapor

liquid

separator

Flow

guide

valve

3

Connect

a

J

way

connector

a

manometer

and

a

l

ul

k

or

an

equivalent

3

wav

change

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

the

pressure

becomes

368

romAq

14

5

in

Aq

5

Shut

the

cock

completely

and

leave

it

that

way

6

After

2

5

minutes

measure

the

height

uf

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

within

25

mmAq

1

0

in

Aq

8

When

the

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

docs

not

drop

to

zero

in

a

short

time

when

the

filler

cap

is

removed

it

is

because

of

the

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thus

causing

insuf

ficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

1

m

eparator

1

Fuel

filler

cap

Y

XI

EC029

Fig

EF

39

Checking

evaporative

emission

control

system

EF

26

Page 426 of 513

ENGINE

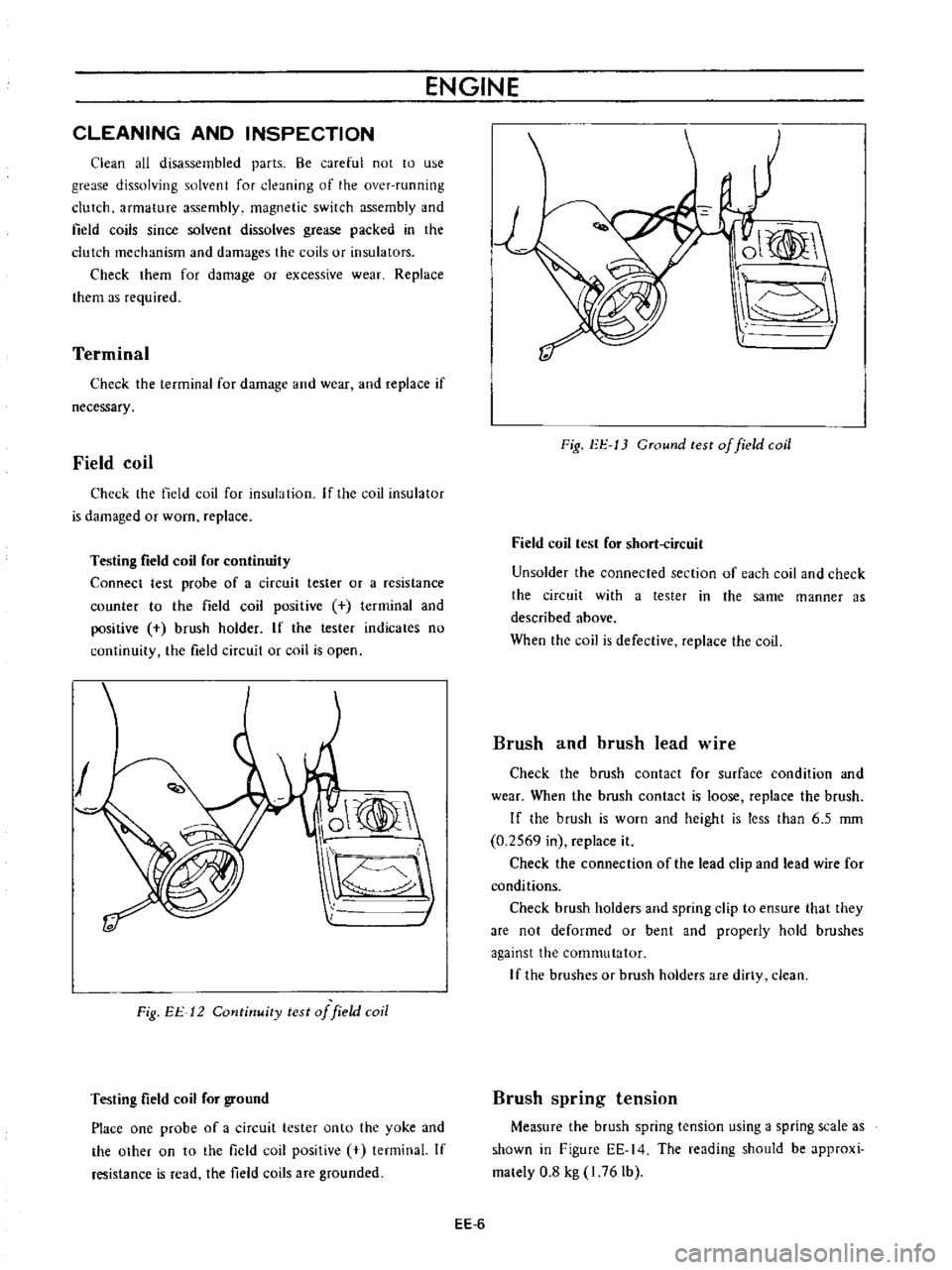

CLEANING

AND

INSPECTION

Clean

all

disassembled

parts

Be

careful

not

to

use

grease

dissolving

solvent

for

cleaning

of

the

over

running

clutch

armature

assembly

magnetic

switch

assembly

and

field

coils

since

solvent

dissolves

grease

packed

in

the

clutch

mechanism

and

damages

the

coils

or

insulators

Check

them

for

damage

or

excessive

wear

Replace

them

as

required

Terminal

Check

the

terminal

for

damage

and

wear

and

replace

if

necessary

Field

coil

Check

the

field

coil

for

insulation

If

the

coil

insulator

is

damaged

or

worn

replace

Testing

field

coil

for

continuity

Connect

