steering DATSUN B110 1973 Service Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 299 of 513

GENERAL

INFORMATION

JACKING

UP

AND

TOWING

THE

CAR

JACK

UP

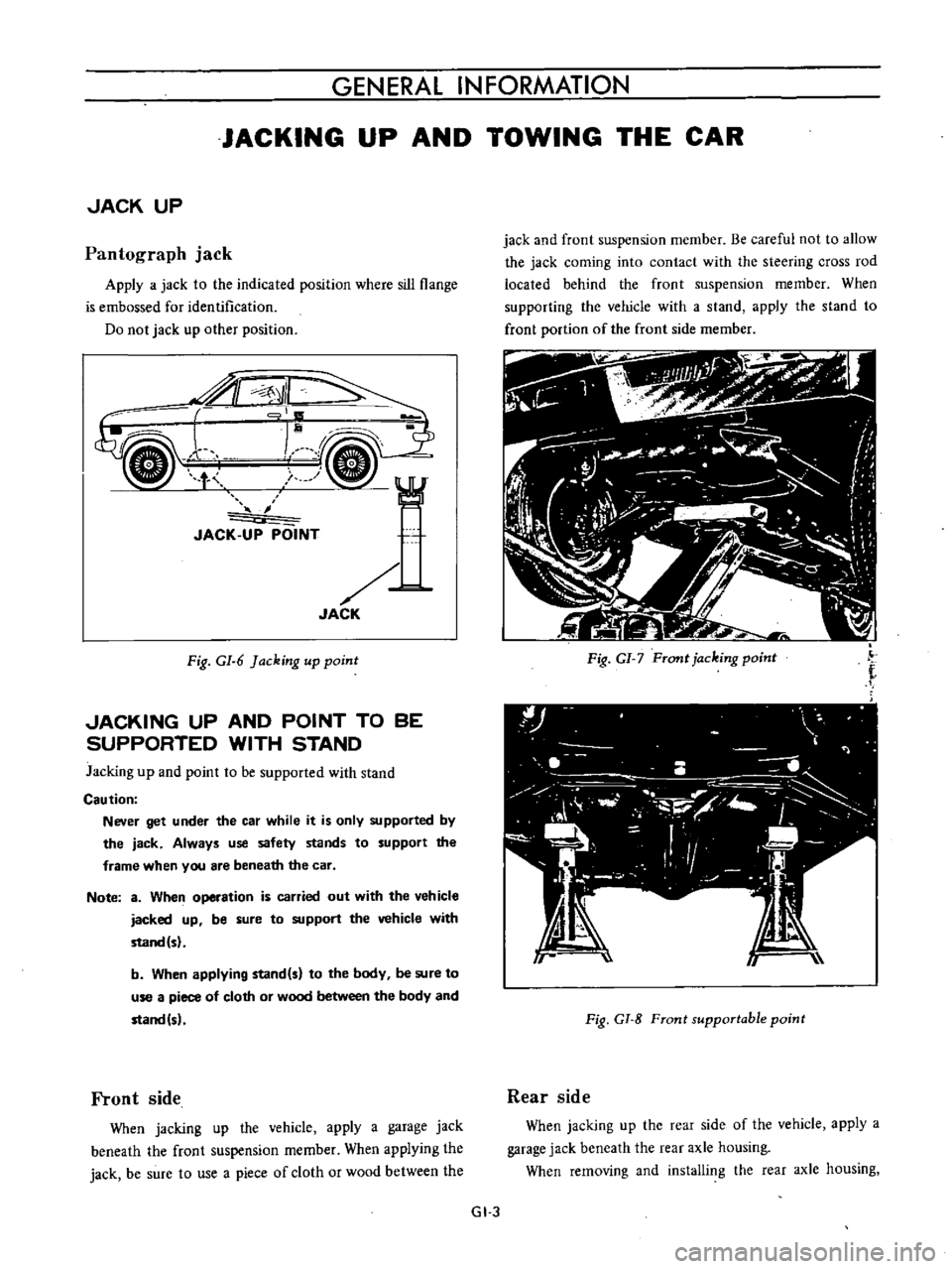

Pantograph

jack

Apply

a

jack

to

the

indicated

position

where

sill

flange

is

embossed

for

identification

Do

not

jack

up

other

position

JACK

UP

POINT

JACK

Fig

GI

6

Jacking

up

point

JACKING

UP

AND

POINT

TO

BE

SUPPORTED

WITH

STAND

Jacking

up

and

point

to

be

supported

with

stand

Caution

Never

get

under

the

car

while

it

is

only

supported

by

the

jack

Always

use

safety

stands

to

support

the

frame

when

you

are

beneath

the

car

Note

8

When

operation

is

carried

out

with

the

veh

icle

jacked

up

be

sure

to

support

the

vehicle

with

stand

s

b

When

applying

stand

s

to

the

body

be

sure

to

use

a

piece

of

cloth

or

wood

between

the

body

and

stand

s

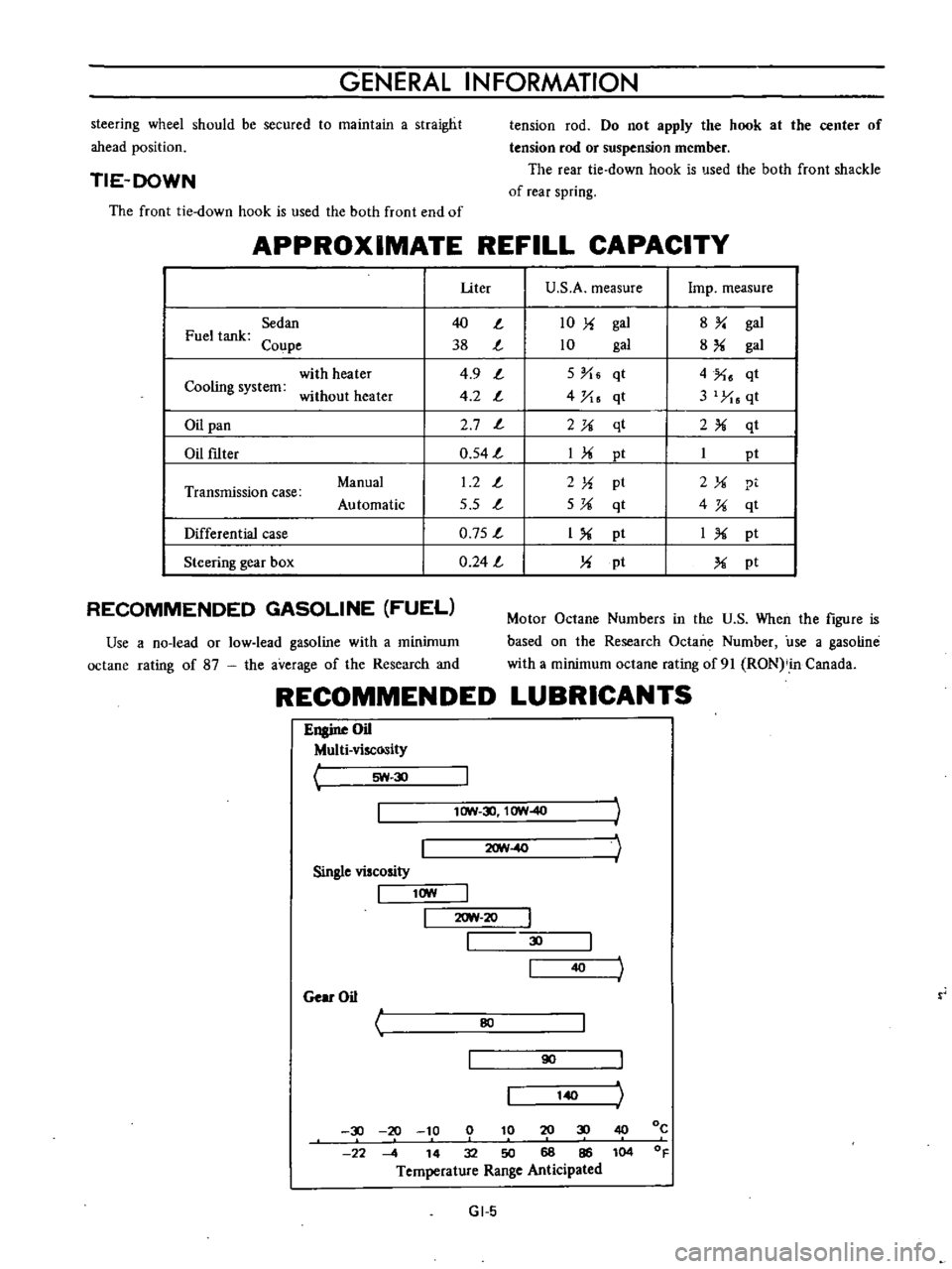

Front

side

When

jacking

up

the

vehicle

apply

a

garage

jack

beneath

the

front

suspension

