key DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 54 of 513

through

all

drive

positions

and

place

the

lever

in

park

P

position

In

this

inspection

the

car

must

be

placed

on

a

level

surface

The

amount

of

the

oil

varies

with

the

temperature

As

a

rule

the

oil

level

must

be

measured

after

its

tempera

ture

becomes

sufficiently

high

I

Fill

the

oil

to

the

line

H

The

difference

of

capacities

between

both

H

and

L

is

approximately

0

4

liter

7

8

U

S

pt

3

4

Imper

pt

and

therefore

take

care

not

to

fill

beyond

the

line

H

2

At

the

time

of

the

above

topping

up

and

changing

of

oil

care

should

be

taken

of

to

prevent

mixing

the

oil

with

dust

and

water

2

Inspecting

oil

condition

The

condition

of

oil

sticking

to

the

level

gauge

indicates

whether

to

over

haul

and

repair

the

transmission

or

look

for

the

defective

part

If

the

oil

has

deteriorated

into

a

varnish

like

quality

it

causes

the

con

trol

valve

to

stick

The

blackened

oil

gives

the

proof

of

the

burned

clutch

brake

band

etc

In

these

cases

the

transmission

must

be

replaced

Notes

a

In

oil

level

checking

use

special

paper

waste

to

handle

the

level

gauge

and

take

care

not

to

let

the

scraps

of

paper

and

cloth

tick

to

the

gauge

b

Insert

the

gauge

fully

and

take

it

out

quickly

before

splashing

oil

adheres

to

the

gauge

and

theu

observe

the

level

c

Use

automatic

transmission

fluid

having

DEXRON

iden

tIficatIon

only

in

the

3N71

B

automatic

transmission

d

Pay

atteutIon

because

the

oil

to

be

used

dIffers

from

that

i

used

in

the

Nissan

Full

Automatic

Transmission

3N7IA

Never

mix

the

oil

with

that

CHASSIS

Inspection

and

repair

of

oil

leakage

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

de

tecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

I

Converter

housing

The

rubber

ring

of

oil

pump

hous

ing

The

oil

eaI

of

oil

pump

housing

The

oil

seal

of

engine

crankshaft

The

bolts

of

converter

housing

to

case

2

Transmission

and

rear

extension

Junction

of

transmission

and

rear

extension

Oil

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

Refer

to

Figure

AT

112

The

mounting

portion

of

vacuum

diaphragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

The

oil

seal

of

rear

extension

To

exactly

locate

the

place

of

oil

leakage

proceeds

as

follows

Place

the

vehicle

in

a

pit

and

by

sampling

the

leaked

oil

examine

whe

ther

it

is

the

torq

le

converter

oil

or

not

The

torque

converter

oil

assumes

color

like

red

wine

when

shipped

from

the

factory

so

it

is

ea

ily

distin

guished

from

engine

oil

or

gear

oil

Cleanly

wipe

off

the

leaking

oil

and

dust

and

detect

the

spot

of

oil

leakage

Use

nonflammable

organic

solvent

such

as

carbon

tetrachloride

for

wip

ing

Raise

the

oil

temperature

by

op

erating

the

engine

and

shift

the

lever

to

0

to

heighten

the

oil

pressure

The

spot

of

oil

leakage

will

then

be

found

more

easily

Note

A

the

oil

leakage

from

the

breather

does

not

take

place

except

when

running

at

high

speed

it

is

impossible

to

locate

the

spot

of

leakage

with

vehicle

stalled

AT

50

Checking

engine

idling

rprn

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

engine

does

not

operate

smoothly

and

if

too

high

a

strong

shock

or

creep

develops

when

changing

over

from

N

to

D

or

R

Specified

idling

speed

650

rpm

at

D

position

800

rpm

at

N

position

Checking

and

adjusting

kick

down

switch

and

downshift

solenoid

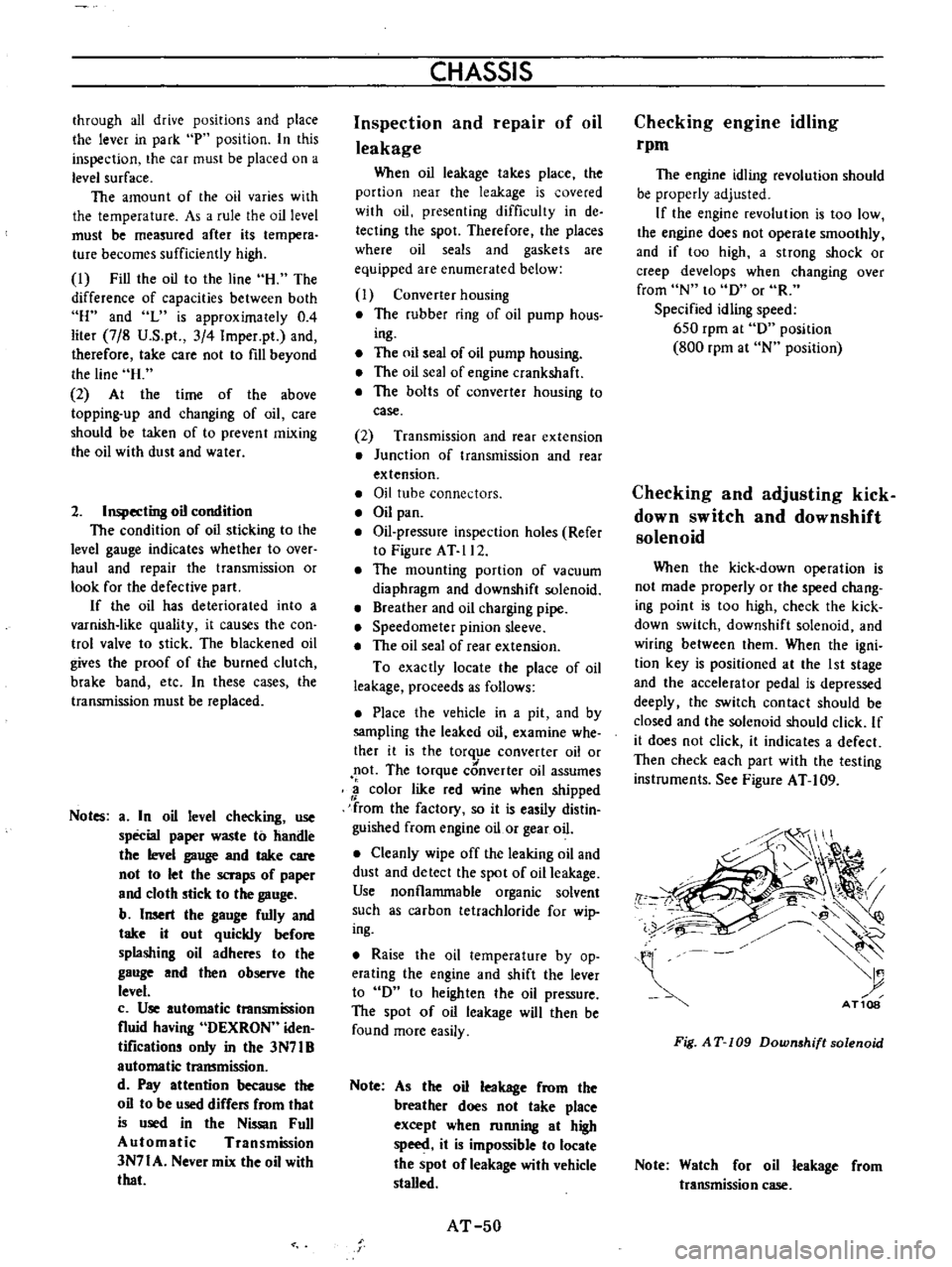

When

the

kick

down

operation

is

not

