differential DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 67 of 513

r

r

QRr

S

IJ

lrll

r

W

bI15

I

Q

ll

rrll

l

0

fl

AU

1

i

L

Ill

J

cr

U

J

r

Jj

I

DATSUN

1200

MODEL

B

11

0

SERIES

L

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

I

I

i

I

I

I

SECTION

PD

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

PROPELLER

SHAFT

AND

UNIVERSAL

JOINT

DIFFERENTIAL

CARRIER

PD

1

PD

4

Page 68 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

PROPELLER

SHAFT

AND

UNIVERSAL

JOINT

CONTENTS

DESC

R

I

PTI

ON

REMOVAL

DISASSEMBL

Y

INSPECTION

ASSEMBL

Y

PD

PD

2

PD

2

PD

2

PD

2

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

PD

3

PD

3

j

j

lI

ID

1

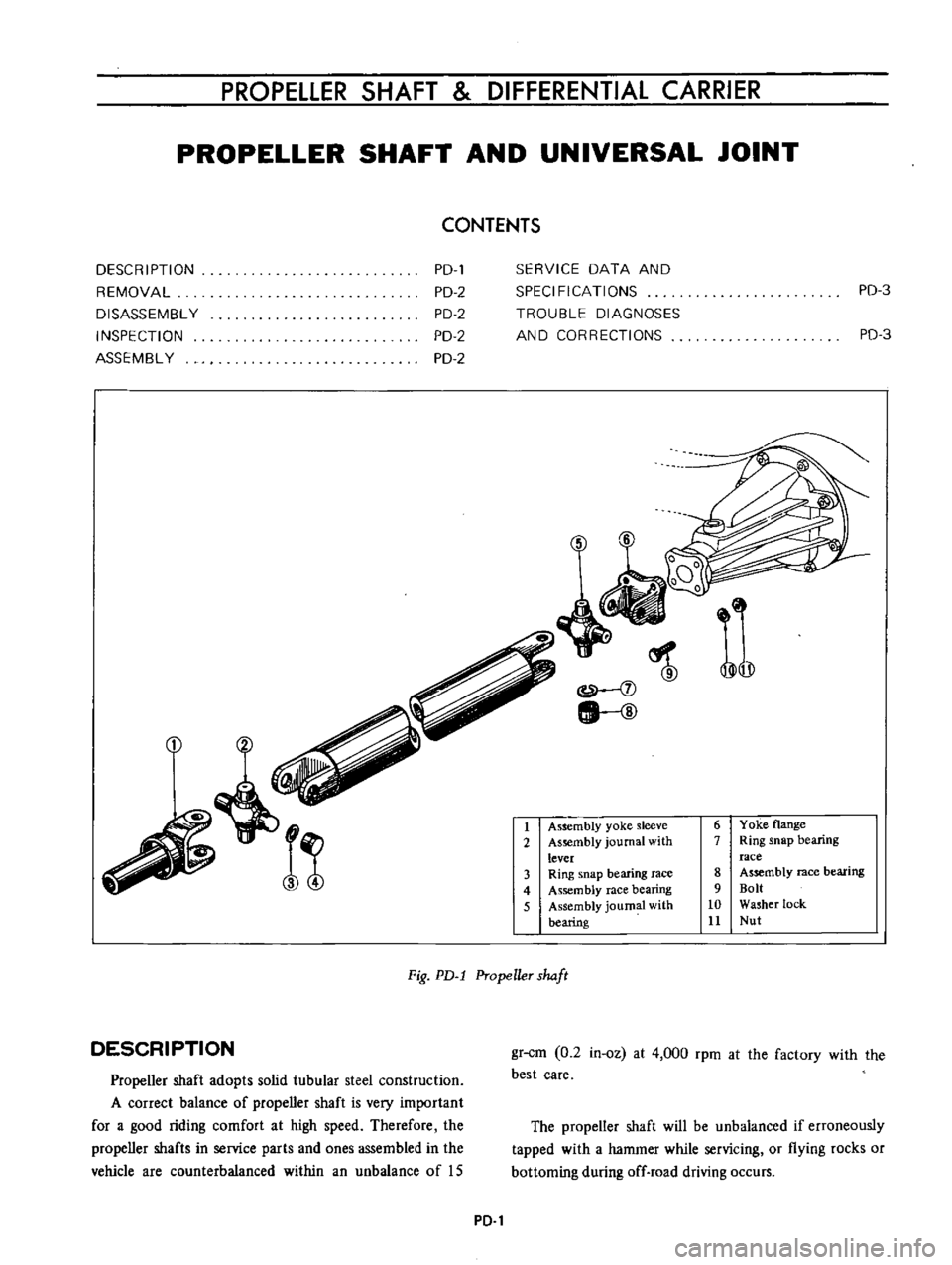

Assembly

yoke

sleeve

2

As

mbly

journal

with

lever

3

Ring

snap

bearing

race

4

Assembly

race

bearing

5

Assembly

journal

with

bearing

6

Yoke

flange

7

Ring

snap

bearing

race

8

Assembly

race

bearing

9

Bolt

10

Washer

lock

11

Nut

Fig

PD

l

Propeller

shaft

DESCRIPTION

Propeller

shaft

adopts

solid

tubular

steel

construction

A

correct

balance

of

propeller

shaft

is

very

important

for

a

good

riding

comfort

at

high

speed

Therefore

the

propeller

shafts

in

service

parts

and

ones

assembled

in

the

vehicle

are

counterbalanced

within

an

unbalance

of

IS

gr

cm

0

2

in

oz

at

4

000

rpm

at

the

factory

with

the

best

care

The

propeller

shaft

will

be

unbalanced

if

erroneously

tapped

with

a

hammer

while

servicing

or

flying

rocks

or

bottoming

during

off

road

driving

occurs

PD

1

Page 70 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Insert

the

journal

into

the

yoke

flange

Tap

the

journal

bearing

into

the

yoke

flange

using

a

brass

drift

smaller

than

the

hole

in

the

yoke

Tap

the

other

bearing

into

the

opposite

end

of

the

yoke

flange

until

the

bearing

is

in

line

with

the

snap

ring

grooves

With

a

pair

of

pliers

install

the

snap

rings

on

both

ends

of

the

yoke

flange

Insert

the

flange

assembly

in

the

sleeve

yoke

Place

the

other

yoke

bearing

into

the

opposite

end

of

the

yoke

and

tap

this

bearing

into

the

yoke

until

the

bearing

is

in

line

with

the

