tires DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 83 of 513

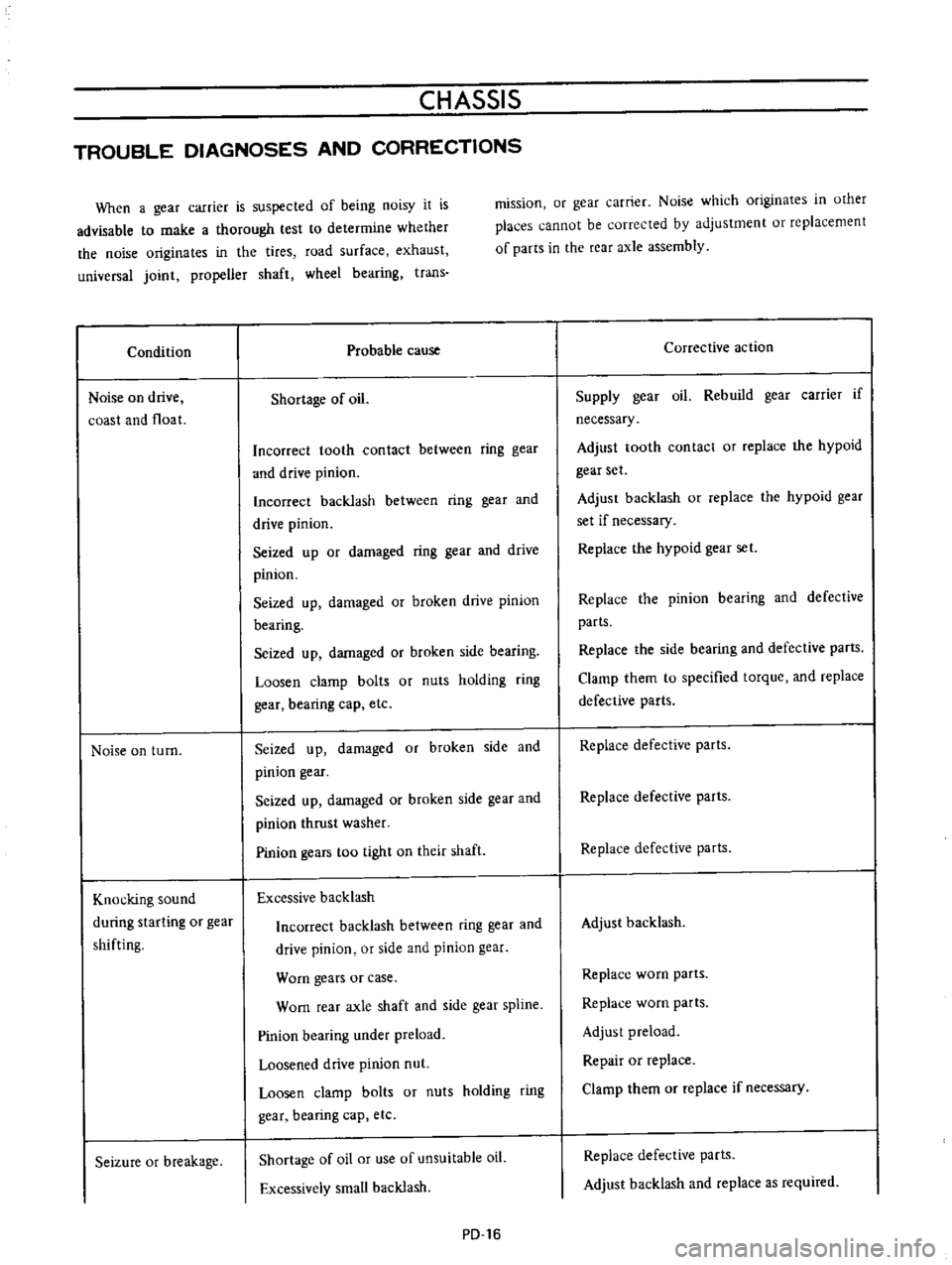

CHASSIS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

a

gear

carrier

is

suspected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearing

trans

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

Seizure

or

breakage

mission

or

gear

carrier

Noise

which

originates

in

other

places

cannot

be

corrected

by

adjustment

or

replacement

of

parts

in

the

rear

axle

assembly

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

backlash

between

ring

gear

and

drive

pinion

Seized

up

or

damaged

ring

gear

and

drive

pinion

Seized

up

damaged

or

broken

drive

pinion

bearing

Seized

up

damaged

or

broken

side

bearing

Loosen

clamp

bolts

or

nuts

holding

ring

gear

bearing

cap

etc

Seized

up

damaged

or

broken

side

and

pinion

gear

I

Seized

up

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

gears

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

between

ring

gear

and

drive

pinion

or

side

and

pinion

gear

Worn

gears

or

case

Worn

rear

axle

shaft

and

side

gear

spline

Pinion

bearing

under

preload

Loosened

drive

pinion

nut

Loosen

clamp

bolts

or

nuts

holding

ring

gear

bearing

cap

etc

Shortage

of

oil

or

use

of

unsuitable

oil

Excessively

small

backlash

PD

16

Corrective

action

Supply

gear

oil

Rebuild

gear

carrier

if

necessary

Adjust

tooth

contact

or

replace

the

hypoid

gear

set

Adjust

backlash

or

replace

the

hypoid

gear

set

if

necessary

Replace

the

hypoid

gear

set

Replace

the

pinion

bearing

and

defective

parts

Replace

the

side

bearing

and

defective

parts

Clamp

them

to

specified

torque

and

replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

them

or

replace

if

necessary

Replace

defective

parts

Adjust

backlash

and

replace

as

required

Page 107 of 513

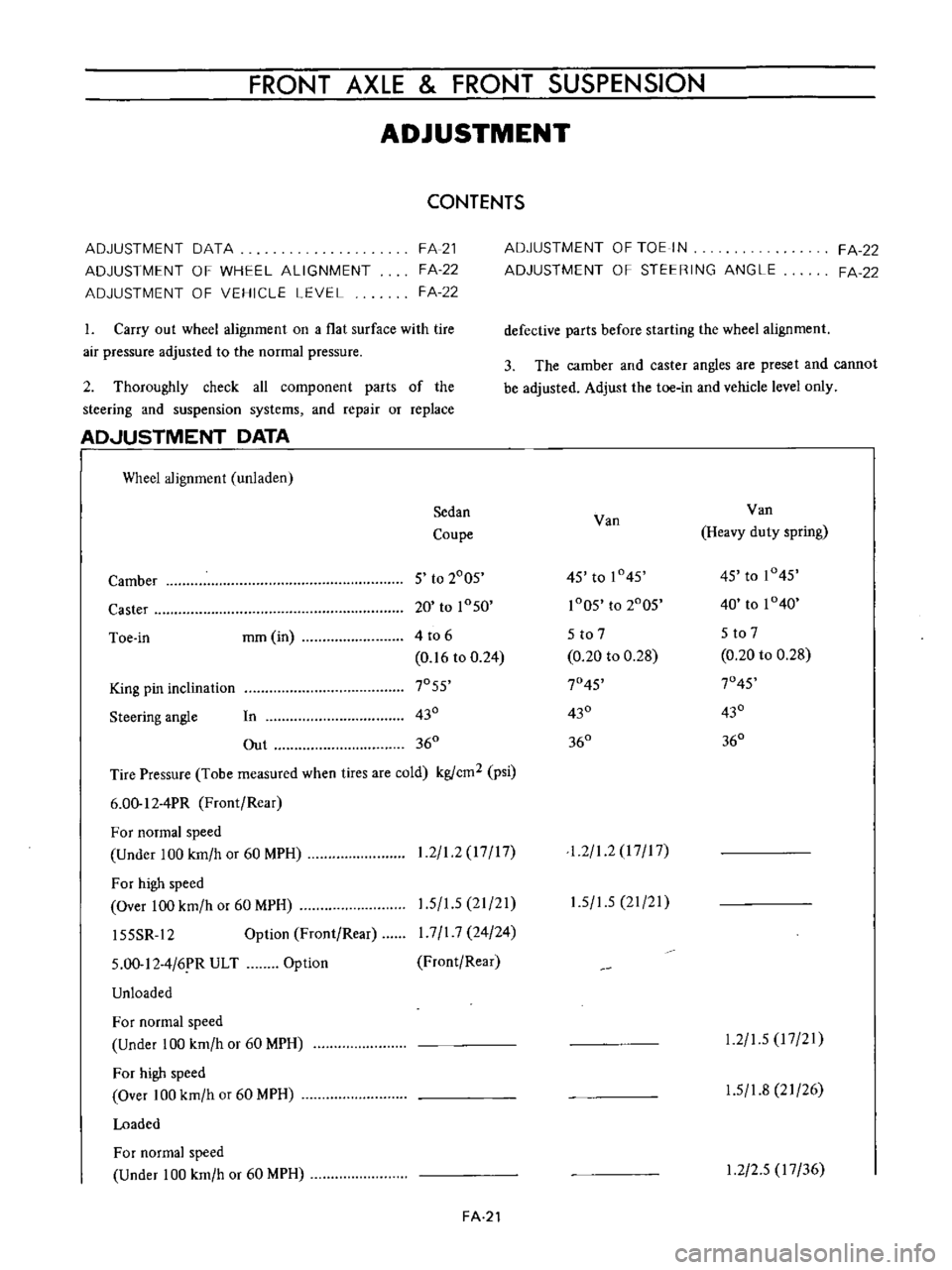

FRONT

AXLE

FRONT

SUSPENSION

ADJUSTMENT

CONTENTS

ADJUSTMENT

DATA

ADJUSTMENT

OF

WHEEL

ALIGNMENT

ADJUSTMENT

OF

VEHICLE

LEVEL

FA

21

FA

22

FA

22

1

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

2

Thoroughly

check

all

component

parts

of

the

steering

and

suspension

systems

and

repair

or

replace

AD

JUSTMENT

DATA

I

Wheel

alignment

unladen

Sedan

Coupe

Camber

5

to

2005

Caster

20

to

1050

Toe

in

