overheating DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 135 of 513

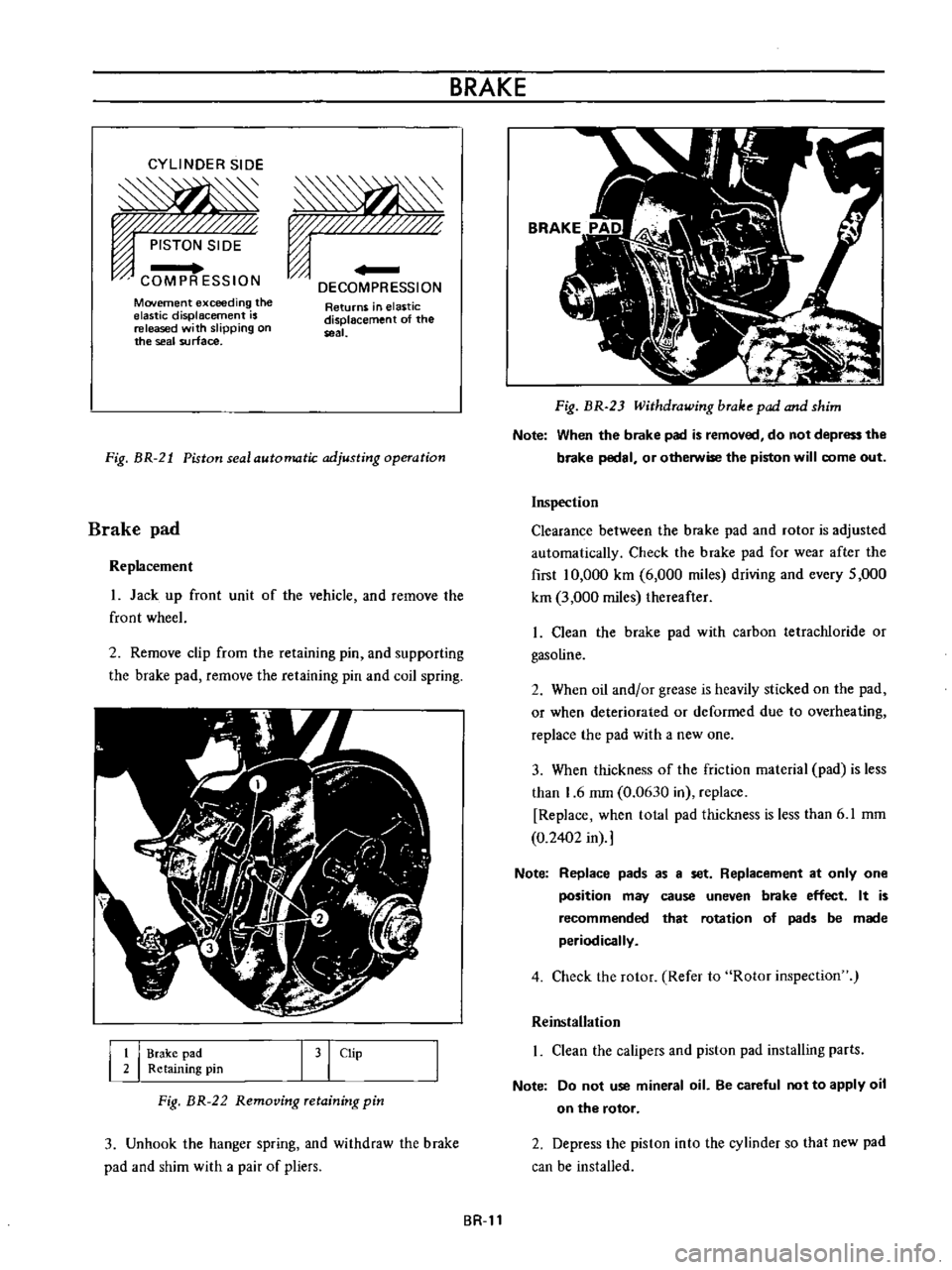

BRAKE

CYLINDER

SIDE

PISTON

SIDE

COMPR

ESSION

DECOMPRESSION

Movement

exceeding

the

elastic

displacement

is

released

with

slipping

on

the

seal

surface

Returns

in

elastic

displacement

of

the

seal

Fig

BR

21

Piston

seal

automatic

adjusting

operation

Brake

pad

Replacement

1

Jack

up

front

unit

of

the

vehicle

and

remove

lhe

front

wheeL

2

Remove

clip

from

the

retaining

pin

and

supporting

the

brake

pad

remove

the

retaining

pin

and

coil

spring

I

I

Brake

pad

2

Retaining

pin

I

31

Clip

Fig

BR

22

Removing

retaining

pin

3

Unhook

the

hanger

spring

and

withdraw

the

brake

pad

and

shim

with

a

pair

of

pliers

BR

ll

Fig

HR

2

Withdrawing

brake

pad

and

shim

Note

When

the

brake

pad

is

removed

do

not

depress

the

brake

pedal

or

otherwise

the

piston

will

come

out

Inspection

Clearance

between

the

brake

pad

and

rotor

is

adjusted

automatically

Check

the

brake

pad

for

wear

after

the

first

10

000

km

6

000

miles

driving

and

every

5

000

km

3

000

miles

thereafter

1

Clean

the

brake

pad

with

carbon

tetrachloride

or

gasoline

2

When

oil

and

or

grease

is

heavily

sticked

on

the

pad

or

when

deteriorated

or

deformed

due

to

overheating

replace

the

pad

with

a

new

one

3

When

thickness

of

the

friction

material

pad

is

less

than

1

6

mm

0

0630

in

replace

Replace

when

total

pad

thickness

is

less

than

6

1

mm

0

2402

in

Note

Replace

pads

as

a

set

Replacement

at

only

one

position

may

cause

uneven

brake

effect

It

is

recommended

that

rotation

of

pads

be

made

periodically

4

Check

the

rotor

Refer

to

Rotor

inspection

Reinstallation

1

Clean

the

calipers

and

piston

pad

installing

parts

Note

Do

not

use

mineral

oil

Be

careful

not

to

apply

oil

on

the

rotor

2

Depress

the

piston

into

the

cylinder

so

that

new

pad

can

be

installed

Page 335 of 513

Air

intake

system

in

trouble

Overheating

Overcooling

Others

NOISY

ENGINE

Car

knocking

Car

knock

when

coasting

ENGINE

Diny

ur

clogged

fuel

strainer

Fuel

pump

will

not

work

properly

Clogged

carburetor

jets

Clogged

air

cleaner

Air

inhaling

from

manifold

gasket

or

carbu

retor

gasket

Insufficient

coolant

Loosened

fan

belt

Worn

or

defective

fan

belt

Defective

thermostat