test

probe

of

a

circuit

tester

or

a

resistance

counter

to

the

field

coil

positive

terminal

and

positive

brush

holder

If

the

tester

indicates

no

continuity

the

field

circuit

or

coil

is

open

O

Fig

EE

12

Cotltinuity

test

of

field

coil

Testing

field

coil

for

ground

Place

one

probe

of

a

circuit

tester

onto

the

yoke

and

the

othef

on

to

the

field

coil

positive

tenninal

If

resistance

is

read

the

field

coils

are

grounded

ol

I

Fig

EE

13

CTound

test

of

field

coil

Field

coil

test

for

short

ircuit

Un

solder

the

connected

section

of

each

coil

and

check

the

circuit

with

a

tester

in

the

same

manner

as

described

above

When

the

coil

is

defective

replace

the

coil

Brush

and

brush

lead

wire

Check

the

brush

contact

for

surface

condition

and

wear

When

the

brush

contact

is

loose

replace

the

brush

If

the

brush

is

worn

and

height

is

less

than

6

5

rom

0

2569

in

replace

it

Check

the

connection

of

the

lead

clip

and

lead

wire

for

conditions

Check

brush

holders

and

spring

clip

to

ensure

that

they

are

not

deformed

or

bent

and

properly

hold

brushes

against

the

commutator

If

the

brushes

Of

brush

holders

are

dirty

clean

Brush

spring

tension

Measure

the

brush

spring

tension

using

a

spring

scale

as

shown

in

Figure

EE

14

The

reading

should

be

approxi

mately

0

8

kg

I

76

Ib

EE

6

Page 431 of 513

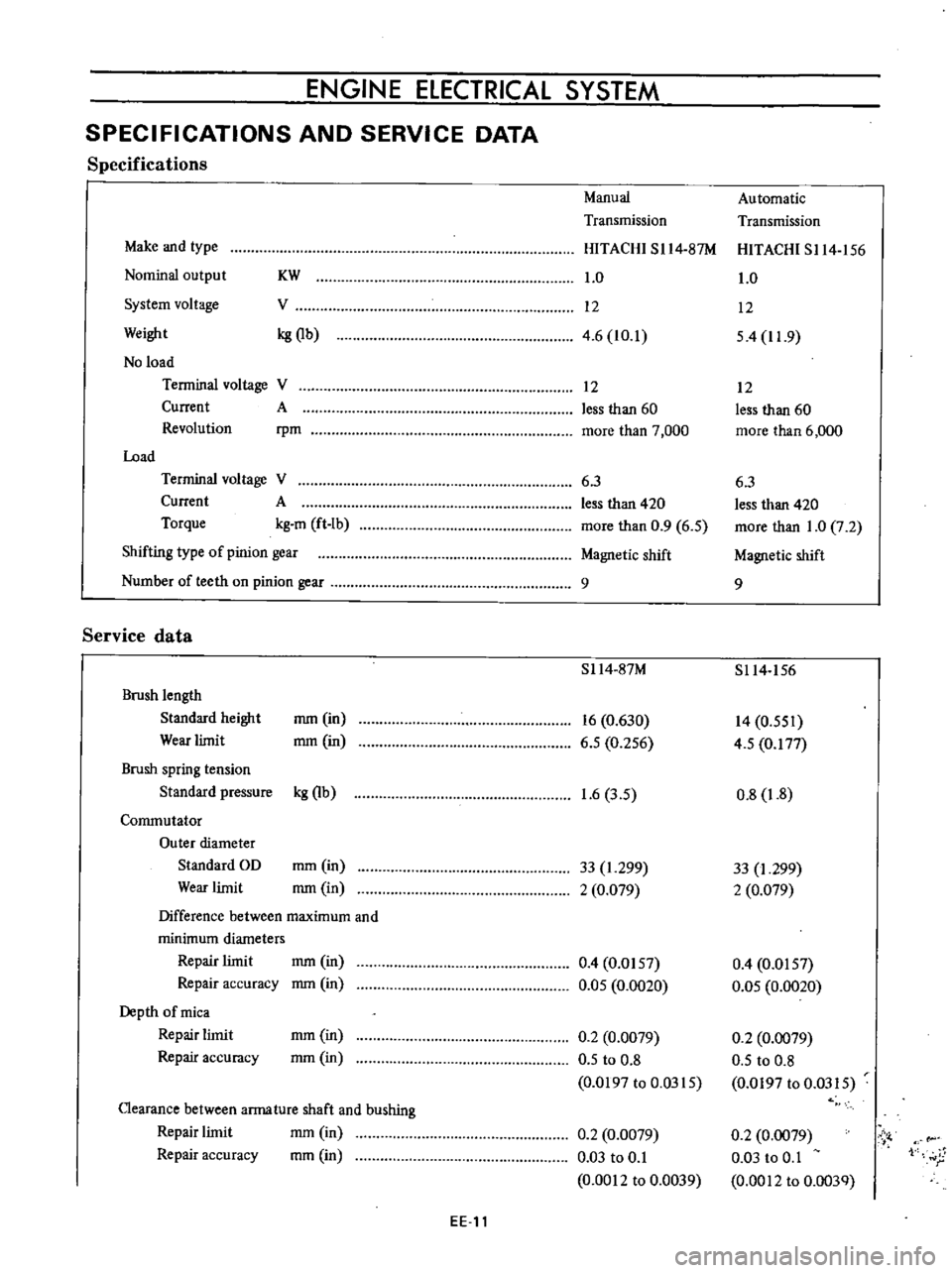

ENGINE

ElECTRICAL

SYSTEM