mm

in

4

to

6

0

16

to

0

24

King

pin

inclination

7055

Steering

angle

In

430

Out

360

Tire

Pressure

Tobe

measured

when

tires

are

cold

kgfcm2

psi

6

00

12

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

15SSR

12

Option

Front

Rear

1

2

1

2

17

17

1

5

1

5

21

21

I

7

I

7

24

24

Front

Rear

5

00

12

4

6

R

ULT

Unloaded

Option

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

Loaded

For

normal

speed

Under

100

km

h

or

60

MPH

FA

21

ADJUSTMENT

OF

TOE

IN

ADJUSTMENT

OF

STEERING

ANGLE

FA

22

FA

22

defective

parts

before

starting

the

wheel

alignment

3

The

camber

and

caster

angles

are

preset

and

cannot

be

adjusted

Adjust

the

toe

in

and

vehicle

level

only

Van

Van

Heavy

duty

spring

45

to

1045

45

to

1045

1005

to

2005

40

to

1040

5

to

7

5

to

7

0

20

to

0

28

0

20

to

0

28

7045

7045

430

430

360

360

1

2

1

2

I

7

I

7

1

5

1

5

21

21

1

2

1

5

17

21

1

5

1

8

21

26

1

2

2

5

17

36

Page 109 of 513

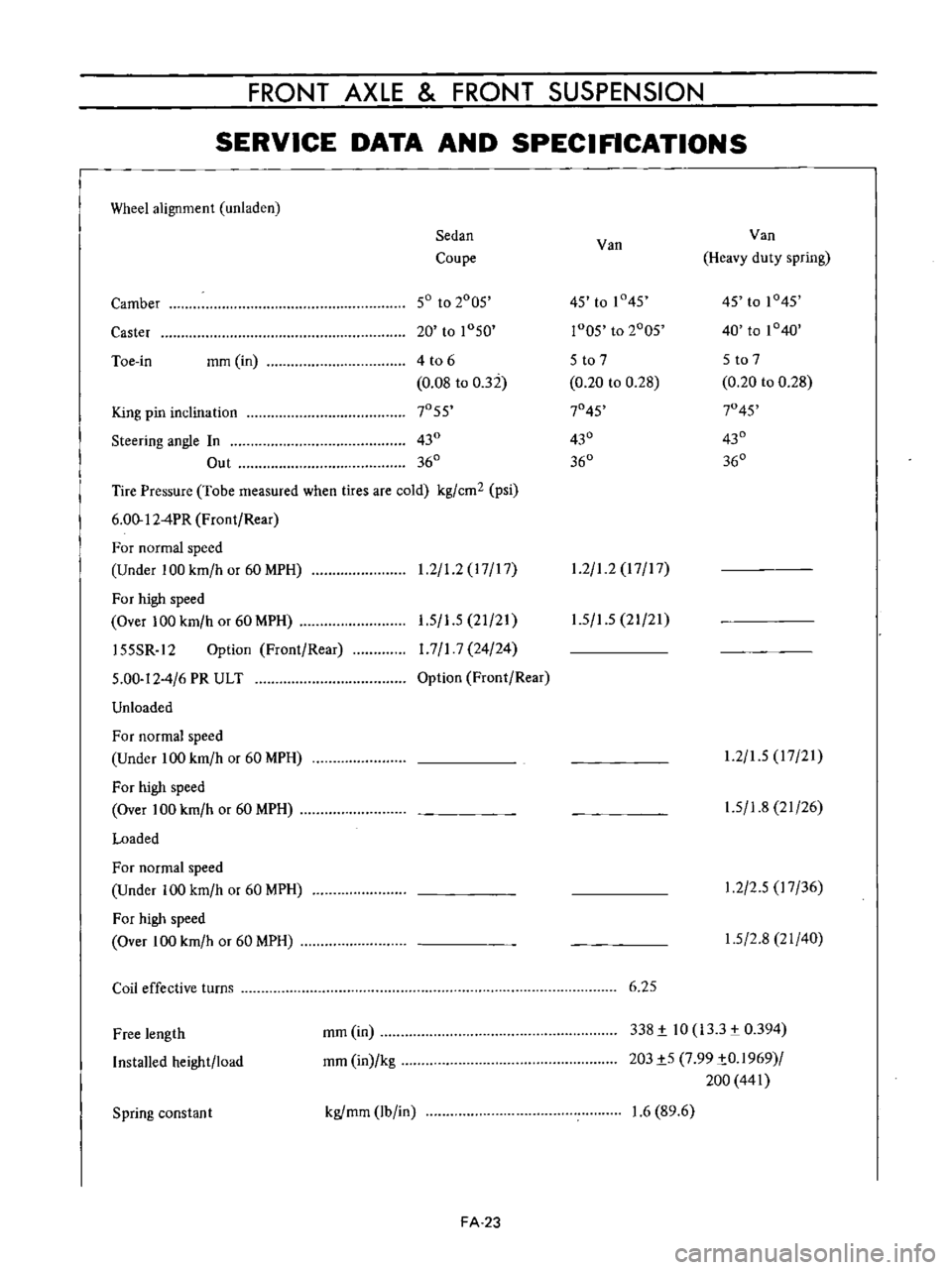

FRONT

AXLE

FRONT

SUSPENSION

SERVICE

DATA

AND

SPECIFICATIONS

Wheel

alignment

unladen

Sedan

Van

Van

Coupe

Heavy

duty

spring

Camber

50

to

2005

45

to

1

45

45

to

1045

Caster

20

to

1050

r005

to

2005

40

to

1040

Toe

in

mm

in

4

t06

5

to

7

5

to

7

0

08

to

032

0

20

to

0

28

0

20

to

0

28

King

pin

inclination

7055

7045

7045

Steering

angle

In

430

430

430

Out

360

360

360

Tire

Pressure

Tobe

measured

when

tires

are

cold

kg

cm2

psi

6

00

12

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

MPH

1

2

1

2

17

17

1

2

1

2

17

17

For

high

speed

Over

100

km

h

or

60

MPH

155SR

12

Option

Front

Rear

5

00

12

4

6

PR

ULT

Unloaded

1

5

1

5

21

21

1

7

1

7

24

24

Option

Front

Rear

1

5

1

5

21

21

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

Loaded

1

2

1

5

17

21

1

5

1

8

21

26

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

1

2

2

5

17

36

1

5

2

8

21

40

Coil

effective

turns

6

25

Free

length

Installed

height

load

mm

in

mm

in

kg

338

i

10

133

0394

203i5

7

99

iO

1969

200

441

Spring

constan

t

kgfmm

lb

in

1

6

89

6

FA

23

Page 112 of 513

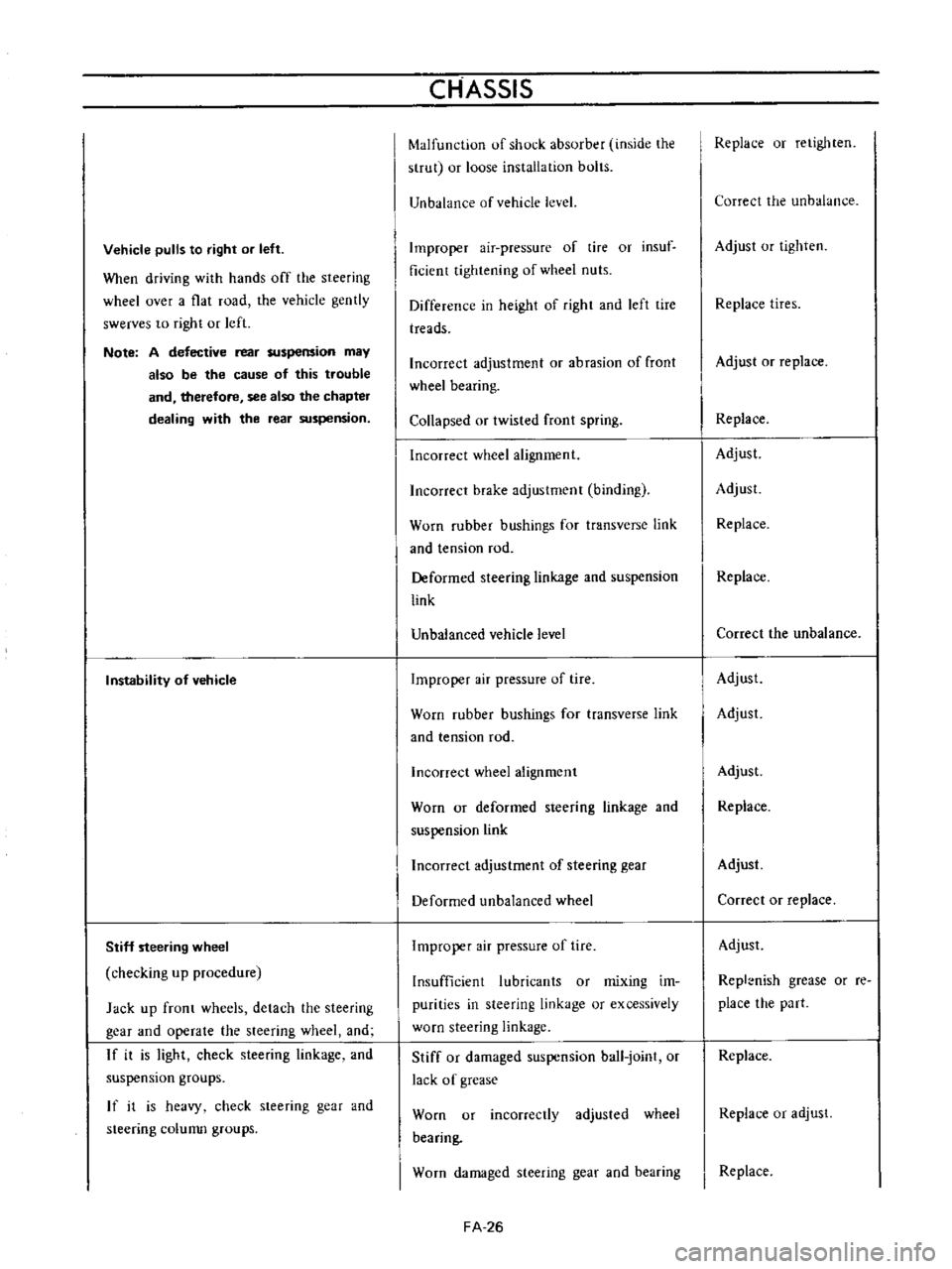

Vehicle

pulls

to

right

or

left

When

driving

with

hands

off

the

steering

wheel

over

a