Defective

water

pump

Clogged

or

leaky

radiator

Defective

radiator

filler

cap

Air

mixing

into

cooling

system

Improper

grade

engine

oil

Incorrect

ignition

timing

Defective

carburetor

lean

mixture

Defective

thermostat

Low

octane

fuel

Improper

tire

pressure

Dragging

brake

Slipping

clutch

Overloading

to

engine

Carbon

knocking

Timing

knocking

Fuel

knocking

Preignition

misusing

of

spark

plug

Incorrect

throttle

opener

adjustment

Trouble

in

PCV

valve

ET

30

Replace

Repair

or

replace

Disassemble

and

clean

Replace

element

Replace

gasket

Replenish

Adjust

Replace

Replace

Replace

Flush

repair

or

replace

Replace

Retighten

each

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaul

carburetor

Replace

Replace

with

specified

octane

fuel

Adjust

to

the

specified

pressure

Adjust

Adjust

Use

right

gear

in

driving

Disassemble

cylinder

head

and

remove

carbon

Adjust

ignition

timing

Use

specified

octane

fuel

Use

specified

spark

plug

Adjust

throttle

opener

Replace

PCV

valve

Page 457 of 513

ENGINE

ElECTRICAL

SYSTEM

SPECIFICATIONS

Make

and

type

Primary

voltage

v

Spark

gap

mm

in

Primary

resistance

at

200C

680

F

n

Secondary

resistance

at

200C

680F

Kn

External

resistor

at

200C

680

F

n

Applied

resistor

HANSHIN

HITACHI

H5

15

2

C6R

601

12

12

more

than

7

more

than

7

0

28

0

28

1

17

to

I

43

l

l

7

to

I

43

11

2

to

16

8

11

2

to

16

8

l

3tol7

l

3tol7

RC

15

5560R

151O

SPARK

PLUG

CONTENTS

DESCRIPTION

INSPECTION

CLEANING

AND

REGAP

EE

37

EE

37

EE

38

DESCRIPTION

The

spark

plugs

are

of

the

resister

type

having

14

mm

0

551

in

threads

and

0

8

to

0

9

mm

0

031

to

0

Q35

in

gap

Note

All

spark

plugs

installed

on

an

engine

must

be

of

the

same

brand

and

number

of

heat

range

INSPECTION

1

Remove

spark

plug

wire

by

pulling

on

boot

not

on

wire

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Figure

EE

74

Normal

Brown

to

grayish

tan

deposits

and

slight

elec

trode

wear

indicate

correct

spark

plug

heat

range

SPECIFICATIONS

AND

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EE

38

EE

39

Carbon

fouled

Dry

fluffy

carbon

deposits

on

the

insula

tor

and

electrode

were

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

en

trance

into

combustion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insulator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

