radiator cap DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 242 of 513

BODY

ELECTRICAL

Note

8

When

a

fuse

is

blown

off

be

sure

to

correct

the

cause

before

installing

new

fuse

b

Be

sure

to

use

fuse

having

the

rated

capacity

Do

not

use

fuse

having

larger

capacity

i

e

20A

JOA

etc

c

Particularly

when

the

fusible

link

is

fused

replace

with

a

designated

fusible

link

Green

color

link

for

model

8110

In

comparison

with

fuse

much

higher

current

flows

through

the

fusible

link

Moreover

it

is

important

to

eliminate

the

cause

of

blown

off

fusible

link

before

replacing

d

When

fuse

is

connected

incorrectly

and

the

contact

is

loose

voltage

drops

and

heat

are

gener

ated

resulting

abnormally

operated

electrical

equip

ment

Remove

dust

or

when

oxidized

polish

with

a

fine

emery

paper

so

that

the

contact

is

improved

LlGHTING

SYSTEM

CONTENTS

HEAD

LAMP

Descri

ption

Sealed

beam

replacement

Aiming

adjustment

FRONT

PARKING

AND

TURN

SIGNAL

SIDE

FLASHER

IMARKER

LAMP

AN

D

LICENSE

LAMP

REAR

COMBINATION

LAMPS

BULB

SPECIFICATIONS

TURN

SIGNAL

AND

DIMMER

COMBINATION

SWITCH

BE

7

BE

7

BE

7

BE

8

LAMP

BE

8

BE

9

BE10

BE10

HEAD

LAMP

Description

All

weather

type

sealed

beam

2

light

system

front

lamps

are

adopted

Each

lamp

of

both

side

head

lamps

is

provided

with

high

beam

filament

for

long

range

SOW

and

low

beam

filarnent

for

dipping

40W

In

other

words

the

lamp

is

of

a

double

filament

type

Sealed

beam

replacement

I

Rernove

the

wiring

socket

from

back

of

the

head

lamp

2

Remove

the

screws

attaching

the

front

grille

to

the

radiator

core

support

Coupe

only