flat

road

the

vehicle

gently

swerves

to

right

or

left

Note

A

defective

rear

suspension

may

also

be

the

cause

of

this

trouble

and

therefore

see

also

the

chapter

dealing

with

the

rear

suspension

Instability

of

vehicle

Stiff

steering

wheel

checking

up

procedure

Jack

up

front

wheels

detach

the

steering

gear

and

operate

the

steering

wheel

and

If

it

is

light

check

steering

linkage

and

suspension

groups

If

it

is

heavy

check

steering

gear

and

steering

colunm

groups

CHASSIS

Malfunction

of

shock

absorber

inside

the

strut

or

loose

installation

bolts

Unbalance

of

vehicle

level

Improper

air

pressure

of

tire

or

insuf

ficient

tightening

of

wheel

nuts

Difference

in

height

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Collapsed

or

twisted

front

spring

Incorrect

wheel

alignment

Incorrect

brake

adjustment

binding

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Deformed

steering

linkage

and

suspension

link

Unbalanced

vehicle

level

Improper

air

pressure

of

tire

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

unbalanced

wheel

Improper

air

pressure

of

tire

Insufficient

lubricants

or

mixing

im

purities

in

steering

linkage

or

excessively

worn

steering

linkage

Stiff

or

damaged

suspension

ball

joint

or

lack

of

grease

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

damaged

steering

gear

and

bearing

FA

26

Replace

or

retighten

Correct

the

unbalance

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Adjust

Adjust

Replace

Replace

Correct

the

unbalance

Adjust

Adjust

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Repl

nish

grease

or

re

place

the

part

Replace

Replace

or

adjust

Replace

Page 130 of 513

CHASSIS

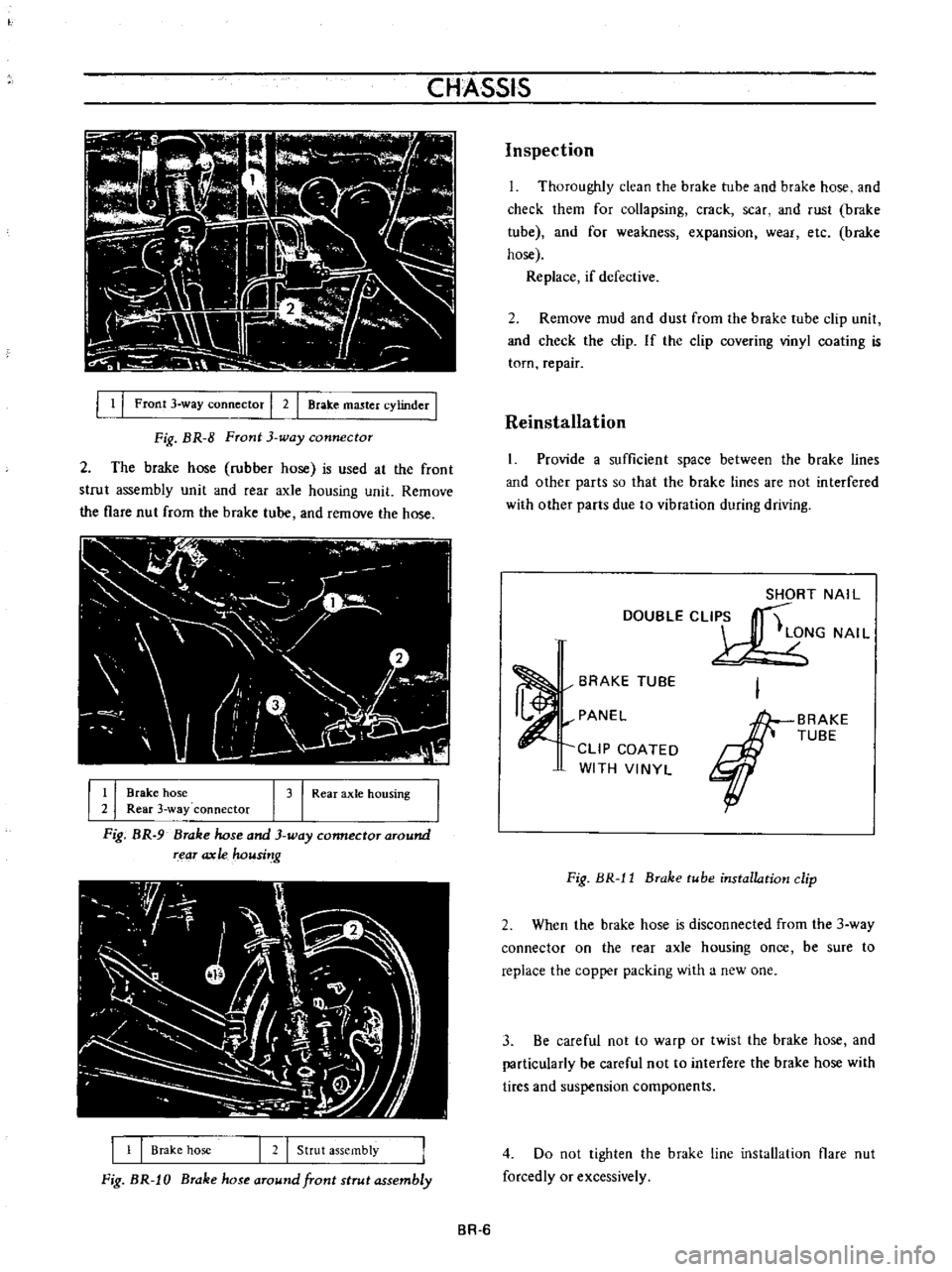

1

I

Front

3

way

connector

I

2

I

Brake

master

cylinder

I

Fig

BR

8

Front

3

way

connector

2

The

brake

hose

rubber

hose

is

used

at

the

front

strut

assembly

unit

and

fear

axle

housing

unit

Remove

the

flare

nut

from

the

brake

tube

and

remove

the

hose

I

r

I

I

l

j

u

l

I

J

II

V

r

1

0

l

I

l

I

I

Brake

hose

I

3

I

Rear

axle

hOUSing

2

Rear

3

way

connector

Fig

BR

9

Brake

hose

and

3

way

connector

around

rear

ax

Ie

housi

g

1

1

Brake

hose

I

2

I

Strut

assembly

Fig

BR

J

0

Brake

hose

around

front

strut