member

When

applying

the

jack

be

sure

to

use

a

piece

of

cloth

or

wood

between

the

jack

and

front

suspension

member

Be

careful

not

to

allow

the

jack

coming

into

contact

with

the

steering

cross

rod

located

behind

the

front

suspension

member

When

supporting

the

vehicle

with

a

stand

apply

the

stand

to

front

portion

of

the

front

side

member

s

Fig

GI

8

Front

supportable

point

Rear

side

When

jacking

up

the

rear

side

of

the

vehicle

apply

a

garage

jack

beneath

the

rear

axle

housing

When

removing

and

installing

the

rear

axle

housing

GI

3

Page 301 of 513

GENERAL

INFORMATION

steering

wheel

should

be

secured

to

maintain

a

straight

ahead

position

TIE

DOWN

The

front

tie

down

hook

is

used

the

both

front

end

of

tension

rod

Do

not

apply

the

hook

at

the

center

of

tension

rod

or

suspension

member

The

rear

tie

down

hook

is

used

the

both

front

shackle

of

rear

spring

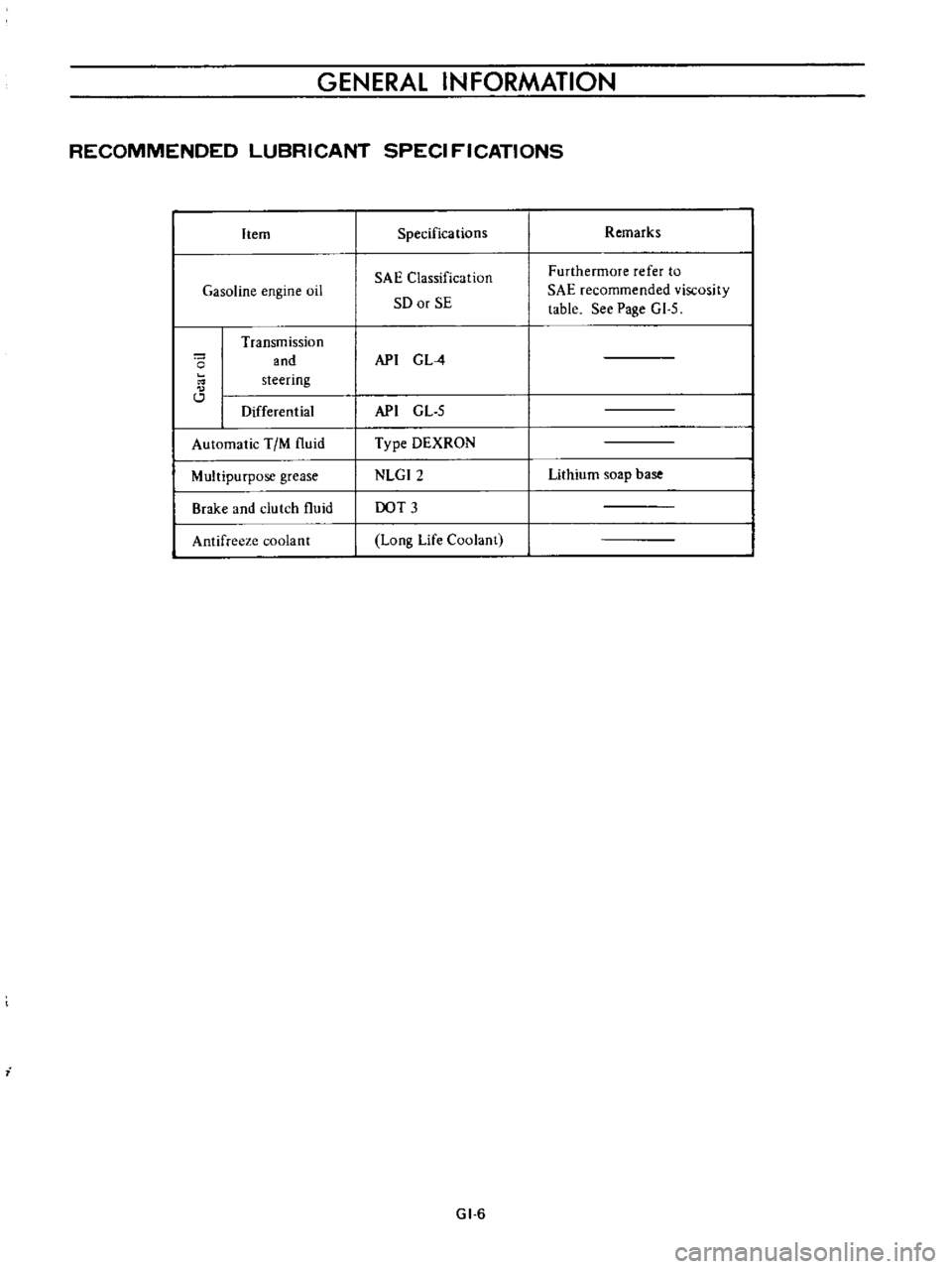

APPROXIMATE

REFILL

CAPACITY

Liter

U

S

A

measure

I