Remove

three

retaining

screws

and

remove

the

head

lamp

rim

All

other

than

coupe

3

Loosen

three

screws

used

to

install

the

retaining

ring

on

the

sealed

bearn

mounting

ring

and

remove

the

sealed

Removal

LIGHTING

SWITCH

Removal

HAZARD

WARNING

SWITCH

PASSING

LIGHT

SWITCH

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Head

lamp

Turn

signal

lamps

Tail

and

stop

lamp

license

lamp

back

up

lamp

BE

10

BE

11

BE

11

BE

11

BE

12

BE

12

BE

12

BE

13

BE

15

i

Ii

beam

unit

4

When

installing

a

new

unit

be

sure

to

position

the

Top

mark

to

the

top

of

ring

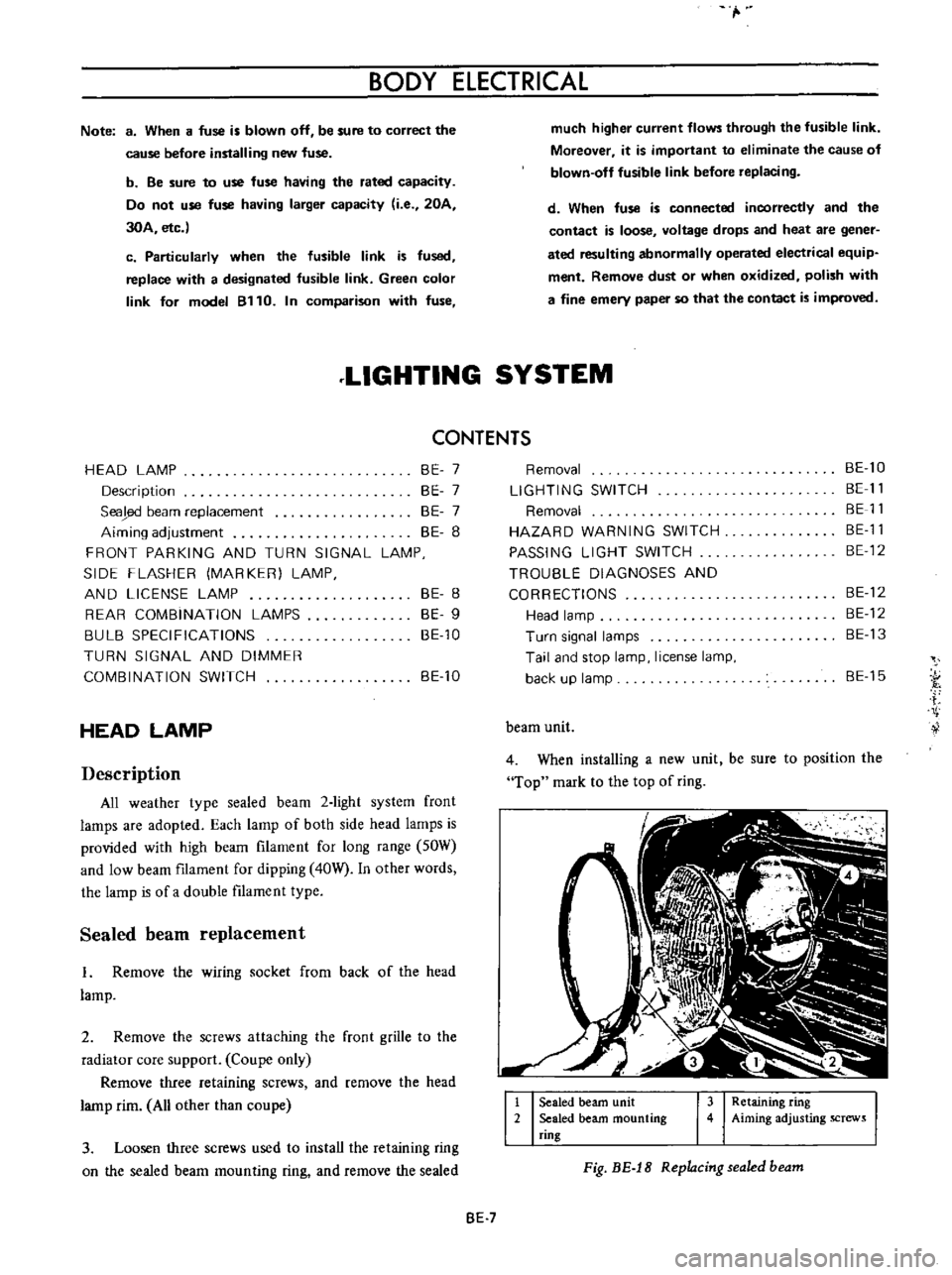

1

2

Sealed

beam

unit

Sealed

beam

mounting

ring

3

Retaining

ring

4

Aiming

adjusting

screws

Fig

BE

18

Replacing

sealed

beam

BE

7

Page 309 of 513

ENGINE

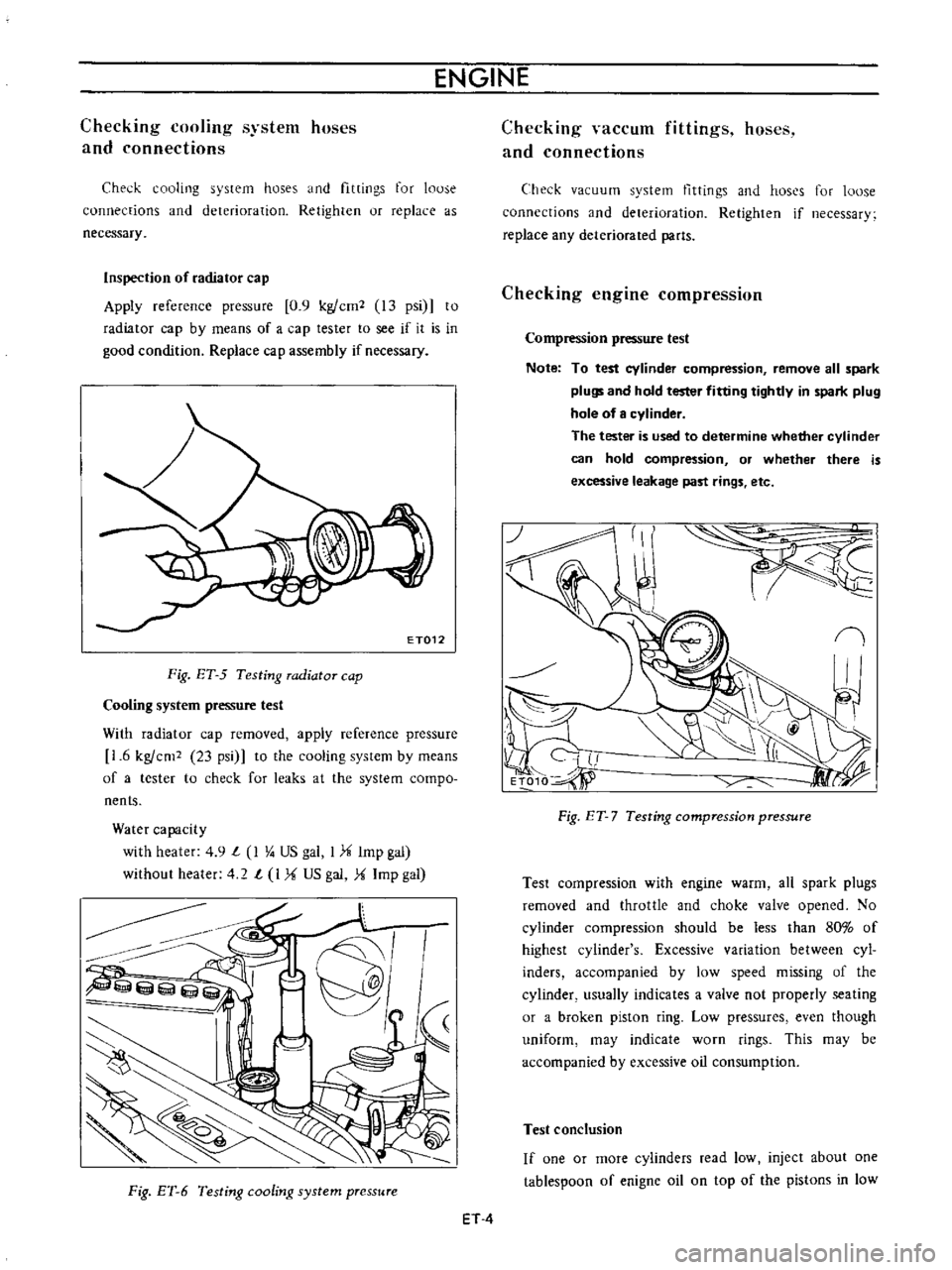

Checking

cooling

system

hoses

and

connections

Check

cooling

system

hoses

and

fiHings

for

loose

connections

and

deterioration

Retighten

or

replace

as

necessary

Inspection

of

radiator

cap

Apply

reference

pressure

0

9

kg

cm1

13

psi

to

radiator

cap

by

means

of

a

cap

tester

to

see

if

it

is

in

good

condition

Replace

cap

assembly

if

necessary

ET012

Fig

ET

5

Testing

radiator

cap

Cooling

system

pressure

test

With

radiator

cap

removed

apply

reference

pressure

1

6

kg

cm1

23

psi

to

the

cooling

system

bv

means

of

a

tester

to

check

for

leaks

at

the

system

compo

nents

Water

capacity

with

heater

4

9

l

I

Y

US

gal

l

i

Imp

gal

without

heater

4

2

l

I

i

US

gal

i

Imp

gal

Fig

ET

6

Testing

cooling

system

pressure

Checking

vaccum

fittings

hoses

and

connections

Check

vacuum

