steering DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 232 of 513

BODY

INSTRUMENT

PANEL

CONTENTS

REMOVAL

BF

42

REMOVAL

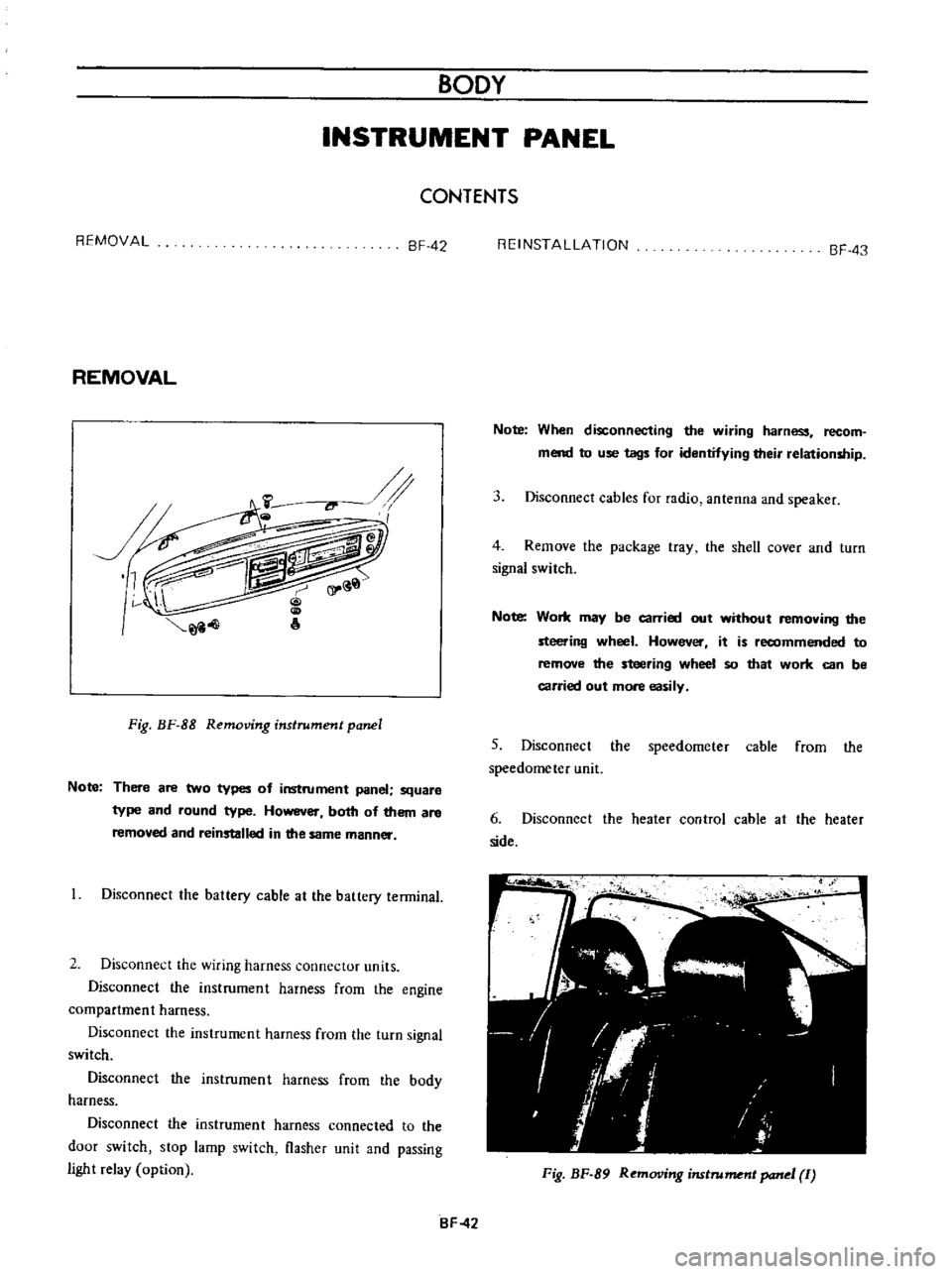

Fig

BF

88

Removing

instrument

panel

Note

There

are

two

types

of

instrument

panel

square

type

and

round

type

However

both

of

them

are

removed

and

reinstalled

in

the

same

manner

Disconnect

the

battery

cable

at

the

battery

terminal

2

Disconnect

the

wiring

harness

connector

units

Disconnect

the

instrument

harness

from

the

engine

compartment

harness

Disconnect

the

instrument

harness

from

the

turn

signal

switch

Disconnect

the

instrument

harness

frorn

the

body

harness

Disconnect

the

instrumen

t

harness

connected

to

the

door

switch

stop

lamp

switch

flasher

unit

and

passing

light

relay

option

REINSTALLATION

BF

43

Note

When

disconnecting

the

wiring

harness

recom

mend

to

use

tags

for

identifying

their

relationship

3

Disconnect

cables

for

radio

antenna

and

speaker

4

Remove

the

package

tray

the

shell

cover

and

turn

signal

switch

Note

Work

may

be

carried

out

without

removing

die

steering

wheel

However

it

is

recommended

to

remove

the

steering

wheel

50

that

work

can

be

carried

out

more

easily

5

Disconnect

the

speedometer

cable

from

the

speedometer

unit

6

Disconnect

the

heater

control

cable

at