made

properly

or

the

speed

chang

ing

point

is

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

tion

key

is

positioned

at

the

1st

stage

and

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

should

be

closed

and

the

solenoid

should

click

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

instruments

See

Figure

AT

I09

0

0

1

M

r

7

I

Y

ATl08

Fig

A

T

l

09

Downshift

solenoid

Note

Watch

for

oil

leakage

from

transmission

case

Page 62 of 513

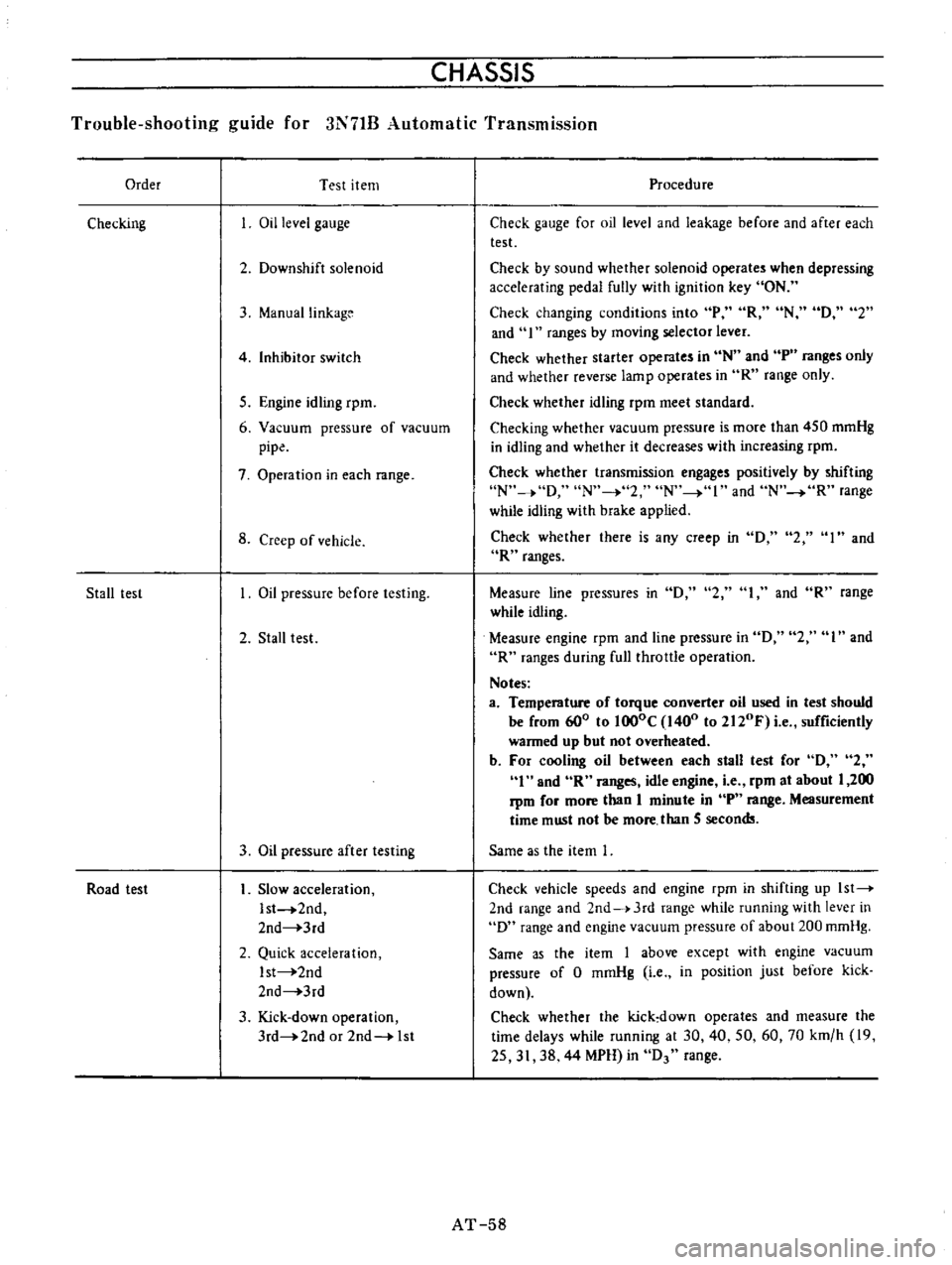

CHASSIS

Trouble

shooting

guide

for

3N71B

Automatic

Transmission

Order

Test

item

Checking

Oil

level

gauge

2

Downshift

solenoid

3

ManuaIlinkage

4

Inhibitor

switch

5

Engine

idling

rpm

6

Vacuum

pressure

of

vacuum

pipe

7

Operation

in

each

range

8

Creep

of

vehicle

Stall

lest

Oil

pressure

before

testing

2

Stall

test

3

Oil

pressure

after

testing

Road

test

Slow

acceleration

Ist

2nd

2nd

3rd

2

Quick

acceleration

Ist

2nd

2nd

3rd

3

Kick

down

operation

3rd

2nd

or

2nd

1st

Procedure

Check

gauge

for

oil

level

and

leakage

before

and

after

each

test

Check

by

sound

whether

solenoid

operates

when

depressing

accelerating

pedal

fully

with

ignition

key

ON

Check

changing

conditions

into

P

R

N

D

2

and

I

ranges

by

moving

selector

lever

Check

whether

starter

operates

in

N

and

tp

ranges

only

and

whether

reverse

lamp

operates

in

R

range

only

Check

whether

idling

rpm

meet

standard

Checking

whether

vacuum

pressure

is

more

than

450

mmHg

in

idling

and

whether

it

decreases

with

increasing

rpm

Check

whether

transmission

engages

positively

by

shifting

N

o

D

N

2

N

I

and

N

R

range

while

idling

with

brake

applied

Check

whether

there

is

any

creep

in

D

2

I

and

R

ranges

2

1

and

R

range

Measure

line

pressures

in

D

while