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Manual

Automatic

Transmission

Transmission

Make

and

type

HITACHI

SI14

87M

HITACHI

S114

156

Nominal

output

KW

1

0

1

0

System

voltage

V

12

12

Weight

kg

Qb

4

6

10

1

54

11

9

No

load

Terminal

voltage

V

12

12

Current

A

less

than

60

less

than

60

Revolution

rpm

more

than

7

000

more

than

6

000

Load

Terminal

voltage

V

6

3

6

3

Current

A

less

than

420

less

than

420

Torque

kg

m

ft

Ib

more

than

0

9

6

5

more

than

1

0

7

2

Shifting

type

of

pinion

gear

Magnetic

shift

Magnetic

shift

Number

of

teeth

on

pinion

gear

9

9

Service

data

S114

87M

S114

156

Brush

length

Standard

height

mm

in

16

0

630

14

0

551

Wear

limit

mm

in

6

5

0

256

4

5

0

177

Brush

spring

tension

Standard

pressure

kg

Qb

1

6

3

5

0

8

1

8

Commutator

Outer

diameter

Standard

OD

mm

in

33

1

299

33

I

299

Wear

limit

mm

in

2

0

079

2

0

079

Difference

between

maximum

and

minimum

diameters

Repair

limit

mm

in

0

4

0

0157

0

4

0

0157

Repair

accuracy

mm

in

0

05

0

0020

0

05

0

0020

Depth

of

mica

Repair

limit

mm

in

0

2

0

0079

0

2

0

0079

Repair

accuracy

mm

in

0

5

to

0

8

0

5

to

0

8

0

0197

to

0

0315

0

0197

to

0

0315

Clearance

between

arma

ture

shaft

and

bushing

mm

in

Repair

limit

0

2

0

0079

0

2

0

0079

Vi

Repair

accuracy

mm

in

0

03

to

0

1

0

03

to

0

1

1

r

0

0012

to

0

0039

0

0012

to

0

003Q

EE

11

Page 473 of 513

CLUTCH

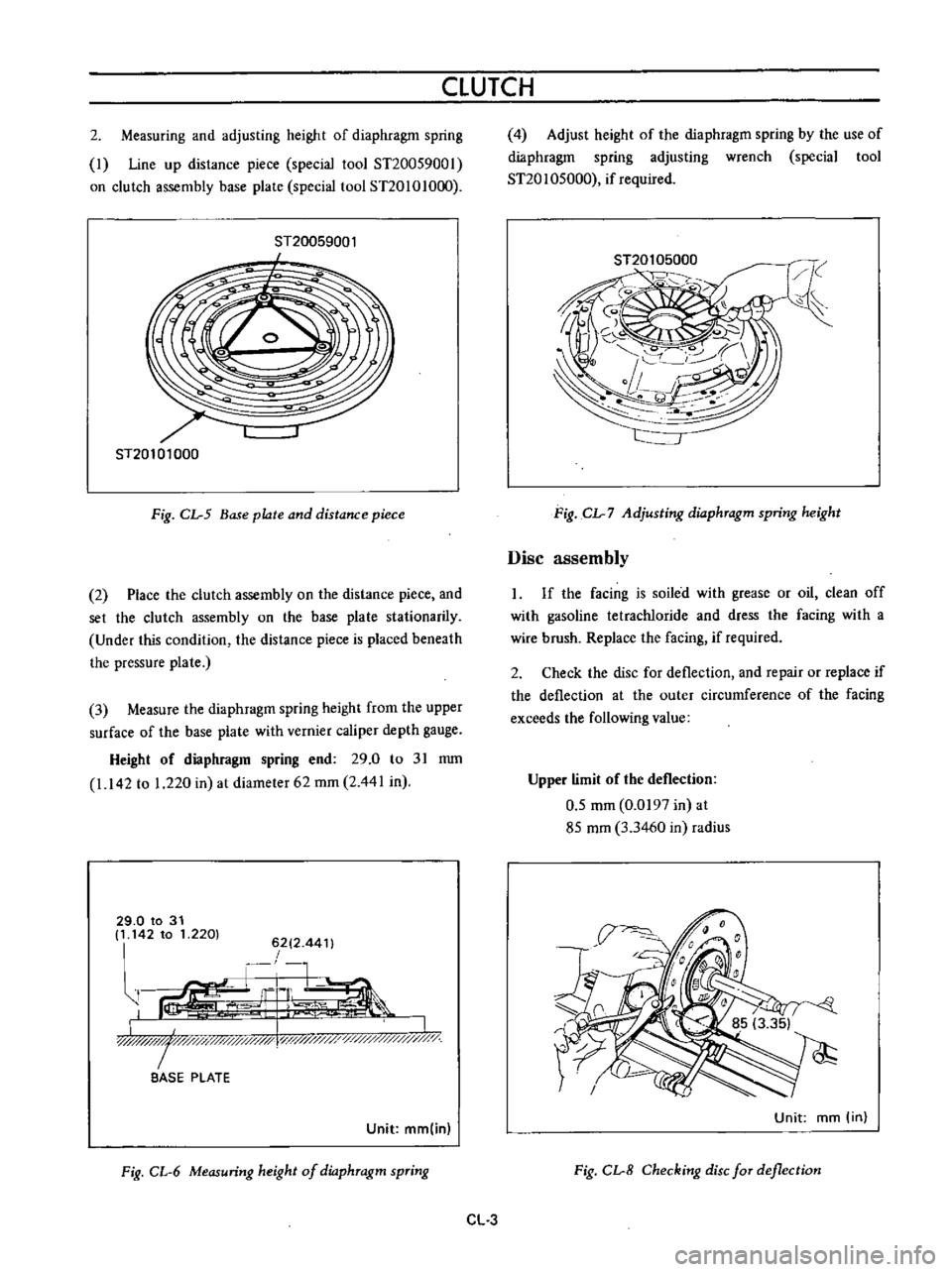