assembly

Inspection

L

Thoroughly

clean

the

brake

tube

and

brake

hose

and

check

them

for

collapsing

crack

scar

and

rust

brake

tube

and

for

weakness

expansion

wear

etc

brake

hose

Replace

if

defective

2

Remove

mud

and

dust

from

the

brake

tube

clip

unit

and

check

the

clip

If

the

clip

covering

vinyl

coating

is

torn

repair

Reinstallation

1

Provide

a

sufficient

space

between

the

brake

lines

and

other

parts

so

that

the

brake

lines

are

not

interfered

with

other

parts

due

to

vibration

during

driving

SHORT

NAIL

DOUBLECLI

S

t

LONG

NAI

L

BRAKE

TUBE

PANEL

CLIP

COATED

WITH

VINYL

BRAKE

TUBE

Fig

BR

l1

Brake

tube

installation

clip

2

When

the

brake

hose

is

disconnected

from

the

3

way

connector

on

the

rear

axle

housing

once

be

sure

to

replace

the

copper

packing

with

a

new

one

3

Be

careful

not

to

warp

or

twist

the

brake

hose

and

particularly

be

careful

not

to

interfere

the

brake

hose

with

tires

and

suspension

components

4

Do

not

tighten

the

brake

line

installation

flare

nut

forcedly

or

excessively

BR

6

Page 149 of 513

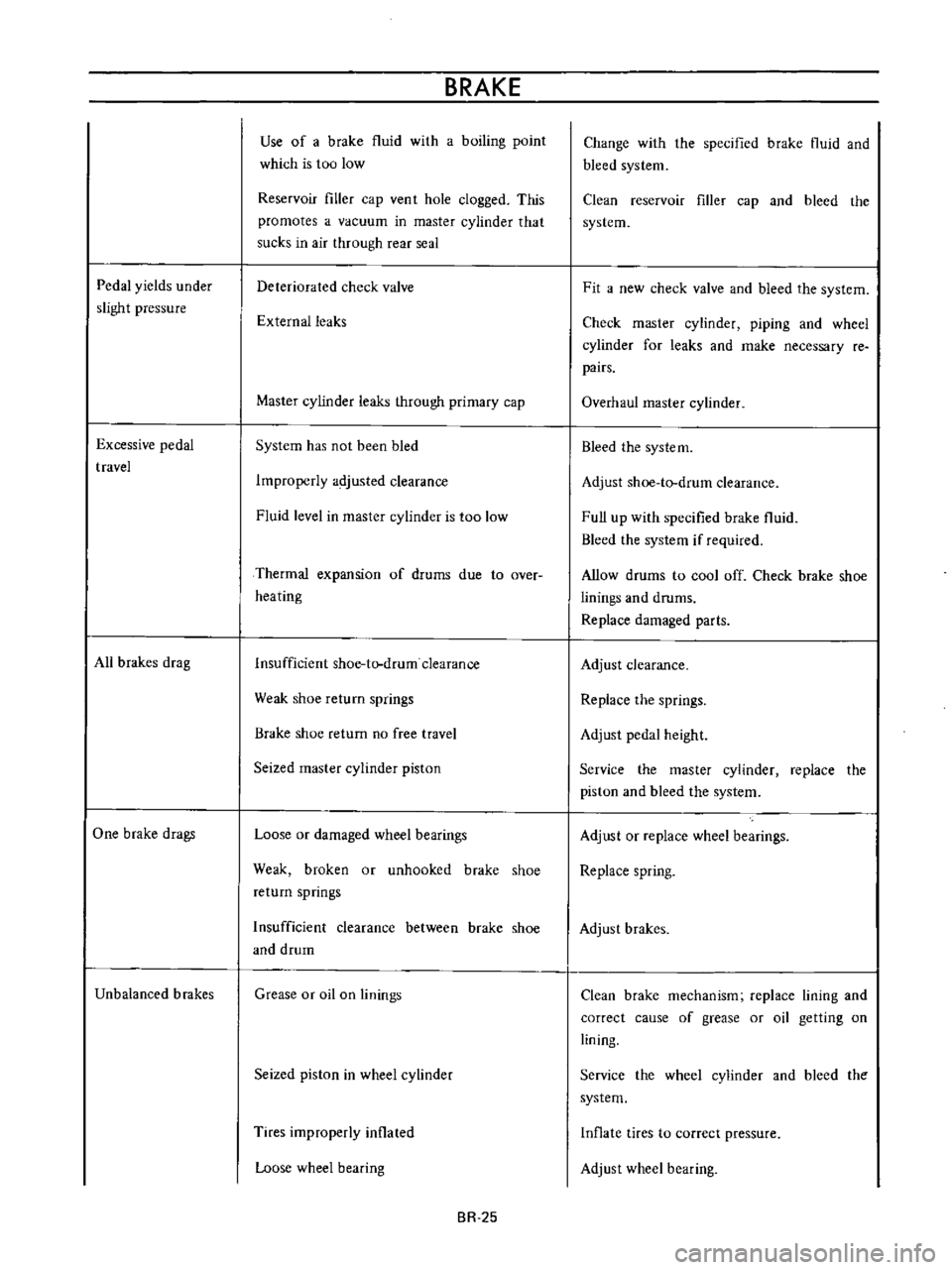

Pedal

yields

under

slight

pressure

Excessive

pedal

travel

All

brakes

drag

One

brake

drags

Unbalanced

brakes

BRAKE

Use

of

a

brake

fluid

with

a

boiling

point

which

is

too

low

Reservoir

filler

cap

ven

t

hole

clogged

This

promotes

a

vacuum

in

master

cylinder

that

sucks

in

air

through

rear

seal

Deteriorated

check

valve

External

leaks

Master

cylinder

leaks

through

primary

cap

System

has

not

been

bled

Improperly

adjusted

clearance

Fluid

level

in

master

cylinder

is

too

low

Thermal

expansion

of

drums

due

to

over

heating

Insufficient

shoe

tlrdrum

clearance

Weak

shoe

return

springs

Brake

shoe

return

no

free

travel

Seized

master

cylinder

piston

Loose

or

damaged

wheel

bearings

Weak

broken

or

unhooked

brake

shoe

return

springs

Insufficient

clearance

between

brake

shoe

and

drum

Grease

or

oil

on

linings

Seized

piston

in

wheel

cylinder

Tires

improperly

inflated

Loose

wheel

bearing

BR

25

Change

with

the

specified

brake

fluid

and

bleed

system

Clean

reservoir

filler

cap

and

bleed

the

system

Fit

a

new

check

valve

and

bleed

the

system

Check

master

cylinder

piping

and

wheel

cylinder