Imp

measure

Sedan

Fuel

tank

Coupe

with

heater

Cooling

system

without

heater

40

L

38

L

4

9

L

4

2

L

2

7

L

0

54

L

1

2

L

5

5

L

0

75

L

0

24

L

Oil

pan

Oilf1lter

Transmission

case

Manual

Automatic

Differential

case

Steering

gear

box

RECOMMENDED

GASOLINE

FUEL

Use

a

no

lead

or

low

lead

gasoline

with

a

minimum

octane

rating

of

87

the

average

of

the

Research

and

1O

gal

8Y

gal

10

gal

8

gal

5

v

qt

4

M

qt

4

Y

6

qt

3

Y

qt

2Ji

qt

2

qt

1

pt

I

pt

2

pt

2

pt

5Ji

qt

4

qt

1

pt

1

pt

pt

pi

Motor

Octane

Numbers

in

the

U

S

When

the

figure

is

based

on

the

Research

Octane

Number

use

a

gasoline

with

a

minimum

octane

rating

of

91

RON

in

Canada

RECOMMENDED

LUBRICANTS

GI

5

r

Page 302 of 513

GENERAL

INFORMATION

RECOMMENDED

LUBRICANT

SPECI

FICATIONS

Item

Gasoline

engine

oil

o

Transmission

and

steering

Differential

Automatic

TIM

fluid

Multipurpose

grease

Brake

and

clutch

fluid

Antifreeze

coolant

i

Specifications

SAE

Classification

SO

or

SE

API

