steering wheel adjustment DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 107 of 513

FRONT

AXLE

FRONT

SUSPENSION

ADJUSTMENT

CONTENTS

ADJUSTMENT

DATA

ADJUSTMENT

OF

WHEEL

ALIGNMENT

ADJUSTMENT

OF

VEHICLE

LEVEL

FA

21

FA

22

FA

22

1

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

2

Thoroughly

check

all

component

parts

of

the

steering

and

suspension

systems

and

repair

or

replace

AD

JUSTMENT

DATA

I

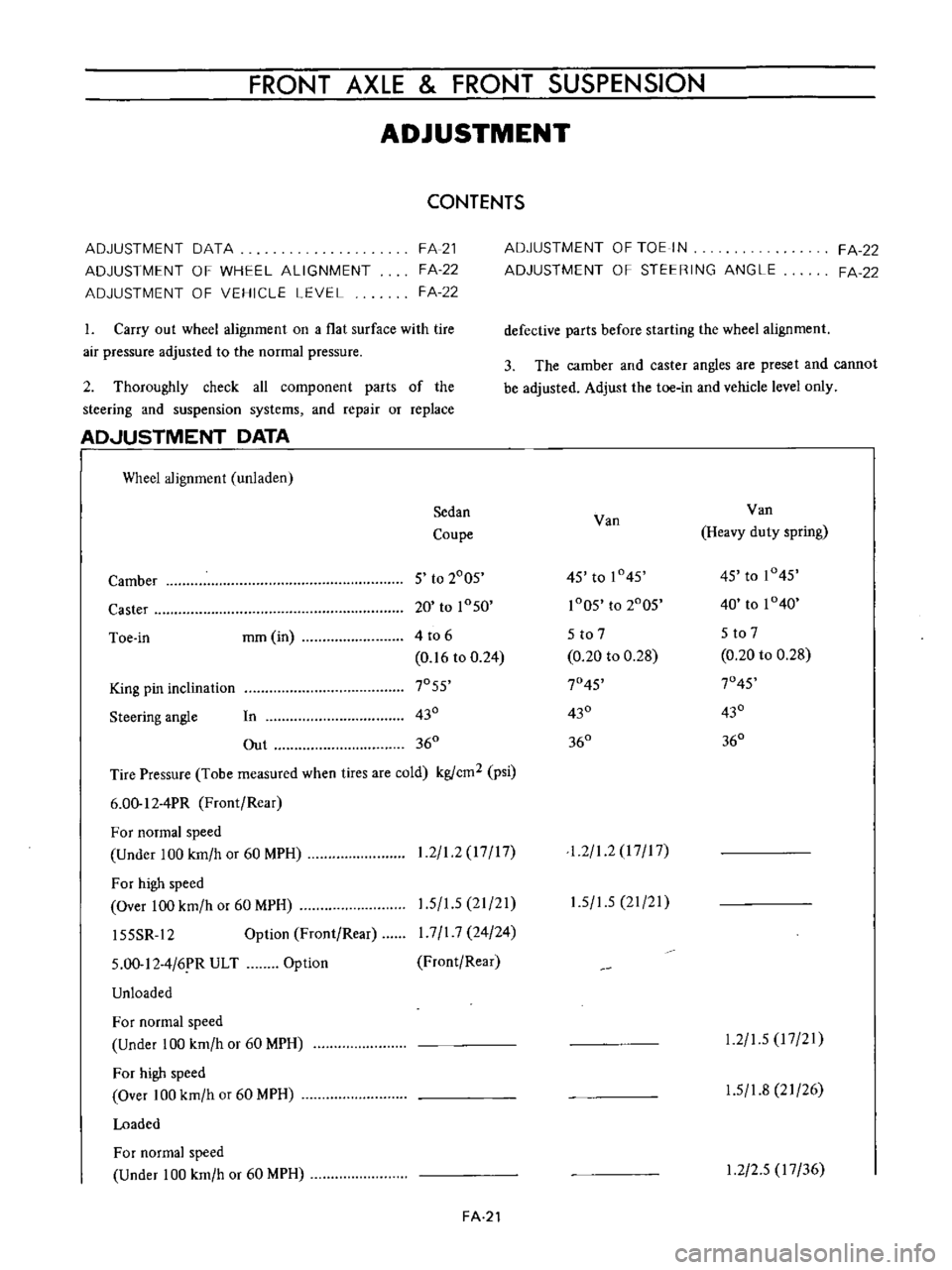

Wheel

alignment

unladen

Sedan

Coupe

Camber

5

to

2005

Caster

20

to

1050

Toe

in

mm

in

4

to

6

0

16

to

0

24

King

pin

inclination

7055

Steering

angle

In

430

Out

360

Tire

Pressure

Tobe

measured

when

tires

are

cold

kgfcm2

psi

6

00

12

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

15SSR

12

Option

Front

Rear

1

2

1

2

17

17

1

5

1

5

21

21

I

7

I

7

24

24

Front

Rear

5

00

12

4

6

R

ULT

Unloaded

Option

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

Loaded

For

normal

speed

Under

100

km

h

or

60

MPH

FA

21

ADJUSTMENT

OF

TOE

IN

ADJUSTMENT

OF

STEERING

ANGLE

FA

22

FA

22

defective

parts

before

starting

the

wheel

alignment

3

The

camber

and

caster

angles

are

preset

and

cannot

be

adjusted

Adjust

the

toe

in

and

vehicle

level

only

Van

Van

Heavy

duty

spring

45

to

1045

45

to

1045

1005

to

2005

40

to

1040

5

to

7

5

to

7

0

20

to

0

28

0

20

to

0

28

7045

7045

430

430

360

360

1

2

1

2

I

7

I

7

1

5

1

5

21

21