for

leaks

and

make

necessary

re

pairs

Overhaul

master

cylinder

Bleed

the

system

Adjust

shoe

to

drum

clearance

Full

up

with

specified

brake

fluid

Bleed

the

system

if

required

Allow

drums

to

cool

off

Check

brake

shoe

linings

and

drums

Replace

damaged

parts

Adjust

clearance

Replace

the

springs

Adjust

pedal

height

Service

the

master

cylinder

replace

the

piston

and

bleed

the

system

Adjust

or

replace

wheel

bearings

Replace

spring

Adjust

brakes

Clean

brake

mechanism

replace

lining

and

correct

cause

of

grease

or

oil

getting

on

lining

Service

the

wheel

cylinder

and

bleed

the

system

Inflate

tires

to

correct

pressure

Adjust

wheel

bearing

Page 154 of 513

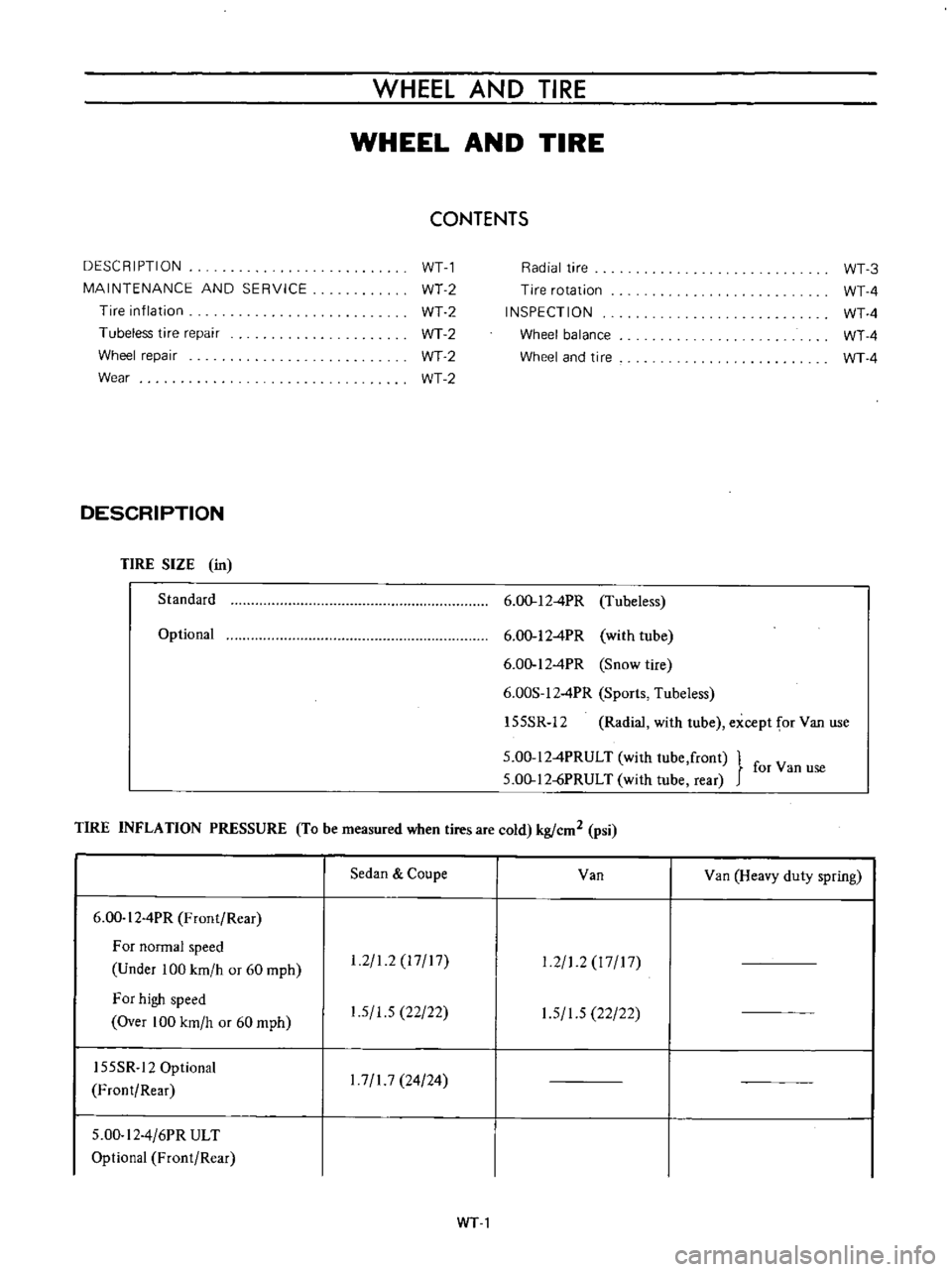

DESCRIPTION

MAINTENANCE

AND

SERVICE

Tire

inflation

Tubeless

tire

repair

Wheel

repair

Wear

DESCRIPTION

TIRE

SIZE

in

Standard

Optional

WHEEL

AND

TIRE

WHEEL

AND

TIRE

CONTENTS

WTl

WT2

WT2

WT2

WT2

WT2

Radial

tire

Tire

rotation

INSPECTION

Wheel

balance

Wheel

and

tire

6

00

12

4PR

Tubeless

6

00

12

4PR

with

tube

6

00

12

4PR

Snow

tire

6

00S

12

4PR

Sports

Tubeless

155SR

12

Radial

with

tube

except

for

Van

use

5

00

12

4PRULT

with

lube

front

for

Van

use

5

00

12

jPRULT

with

tube

rear

TIRE

INFLATION

PRESSURE

To

be

measured

when

tires

are

cold

kg

cm2

psi

6

00

I

2

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

mph

For

high

speed

Over

100

km

h

or

60

mph

155SR

12

Optional

Front

Rear

5

00

I

2

4

6PR

ULT

Optional

Front

Rear

Sedan

Coupe

1

2

1

2

17

17

1

5

1

5

22

22

1

7

1

7

24

24

Van

Van

Heavy

duty

spring

1

2

1

2

I

7

17

1

5

1

5

22

22

WTl

WT

3

WT

4

WT

4

WT

4

WT

4

Page 155 of 513

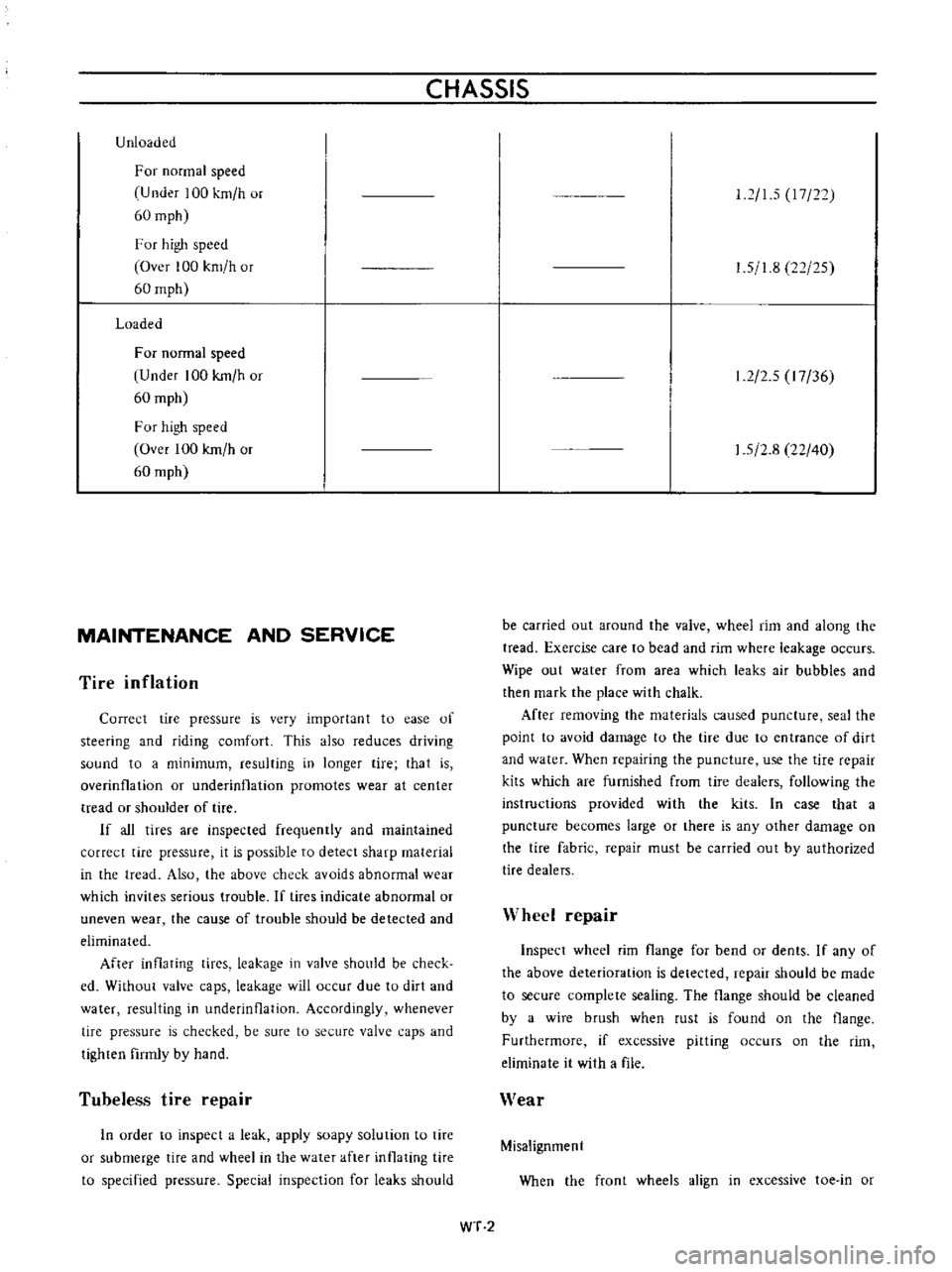

CHASSIS

Unloaded

For

normal

speed

U

nder

100

km

h

or

60

mph

F

or

high

speed

Over

100

km

h

or

60

mph

Loaded

For

normal

speed

Under

100

kmlh

or

60

mph

For

high

speed

Over

100

kmlh

or

60

mph

MAINTENANCE

AND

SERVICE

Tire

inflation

Correct

tire

pressure

is

very

importan

t

to

ease

of

steering

and

riding

comfort

This

also

reduces

driving

sound

to

a

minimum

resulting

in

longer

tire

that

is

overinfla

lion

or

underinflation

promotes

wear

at

center

tread

or

shoulder

of

tire

If

all

tires

are

inspected