the

heater

side

Fig

BF

89

Removing

imtrument

panel

Ii

BF

42

Page 233 of 513

7

Remmre

three

screws

from

top

of

the

instrument

one

each

installation

bolt

frorn

both

sides

of

the

bottorn

and

two

bolts

used

to

secure

the

instrument

panel

together

with

the

steering

column

clamp

8

Raising

the

instrument

panel

slightly

pull

it

toward

rear

side

of

the

vehicle

and

remove

it

Note

Ensuring

that

all

cables

are

disconnected

remove

the

instrument

panel

slowly

aoo

carefully

REINSTALLATION

Reinstall

the

instrument

panel

in

reverse

sequence

of

removal

BODY

Fig

BF

90

Removing

instrument

panel

II

ROOM

TRIM

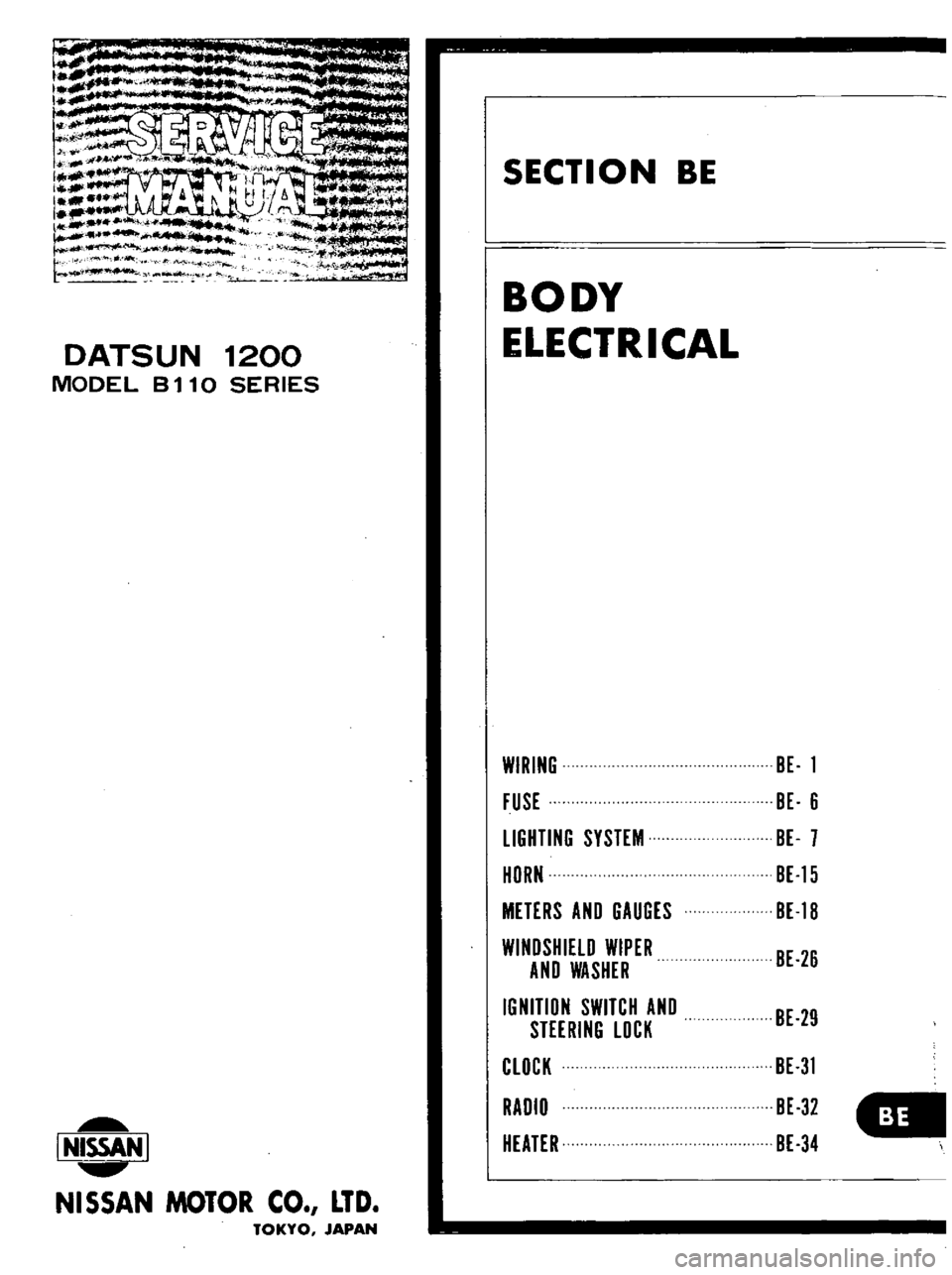

INSTALLING

HEAD

LINING

IA

P

AV

FRONT

A

A

IB

A

L

Adhesive

Detailed

view

of

A

portion

B

B

Be

sure

to

hook

the

clamp

securely

Fig

BF

91

Installing

head

lining

Note

Be

sure

to

install

the

roof

insulator

before

installing

the

head

lining

J

BF

43

Page 235 of 513

DATSUN

1200

MODEL

B

11

0

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BE

BODY

ELECTRICAL

WIRING

FUSE

LIGHTING

SYSTEM

HORN

METERS

AND

GAUGES

WINDSHIELD

WIPER

AND

WASHER

IGNITION

SWITCH

AND

STEERING

LOCK

CLOCK

RADIO

HEATER

BE

1

BE

6

BE

7

BE

15

BE

18

BE

26

BE

29

BE

31

BE

32

BE

34

Page 245 of 513

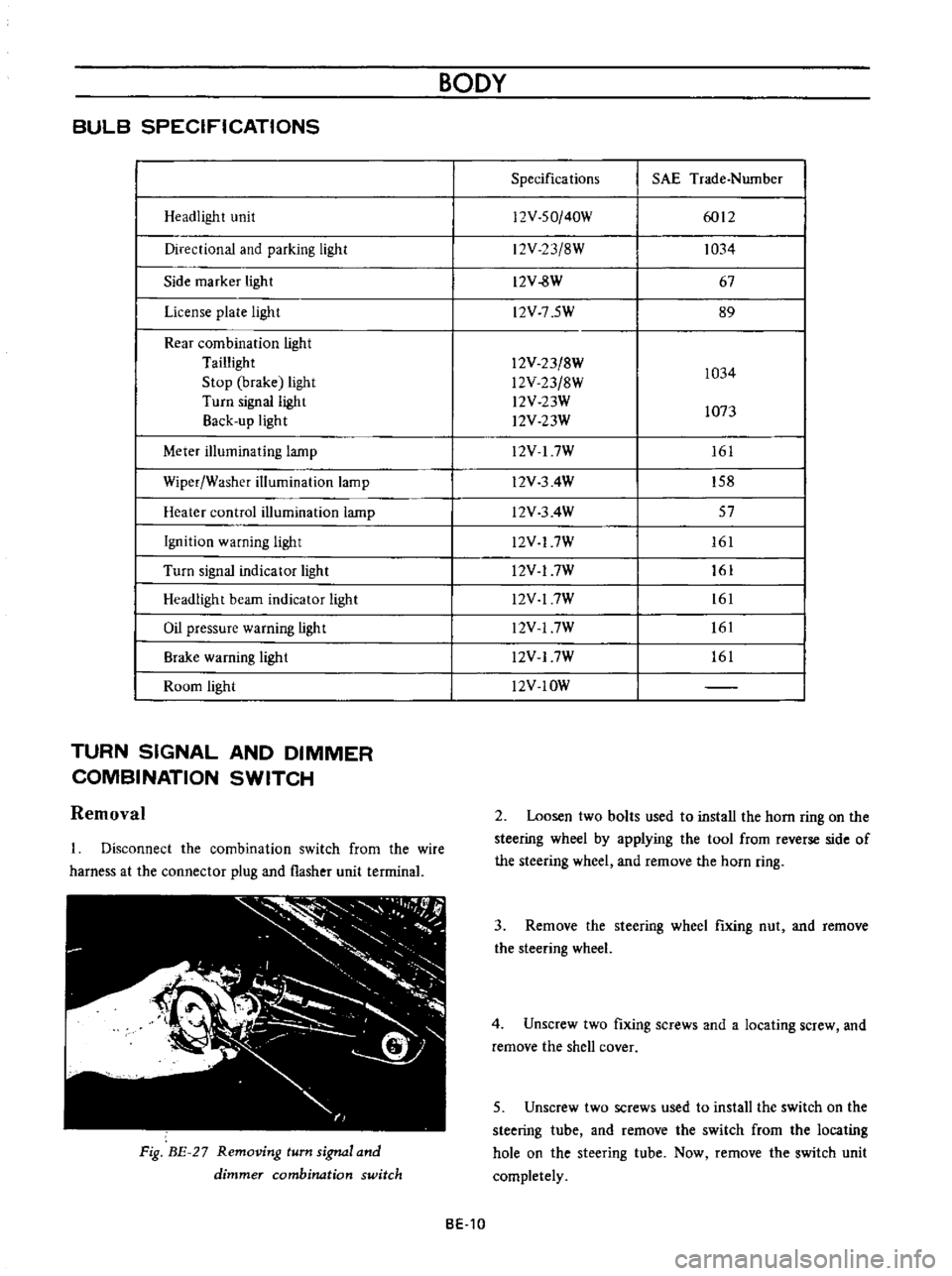

BULB

SPECIFICATIONS