1

2

1

5

17

21

1

5

1

8

21

26

1

2

2

5

17

36

Page 108 of 513

CHASSIS

For

high

speed

Over

100

km

h

or

60

MPH

ADJUSTMENT

OF

WHEEL

ALIGNMENT

Use

a

turning

radius

gauge

and

alignment

gauge

for

the

measurement

2

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

ADJUSTMENT

OF

VEHICLE

LEVEL

Vehicle

level

is

adjusted

by

changing

springs

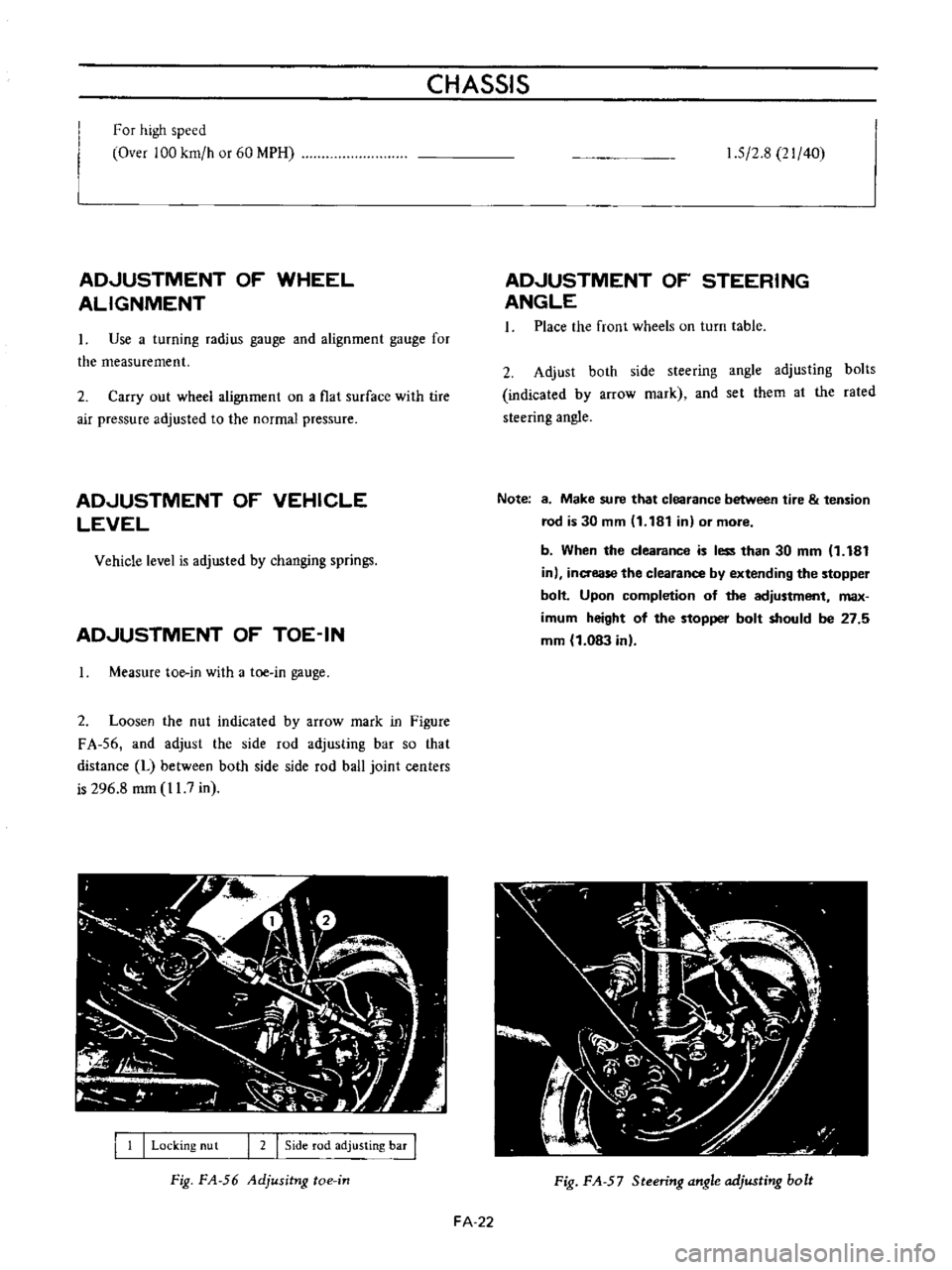

ADJUSTMENT

OF

TOE

IN

Measure

toe

in

with

a

toe

in

gauge

2

Loosen

the

nut

indicated

by

arrow

mark

in

Figure

FA

56

and

adjust

the

side

rod

adjusting

bar

so

that

distance

L

between

both

side

side

rod

ball

joint

centers

is

296

8

mm

11

7

in

I

1

I

Locking

nu

t

I

2

I

Side

rod

adjusting

bar

I

Fig

FA

56

Adjusitng

toe

in

1

5

2

8

21

40

ADJUSTMENT

OF

STEERING

ANGLE

1

Place

the

front

wheels

on

turn

table

2

Adjust

both

side

steering

angle

adjusting

bolts

indicated

by

arrow

mark

and

set

them

al

the

rated

steering

angle

Note

8

Make

sure

that

clearance

between

tire

tension

rod

is

30

mm

11

181

in

or

more

b

When

the

clearance

is

less

than

30

mm

1

181

in

inaease

the

clearance

by

extending

the

stopper

bolt

Upon

completion

of

the

adjustment

max

imum

height

of

the

stopper

bolt

should

be

27

5

mm

1

083

in

Fig

FA

57

Steering

angle

adjusting

bolt

FA

22

Page 112 of 513

Vehicle

pulls

to

right

or

left

When

driving

with

hands

off

the

steering

wheel

over

a

flat

road

the

