wheel bolts DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 55 of 513

c

Inspection

and

adJu

Stmenf

trouble

first

check

the

linhge

f

no

1

i

jI

fect

is

found

in

the

lin1

age

check

of

manu

a

l

liiiJ

i

the

inhibitor

switch

Th

d

1F

aI

S

t

th

I

I

f

e

a

JU

i

J

u

epara

e

e

range

se

eet

ever

rom

Iy

important

ii

s3

ns

etion

of

oil

the

lower

shift

rod

and

turn

the

range

1

level

for

the

automatiC

tran

smission

select

lever

to

N

Therefore

great

care

should

be

exer

Note

In

the

position

N

the

slot

of

cised

because

defective

adjustment

will

the

manual

shaft

is

vertical

result

in

the

breakdown

of

the

trans

By

the

use

of

the

tester

check

the

two

bIack

yellow

BY

wires

from

the

inhibitor

switch

in

the

ranges

N

and

P

and

the

two

red

bIack

RB

wires

in

the

range

R

for

continuity

Turn

range

select

lever

to

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

3

0

on

both

sides

from

each

lever

set

line

How

ever

if

its

continuity

range

is

obvi

ously

unequal

on

both

sides

the

adjustment

is

required

f

any

malfunction

is

found

un

screw

the

fastening

nut

of

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

ly

to

the

position

N

by

means

of

the

selector

lever

When

the

slot

of

the

shaft

becomes

vertical

the

detent

works

to

position

the

shaft

correctly

with

a

click

sound

Move

the

switch

slightly

aside

so

that

the

screw

hole

will

be

aligned

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

0101

0

0591

in

diameter

pin

into

the

holes

If

the

alignment

is

made

correct

1

5ten

the

switch

body

with

the

bolts

pull

out

the

pin

and

tighten

up

the

screw

again

into

the

hole

and

fasten

the

selector

lever

as

before

Check

over

again

the

continuity

with

the

tester

If

the

malfunction

still

remains

replace

the

inhibitor

switch

mission

Inspection

Pull

the

selector

lever

toward

you

and

turn

it

so

far

as

p

to

1

range

where

clicks

will

be

felt

by

hand

This

is

the

detent

of

manual

valve

in

the

body

and

indicates

the

correct

posi

tion

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

tion

plate

when

it

is

released

Adjustment

This

procedure