idling

Measure

engine

rpm

and

line

pressure

in

D

2

I

and

R

ranges

during

fullthrallIe

operation

Notes

a

Temperature

of

torque

converter

oil

used

in

test

should

be

from

600

to

lOOoC

1400

to

2120F

i

e

sufficiently

warmed

up

but

not

overheated

b

For

cooling

oil

between

each

stall

test

for

D

2

1

and

R

ranges

idle

engine

i

e

rpm

at

about

1

200

rpm

for

more

than

1

minute

in

P

range

Measurement

time

must

not

be

more

than

5

secon

Same

as

the

item

I

Check

vehicle

speeds

and

engine

rpm

in

shifting

up

1st

2nd

range

and

2nd

J

3rd

range

while

running

with

lever

in

D

range

and

engine

vacuum

pressure

of

about

200

mmHg

Same

as

the

item

1

above

except

with

engine

vacuum

pressure

of

0

mmHg

i

e

in

position

just

before

kick

down

Check

whether

the

kick

down

operates

and

measure

the

time

delays

while

running

at

30

40

50

60

70

km

h

19

25

31

38

44

MPH

in

D

range

AT

58

Page 264 of 513

BODY

ELECTRICAL

Improper

stop

position

of

wiper

arm

Improperly

positioned

blade

and

arm

Correct

position

Damaged

or

worn

auto

stop

point

Replace

motor

Improper

wiping

Worn

rubber

blade

Replace

blade

Inadequate

pressing

force

of

wiper

arm

Replace

wiper

arm

IGNITION

SWITCH

AND

STEERING

LOCK

CONTENTS

IGNITION

SWITCH

Removal

IGNITION

SWITCH

WITH

STEER

ING

LOCK

BE

29

BE

29

BE

29

IGNITION

SWITCH

This

3

or

4

position

switch

is

installed

on

the

ignition

switch

bracket

which

is

installed

on

the

instrument

panel

with

two

screws

and

controls

the

engine

ignition

system

and

most

of

electrical

equipment

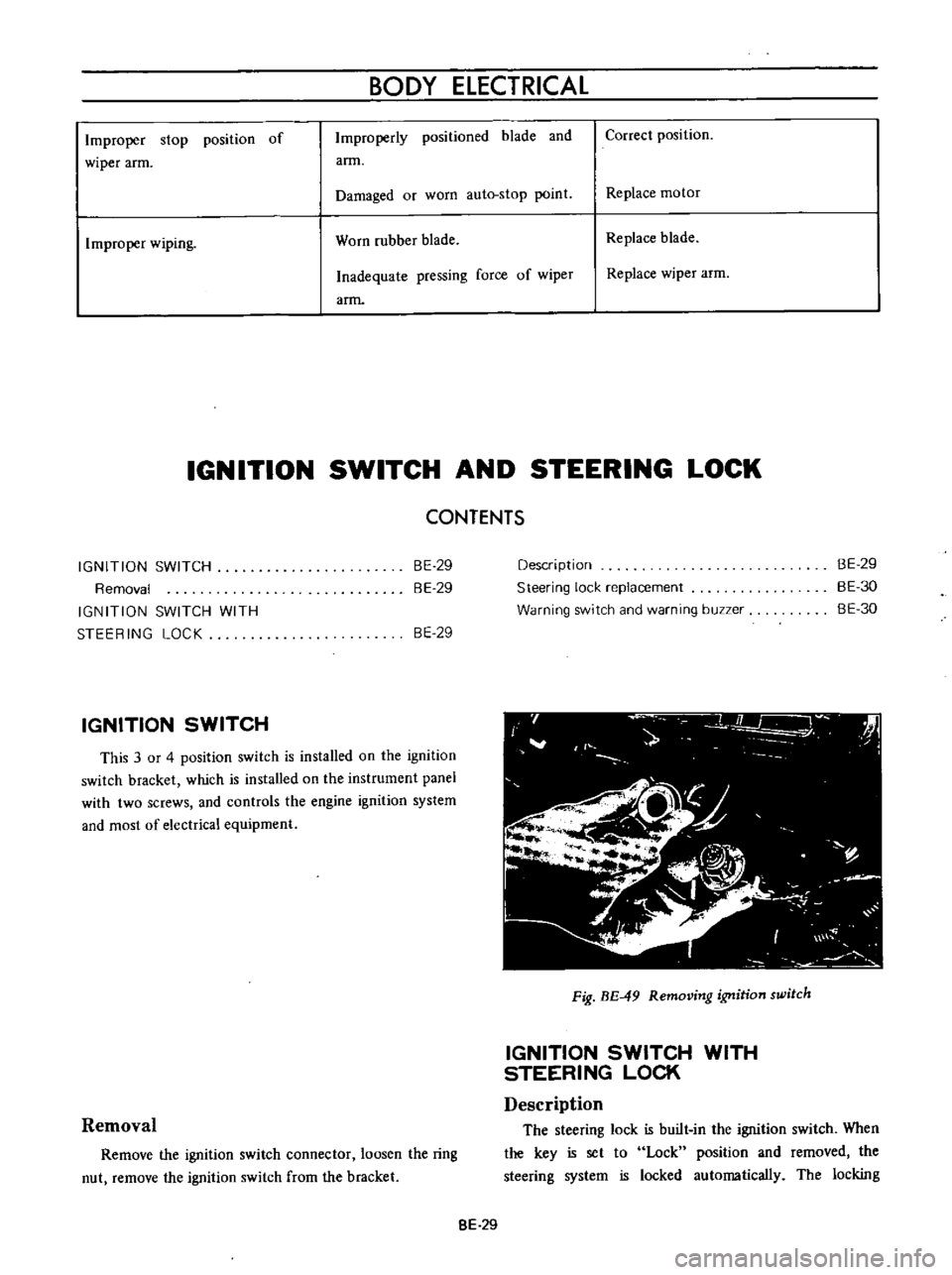

Removal

Remove

the

ignition

switch

connector

loosen

the

ring

nut

remove

the

ignition

switch

from

the

bracket

Description

Steering

lock

replacement

Warning