vehicle

gently

swerves

to

right

or

left

Note

A

defective

rear

suspension

may

also

be

the

cause

of

this

trouble

and

therefore

see

also

the

chapter

dealing

with

the

rear

suspension

Instability

of

vehicle

Stiff

steering

wheel

checking

up

procedure

Jack

up

front

wheels

detach

the

steering

gear

and

operate

the

steering

wheel

and

If

it

is

light

check

steering

linkage

and

suspension

groups

If

it

is

heavy

check

steering

gear

and

steering

colunm

groups

CHASSIS

Malfunction

of

shock

absorber

inside

the

strut

or

loose

installation

bolts

Unbalance

of

vehicle

level

Improper

air

pressure

of

tire

or

insuf

ficient

tightening

of

wheel

nuts

Difference

in

height

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Collapsed

or

twisted

front

spring

Incorrect

wheel

alignment

Incorrect

brake

adjustment

binding

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Deformed

steering

linkage

and

suspension

link

Unbalanced

vehicle

level

Improper

air

pressure

of

tire

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

unbalanced

wheel

Improper

air

pressure

of

tire

Insufficient

lubricants

or

mixing

im

purities

in

steering

linkage

or

excessively

worn

steering

linkage

Stiff

or

damaged

suspension

ball

joint

or

lack

of

grease

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

damaged

steering

gear

and

bearing

FA

26

Replace

or

retighten

Correct

the

unbalance

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Adjust