snap

ring

grooves

Install

the

snap

rings

on

both

ends

of

the

yoke

When

all

parts

are

assembled

check

the

spider

and

surroundings

for

tightness

When

the

clearance

is

excessive

adjust

with

over

size

snap

rings

as

follows

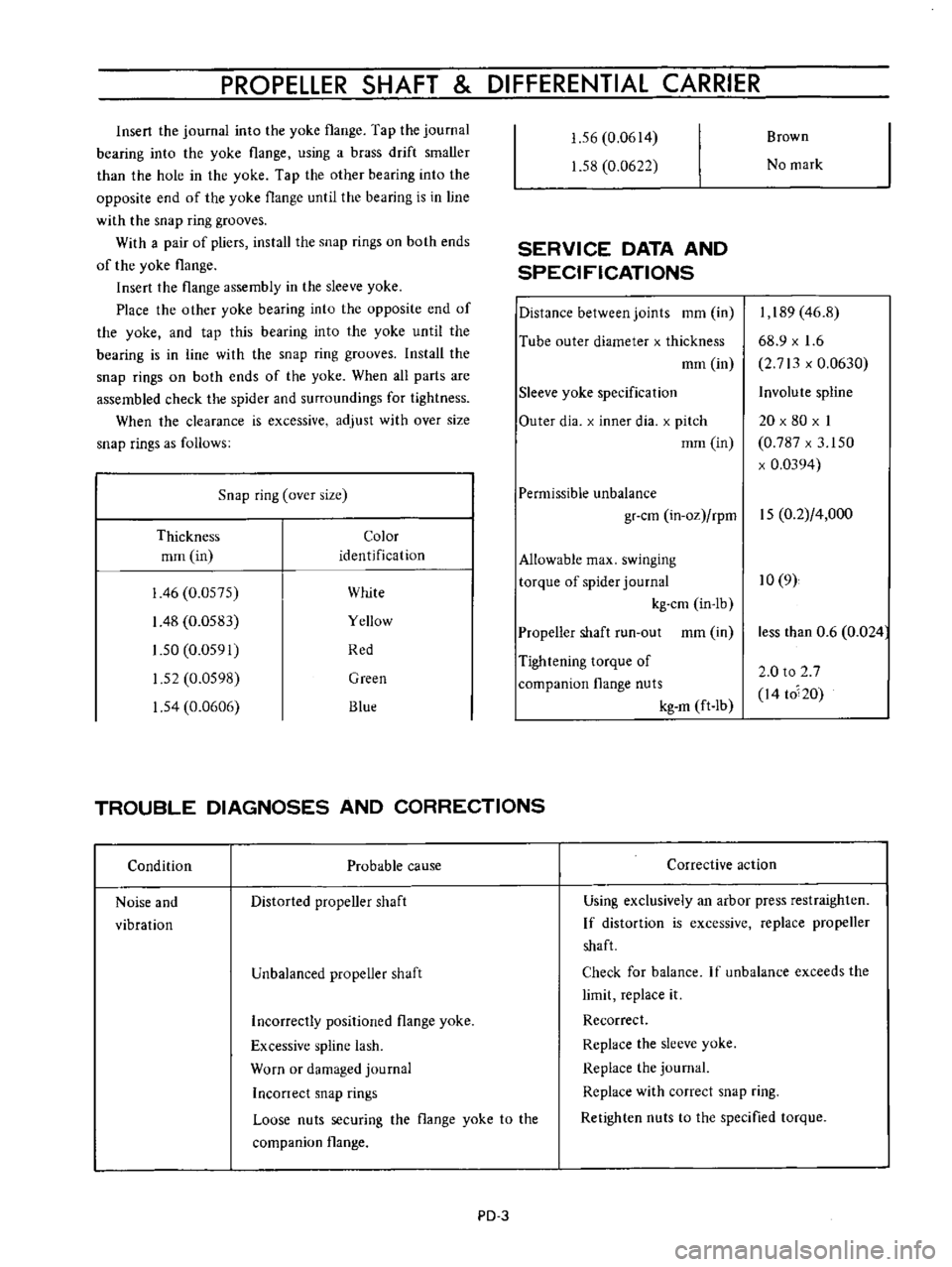

Snap

ring

over

size

Thickness

Color

mrn

in

identification

I

46

0

0575

White

I

48

0

0583

Yellow

1

50

0

0591

Red

1

52

0

0598

Green

1

54

0

0606

Blue

1

56

0

0614

1

58

0

0622

SERVICE

DATA

AND

SPECIFICATIONS

Distance

between

joints

mm

in

Tube

outer

diameter

x

thickness

mm

in

Sleeve

yoke

specification

Outer

dia

x

inner

dia

x

pitch

mm

in

Brown

No

mark

I

189

46

8

68

9

x

1

6

2

713

x

0

0630

Involute

spline

20

x

80

x

I

0

787

x

3

150

x

0

0394

Permissible

unbalance

gr

cm

in

oz

rpm

15

0

2

4

000

Allowable

max

swinging

torque

of

spider

journal

10

9

kg

cm

in

lb

Propeller

shaft

run

out

mm

in

Tightening

torque

of

companion

flange

nuts

kg

m

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Noise

and

vibration

Distorted

propeller

shaft

Unbalanced

propeller

shaft

Corrective

action

less

than

0

6

0

024

2

0

to

2

7

I4

to

20

Using

exclusively

an

arbor

press

restraighten

If

distortion

is

excessive

replace

propeller

shaft

Check

for

balance

If

unbalance

exceeds

the

limit

replace

it

Recorrect

Replace

the

sleeve

yoke

Replace

the

journal

Replace

with

correct

snap

ring

Retighten

nuts

to

the

specified

torque

Incorrectly

positioned

flange

yoke

Excessive

spline

lash

Worn

or

damaged

journal

Inconect

snap

rings

Loose

nuts

securing

the

flange

yoke

to

the

companion

flange

PD

3

Page 71 of 513

CHASSIS

DIFFERENTIAL

CARRIER

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

REPAIR

ASSEMBLY

AND

ADJUSTMENT

Assembling

differential

gear

case

Setting

and

adjusting

drive

pinion

PD

4

PD

5

PD

5

PD

7

PD

8

PD

9

PD

10

Adjusting

drive

pinion

preload

Setting

and

adjusting

side

bearing

shims

INSTALLATION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SERVICE

DATA

AND

SPECIFICATIONS

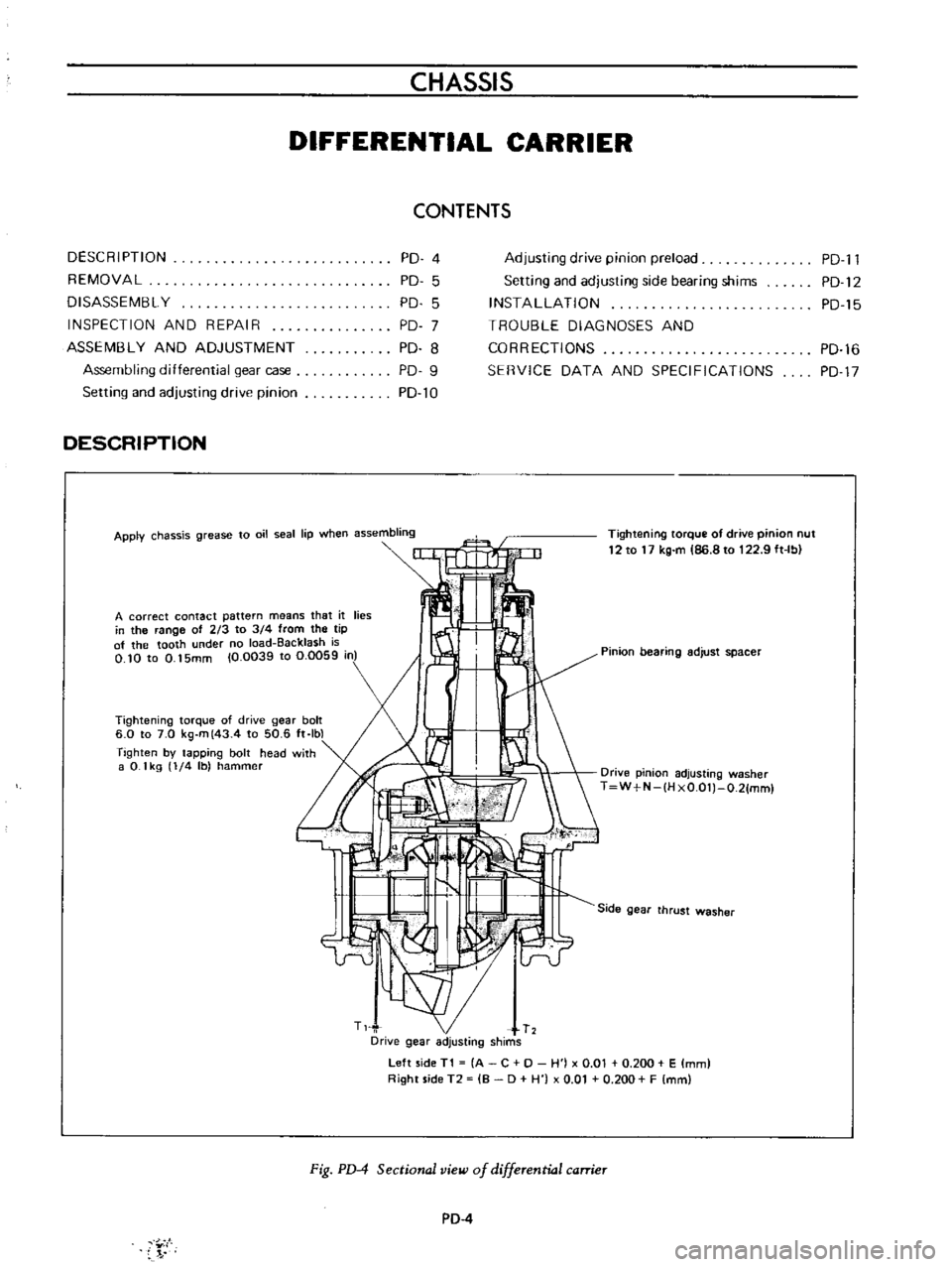

DESCRIPTION

Apply

chassis

grease

to

oil

seal

lip

when

assembling