switch

and

warning

buzzer

BE

29

BE

30

BE

30

Fig

BE

49

Removing

ignition

switch

IGNITION

SWITCH

WITH

STEERING

LOCK

Description

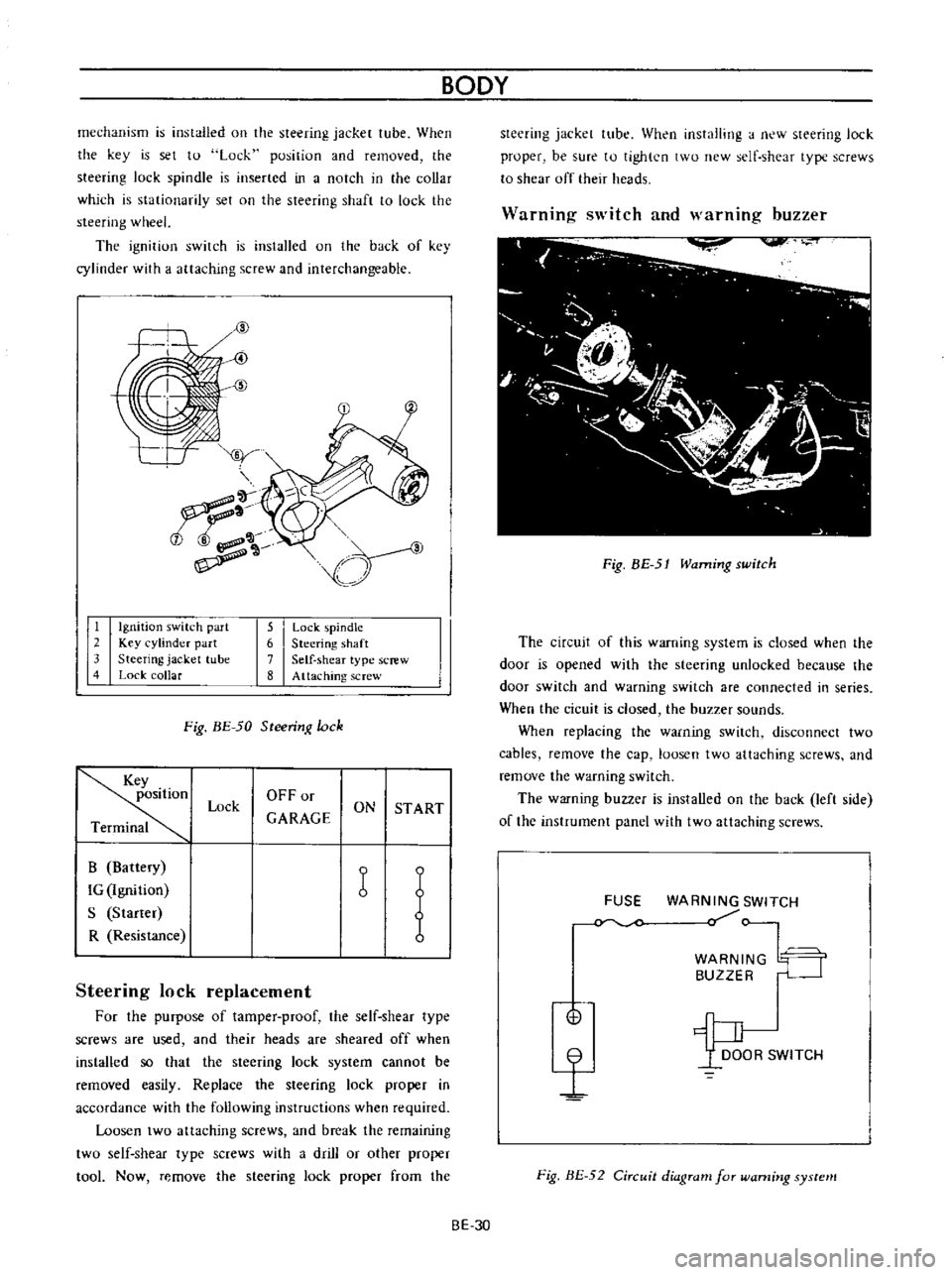

The

steering

lock

is

built

in

the

ignition

switch

When

the

key

is

set

to

Lock

position

and

rernoved

the

steering

system

is

locked

automatically

The

locking

8E

29

Page 265 of 513

mechanism

is

installed

on

the

steering

jacket

tube

When

the

key

is

set

to

Lock

position

and

removed

the

steering

lock

spindle

is

inserted

in

a

notch

in

the

collar

which

is

stationarity

set

on

the

steering

shaft

to

lock

the

steering

wheel

The

ignitiun

switch

is

installed

on

the

back

of

key

cylinder

with

a

attaching

screw

and

interchangeable

tf

iY

t

7

a

1

Ignition

switch

part

2

Key

cylinder

part

3

Steering

jacket

tube

4

Lock

collar

5

Lock

pindle

6

Steering

shaft

7

Self

shear

type

screw

8

Attaching

screw

Fig

BE

50

Steering

lock

Key

position

Terminal

OFFor

GARAGE

Lock

ON

ST

ART

B

Battery

IG

Ignition

S

Starter

R

Resistance

b

1

Steering

lock

replacement

For

the

purpuse

of

tamper

proof

the

self

shear

type

screws

are

used

and

their

heads

are

sheared

off

when

installed

so

that

the

steering

lock

system

cannot

be

removed

easily

Replace

the

steering

lock

proper

in

accordance

with

the

following

instructions

when

required

Loosen

two

attaching

screws

and

break

the

remaining

twu

self

shear

type

screws

with

a

drill

or

other

proper

tool

Now

remove

the

steering

lock

proper

from

the

BODY

BE

30

steering

jacket

tube

When

installing

a

new

steering

lock

proper

be

sure

tu

tighten

two

new

self

shear

type

screws

to

shear

off

their

heads

Warning

switch

and

warnmg

buzzer

Fig

BE

51

Warning

switch

The

circuit

of

this

warning

system