G

L

4

API

GL

5

Type

DEXRON

NLGI2

DOT

3

Long

Life

Coolant

GI

6

Remarks

Furthermore

refer

to

SAE

recommended

viscosity

table

See

Page

GI

5

Lithium

soap

base

Page 475 of 513

CLUTCH

J

I

I

Withdrawal

lever

2

Return

spring

I

31

Release

bearing

ST20610000

iwn

rm

hj

sf

W

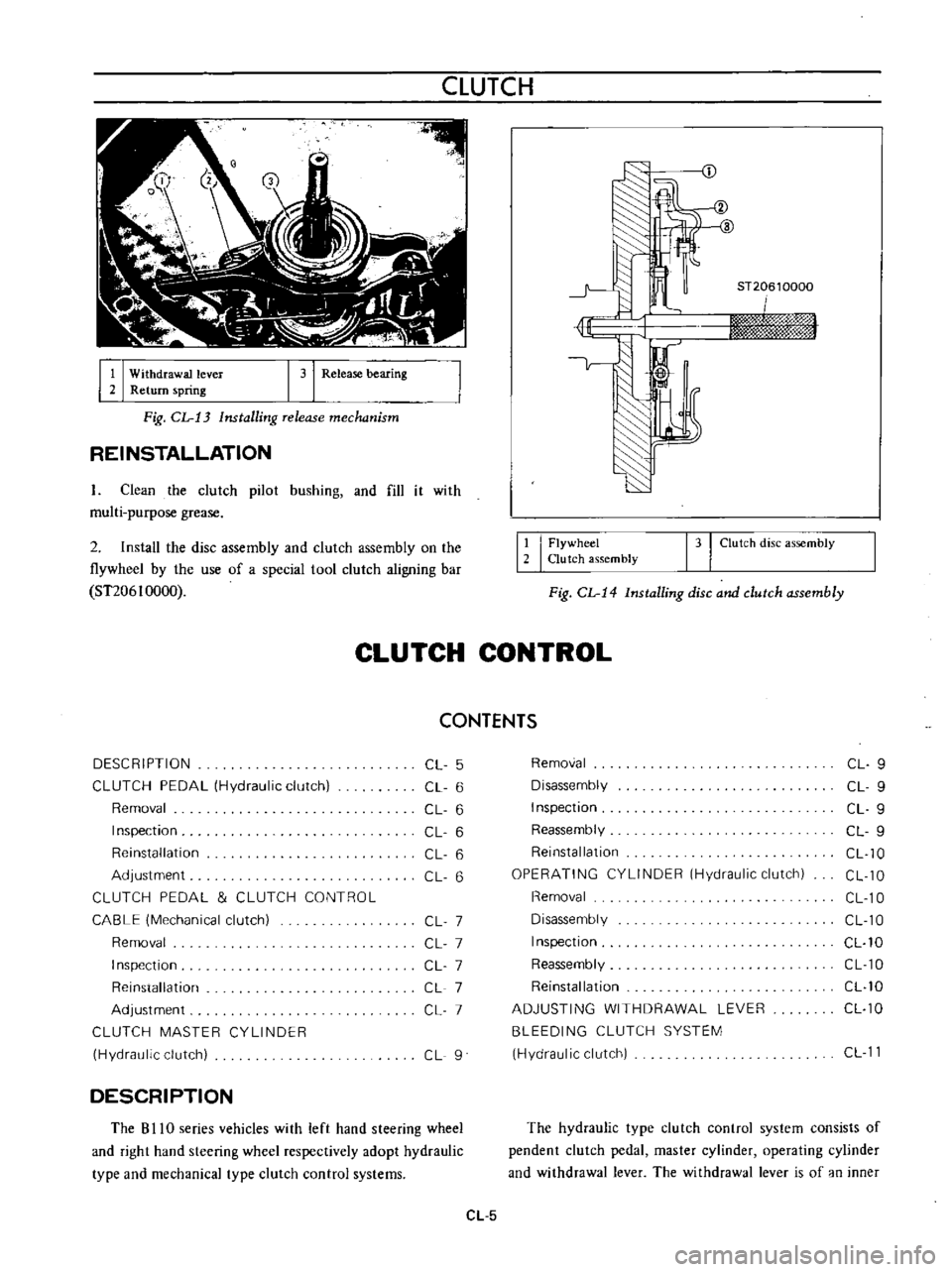

Fig

CL

13

Installing

release

mechanism

REINSTALLATION

L

Clean

the

clutch

pilot

bushing

and

fill

it

with

multi

purpose

grease

2

Install

the

disc

assembly

and

clutch

assembly

on

the

flywheel

by

the

use

of

a

special

tool

clutch

aligning

bar

ST206

I

0000

12

I

Flywheel

Clutch

assembly

131

Clutch

disc

assembly

Fig

CL

14

Installing

disc

and

clutch

assembly

CLUTCH

CONTROL

CONTENTS

DESCRIPTION

CL

5

Removal

CL

9

CLUTCH

PEDAL

Hydraulic

clutch

CL

6

Disassembly

CL

9

Removal

CL

6

Inspection

CL

9

Inspection

CL

6

Reassembly

CL

9

Reinstallation

CL

6

Reinstallation

CL

10

Adjustment

CL

6

OPERATING

CYLINDER

Hydraulic

clutch

CL

10

CLUTCH

PEDAL

CLUTCH

CONTROL