Headlight

unit

Directional

and

parking

light

Side

marker

light

License

plate

light

Rear

combination

light

Taillight

Stop

brake

light

Turn

signal

light

Back

up

light

Meter

illuminating

lamp

Wiper

Washer

illumination

lamp

Heater

control

illumination

lamp

Ignition

warning

light

Turn

signal

indicator

light

Headlight

beam

indicator

light

Oil

pressure

warning

light

Brake

warning

ligh

t

Room

light

TURN

SIGNAL

AND

DIMMER

COMBINATION

SWITCH

Removal

Disconnect

the

combination

switch

from

the

wire

harness

at

the

connector

plug

and

flasher

unit

terrninal

Fig

BE

27

Removing

turn

signal

and

dimmer

combination

switch

BODY

Specifications

SAE

Trade

Number

12V

SO

40W

6012

12V

23

8W

1034

12V

8W

67

l2V

7

5W

89

12V

23

8W

1034

l2V

23

8W

l2V

23W

1073

l2V

23W

12V

I

7W

161

l2V

3

4W

158

l2V

3

4W

57

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

17W

161

l2V

IOW

2

Loosen

two

bolts

used

to

install

the

horn

ring

on

the

steering

wheel

by

applying

the

tool

from

reverse

side

of

the

steering

wheel

and

remove

the

horn

ring

3

Remove

the

steering

wheel

fixing

nut

and

remove

the

steering

wheel

4

Unscrew

two

fixing

screws

and

a

locating

screw

and

remove

the

shell

cover

5

Unscrew

two

screws

used

to

install

the

switch

on

the

steering

tube

and

remove