is

closed

when

the

door

is

opened

with

the

steering

unlocked

because

the

door

switch

and

warning

switch

are

connected

in

series

When

the

cicuit

is

closed

the

buzzer

sounds

When

replacing

the

warning

switch

disconnect

two

cables

remove

the

cap

loosen

two

attaching

screws

and

remove

the

warning

switch

The

warning

buzzer

is

installed

on

the

back

left

side

of

the

instrument

panel

with

two

attaching

screws

FUSE

WARNING

SWITCH

WARN

BUZZ

G

n

WITCH

t

Fig

BE

52

Circuit

diagram

for

warning

system

Page 369 of 513

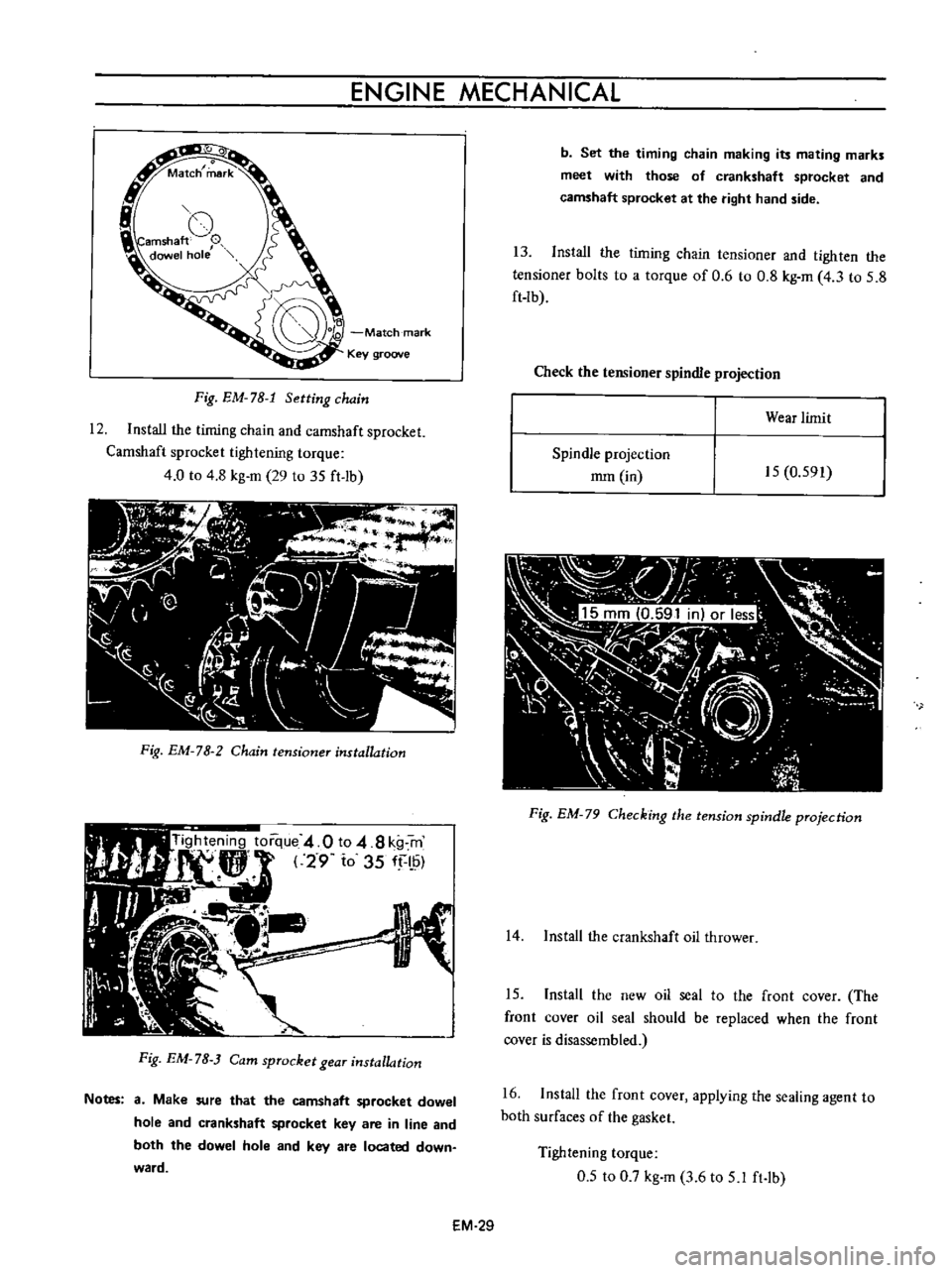

ENGINE

MECHANICAL

o

Match

mark

Key

groove

Fig

EM

78

1

Setting

chain

12

Install

the

timing

chain

and

camshaft

sprocket

Camshaft

sprocket

tightening

torque

4

0

to

4

8

kg

m

29

to

35

ft

lb

Fig

EM

78

2

Chain

tensioner

installation

Fig

EM

7B

Cam

sprocket

gear

installation

Notes

a

Make

sure

that

the

camshaft

sprocket

dowel

hole

and

crankshaft

sprocket

key

are

in

line

and

both

the

dowel

hole

and

key

are

located

down

ward

b

Set

the

timing

chain

making

its

mating

marks

meet

with

those

of

crankshaft

sprocket

and

camshaft

sprocket

at

the

right

hand

side

13

Install

the

timing

chain

tensioner

and

tighten

the

tensioner

bolts

to

a

torque

of

0

6

to

0

8

kg

m

4

3

to

5

8

ft

lb

Check

the

tensioner

spindle

projection

Wear

limit

Spindle

projection

mm

in

15

0

591

Fig

EM

79

Checking

the

tension

spindle

projection

14

Install

the

crankshaft

oil

thrower

15

Install

the

new

oil

seal

to

the

front

cover

The

front

cover

oil

seal

should

be

replaced

when

the

front

cover

is

disassembled

16

Install

the

front

cover

applying

the

sealing

agent

to

both

surfaces

of

the

gasket

Tightening

torque

0

5

to

0

7

kg

m

3

6

to

5

1

ft

lb

EM

29