Tightening

torque

of

drive

pinion

nut

12

to

17

kg

m

86

8

to

122

9

ft

Ib

A

correct

contact

pattern

means

that

it

lies

in

the

range

of

213

to

3

4

from

the

tip

of

the

tooth

under

no

load

Backlash

is

O

10

to

0

15mm

10

0039

to

0

0059

in

Pinion

bearing

adjust

spacer

Tightening

torque

of

drive

gear

bolt

6

0

to

7

0

kg

m

43

4

to

50

6

ft

Ibl

Tighten

by

tapping

bolt

head

with

a

0

1

kg

1

4

Ib

hammer

Drive

pinion

adjusting

washer

T

W

N

IH

xO

OlJ

O

21mml

Side

gear

thrust

washer

Left

side

T1

A

C

0

H

j

x

0

01

0

200

E

mm

Right

side

T2

B

0

H

0

01

0

200

F

mm

Fig

PD

4

Sectional

view

of

differential

carrier

PD

4

Y

I

PD

l1

PD

12

PD

15

PD

16

PD

17

Page 72 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

The

gear

carrier

is

made

of

light

and

strong

aluminum

alloy

metal

and

hypoid

bevel

gear

is

used

Adjust

drive

pinion

bearing

preload

with

non

adjusting

type

spacer

and

pinion

height

and

side

bearing

adjust

ment

with

spacer

shim

s

Millimeter

standardization

stilI

remains

for

all

the

screw

threads

of

this

unit

Therefore

adjustment

figures

stamped

on

screws

adjusting

shims

washers

differential

case

drive

pinion

and

carrier

are

in

millimeters

in

accordance

with

the

millimeter

standardization

of

parts

The

proper

lubrication

to

the

gear

housing

is

necessary

otherwise

it

would

shorten

the

durability

of

the

gear

and

cause

other

troubles

The

lubricant

should

be

checked

each

5

000

km

3

000

miles

and

replenished

each

50

000

km

30

000

miles

The

lubricant

should

be

drained

and

ref11led

at

the

end

of

the

first

1

000

km

600

miles

to

eliminate

any

loose

material

from

the

sump

which

results

from

breaking

Differential

lubricant

should

be

changed

at

least

every

50

000

km

30

000

miles

ConsIderations

should

be

given

to

the

following

matters

I

Nominated

hypoid

gear

oil

must

be

used

2

It

is

prohibited

to

use

any

gear

oil

of

different

viscosity

The

same

brand

must

always

be

selected

3

The

standard

oil

capacity

is

about

0

75

liter

0

198

US

gal

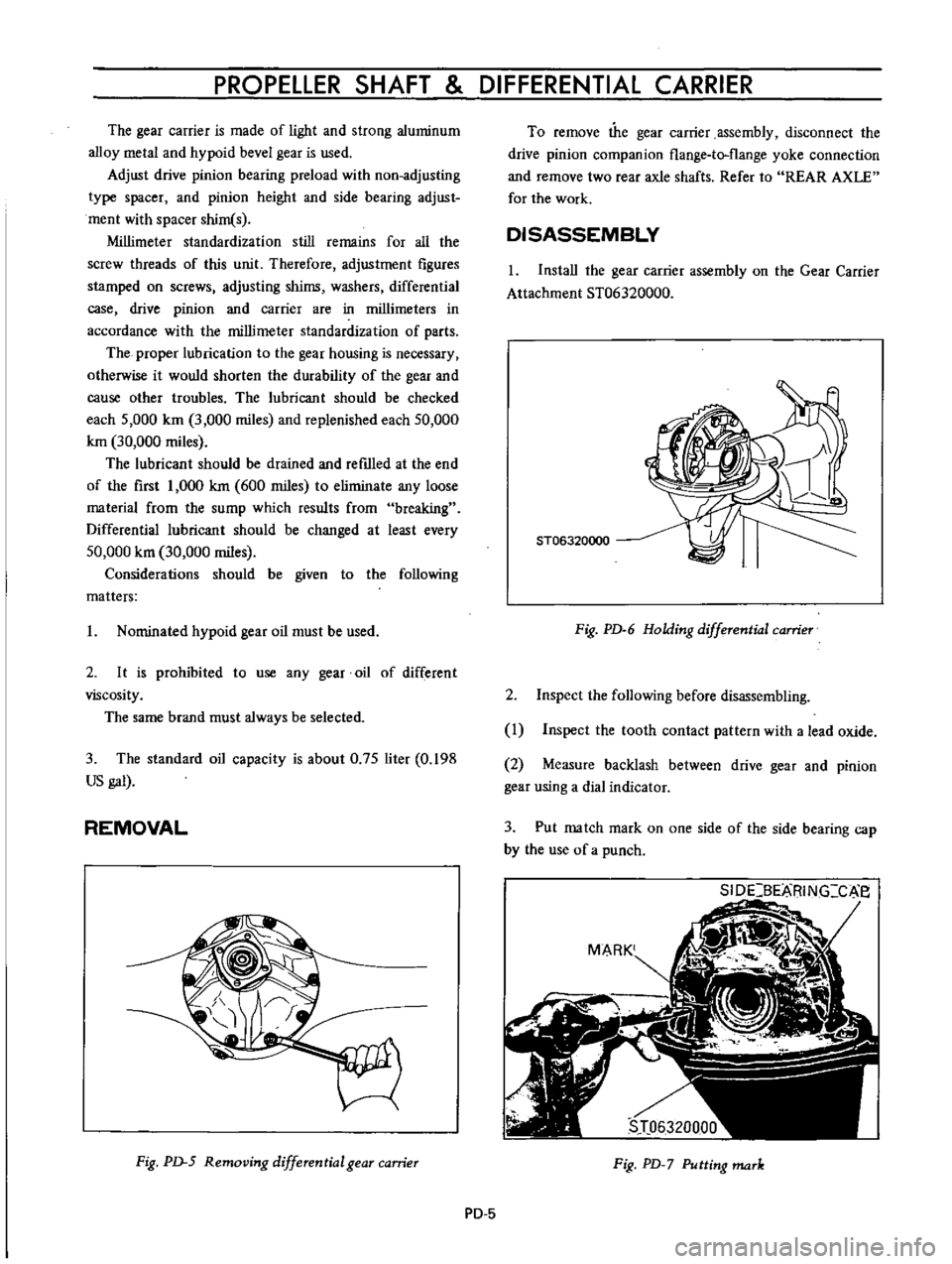

REMOVAL