the

switch

from

the

locating

hole

on

the

steering

tube

Now

remove

the

switch

unit

completely

BE

10

Page 253 of 513

BODY

METERS

AND

GAUGES

CONTENTS

CLUSTER

LID

Oescri

ption

Removal

SPEEDOMETER

Replacement

FUEL

GAUGE

AND

TEMPERATURE

GAUGE

Description

Replacement

BE

1B

BE

18

BE

18

BE

19

BE

19

BE

19

BE

19

BE

20

CLUSTER

LID

Description

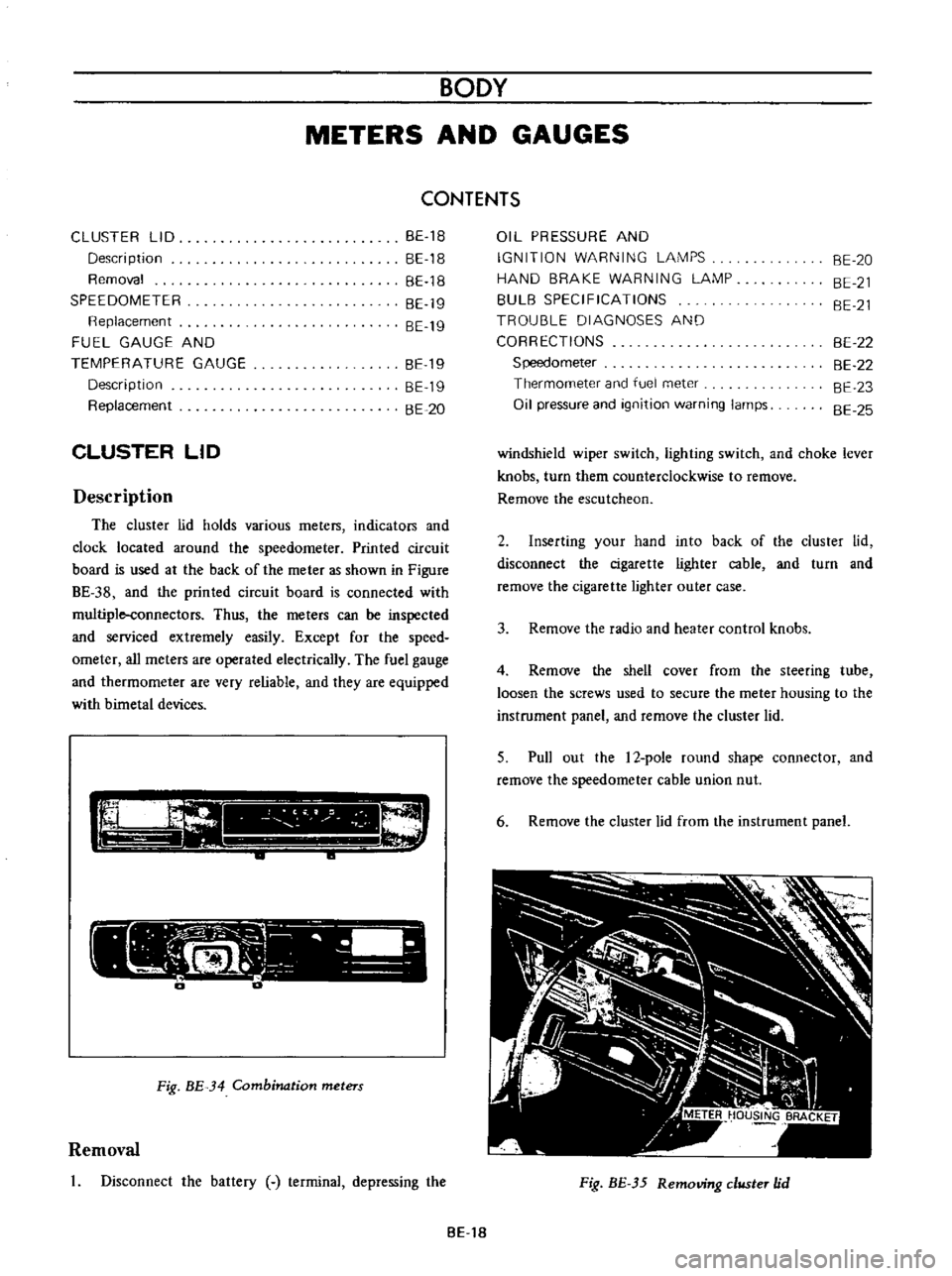

The

cluster

lid

holds

various

rneters

indicators

and

clock

located

around

the

speedorneter

Printed

circuit

board

is

used

at

the

back

of

the

meter

as

shown

in

Figure

BE

38

and

the

printed

circuit

board

is

connected

with

multiple

connectors

Thus

the

meters

Can

be

inspected

and

serviced

extremely

easily

Except

for

the

speed

ometer

all

rneters

are

operated

electrically

The

fuel

gauge

and

therrnometer

are

very

reliable

and

they

are

equipped

with

bimetal

devices

F

a

o

ill

I

1

a

a

Fig

BE

34

Combination

meters

Removal

Disconnect

the

battery

terminal

depressing

the

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

HAND

BRAKE

WARNING

LAMP

BULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Speedometer

Thermometer

and

fuel

meter

Oil

pressure

and

ignition

warning

lamps

BE

20

BE

21

BE

21

BE

22

BE

22

BE

23

BE

25

windshield

wiper

switch

lighting

switch

and

choke

lever

knobs