system

fittings

and

hoses

for

loose

connections

and

deterioration

Retighten

if

necessary

replace

any

deteriorated

parts

Checking

engine

compression

Compression

pressure

test

Note

To

test

cylinder

compression

remove

all

spark

plugs

and

hold

tester

fitting

tightly

in

spark

plug

hole

of

cylinder

The

tester

is

used

to

determine

whether

cylinder

can

hold

compression

or

whether

there

is

excessive

leakage

past

rings

etc

I

Td10

l

y

Fig

ET

7

Testing

compression

pressure

Test

compression

with

engine

warm

all

spark

plugs

removed

and

throttle

and

choke

valve

opened

No

cylinder

compression

should

be

less

than

80

of

highest

cylinder

s

Excessive

variation

between

cyl

inders

accompanied

by

low

speed

missing

of

the

cylinder

usually

indicates

a

valve

not

properly

seating

or

a

broken

piston

ring

Low

pressures

even

though

uniform

may

indicate

worn

rings

This

may

be

accompanied

by

excessive

oil

consumption

Test

conclusion

If

one

or

more

cylinders

read

low

inject

about

one

tablespoon

of

enigne

oil

on

top

of

the

pistons

in

low

ET

4

Page 335 of 513

Air

intake

system

in

trouble

Overheating

Overcooling

Others

NOISY

ENGINE

Car

knocking

Car

knock

when

coasting

ENGINE

Diny

ur

clogged

fuel

strainer

Fuel

pump

will

not

work

properly

Clogged

carburetor

jets

Clogged

air

cleaner

Air

inhaling

from

manifold

gasket

or

carbu

retor

gasket

Insufficient

coolant

Loosened

fan

belt

Worn

or

defective

fan

belt

Defective

thermostat

Defective

water

pump

Clogged

or

leaky

radiator

Defective

radiator

filler

cap

Air

mixing

into

cooling

system

Improper

grade

engine

oil

Incorrect

ignition