Fig

PD

5

Removing

differential

gear

carrier

To

remove

the

gear

carrier

assembly

disconnect

the

drive

pinion

companion

flange

te

flange

yoke

connection

and

remove

two

rear

axle

shafts

Refer

to

REAR

AXLE

for

the

work

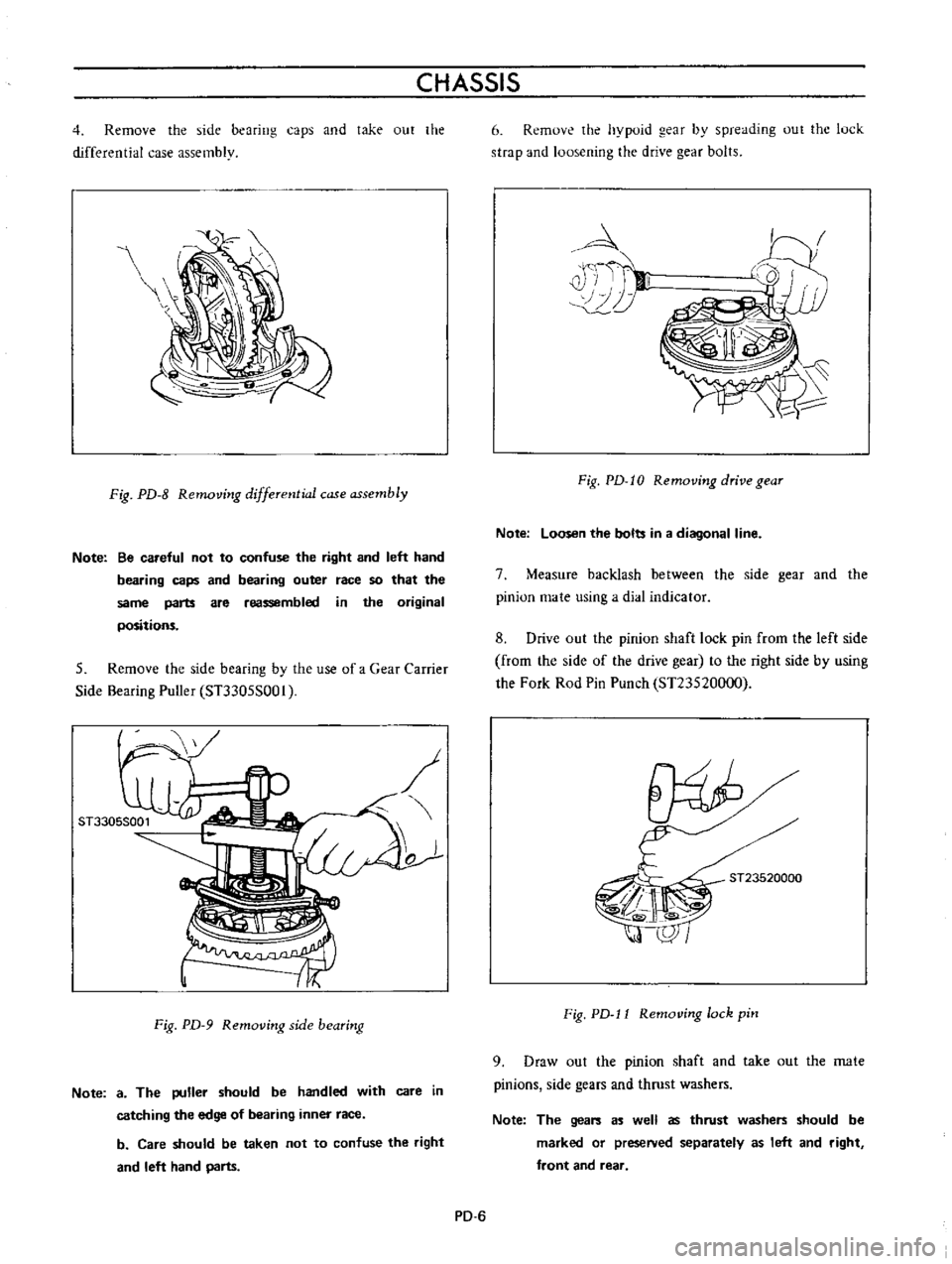

DISASSEMBLY

I

Install

the

gear

carrier

assembly

on

the

Gear

Carrier

Attachment

ST06320000

ST06320000

Fig

PD

6

Holding

differential

camer

2

Inspect

the

following

before

disassembling

I

Inspect

the

tooth

contact

pattern

with

a

lead

oxide

2

Measure

backlash

between

drive

gear

and

pinion

gear

using

a

dial

indicator

3

Put

match

mark

on

one

side

of

the

side

bearing

cap

by

the

use

of

a

punch

SIDCBEMING

c

e

Fig

PD

7

Putting

mark

PD

5

Page 73 of 513

CHASSIS

4

Remove

the

side

bearing

caps

and

take

out

the

differential

case

assembly

Fig

PD

8

Removing

differential

case

assembly

Note

Be

careful

not

to

confuse

the

right

and

left

hand

bearing

caps

and

bearing

outer

race

so

that

the

same

parts

are

reassembled

in

the

original

positions

5

Remove

the

side

bearing

by

the

use

of

a

Gear

Carrier

Side

Bearing

Puller

ST3305S001

o

Fig

PD

9

Removing

side

bearing

Note

a

The

puller

should

be

handled

with

care

in

catching

the

edge

of

bearing

inner

race

b

Care

should

be

taken

not

to

confuse

the

right

and

left

hand

parts

6

Remove

the

hypoid

gear

by

spreading

out

the

luck

strap

and

loosening

the

drive

gear

bolts

4

i

T

II

10

Fig

PD

I0

Removing

drive

gear

Note

Loosen

the

bolts

in

a

diagonal

line

7

Measure

backlash

between

the

side

gear

and

the

pinion

mate

using

a

dial

indicator

8

Drive

out

the

pinion

shaft

lock

pin

from

the

left

side

from

the

side

of

the

drive

gear

to

the

right

side

by

using

the

Fork

Rod

Pin

Punch

ST23520000

ST23520000

Fig

PD

l1

Removing

lock

pin

9

Draw

out

the

pinion

shaft

and

take

out

the

mate

pinions

side

gears

and

thrust

washers

Note

The

gears

as

well

as

thrust

washers

should

be

marked

or

preseNed

separately

as

left

and

right

front

and

rear

PD

6

Page 74 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

10

Measure

the

initial

turning