can

be

accom

plished

by

referring

to

Removal

and

nstallation

Checking

and

adjusting

inhibitor

switch

The

inhibitor

switch

serves

to

light

the

reverse

lamp

in

the

range

R

of

the

transmission

operation

and

also

to

rotate

the

starter

motor

in

the

ranges

N

and

P

j

r@

I

If

r

f

B

@

I

Jt

@

@

c

v@

i

r

fji

AT109

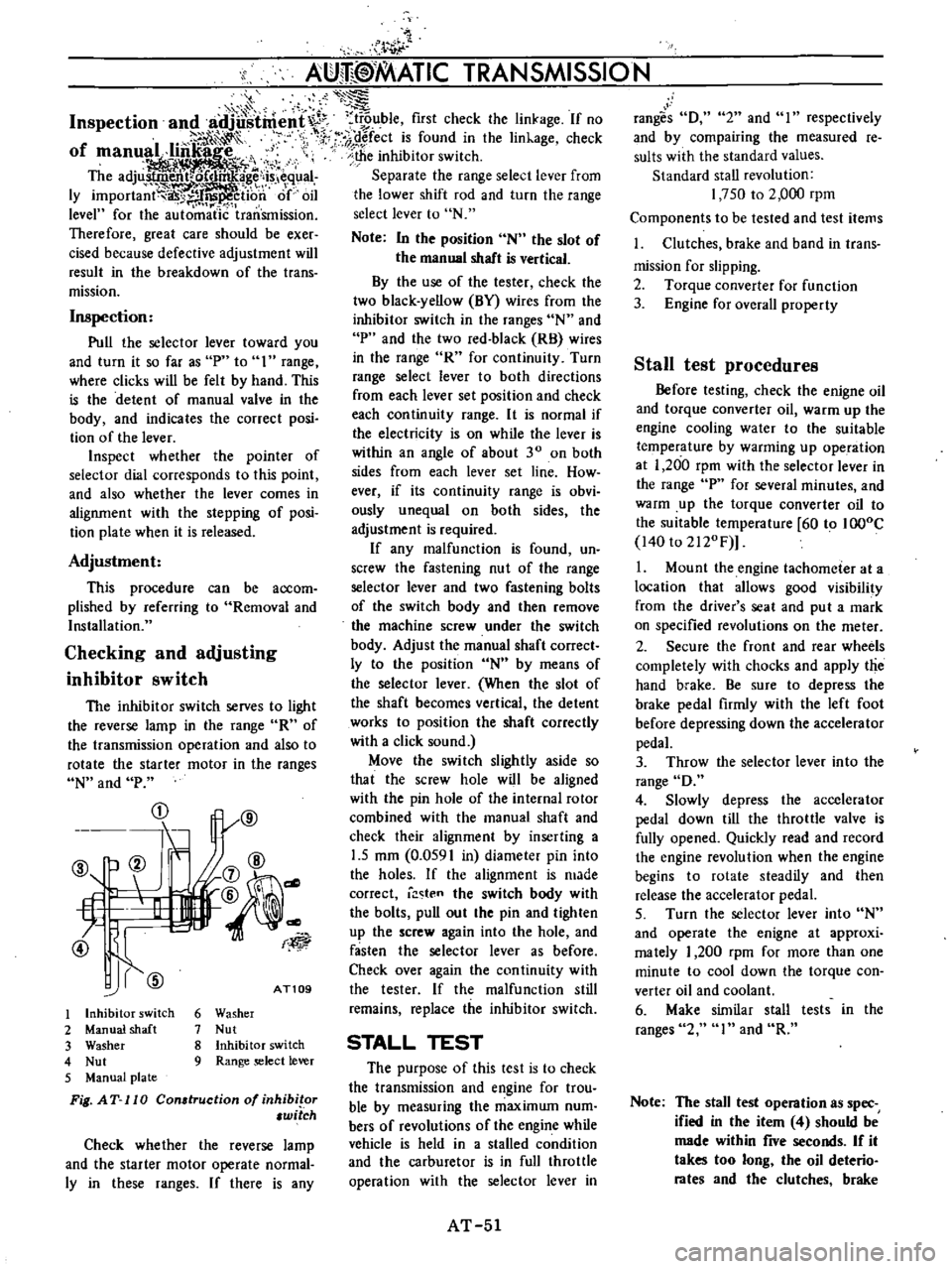

1

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fig

AT

II

0

Con

truction

of

inhibitor

witch

6

Washer

7

Nut

8

Inhibitor

switch

9

Range

select

lever

Check

whether

the

reverse

lamp

and

the

starter

motor

operate

normal

ly

in

these

ranges

If

there

is

any

t

ki

A

mm

ATIC

TRANSMISSION

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximwn

num

bers

of

revolutions

of

the

engine

while

vehicle

is

held

in

a

stalled

condition

and

the

carburetor

is

in

full

throttle

operation

with

the

selector

lever

in

AT

51

rang

s

D

2

and

I

respectively

and

by

com

pairing

the

measured

re

sults

with

the

standard

values

Standard

stall

revolution

1

750

to

2

000

rpm

Components

to

be

tested

and

test

items

1

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

function

3

Engine

for

overall

property

Stall

test

procedures

Before

testing

check

the

enigne

oil

and

torque

converter

oil

warm

up

the

engine

cooling

water

to

the

suitable

temperature

by

warming

up

ope

ration

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

several

minutes

and

warm

up

the

torque

converter

oil

to

the

suitable

temperature

60

to

IOOoC

140

to

2120F

1

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

from

the

driver

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

completely

with

chocks

and

apply

the

hand

brake

Be

sure

to

depress

the

brake

pedal

firmly

with

the

left

foot

before

depressing

down

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

D

4

Slowly

depress

the

accelerator

pedal

down

till

the

throttle

valve

is

fully

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Turn

the

selector

lever

into

N

and

operate

the

enigne

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

verter

oil

and

coolant

6

Make

similar

stall

tests

in

the

ranges

2

I

and

R

Note