2

Measuring

and

adjusting

height

of

diaphragm

spring

I

Line

up

distance

piece

special

tool

ST20059001

on

clutch

assembly

base

plate

special

tool

ST20101O

0

ST20059001

I

ST20101000

Fig

CL

5

Base

plate

and

distance

piece

2

Place

the

clutch

assembly

on

the

distance

piece

and

set

the

clutch

assembly

on

the

base

plate

stationarily

Under

this

condition

the

distance

piece

is

placed

beneath

the

pressure

plate

3

Measure

the

diaphragm

spring

height

from

the

upper

surface

of

the

base

plate

with

vernier

caliper

depth

gauge

Height

of

diaphragm

spring

end

29

0

to

31

mm

1

142

to

1

220

in

at

diameter

62

mm

2

441

in

29

0

to

31

It

142

to

1

2201

6212

44

t

r

1

G

L

ir

I

LJIlW

I

y

y

x

l

i

0

BASE

PLATE

Unit

mm

in

Fig

CL

6

Measuring

height

of

dio

phTagm

spTing

4

Adjust

height

of

the

diaphragm

spring

by

the

use

of

diaphragm

spring

adjusting

wrench

special

tool

ST20

1

05000

if

required

Fig

CL

7

Adjusting

dio

phTagm

spring

height

Disc

assembly

If

the

facing

is

soiled

with

grease

or

oil

clean

off

with

gasoline

tetracWoride

and

dress

the

facing

with

a

wire

brush

Replace

the

facing

if

required

2

Check

the

disc

for

deflection

and

repair

or

replace

if

the

deflection

at

the

outer

circumference

of

the

facing

exceeds

the

following

value

Upper

limit

of

the

deflection

0

5

mm

0

0197

in

at

85

mm

3

3460

in

radius

Unit

mm

in

Fig

CL

8

Checking

disc

fOT

deflection

CL

3