torque

drive

pinion

gear

by

using

Drive

Pinion

Preload

Gauge

Sn127S000

11

Remove

the

drive

pinion

nut

and

draw

out

the

companion

flange

assembly

Note

Use

the

Drive

Pinion

Flange

Wrench

to

hold

the

companion

flange

IST31540000

Fig

PD

12

Removing

drive

pinion

unit

12

Remove

the

drive

pinion

assembly

to

the

rearward

by

tapping

the

front

end

with

a

plastic

mallet

The

drive

pinion

can

be

taken

out

together

with

the

INSPECTION

AND

REPAIR

inner

race

of

rear

bearing

bearing

spacer

and

adjusting

washer

13

Remove

the

oil

seal

and

take

out

the

front

bearing

inner

race

Note

The

removed

oil

seal

should

not

be

reused

14

Draw

out

the

outer

races

of

both

front

and

rear

bearings

using

drift

15

Draw

out

drive

pinion

rear

bearing

inner

race

using

Drive

Pinion

Rear

Inner

Race

Replacer

ST30031000

ST30031

000

AI

n

Fig

PD

13

Removing

bearing

10

y@

@

0

0

0

00

eo

00

j

l

I

@

o

q@

@

t

I

7

c9

@

@@

@

l2

4

o

OO

r

j

T

I

i

cb

3

0

0

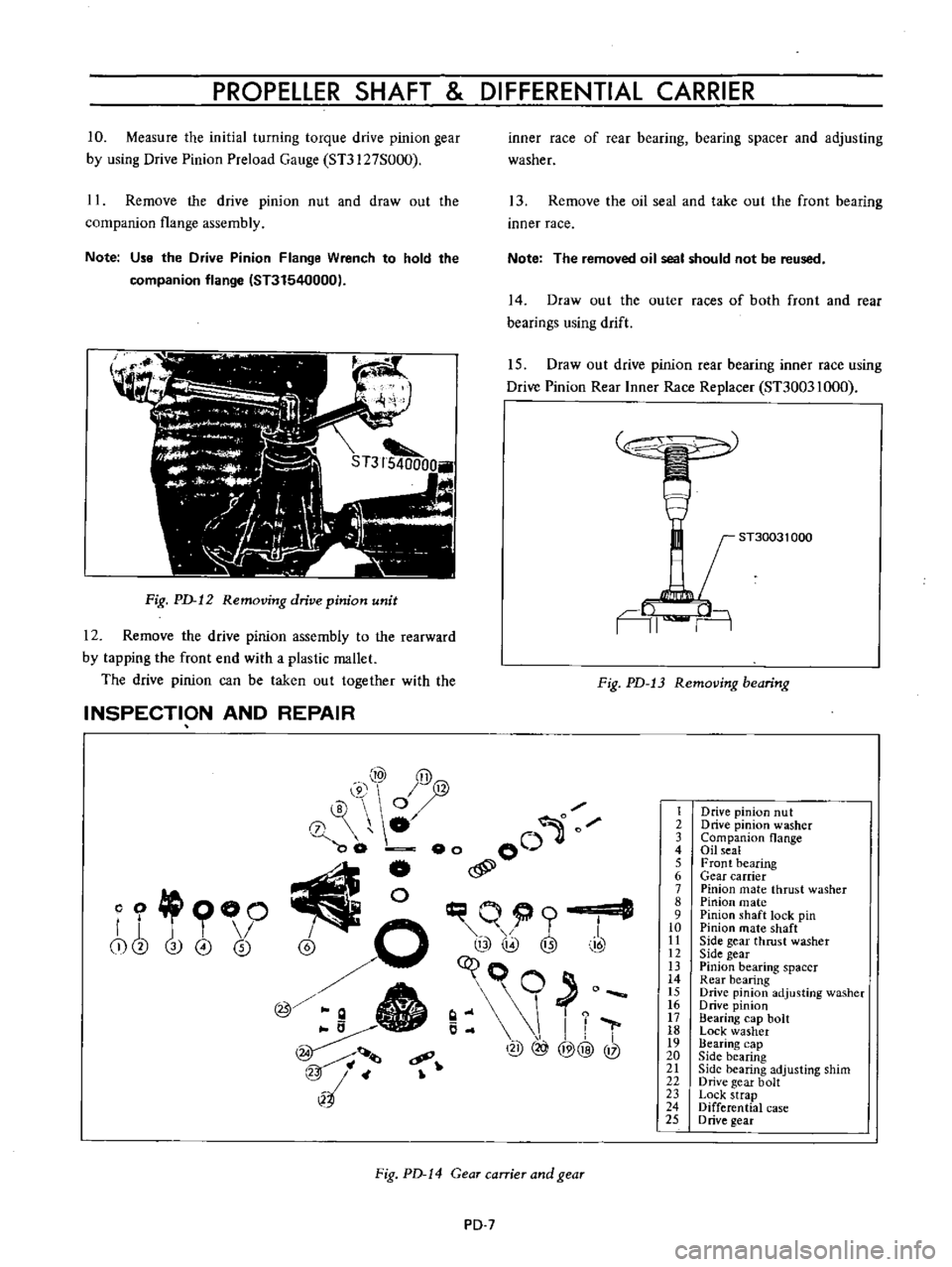

Fig

PD

14

Gear

carrier

and

gear

PD

7

1

2

3

4

S

6

7

8

9

10

II

12

IJ

14

IS

16

17

18

19

20

21

22

23

24

25

Drive

pinion

nut

Drive

pinion

washer

Companion

flange

Oil

seal

Front

bearing

Gear

carrier

Pinion

mate

thrust

washer

Pinion

mate

Pinion

shaft

lock

pin

Pinion

mate

shaft

Side

gear

thrust

washer

Side

gear

Pinion

bearing

spacer

Rear

bearing

Drive

pinion

adjusting

washer

o

rive

pinion

Bearing

cap

bolt

Lock

washer

Bearing

cap

Side

bearing

Side

bearing

adjusting

shim

Drive

gear

bolt

Lock

strap

Differential

case

D

rive

gear

Page 75 of 513

CHASSIS

Before

inspecting

various

parts

thoroughly

wash

them

so

that

damage

and

wear

can

be

easily

detected

Then

proceed

as

follows

Check

gear

teeth

for

scoring

cracking

and

chipping

and

make

sure

that

tooth

pattern

indicates

correct

meshing

depth

If

any

defect

is

evident

replace

parts

as

required

Note

Drive

pinion

and

drive

gear

are

supplied

for

replacement

as

a

set

therefore

should

either

part

be

damaged

replace

as

a

set

Check

the

pinion

gear

shaft

and

pinion

gear

mating

faces

for

scoring