Removal

CL

10

CABLE

Mechanical

clutch

CL

7

Disassembly

CL

10

Removal

CL

7

Inspection

CL

10

Inspection

CL

7

Reassembly

CL

10

Reinstallation

CL

7

Reinstallation

CL

10

Adjustment

CL

7

ADJUSTING

WITHDRAWAL

LEVER

CL

10

CLUTCH

MASTER

CYLINDER

BLEEDING

CLUTCH

SYSTEM

Hydraulic

clutch

CL

9

Hydraulic

clutch

CL

11

DESCRIPTION

The

B

I

IO

series

vehicles

with

left

hand

steering

wheel

and

right

hand

steering

wheel

respectively

adopt

hydraulic

type

and

mechanical

type

clutch

control

systems

The

hydraulic

type

clutch

control

system

consists

of

pendent

clutch

pedal

master

cylinder

operating

cylinder

and

withdrawal

lever

The

withdrawal

lever

is

of

an

inner

CL

5

Page 488 of 513

TRANSMISSION

TRANSMISSION

CONTENTS

DESCRIPTION

Specifications

REMOVAL

DISASSEMBLY

INSPECTION

Transmission

case

and

rear

extension

Bearing

Gear

and

shaft

TM

l

TM

l

TM

2

TM

4

TM

7

TM

7

TM

8

TM

8

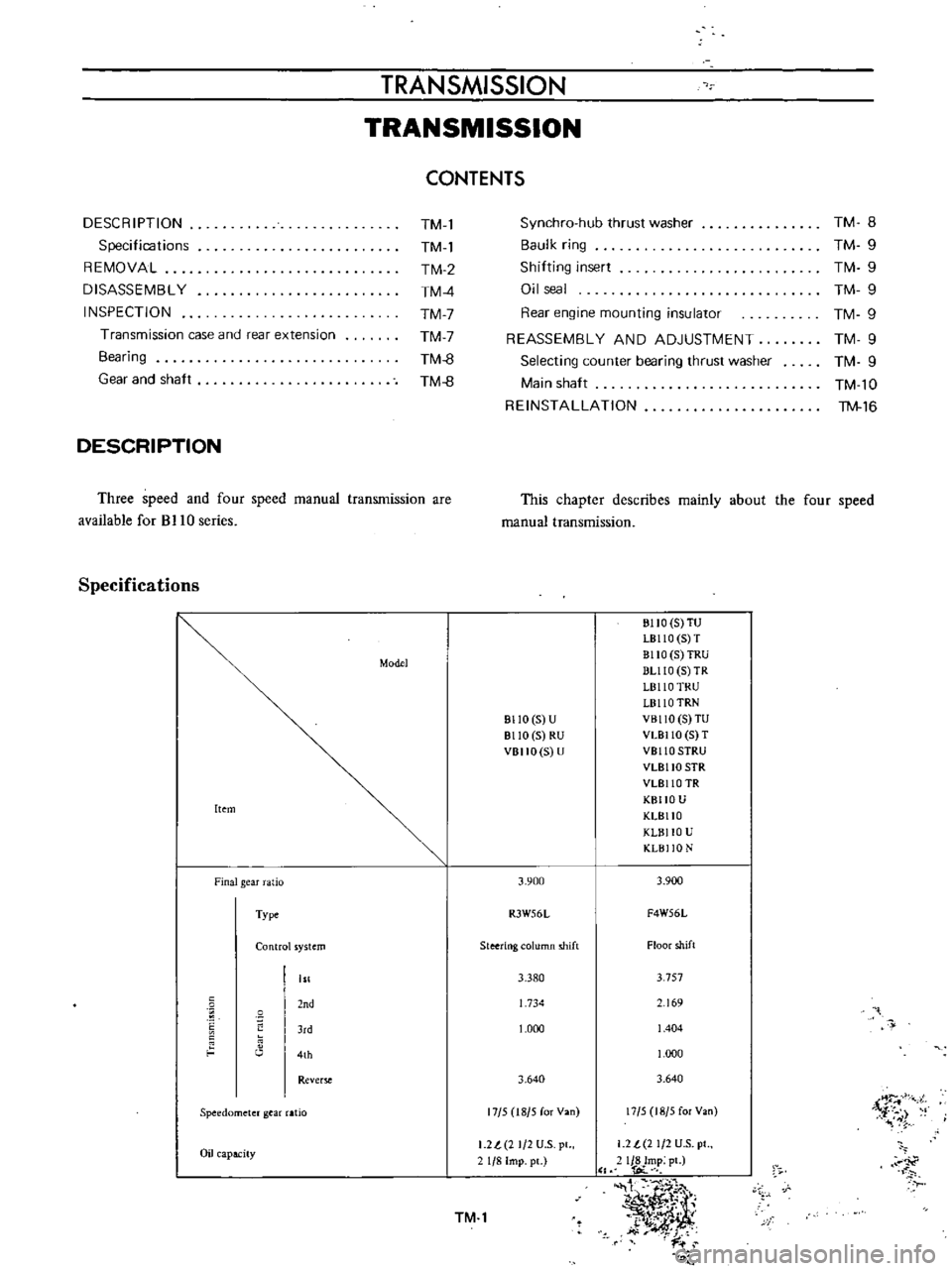

DESCRIPTION

Three

speed

and

four

speed

manual

transmission

are