Adjust

Replace

Replace

Correct

the

unbalance

Adjust

Adjust

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Repl

nish

grease

or

re

place

the

part

Replace

Replace

or

adjust

Replace

Page 161 of 513

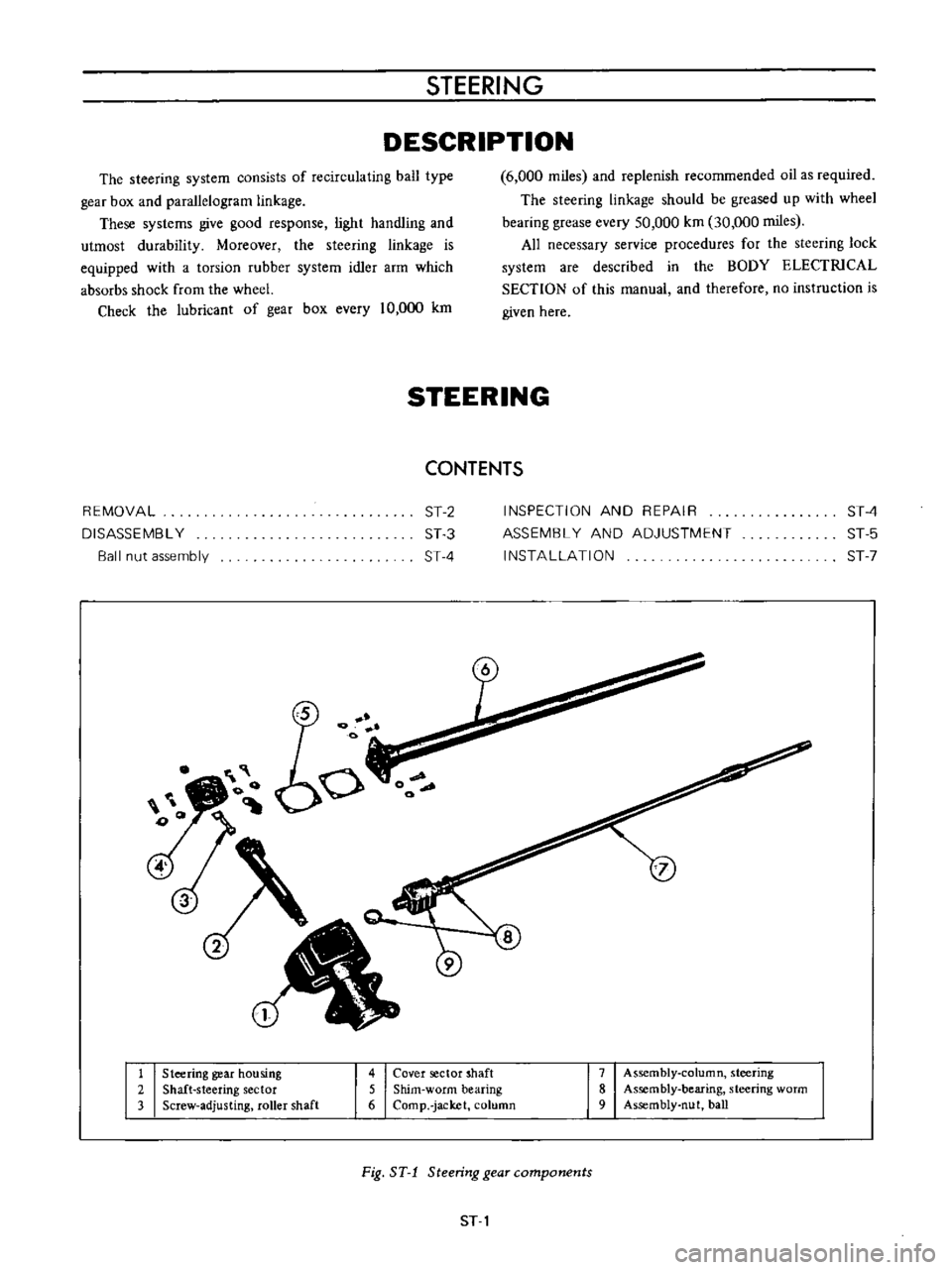

STEERING

DESCRIPTION

The

steering

system

consists

of

recirculating

ball

type

gear

box

and

parallelogram

linkage

These

systems

give

good

response

light

handling

and

utmost

durability

Moreover

the

steering

linkage

is

equipped

with

a

torsion

rubber

system

idler

arm

which

absorbs

shock

from

the

wheel

Check

the

lubricant

of

gear

box

every

10

000

km

6

000

miles

and

replenish

recommended

oil

as

required

The

steering

linkage

should

be

greased

up

with

wheel

bearing

grease

every

50

000

km

30

000

miles

All

necessary

service

procedures

for

the

steering

lock

system

are

described

in

the

BODY

ELECTRICAL

SECTION

of

this

manual

and

therefore

no

instruction

is

given

here

STEERING

CONTENTS

REMOVAL

DISASSEMBL

Y

Ball

nut

assembly

ST

2

ST

3

ST

4

INSPECTION

AND

REPAIR

ASSEMBL

Y

AND

ADJUSTMENT

INSTALLATION

ST

4

ST

5

ST

7

1

Steering

gear

housing

2

Shaft

steering

sector

3

Screw

adjusting

roller

shaft

4

Cover

sector

shaft

5

Shim

worm

bearing

6

Comp

jacket

column

7

Assembly

column

steering

8

Assembly

bearing

steering

worm

9

Assembly

nut

ball

Fig

ST

1

Steering

gear

components

ST

1

Page 176 of 513

CHASSIS

The

following