Page 400 of 513

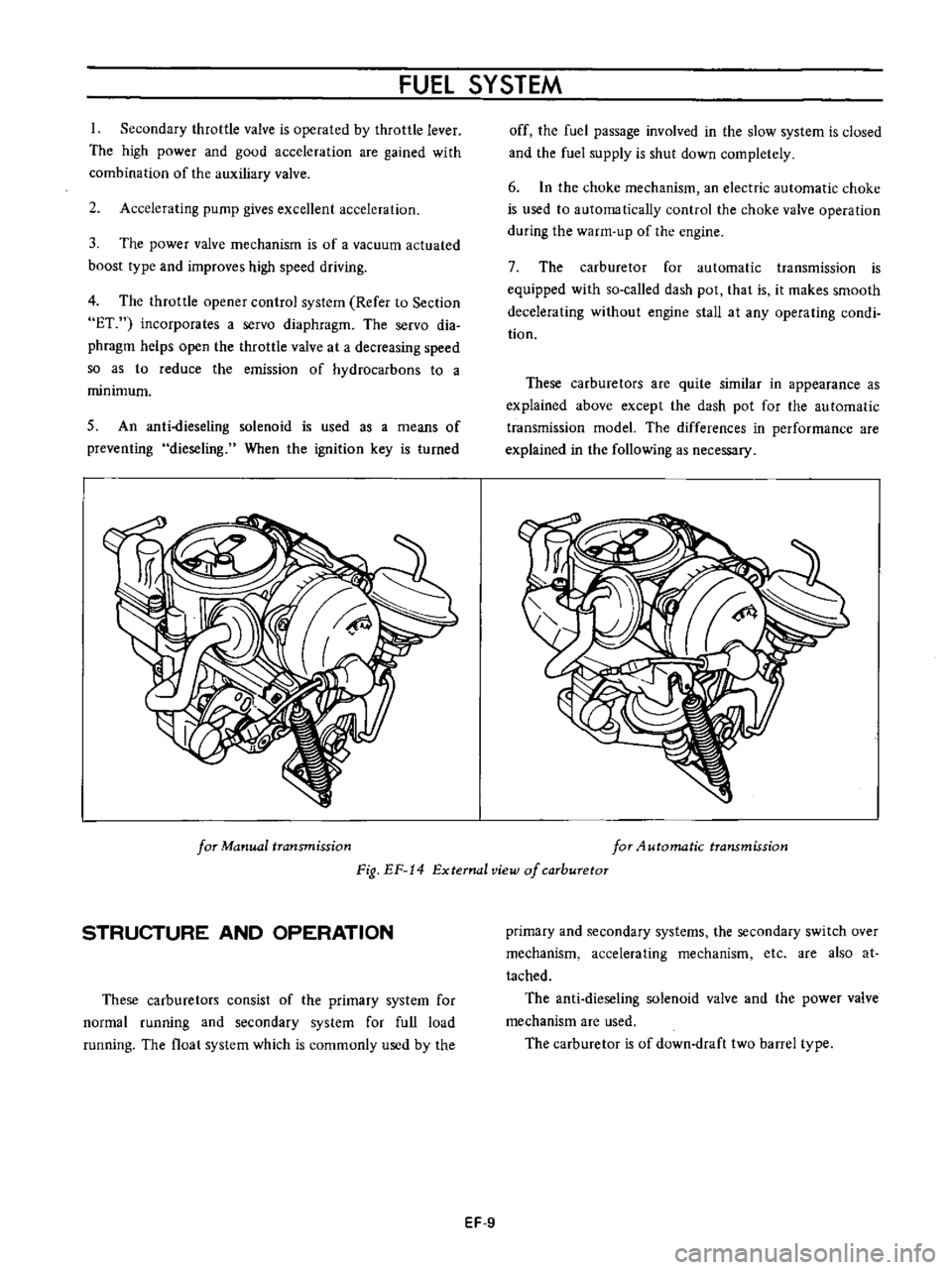

FUEl

SYSTEM

Secondary

throttle

valve

is

operated

by

throttle

lever

The

high

power

and

good

acceleration

are

gained

with

combination

of

the

auxiliary

valve

2

Accelerating

pump

gives

excellent

acceleration

3

The

power

valve

mechanism

is

of

a

vacuum

actuated

boost

type

and

improves

high

speed

driving

4

The

throttle

opener

control

system

Refer

to

Section

ET

incorporates

a

servo

diaphragm

The

servo

dia

phragm

helps

open

the

throttle

valve

at

a

decreasing

speed

so

as

to

reduce

the

emission

of

hydrocarbons

to

a

minimum

5

An

anti

dieseling

solenoid

is

used

as

a

means

of

preventing

dieseling

When

the

ignition

key

is

turned

off

the

fuel

passage

involved

in

the

slow

system

is

closed

and

the

fuel

supply

is

shut

down

completely

6

In

the

choke

mechanism

an

electric

automatic

choke

is

used

to

automatically

control

the

choke

valve

operation

during

the

warm

up

of

the

engine

7

The

carburetor

for

automatic

transmission

is

equipped

with

so

called

dash

pot

that

is

it

makes

smooth

decelerating

without

engine

stall

at

any

operating

condi

tion

These

carburetors

are

quite

similar

in

appearance

as

explained

above

except

the

dash

pot

for

the

au

tomatic

transmission

model

The

differences

in

performance

are

explained

in

the

following

as

necessary

for

Manual

transmission

for

4utomatic

transmission

Fig

EF

14

External

view

of

carburetor

STRUCTURE

AND

OPERATION

These

carburetors

consist

of

the

primary

system

for

normal

running

and

secondary

system

for

full

load

running

The

float

system

which

is

commonly

used

by

the

primary

and

secondary

systems

the

secondary

switch

over

mechanism

accelerating

mechanism

etc

are

also

at

tached

The

anti

dieseling