available

for

BJ

10

series

Specifications

Model

Item

Finalgear

atio

Type

Control

ystem

nd

J

d

4th

Rever

Speedometer

gear

aHo

Oil

apacity

TM

8

TM

9

TM

9

TM

9

TM

9

TM

9

TM

9

TM

l0

TM

16

Synchro

hub

thrust

washer

Baulk

ring

Shilting

insert

Oil

seal

Rear

engine

mounting

insulator

REASSEMBLY

AND

ADJUSTMENT

Selecting

counter

bearing

thrust

washer

Main

shaft

REINSTALLATION

This

chapter

describes

mainly

about

the

four

speed

manual

transmission

811O

5

U

8110

5

RU

VBIIO

S

U

3

900

R3W56L

Steering

olumn

shift

3

380

1

734

1

000

3

640

17

5

18

5

for

Van

I

2l

2

1

2

U

S

pl

1

8

Imp

pc

TM

l

BIIO

S

TU

LB110

S

T

BllO

5

TRU

DUlO

5

TR

L8110

TRU

L8110

TRN

VBllO

S

TU

VLBllO

5

T

VBllO

SIRU

VLBllO

SIR

VLBllO

TR

KBIIO

U

KLBllO

KLBllO

U

KLBI

O

N

3

900

F4W56L

Floor

shift

3

757

69

1

404

1

000

3

640

17

5

18

5

for

Van

i

r

i

1

2

t

2

1

2

U

S

pt

IJ8Imp

pt

l

OC

t

1

I

t

y

y

dt

k

J

t

i

r

Page 503 of 513

CHASSIS

REINSTALLATION