turn

them

counterclockwise

to

remove

Remove

the

escutcheon

2

Inserting

your

hand

into

back

of

the

cluster

lid

disconnect

the

cigarette

lighter

cable

and

turn

and

remove

the

cigarette

lighter

outer

case

3

Remove

the

radio

and

heater

control

knobs

4

Remove

the

shell

cover

from

the

steering

tube

loosen

the

screws

used

to

secure

the

meter

housing

to

the

instrument

panel

and

remove

the

cluster

lid

5

Pull

out

the

l2

pole

round

shape

connector

and

remove

the

speedometer

cable

union

nut

6

Remove

the

cluster

lid

from

the

instrument

panel

Fig

BE

35

Removing

clllSter

jd

BE

18

Page 264 of 513

BODY

ELECTRICAL

Improper

stop

position

of

wiper

arm

Improperly

positioned

blade

and

arm

Correct

position

Damaged

or

worn

auto

stop

point

Replace

motor

Improper

wiping

Worn

rubber

blade

Replace

blade

Inadequate

pressing

force

of

wiper

arm

Replace

wiper

arm

IGNITION

SWITCH

AND

STEERING

LOCK

CONTENTS

IGNITION

SWITCH

Removal

IGNITION

SWITCH

WITH

STEER

ING

LOCK

BE

29

BE

29

BE

29

IGNITION

SWITCH

This

3

or

4

position

switch

is

installed

on

the

ignition

switch

bracket

which

is

installed

on

the

instrument

panel

with

two

screws

and

controls

the

engine

ignition

system

and

most

of

electrical

equipment

Removal

Remove

the

ignition

switch

connector

loosen

the

ring