timing

Defective

carburetor

lean

mixture

Defective

thermostat

Low

octane

fuel

Improper

tire

pressure

Dragging

brake

Slipping

clutch

Overloading

to

engine

Carbon

knocking

Timing

knocking

Fuel

knocking

Preignition

misusing

of

spark

plug

Incorrect

throttle

opener

adjustment

Trouble

in

PCV

valve

ET

30

Replace

Repair

or

replace

Disassemble

and

clean

Replace

element

Replace

gasket

Replenish

Adjust

Replace

Replace

Replace

Flush

repair

or

replace

Replace

Retighten

each

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaul

carburetor

Replace

Replace

with

specified

octane

fuel

Adjust

to

the

specified

pressure

Adjust

Adjust

Use

right

gear

in

driving

Disassemble

cylinder

head

and

remove

carbon

Adjust

ignition

timing

Use

specified

octane

fuel

Use

specified

spark

plug

Adjust

throttle

opener

Replace

PCV

valve

Page 387 of 513

COOLING

SYSTEM

COOLING

SYSTEM

CONTENTS

DESCRIPTION

WATER

PUMP

Removal

THERMOSTAT

Removal

Inspection

CO

1

CO

2

CO

2

CO

2

CO

2

CO

2

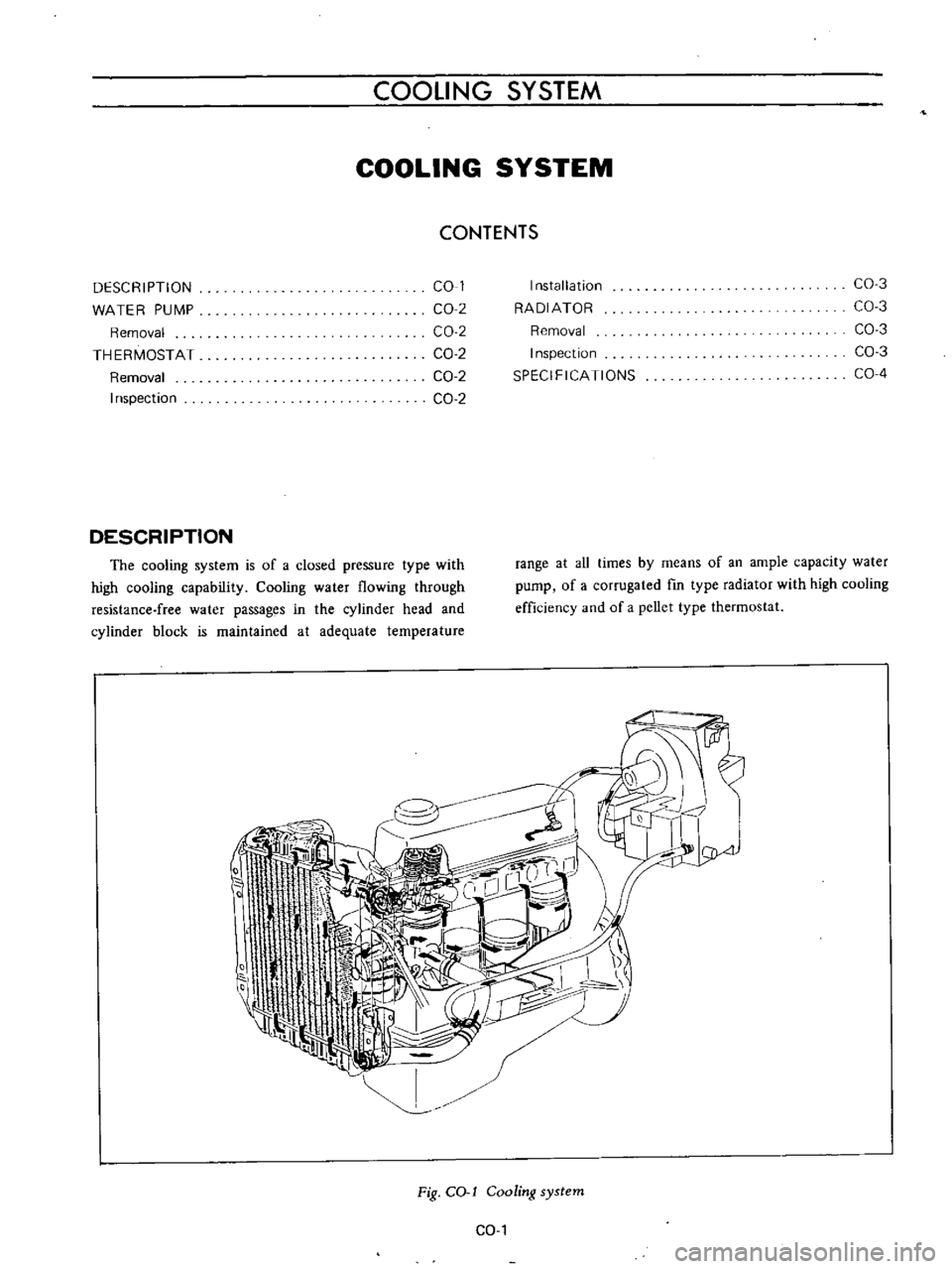

DESCRIPTION

The

cooling

system

is

of

a

closed

pressure

type

with

high

cooling

capability

Cooling

water

flowing

through

resistance

free

water

passages

in

the

cylinder

head

and

cylinder

block

is

maintained

at

adequate

temperature

Installation

RADIATOR

Removal

Inspection

SPECIFICATIONS

CO

3

CO

3

CO

3

CO

3

CO

4

range

at

aU

times

by

means

of

an

ample

capacity

water

pump

of

a

corrugated

fm

type

radiator

with

high

cooling

efficiency

and

of

a

pellet

type

thermostat

I

I

I

0

Jrl

oA

Fig

COol

Cooling

system

CO

I

Page 389 of 513

COOLING

SYSTEM

Measure

temperature

when

the

thermostat