tightening

torque

of

nuts

shall

be

adopted

Ball

stud

nut

3

0

to

5

0

kg

m

21

7

to

36

2

ft

lb

Gear

arm

nut

14

kg

m

101

ft

lb

Idler

arm

nut

57

to

6

3

kg

m

41

2

to

45

6

ft

lb

2

Assembly

of

the

idler

assembly

is

accomplished

as

follows

I

Apply

soap

water

on

the

outer

circumference

of

bushing

Press

the

bushing

into

the

idler

arm

carefully

until

the

bushing

protrudes

equally

at

the

both

sides

2

Fit

idler

arm

body

in

the

rubber

bushing

Keep

the

idler

arm

center

line

in

parallel

with

the

chassis

center

line

INSTALLATION

Installation

can

be

accomplished

in

the

reverse

order

of

removal

Pay

attention

to

the

following

points

Set

the

length

of

both

side

rods

to

296

8

mm

11

69

in

It

should

be

done

between

the

ball

stud

centers

2

Check

wheel

alignment

and

if

necessary

adjust

it

ACCIDENT

COLLISION

When

accident

collision

occurs

unfortunately

and

the

vehicle

especially

its

front

unit

is

damaged

conduct

inspection

in

accordance

with

the

following

instruction

Inspect

the

steering

system

particularly

carefully

because

it

is

a

very

important

unit

for

driving

I

Check

both

side

steering

angles

for

correct

balance

2

With

the

tires

positioned

at

neutral

steering

wheel

bar

for

correct

position

check

the

l

3

Operate

the

steering

system

and

check

it

for

sliding

noise

4

Check

the

operation

for

smoothness

l

5

Check

the

side

rod

and

cross

rod