Remount

the

transmission

in

reverse

sequence

of

dismounting

TRANSMISSION

GEAR

CONTROL

CONTENTS

DESCRIPTION

COLUMN

SHIFT

CONTROL

SYSTEM

Removal

TM

16

TM

17

TM

17

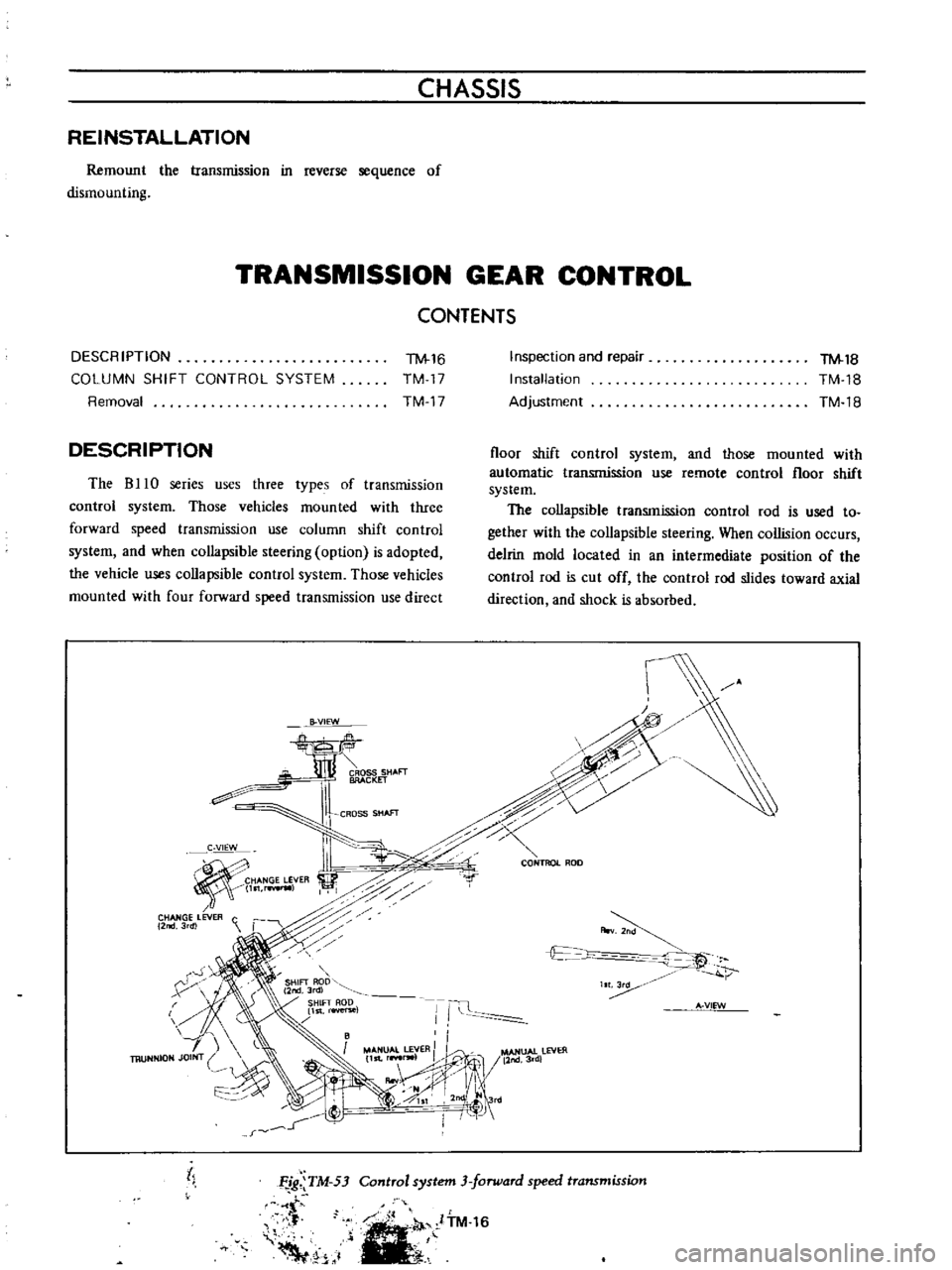

DESCRIPTION

The

B

10

series

uses

three

types

of

transmission

control

system

Those

vehicles

mounted

with

three

forward

speed

transmission

use

column

shift

control

system

and

when

collapsible

steering

option

is

adopted

the

vehicle

uses

collapsible

control

system

Those

vehicles

mounted

with

four

forward

speed

transmission

use

direct

B

VIEW

CROSS

SHAFT

BRACKET

CROSS

SHAfT

C

VIEW

HANGE

LEVER

l

rwIl

CHANGE

LEVER

C

2

3rdl

r

X

h

Inspection

and

repair

Installation

Adjustment

TM

18

TM

18

TM

18

floor

shift

control

system

and

those

mounted

with

automatic

transmission

use

remote

control

floor

shift

system

The

collapsible

transmission

control

rod

is

used

to

gether

with

the

collapsible

steering

When

collision

occurs

delrin

mold

located

in

an

intermediate

position

of

the