nut

remove

the

ignition

switch

from

the

bracket

Description

Steering

lock

replacement

Warning

switch

and

warning

buzzer

BE

29

BE

30

BE

30

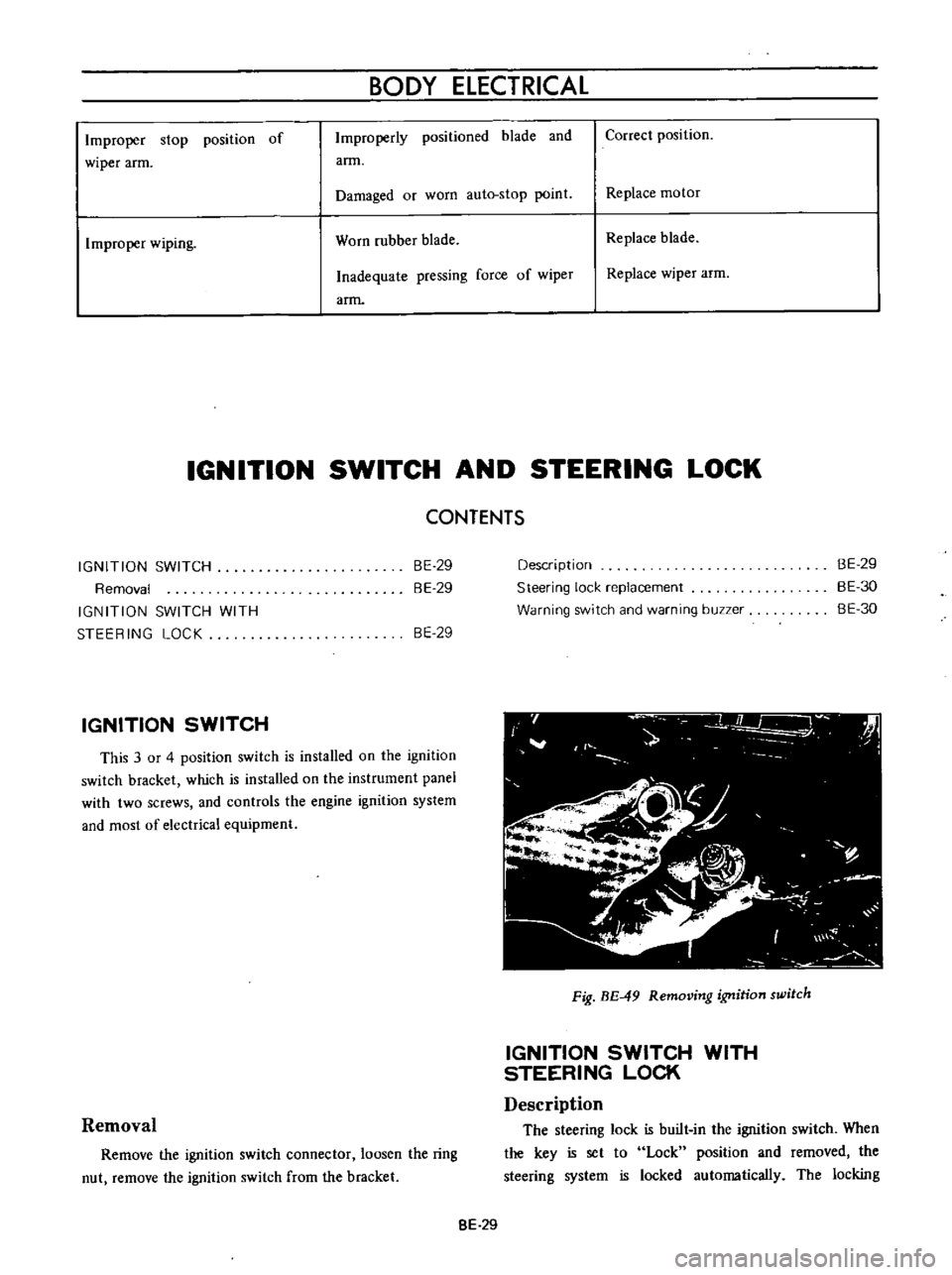

Fig

BE

49

Removing

ignition

switch

IGNITION

SWITCH

WITH

STEERING

LOCK

Description

The

steering

lock

is

built

in

the

ignition

switch

When

the

key

is

set

to

Lock

position

and

rernoved

the

steering

system

is

locked

automatically

The

locking

8E

29

Page 265 of 513

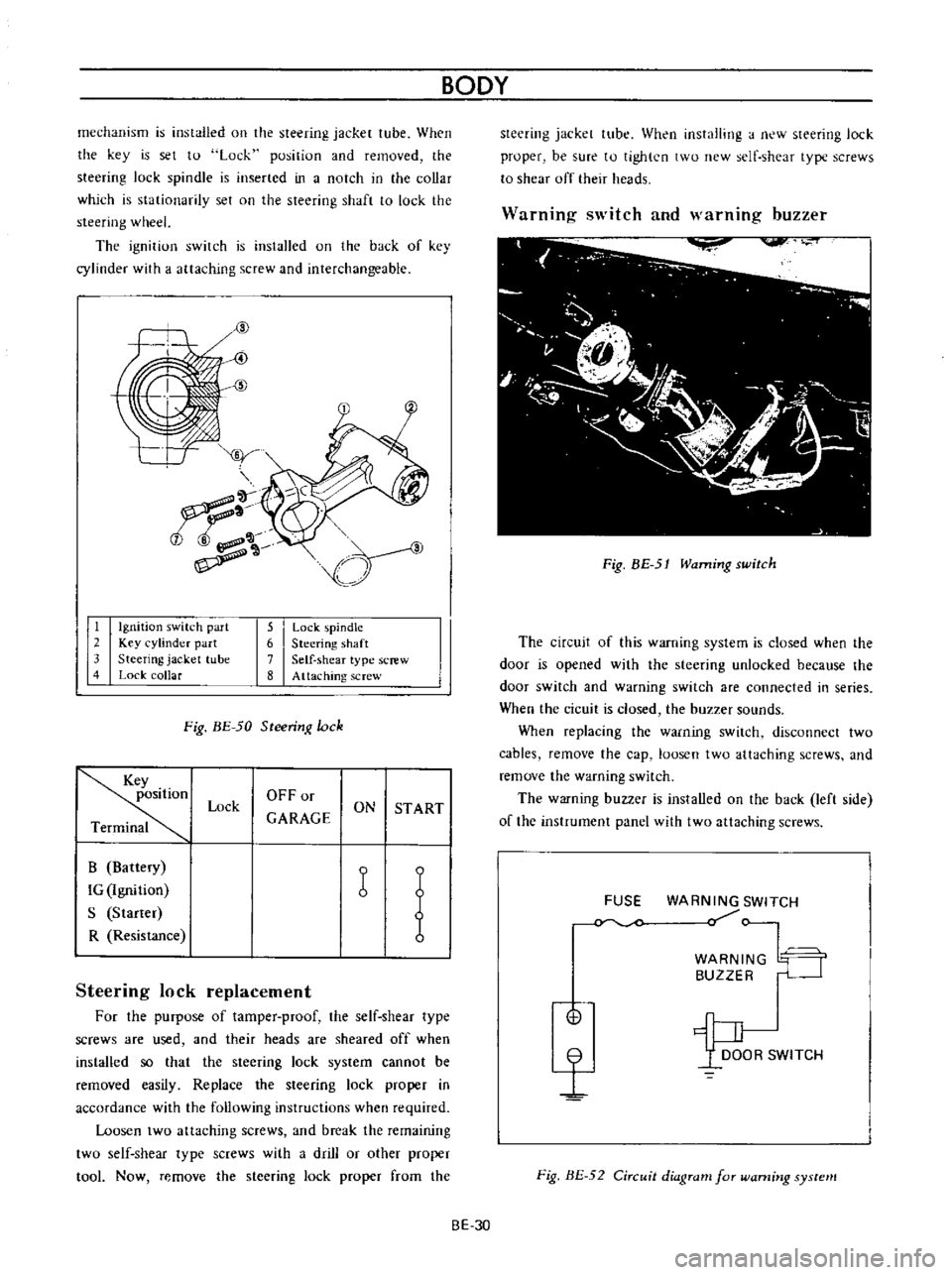

mechanism

is

installed

on

the

steering

jacket

tube

When

the

key

is

set

to

Lock

position

and

removed

the

steering

lock

spindle

is

inserted

in

a

notch

in

the

collar

which

is

stationarity

set

on

the

steering

shaft

to

lock

the

steering

wheel

The

ignitiun

switch

is

installed

on

the

back

of

key

cylinder

with

a

attaching

screw

and

interchangeable

tf

iY

t

7

a

1

Ignition

switch

part

2

Key

cylinder

part

3

Steering

jacket

tube

4

Lock

collar

5

Lock

pindle

6

Steering

shaft

7

Self

shear

type

screw

8

Attaching

screw

Fig

BE

50

Steering

lock

Key

position

Terminal

OFFor

GARAGE

Lock

ON

ST

ART

B

Battery

IG

Ignition

S

Starter

R

Resistance

b

1

Steering

lock

replacement

For

the

purpuse

of

tamper

proof

the

self

shear

type

screws

are

used

and

their

heads

are

sheared

off

when