valve

just

starts

rising

U

S

A

Canada

Other

countries

Valve

opening

80

5

to

83

5

86

5

to

89

5

75

to

78

temperature

l77

to

l87

to

167

to

OCeF

183

193

173

Valve

lift

8

95

8

100

8

90

mm

C

0

31

203

0

31

212

0

31

194

in

F

C0011

Fig

CQ

5

Thermostat

inspection

If

thermostat

does

not

operate

at

the

above

specified

temperatures

it

must

be

replaced

Installation

I

When

installing

the

thermostat

apply

adhesive

Three

Bond

to

both

sides

of

the

packing

for

prevention

of

water

leakage

2

Install

the

thermostat

in

reverse

sequence

of

re

moval

RADIATOR

The

radiator

is

of

a

down

flow

type

with

an

expansion

tank

located

on

the

top

of

tube

section

Pressure

is

applied

to

the

system

and

the

relief

valve

incorporated

in

the

radiator

filler

cap

controls

the

pressure

at

approximately

0

9

kg

cm2

l3

Ib

sq

in

Fig

CO

6

Radiator

removal

Removal

I

Drain

cooling

water

2

Disconnect

radiator

upper

hose

lower

hose

and

hose

to

the

reservoir

tank

3

Detach

the

radiator

assembly

by

removing

six

fixing

bolts

Inspection

Check

for

water

leakage

and

cracks

using

a

cap

tester

If

such

defects

are

detected

repair

or

replace

the

radiator

assembly

CO

3

Page 390 of 513

ENGINE

SPECIFICATIONS

Dimensions

of

radiator

core

Height

x

Width

x

Thickness

mm

in

330

x

344

x

32

13

0

x

13

5

x

1

26

Type

Corrugate

fin

type

Radiator

fin

spacing

mm

in

2

5

0

098

Radiator

capacity

K

cal

hoC

335

Water

capacity

with

heater

kg

em

lb

sq

in

t

US

qt

Imp

qt

0

9IO

l

13II4

4

9

5

I

4

X

Cap

working

pressure

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

CQ

4