control

rod

is

cut

off

the

control

rod

slides

toward

axial

direction

and

shock

is

absorbed

c

0

CONTROL

ROD

r

A

v

t

c

t

IT

Ii

A

VIEW

MANUAL

LEVER

II

l

MANUAl

lEVER

11st

r

lW1

11nd3rd

IIooV

j

II

1

0SI

2nd

Jrd

I

I

j

tl

Control

system

3

forward

speed

transmission

Ffg

TM

53

t

f

Voo

1

ITM

16

Page 504 of 513

TRANSMISSION

COLUMN

SHIFT

CONTROL

SYSTEM

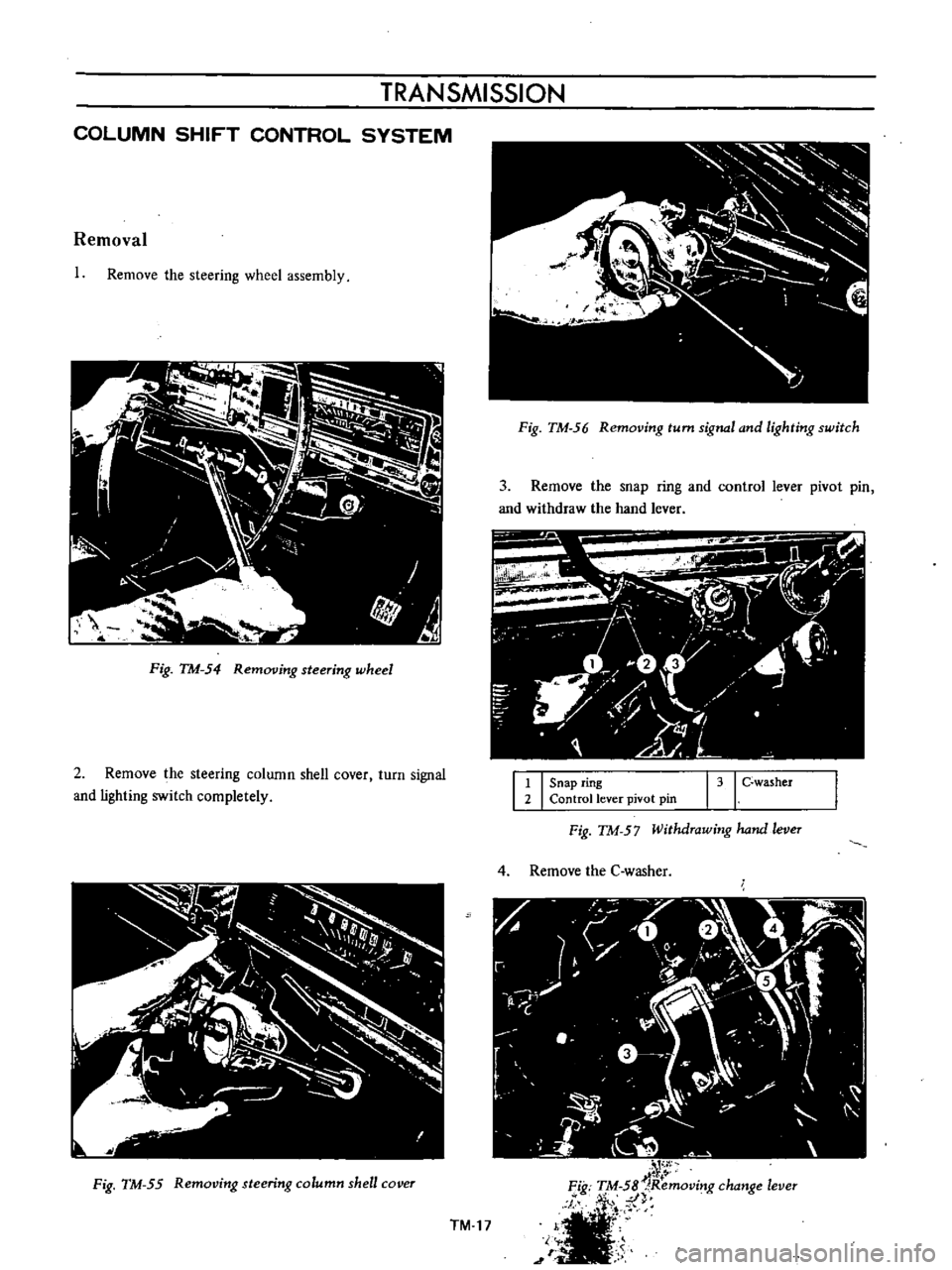

Removal

Remove

the

steering

wheel

assembly

Fig

TM

54

Rem01

ing

steering

wheel

2

Remove

the

steering

column

shell

cover

turn

signal

and

lighting

switch

completely

Fig

TM

55

Removing

steering

column

shell

cover

Fig

TM

56

Removing

turn

signal

and

lighting

switch

3

Remove

the

snap

ring

and

control

lever

pivot

pin

and

withdraw

the

hand

lever

A

A

V

l

Y

e

f

I

1

I

V

e

tl

f

r

4

2i

L

1

I

Snap

ring

2

Control

lever

pivot

pin

I

3

I

C

washer

Fig

TM

57

Withdrawing

hand

ever

4

Remove

the

C

washer

TM

17

i

MI

ig

r

M

5J

emOVing

change

lever

J

y

Ji

1

r

oJ