and

signs

of

wear

and

replace

as

required

Follow

the

same

procedure

for

inner

faces

of

side

gear

and

their

seats

on

differential

case

3

Inspect

all

bearing

races

and

rollers

for

scoring

chipping

or

evidence

of

excessive

wear

They

should

be

in

tiptop

condition

not

worn

with

mirror

like

surfaces

Replace

if

there

is

a

doubt

on

their

efficiency

since

an

incorrect

bearing

operation

may

result

in

noisiness

and

gear

seizure

4

Inspect

thrust

washer

faces

Small

defects

can

be

corrected

with

emery

paper

In

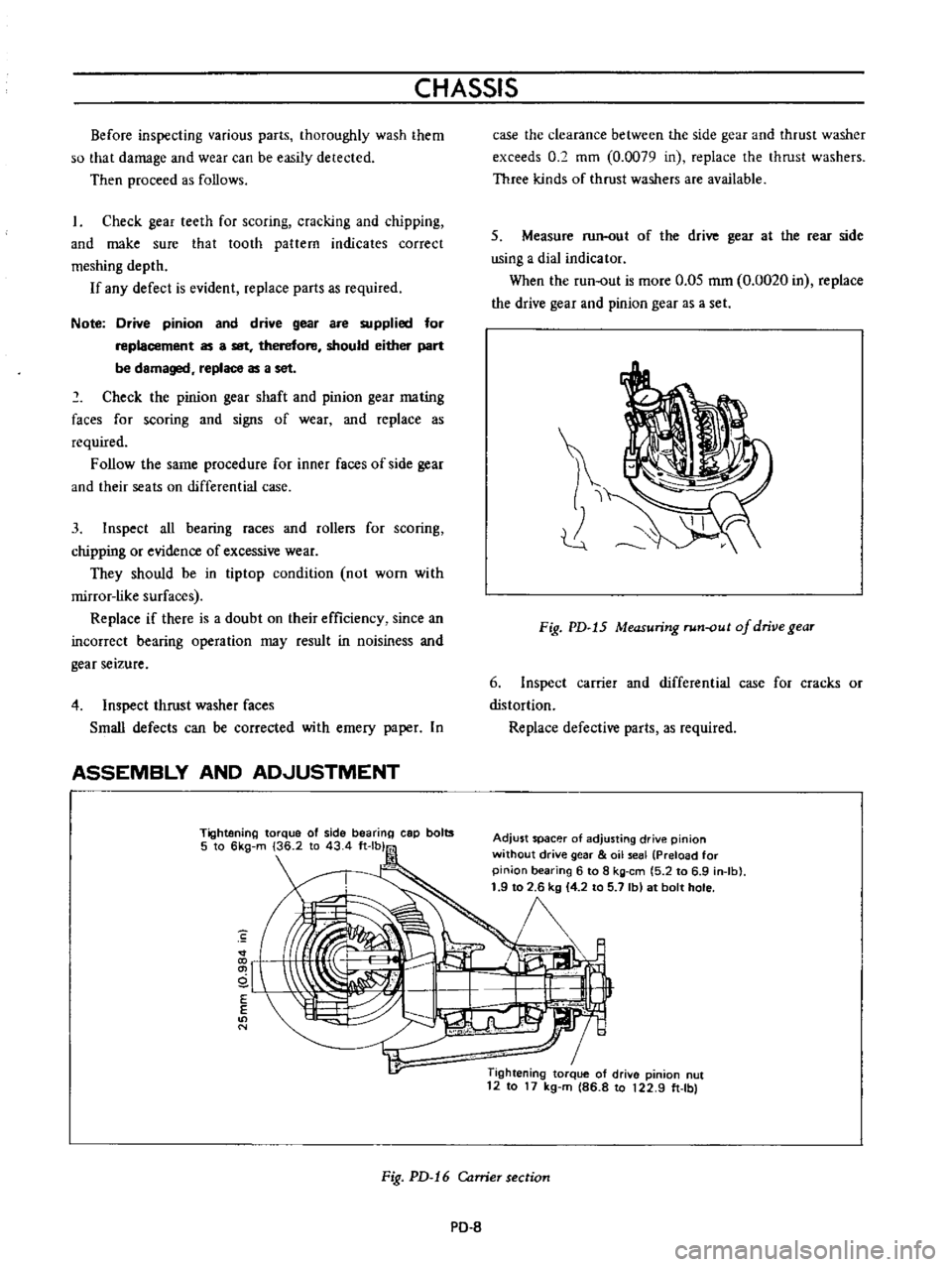

ASSEMBLY

AND

AD

JUSTMENT

Tightening

torque

of

side

bearing

cap

bolts

5

to

6kg

m

36

2

to

43

4

ft

lb

co

g

E

E

on

N

case

the

clearance

between

the

side

gear

and

thrust

washer

exceeds

0

2

mm

0

0079

in

replace

the

thrust

washers

Three

kinds

of

thrust

washers

are

available

5

Measure

run

out

of

the

drive

gear

at

the

rear

side

using

a

dial

indicator

When

the

run

out

is

more

0

05

mm

0

0020

in

replace

the

drive

gear

and

pinion

gear

as

a

set

Fig

PD

15

Measuring

run

out

of

drive

gear

6

Inspect

carrier

and

differential

case

for

cracks

or

distortion

Replace

defective

parts

as

required

Adjust

spacer

of

adjusting

drive

pinion

without

drive

gear

oil

seal

Preload

for

pinion

bearing

6

to

8

kg

em

5

2

to

6

9

in

Ib

1

9

to

2

6

kg

4

2

to

5

7

Ib

at

bolt

hole

1

Tightening

torque

of

drive

pinion

nut

12

to

17

kg

m

86

8

to

122

9

ft

Ibl

Fig

PD

16

Carrier

section

PO

8

Page 76 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Reassemble

the

differential

carrier

in

reverse

order

of

disassembly

The

following

instructions

for

adjustment

and

usage

of

special

tuols

are

essential

to

obtain

perfect

differential

operation

Assembling

differential

gear

case

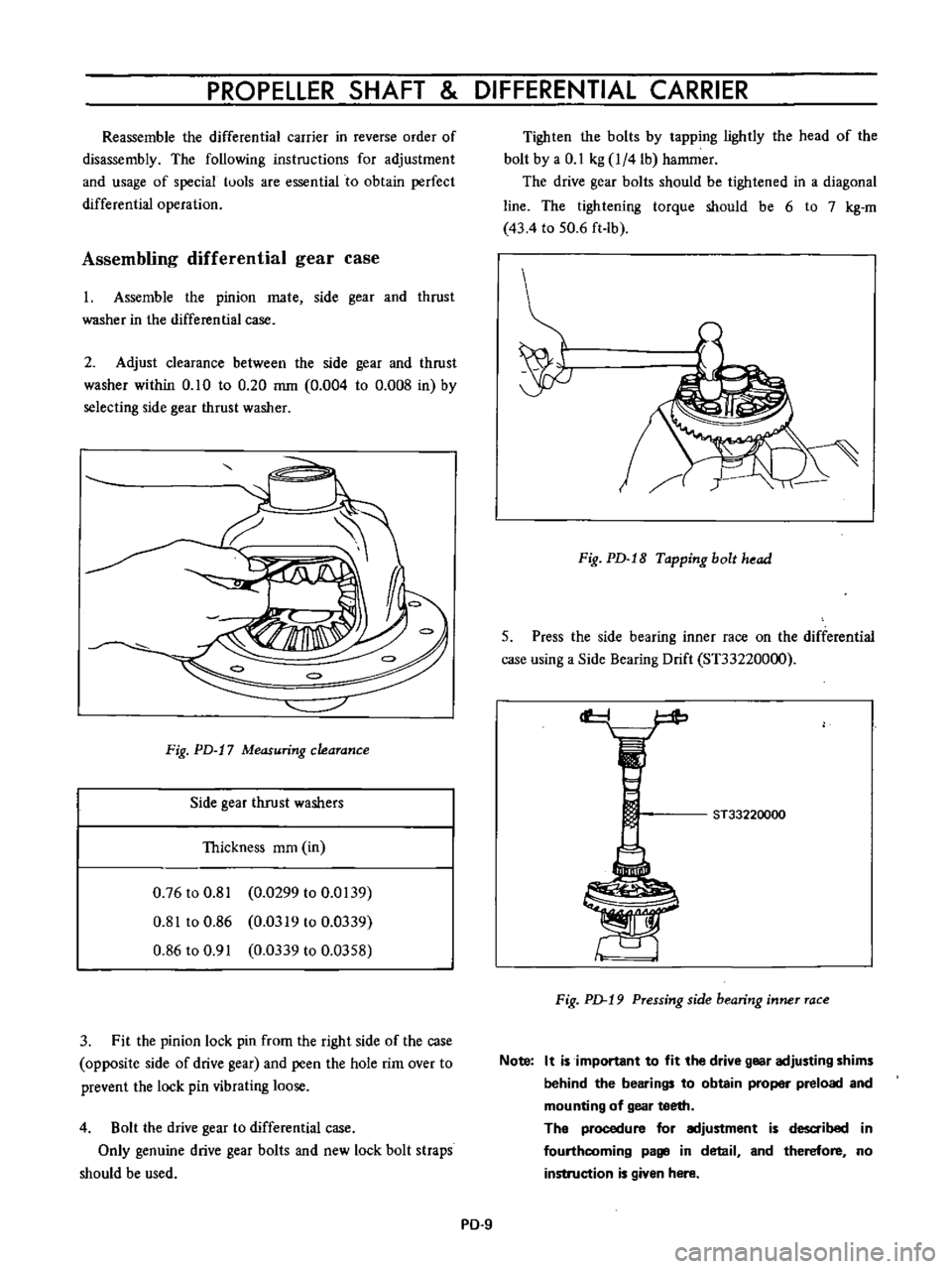

1

Assemble

the

pinion

mate

side

gear

and

thrust

washer

in

the

differential

case

2

Adjust

clearance

between

the

side

gear

and

thrust

washer

within

0

10

to

0

20

mm

0

004

to

0

008

in

by

selecting

side

gear

thrust

washer

Fig

PD

17

Measuring

clearance

Side

gear

thrust

washers

Thickness