frequently

and

maintained

correct

tire

pressure

it

is

possible

to

detect

sharp

material

in

the

tread

Also

the

above

check

avoids

abnormal

wear

which

invites

serious

trouble

If

tires

indicate

abnormal

or

uneven

wear

the

cause

of

trouble

should

be

detected

and

eliminated

After

inflating

tices

leakage

in

valve

should

be

check

cd

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinOation

Accordingly

whenever

tire

pressure

is

checked

be

sure

to

secure

valve

caps

and

tighten

firmly

by

hand

Tubeless

tire

repair

In

urder

to

inspect

a

leak

apply

soapy

solution

to

tire

or

submerge

tire

and

wheel

in

the

water

after

inflating

tire

to

specified

pressure

Special

inspection

for

leaks

should

12

15

17

22

1

5

1

8

22

25

1

2

2

5

I

7

36

1

5

2

8

22

40

be

carried

out

around

the

valve

wheel

rim

and

along

the

tread

Exercise

care

to

bead

and

rim

where

leakage

occurs

Wipe

out

water

from

area

which

leaks

air

bubbles

and

then

mark

the

place

with

chalk

After

remuving

the

materials

caused

puncture

seal

the

point

to

avoid

damage

to

the

tire

due

to

entrance

of

dirt

and

water

When

repairing

the

puncture

use

the

tire

repair

kits

which

are

furnished

from

tire

dealers

following

the

instructions

provided

with

the

kits

In

case

that

a

puncture

becomes

large

or

there

is

any

other

damage

on

the

tire

fabric

repair

must

be

carried

out

by

authorized

tire

dealers

Wheel

repair

Inspect

wheel

rim

flange

for

bend

or

dents

If

any

of

the

above

deterioration

is

detected

repair

should

be

made

to

secure

complete

sealing

The

flange

should

be

cleaned

by

a

wire

brush

when

rust

is

found

on

the

flange

Furthermore

if

excessive

pitting

occurs

on

the

rim

eliminate

it

with

a

file

Wear

Misalignment

When

the

front

wheels

align

in

excessive

toe

in

or

WT

2

Page 156 of 513

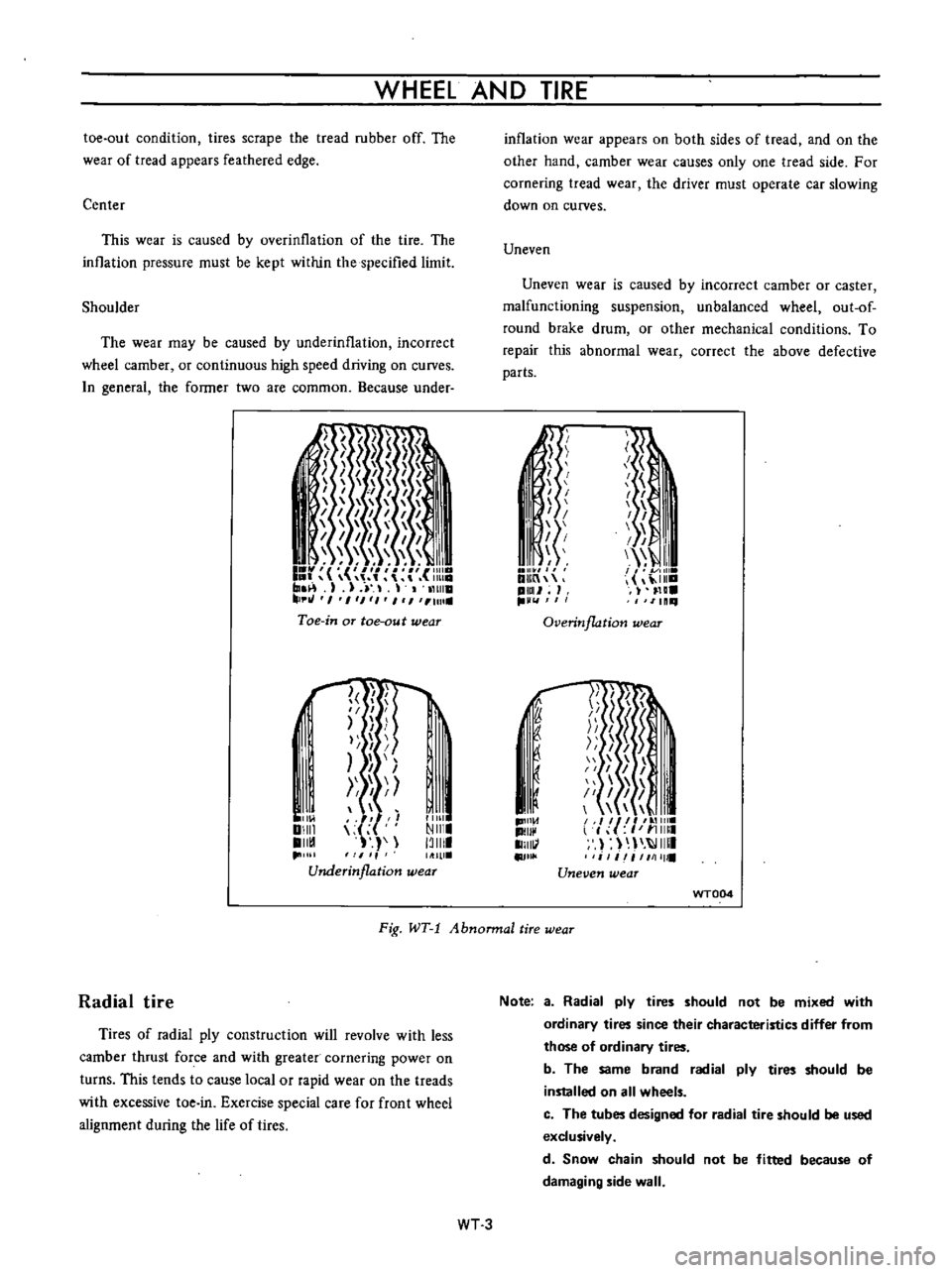

WHEEL

AND

TIRE

toe

out

condition

tires

scrape

the

tread

rubber

off

The

wear

of

tread

appears

feathered

edge

Center

This

wear

is

caused

by

overinllation

of

the

tire

The

inllation

pressure

must

be

kept

within

the

specified

limit

Shoulder

The

wear

may

be

caused

by

underinflation

incorrect

wheel

camber

or

continuous

high

speed

driving

on

curves