solenoid

valve

and

the

power

valve

mechanism

are

used

The

carburetor

is

of

down

draft

two

barrel

type

EF

9

Page 403 of 513

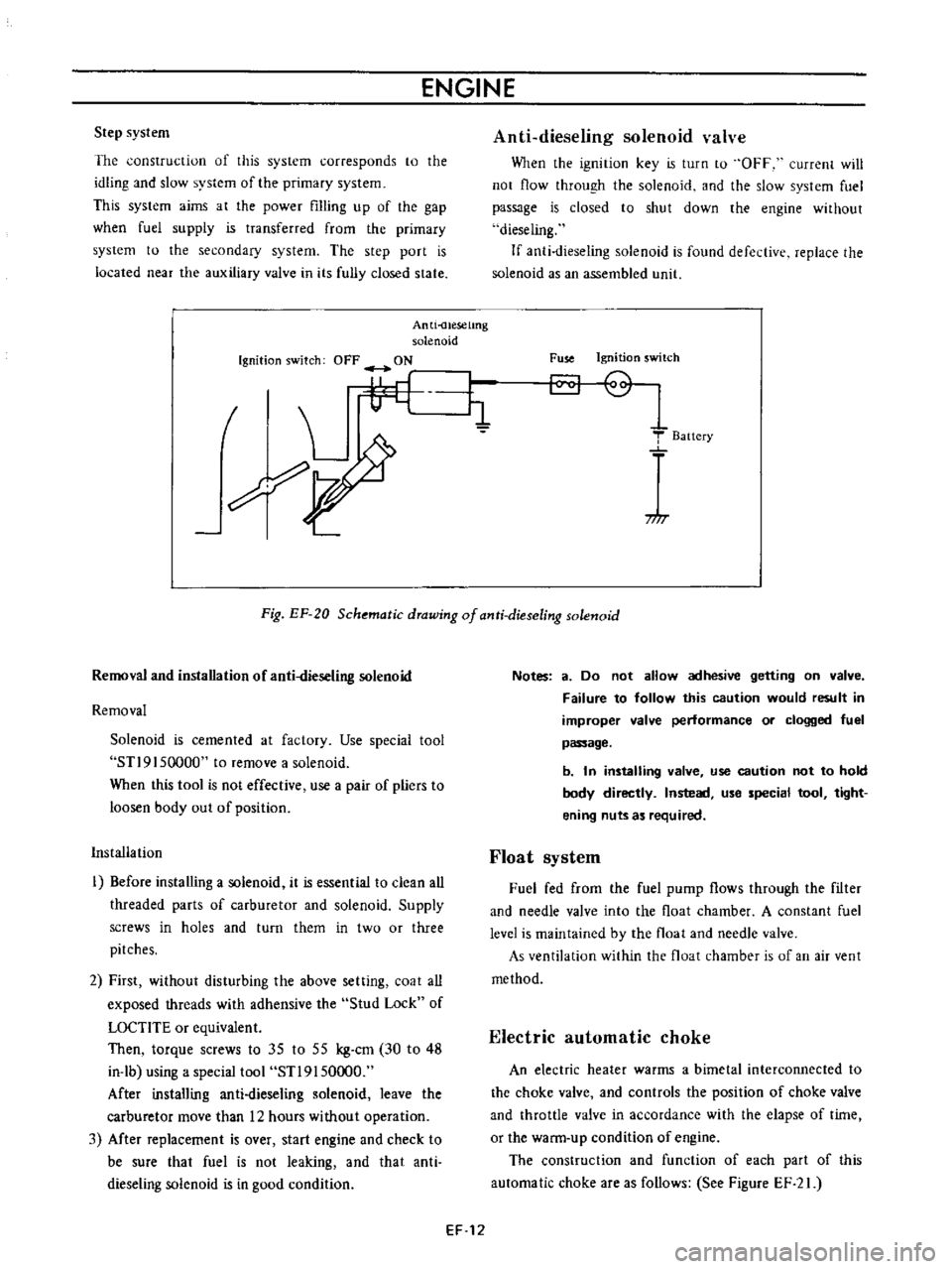

ENGINE

Step

system

The

construction

of

this

system

corresponds

to

the

idling

and

slow

system

of

the

primary

system

This

system

aims

at

the

power

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

system

The

step

port

is

located

near

the

auxiliary

valve

in

its

fully

closed

state

Anti

uesetmg

solenoid

Ignition

switch

OFF

ON

I

L

i1

7

I

Anti

dieseling

solenoid

valve

When

the

ignition

key

is

turn

to

OFF

current

will

not

flow

through

the

solenoid

and

the

slow

system

fuel

passage

is

closed

to

shut

down

the

engine

without

dieseling

If

anti

dieseling

solenoid

is

found

defective

replace

the

solenoid

as

an

assembled

llnit

Fuse

Ignition

switch

T

Baitery

717

Fig

EF

20

Schematic

drawing

of

anti

dieseling

solenoid

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl9

I

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

Installation

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carburetor

move

than

12

hours

without

operation

3

Mter

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

In

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tight

ening

nuts

as

required

Float

system

Fuel

fed

from

the

fuel

pump

flows

through

the

filter

and

needle

valve

into

the

float

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

As

ventilation

within

the

float

chamber

is

of

an

air

vent

method

Electric

automatic

choke

An

electric

heater

warms

a

bimetal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

elapse

of

time

or

the

warm

up

condition

of

engine

The

construction

and

function

of

each

part

of

this

automatic

choke

are

as

follows

See

Figure

EF

21

EF

12