Moreover

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pressure

wrong

selection

of

fuel

a

hotter

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

EE

37

Page 458 of 513

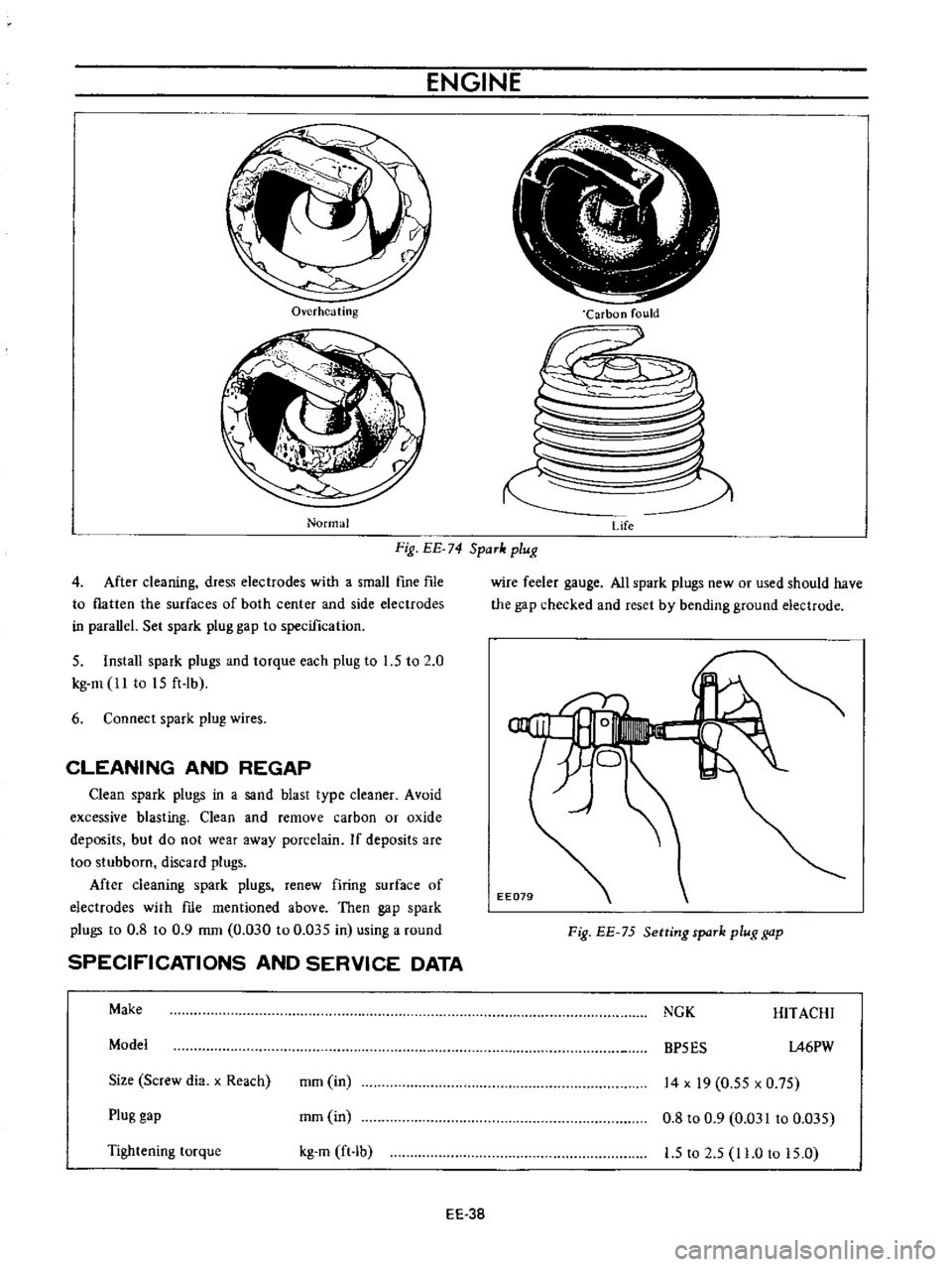

ENGINE

Overheating

Normal

Carbon

fould

Fig

EE

74

SpaTk

plug

Life

4

After

cleaning

dress

electrodes

with

a

small

fine

fIle

to

flatten

the

surfaces

of

both

center

and

side

electrodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

to

1

5

to

2

0

kg

m

ll

to

15

ft

lb

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

discard

plugs

Mter

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

above

Then

gap

spark

plugs

to

0

8

to

0

9

mm

0

030

to

0

035

in

using

a

round

SPECIFICATIONS

AND

SERVICE

DATA

Make

Model

Size

Screw

dia

x

Reach

mm

in

Plug

gap

mm

in

Tightening

torque

kg

m

ft

b

EE

38

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

Fig

EE

75

Setting

spaTk

plug

gap

NGK

HITACHI

BP5ES

1A6PW

14

x

19

0

55

x

0

75

0

8

to

0

9

0

031

to

0

035

1

5

to

2

5

11

0

to

15

0