for

bending

6

Check

the

gear

arm

for

crack

7

Check

the

gear

housing

tiglltening

bolt

for

slackness

and

installation

boss

for

crack

8

Check

the

sector

shaft

serration

for

twisting

9

Check

the

sector

gear

for

crack

10

Check

the

ball

screw

for

pitting

II

Check

the

column

shaft

for

bending

crack

and

sliding

scar

12

Check

the

jacket

tube

for

bending

13

Check

the

steering

post

clamp

for

existance

of

column

offset

14

Check

the

side

member

gear

housing

installation

unit

for

deformation

IS

Check

the

portion

of

the

steering

post

bracket

installed

on

the

steering

post

clamp

for

correct

installation

AD

JUSTMENT

I

Toe

in

The

procedure

of

toe

in

adjustment

is

outlined

in

section

FRONT

AXLE

AND

FRONT

SUSPENSION

2

Steering

angle

Under

the

specified

load

4

passengers

adjust

the

stopper

bolt

of

the

knuckle

arm

so

that

the

inner

wheel

has

an

angle

of

430

Note

Specified

steering

angle

of

wheel

is

430

for

inner

wheel

and

36005

for

outer

wheel

ST

16

Page 178 of 513

CHASSIS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

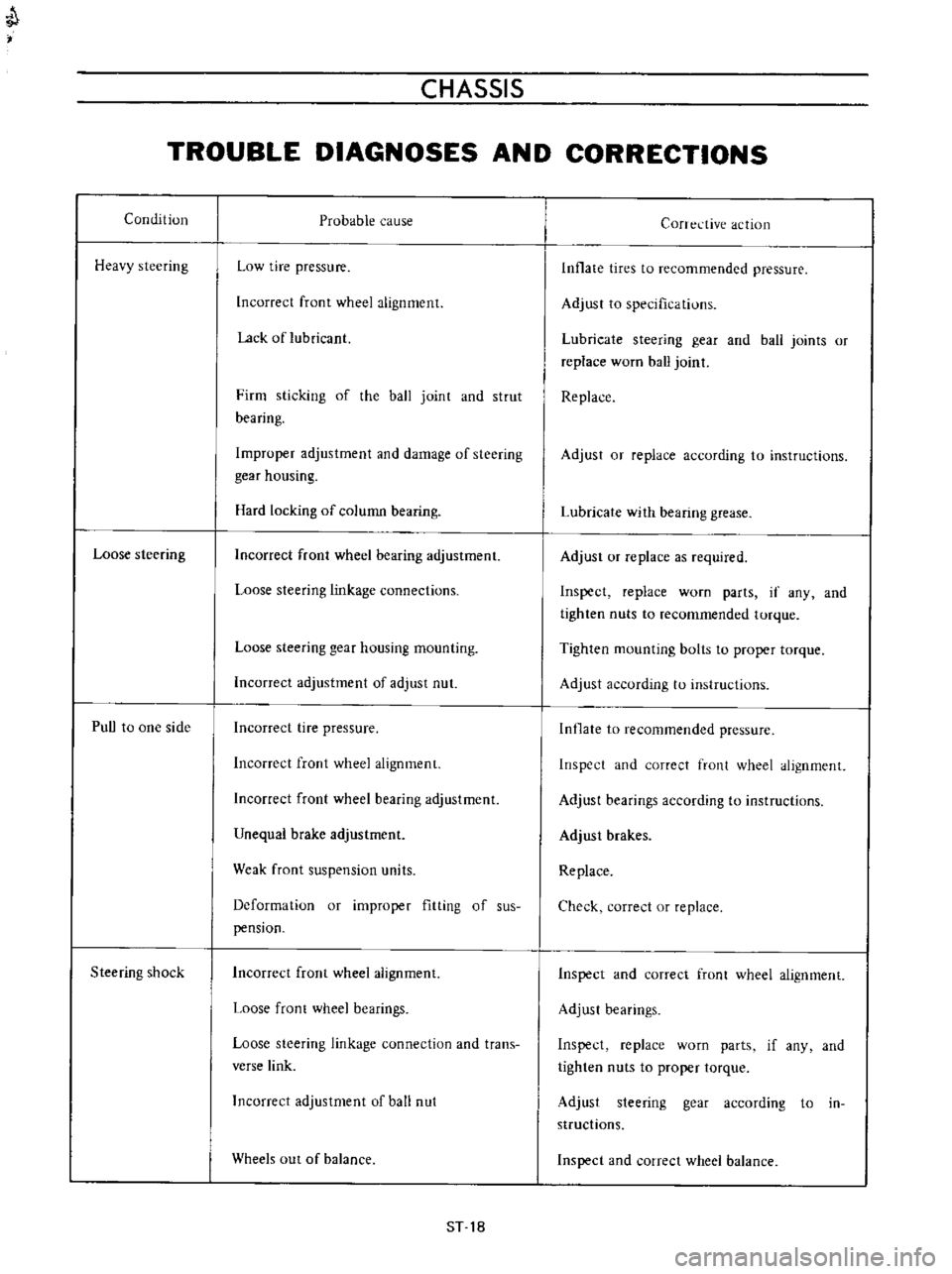

Condition

Heavy

steering

Loose

steering

PuU

to

one

side

Steering

shock

Probable

cause

Low

tire

pressure

Incorrect

front

wheel

alignment

Lack

of

lubricant

Firm

sticking

of

the

ball

joint

and

strut

bearing

Improper

adjustment

and

damage

of

steering

gear

housing

Hard

locking

of

column

bearing

Incorrect