n

general

the

former

two

are

common

Because

under

I

I

I

I

1

1111

I

r

r

m

1

J

11

tHlla

tJ

I

1

1

1

I

1

Ull

Toe

in

aT

toe

au

t

wear

l

f

I

II

I

I

I

I

Ill

Ill

Underinflation

wear

I

11

01

DIIII

II

1

11111

NIII

13111

inflation

wear

appears

on

both

sides

of

tread

and

on

the

other

hand

camber

wear

causes

only

one

tread

side

For

cornering

tread

wear

the

driver

must

operate

car

slowing

down

on

curves

Uneven

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

suspension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechanical

conditions

To

repair

this

abnormal

wear

correct

the

above

defective

parts

Ii

I

I

I

I

1

i

f

I

I

I

I

I

III

I

I

11

DlIIn

ilia

pml

H

IlLl

11111

Overinflation

wear

1D1I1

d

II

1I111

II

j

J

1

51

I

I

I

1

il

I

I

II

l

f

I

11

11111

I

IIIII

i

1

iI

1111111

Uneven

wear

f

I

I

u

WT004

Fig

WT

1

Abnonnal

tire

wear

Radial

tire

Tires

of

radial

ply

construction

will

revolve

with

less

camber

thrust

force

and

with

greater

cornering

power

on

turns

This

tends

to

cause

local

or

rapid

wear

on

the

treads

with

excessive

toe

in

Exercise

special

care

for

front

wheel

alignment

during

the

life

of

tires

Note

a

Radial

ply

tires

should

not

be

mixed

with

ordinary

tires

since

their

characteristics

differ

from

those

of

ordinary

tires

b

The

same

brand

radial

ply

tires

should

be

installed

on

all

wheels

c

The

tubes

designed

for

radial

tire

should

be

used

exclusively

d

Snow

chain

should

not

be

fitted

because

of

damaging

side

wall

WT3

Page 157 of 513

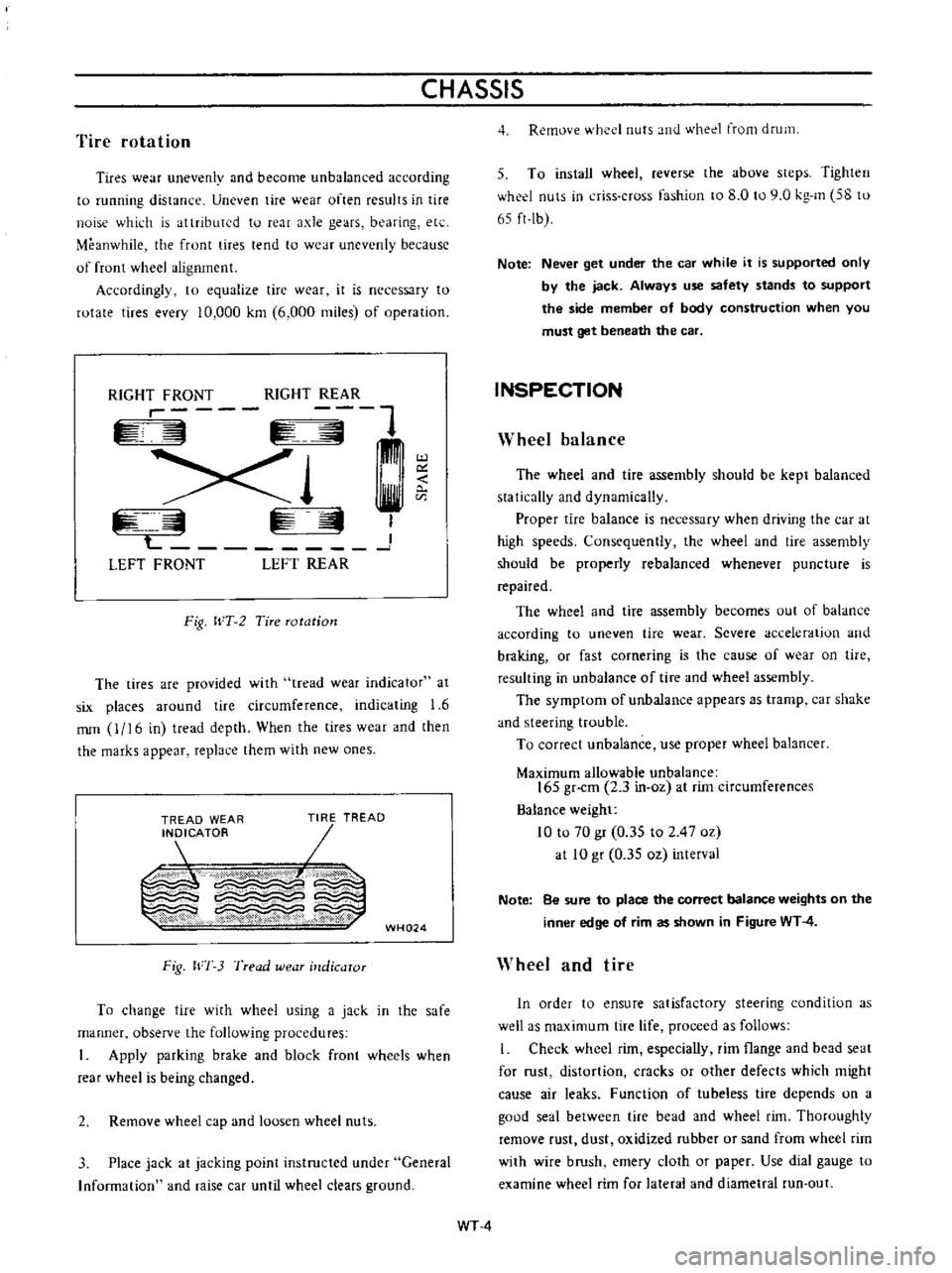

CHASSIS

Tire

rotation

Tires

wear

unevenly

and

become

unbalanced

according

to

running

distance

Uneven

tire

wear

often

results

in

tire

noise

whkh

is

attributed

to

rear

axle

gears

bearing

ell

Meanwhile

the

front

tires

tend

to

wear

unevenly

because

of

front

wheel

alignment

Accordingly

to

equalize

tire

wear

it

is

necessary

to

rotate

tires

every

10

000

km

6

000

miles

of

operation

RIGHT

FRONT

RIGHT

REAR

r

1

Xl

L

J

LEFT

FRONT

LEFT

REAR

Fig

WT

2

Tire

rotation

The

tires

are

provided

with

tread

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

nun

0

16

in

tread

depth

When

the

tires

wear

and

then

the

marks

a

ppear