installed

so

that

the

steering

lock

system

cannot

be

removed

easily

Replace

the

steering

lock

proper

in

accordance

with

the

following

instructions

when

required

Loosen

two

attaching

screws

and

break

the

remaining

twu

self

shear

type

screws

with

a

drill

or

other

proper

tool

Now

remove

the

steering

lock

proper

from

the

BODY

BE

30

steering

jacket

tube

When

installing

a

new

steering

lock

proper

be

sure

tu

tighten

two

new

self

shear

type

screws

to

shear

off

their

heads

Warning

switch

and

warnmg

buzzer

Fig

BE

51

Warning

switch

The

circuit

of

this

warning

system

is

closed

when

the

door

is

opened

with

the

steering

unlocked

because

the

door

switch

and

warning

switch

are

connected

in

series

When

the

cicuit

is

closed

the

buzzer

sounds

When

replacing

the

warning

switch

disconnect

two

cables

remove

the

cap

loosen

two

attaching

screws

and

remove

the

warning

switch

The

warning

buzzer

is

installed

on

the

back

left

side

of

the

instrument

panel

with

two

attaching

screws

FUSE

WARNING

SWITCH

WARN

BUZZ

G

n

WITCH

t

Fig

BE

52

Circuit

diagram

for

warning

system

Page 286 of 513

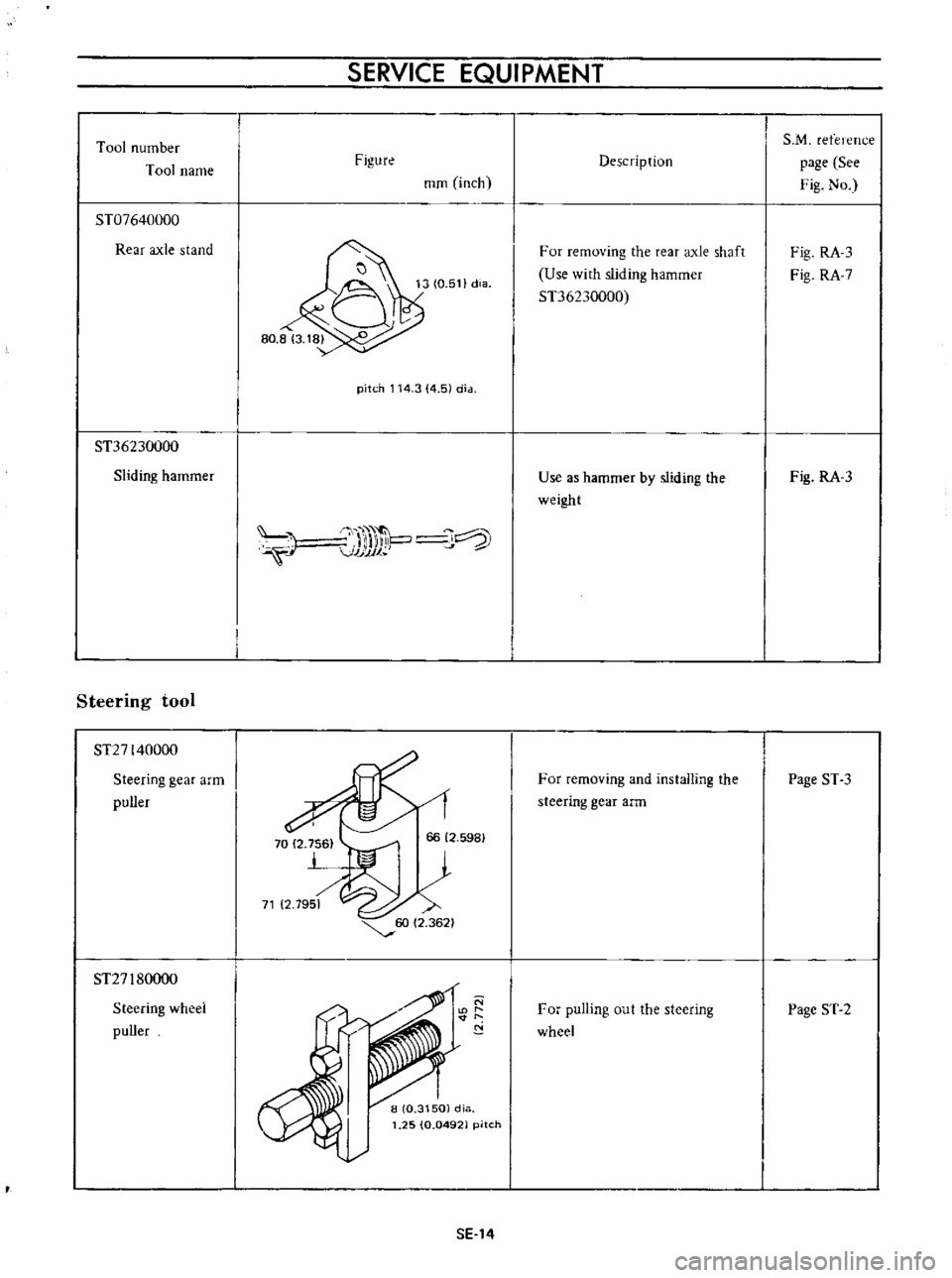

Tool

number

Tool

name

ST07640000

Rear

axle

stand

ST36230000

Sliding

hammer

Steering

tool

ST27140000

Steering

gear

arm

puller

ST27

I