front

wheel

bearing

adjustment

Loose

steering

linkage

connections

Loose

steering

gear

housing

mounting

Incorrect

adjustment

of

adjust

nut

Incorrect

tire

pressure

Incorrect

front

wheel

alignment

Incorrect

front

wheel

bearing

adjustment

Unequal

brake

adjustment

Weak

front

suspension

units

Deformation

or

improper

fitting

of

sus

pension

Incorrect

front

wheel

alignment

Loose

front

wheel

bearings

Loose

steering

linkage

connection

and

trans

verse

link

Incorrect

adjustment

of

ball

nut

Wheels

out

of

balance

ST

18

Corrective

action

Inflate

tires

to

recommended

pressure

Adjust

to

specifications

Lubricate

steering

gear

and

ball

joints

or

replace

worn

ball

joint

Replace

Adjust

or

replace

according

to

instructions

Lubricate

with

bearing

grease

Adjust

or

replace

as

required

Inspect

replace

worn

parts

if

any

and

tighten

nuts

to

recommended

torque

Tighten

mounting

bolts

to

proper

torque

Adjust

according

to

instructions

Inflate

to

recommended

pressure

Inspect

and

correct

front

wheel

alignment

Adjust

bearings

according

to

instructions

Adjust

brakes

Replace

Check

correct

or

replace

Inspect

and

correct

front

wheel

alignment

Adjust

bearings

Inspect

replace

worn

parts

if

any

and

tighten

nuts

to

proper

torque

Adjust

steering

gear

according

to

in

structions

Inspect

and

correct

wheel

balance

Page 475 of 513

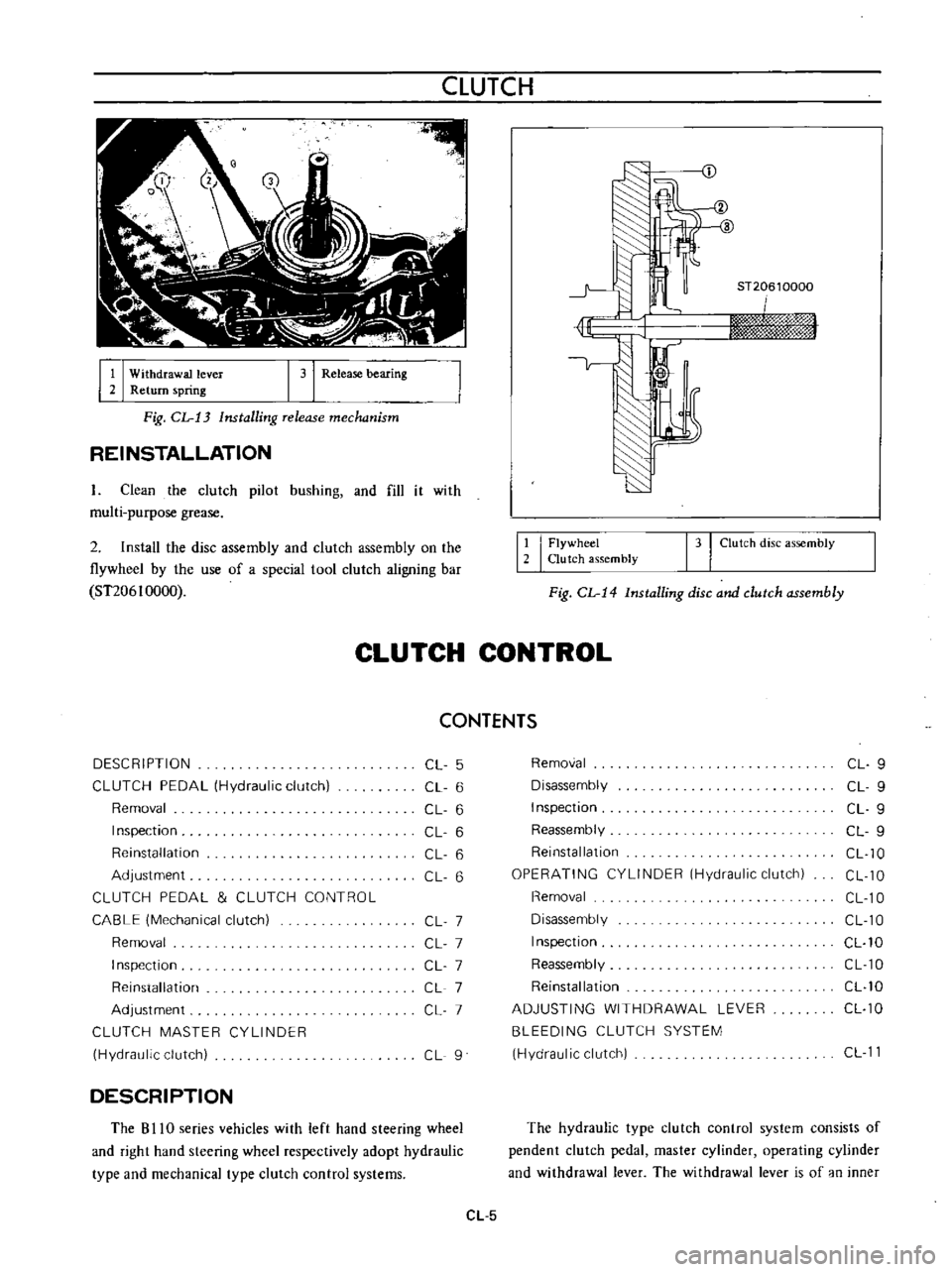

CLUTCH

J

I

I

Withdrawal

lever

2

Return