mm

in

0

76

to

0

81

0

0299

to

0

0139

0

81

to

0

86

0

0319

to

0

0339

0

86

to

0

91

0

0339

to

0

0358

3

Fit

the

pinion

lock

pin

from

the

right

side

of

the

case

opposite

side

of

drive

gear

and

peen

the

hole

rim

over

to

prevent

the

lock

pin

vibrating

loose

4

Bolt

the

drive

gear

to

differential

case

Only

genuine

drive

gear

bolts

and

new

lock

bolt

straps

should

be

used

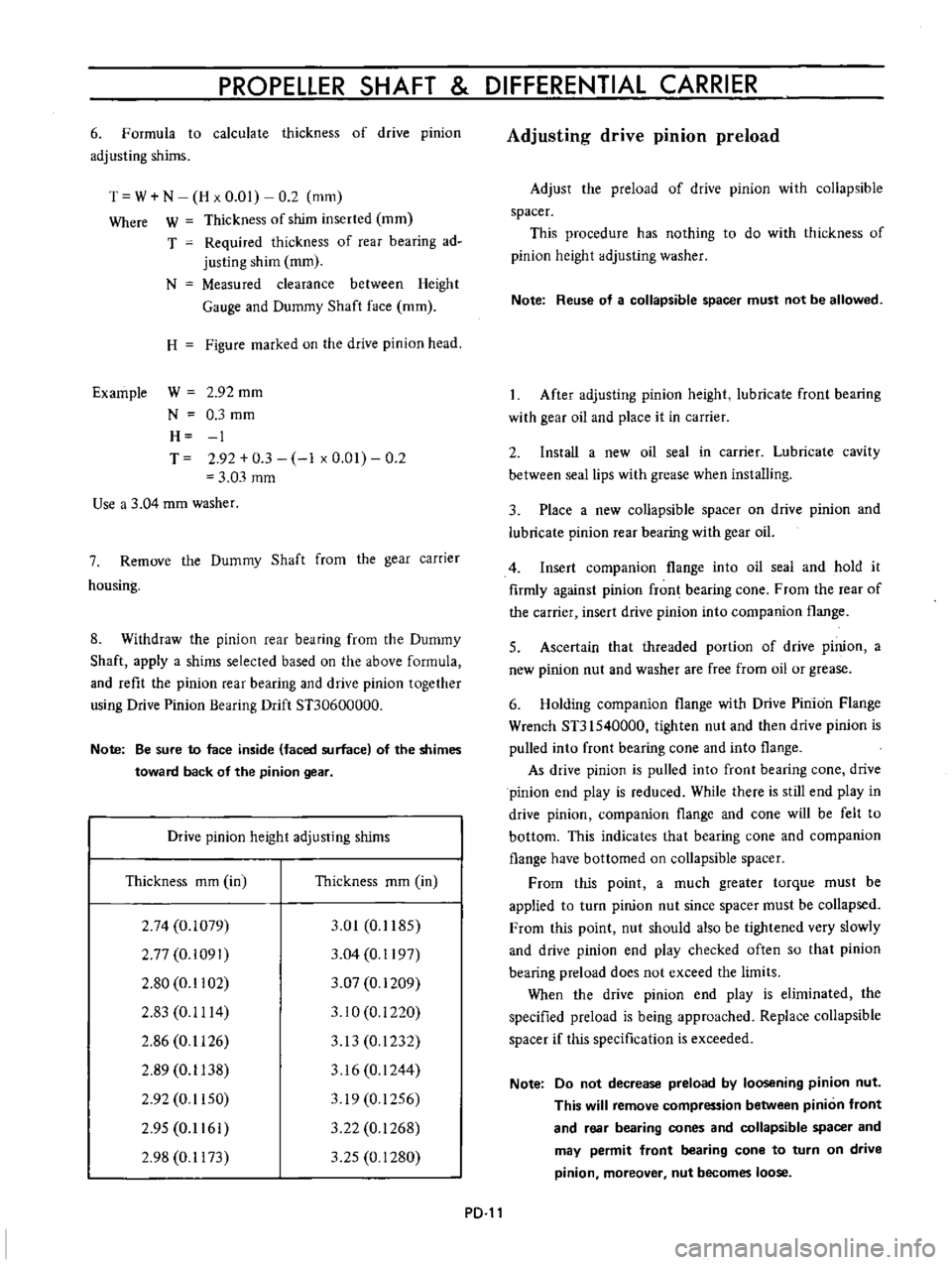

Tighten

the

bolts

by

tapping

lightly

the

head

of

the

bolt

by

a

0

1

kg

l

4lb

hammer

The

drive

gear

bolts

should

be

tightened

in

a

diagonal

line

The

tightening

torque

should

be

6

to

7

kg

m

43

4

to

50

6

ft

lb

Fig

PD

18

Tapping

bolt

head

5

Press

the

side

bearing

inner

race

on

the

differential

case

using

a

Side

Bearing

Drift

ST33220000

cf

ST33220000

F

ig

p

19

Pressing

side

bearing

inner

race

Note

It

is

important

to

fit

the

drive

gear

adjusting

shims

behind

the

bearings

to

obtain

proper

preload

and

mounting

of

gear

teeth

The

procedure

for

adjustment

is

d

ibed

in

fourthcoming

page

in

detail

and

therefore

no

instruction

is

given

here

PD

9

Page 78 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

6

Formula

to

calculate

thickness

of

drive

pinion

adjusting

shims

T

W

N

H

x

0

01

0

2

mm

Where

W

Thickness

of

shim

inserted

mm

T

Required

thickness

of

rear

bearing

ad

justing

shim

mm

N

Measured

clearance

between

Height

Gauge

and

Dummy

Shaft

face

mm

H

Figure

marked

on

the

drive

pinion

head

Example

W

2

92

mm

N

0

3

mm

H

1

T

2

92

0

3

1

x

0

01

0

2

3

03

mm

Use

a

3

04

mm

washer

7

Remove

the

Dummy

Shaft

from

the

gear

carrier

housing

8

Withdraw

the

pinion

rear

bearing

from

the

Dummy

Shaft

apply

a

shims

selected

based

on

the

above

formula

and

refit

the

pinion

rear

bearing

and

drive

pinion

together

using

Drive

Pinion

Bearing

Drift

STJ0600000

Note

Be

sure

to

face

inside

faced

surface

of

the

shimes

toward

back

of

the

pinion

gear

Drive

pinion

height

adjusting

shims

Thickness

mm

in

Thickness

mm

in

2

74

0

1079

2

77

0

i091

2

80

0

1102

2

83

0

1114

2

86

0

1126

2

89