80000

Steering

wheel

puller

SERVICE

EQUIPMENT

Figure

mm

inch

pitch

114

3

4

51

dia

J

l

VJJJJ1

P

J

SE

14

Description

For

removing

the

rear

axle

shaft

Use

with

sliding

hammer

ST36230000

Use

as

hammer

by

sliding

the

weight

For

removing

and

installIng

the

steering

gear

arm

For

pulling

out

the

steering

wheel

S

M

refelcTu

e

page

See

Fig

No

Fig

RA

3

Fig

RA

7

Fig

RA

3

Page

ST

3

Page

ST

2

Page 287 of 513

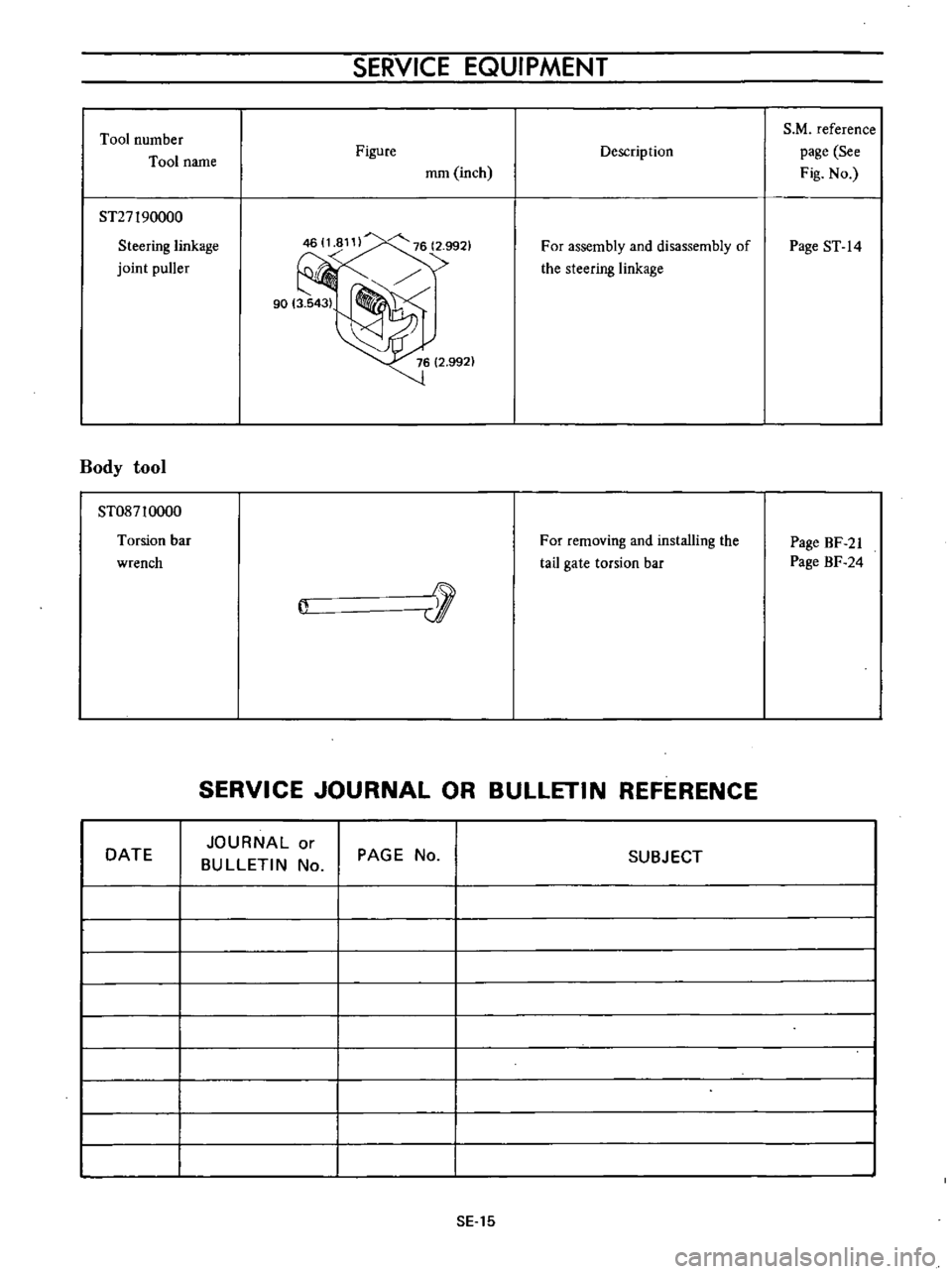

Tool

number

Tool

name

ST27

190000

Steering

linkage

joint

puller

Body

tool

ST08710000

Torsion

bar

wrench

SERVICE

EQUIPMENT

Figure

mm

inch

n

J

Description

For

assembly

and

disassembly

of

the

steering

linkage

For

removing

and

installing

the

tail

gate

torsion

bar

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SE

15

SUBJECT

S

M

reference

page

See

Fig

No

Page

ST

14

Page

BF

21

Page

BF

24

Page 291 of 513

ti

r

f

o

1

b

4

AI

I

W

n

t

i

i

1

i

f

f

7i

ii

y

0

r

1

J

1

t

I

r

I

DATSUN

1200

SERVICE

MANUAL

MODEL

8110

SERIES

N

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

j

QUICK

REFERENCE

INDEX

GENERAL

INfORMATION

GI

EMISSION

CONTROL

AND

TUNE

UP

ET

ENGINE

MECHANICAL

EM

REAR

AXlE

8

REAR

SUSPENSiON

BRAKE

WHEEL

AND

TIRE

STEERING

ENGINE

CONTROL

fUEL

8

EXHAUST

BODY

BODY

ElECTRICAL

SERVICE

EQUIPMENT