spring

I

31

Release

bearing

ST20610000

iwn

rm

hj

sf

W

Fig

CL

13

Installing

release

mechanism

REINSTALLATION

L

Clean

the

clutch

pilot

bushing

and

fill

it

with

multi

purpose

grease

2

Install

the

disc

assembly

and

clutch

assembly

on

the

flywheel

by

the

use

of

a

special

tool

clutch

aligning

bar

ST206

I

0000

12

I

Flywheel

Clutch

assembly

131

Clutch

disc

assembly

Fig

CL

14

Installing

disc

and

clutch

assembly

CLUTCH

CONTROL

CONTENTS

DESCRIPTION

CL

5

Removal

CL

9

CLUTCH

PEDAL

Hydraulic

clutch

CL

6

Disassembly

CL

9

Removal

CL

6

Inspection

CL

9

Inspection

CL

6

Reassembly

CL

9

Reinstallation

CL

6

Reinstallation

CL

10

Adjustment

CL

6

OPERATING

CYLINDER

Hydraulic

clutch

CL

10

CLUTCH

PEDAL

CLUTCH

CONTROL

Removal

CL

10

CABLE

Mechanical

clutch

CL

7

Disassembly

CL

10

Removal

CL

7

Inspection

CL

10

Inspection

CL

7

Reassembly

CL

10

Reinstallation

CL

7

Reinstallation

CL

10

Adjustment

CL

7

ADJUSTING

WITHDRAWAL

LEVER

CL

10

CLUTCH

MASTER

CYLINDER

BLEEDING

CLUTCH

SYSTEM

Hydraulic

clutch

CL

9

Hydraulic

clutch

CL

11

DESCRIPTION

The

B

I

IO

series

vehicles

with

left

hand

steering

wheel

and

right

hand

steering

wheel

respectively

adopt

hydraulic

type

and

mechanical

type

clutch

control

systems

The

hydraulic

type

clutch

control

system

consists

of

pendent

clutch

pedal

master

cylinder

operating

cylinder

and

withdrawal

lever

The

withdrawal

lever

is

of

an

inner

CL

5