0

1138

2

92

0

1150

2

95

0

1161

2

98

0

1173

3

01

0

1185

3

04

0

1197

3

07

0

1209

3

10

0

i

220

3

13

0

1232

3

16

0

1244

319

0

1256

3

22

0

1268

3

25

0

1280

PD

Adjusting

drive

pinion

preload

Adjust

the

preload

of

drive

pinion

with

collapsible

spacer

This

procedure

has

nothing

to

do

with

thickness

of

pinion

height

adjusting

washer

Note

Reuse

of

a

collapsible

spacer

must

not

be

allowed

After

adjusting

pinion

height

lubricate

front

bearing

with

gear

oil

and

place

it

in

carrier

2

Install

a

new

oil

seal

in

carrier

Lubricate

cavity

between

seal

lips

with

grease

when

installing

3

Place

a

new

collapsible

spacer

on

drive

pinion

and

lubricate

pinion

rear

bearing

with

gear

oil

4

Insert

companion

flange

into

oil

seal

and

hold

it

firmly

against

pinion

fron

bearing

cone

From

the

rear

of

the

carrier

insert

drive

pinion

into

companion

flange

5

Ascertain

that

threaded

portion

of

drive

pinion

a

new

pinion

nut

and

washer

are

free

from

oil

or

grease

6

Holding

companion

flange

with

Drive

Pinion

Flange

Wrench

ST31540000

tighten

nut

and

then

drive

pinion

is

pulled

into

front

bearing

cone

and

into

flange

As

drive

pinion

is

pulled

into

front

bearing

cone

drive

pinion

end

play

is

reduced

While

there

is

still

end

play

in

drive

pinion

companion

flange

and

cone

will

be

felt

to

bottom

This

indicates

that

bearing

cone

and

companion

flange

have

bottomed

on

collapsible

spacer

From

this

point

a

much

greater

torque

must

be

applied

to

turn

pinion

nut

since

spacer

must

be

collapsed

From

this

point

nut

should

also

be

tightened

very

slowly

and

drive

pinion

end

play

checked

often

so

that

pinion

bearing

preload

does

not

exceed

the

limits

When

the

drive

pinion

end

play

is

eliminated

the

specified

preload

is

being

approached

Replace

collapsible

spacer

if

this

specification

is

exceeded

Note

Do

not

decrease

preload

by

loosening

pinion

nut

This

will

remove

compression

between

pinion

front

and

rear

bearing

cones

and

collapsible

spacer

and

may

permit

front

bearing

cone

to

turn

on

drive

pinion

moreover

nut

becomes

loose