replace

them

with

new

ones

TREAD

WEAR

INDICATOR

7

TREAD

m

Y

X

W

X

v

w

WH024

Fig

WI

3

Tread

wear

illdicator

To

change

tire

with

wheel

using

a

jack

in

the

safe

manner

observe

the

following

procedures

I

Apply

parking

brake

and

block

front

wheels

when

rear

wheel

is

being

changed

2

Remove

wheel

cap

and

loosen

wheel

nuts

3

Place

jack

at

jacking

point

instructed

under

General

Information

and

raise

car

until

wheel

clears

ground

4

Remove

wheel

nuts

and

whed

from

drum

5

To

install

wheel

reverse

the

above

steps

Tighten

whed

nuts

in

criss

cross

fashion

to

8

0

to

9

0

kg

m

58

to

65

ft

lb

Note

Never

get

under

the

car

while

it

is

supported

only

by

the

jack

Always

use

safety

stands

to

support

the

side

member

of

body

construction

when

you

must

get

beneath

the

car

INSPECTION

Wheel

balance

The

wheel

and

tire

assembly

should

be

kept

balanced

statically

and

dynamically

Proper

tire

balance

is

necessary

when

driving

the

car

at

high

speeds

Consequently

the

wheel

and

tire

assembly

should

be

properly

rebalanced

whenever

puncture

is

repaired

The

wheel

and

tire

assembly

becomes

out

of

balance

according

to

uneven

tire

wear

Severe

acceleration

and

braking

or

fast

cornering

is

the

cause

of

wear

on

tire

resulting

in

unbalance

of

tire

and

wheel

assembly

The

symptom

of

unbalance

appears

as

tramp

car

shake

and

steering

trouble

To

correct

unbalance

use

proper

wheel

balancer

Maximum

allowable

unbalance

165

gr

cm

2

3

in

ol

at

rim

circumferences

Balance

weight

10

to

70

gr

0

35

to

2

47

Ol

at

10

gr

0

35

Ol

interval

Note

Be

sure

to

place

the

correct

balance

weights

on

the

inner

edge

of

rim

as

shown

in

Figure

WT

4

Wheel

and

tire

In

order

to

ensure

satisfactory

steering

condition

as

well

as

maximum

tire

life

proceed

as

follows

I

Check

wheel

rim

especially

rim

flange

and

bead

seat

for

rust

distortion

cracks

or

other

defects

which

might

cause

air

leaks

Function

of

tubeless

tire

depends

on

a

good

seal

between

tire

bead

and

wheel

rim

Thoroughly

remove

rust

dust

oxidized

rubber

or

sand

from

wheel

rim

with

wire

brush

emery

cloth

or

paper

Use

dial

gauge

to

examine

wheel

rim

for

lateral

and

diametral

run

out

WT

4