The

stall

test

operation

as

spec

ified

in

the

item

4

should

be

made

within

five

seconds

If

it

takes

too

long

the

oil

deterio

rates

and

the

clutches

brake

Page 83 of 513

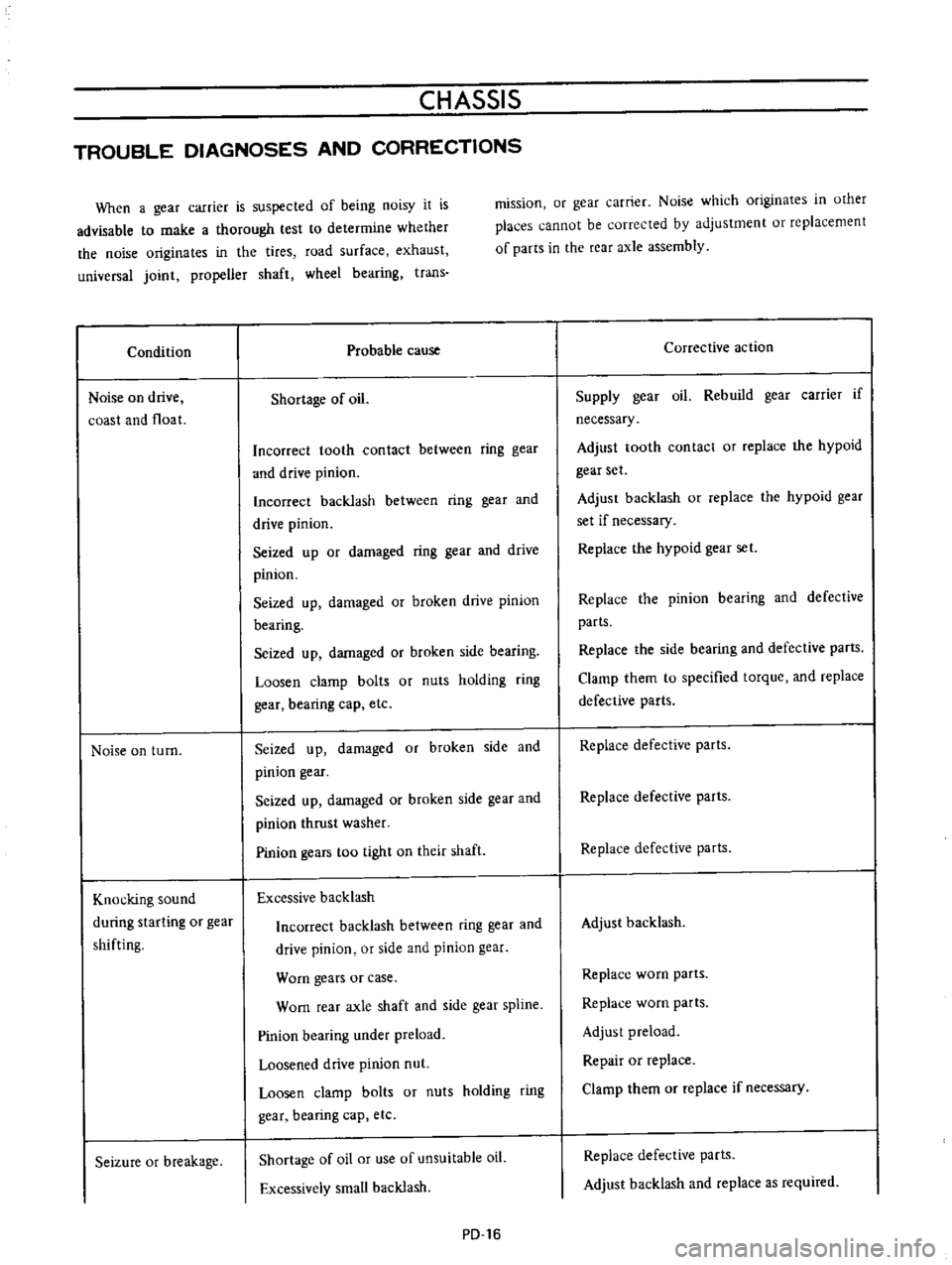

CHASSIS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

a

gear

carrier

is

suspected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearing

trans

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

Seizure

or

breakage

mission

or

gear

carrier

Noise

which

originates

in

other

places

cannot

be

corrected

by

adjustment

or

replacement

of

parts

in

the

rear

axle

assembly

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

backlash

between

ring

gear

and

drive

pinion

Seized

up

or

damaged

ring

gear

and

drive

pinion

Seized

up

damaged

or

broken

drive

pinion

bearing

Seized

up

damaged

or

broken

side

bearing

Loosen

clamp

bolts

or

nuts

holding

ring

gear

bearing

cap

etc

Seized

up

damaged

or

broken

side

and

pinion

gear

I

Seized

up

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

gears

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

between

ring

gear

and

drive

pinion

or

side

and

pinion

gear

Worn

gears

or

case

Worn

rear

axle

shaft

and

side

gear

spline

Pinion

bearing

under

preload

Loosened

drive

pinion

nut

Loosen

clamp

bolts

or

nuts

holding

ring

gear

bearing

cap

etc

Shortage

of

oil

or

use

of

unsuitable

oil

Excessively

small

backlash

PD

16

Corrective

action

Supply

gear

oil

Rebuild

gear

carrier

if

necessary

Adjust

tooth

contact

or

replace

the

hypoid

gear

set

Adjust

backlash

or

replace

the

hypoid

gear

set

if

necessary

Replace

the

hypoid

gear

set

Replace

the

pinion

bearing

and

defective

parts

Replace

the

side

bearing

and

defective

parts

Clamp

them

to

specified

torque

and

replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

them

or

replace

if

necessary

Replace

defective

parts

Adjust

backlash

and

replace

as

required

Page 89 of 513

FRONT

AXLE

FRONT

SUSPENSION

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

Removal

1

Jack

up

the

vehicle

and

support

the

vehicle

with

stands

See

the

Section

GL

2

Remove

the

hub

nuts

and

remOve

the

wheel

3

Remove

the

splash

board

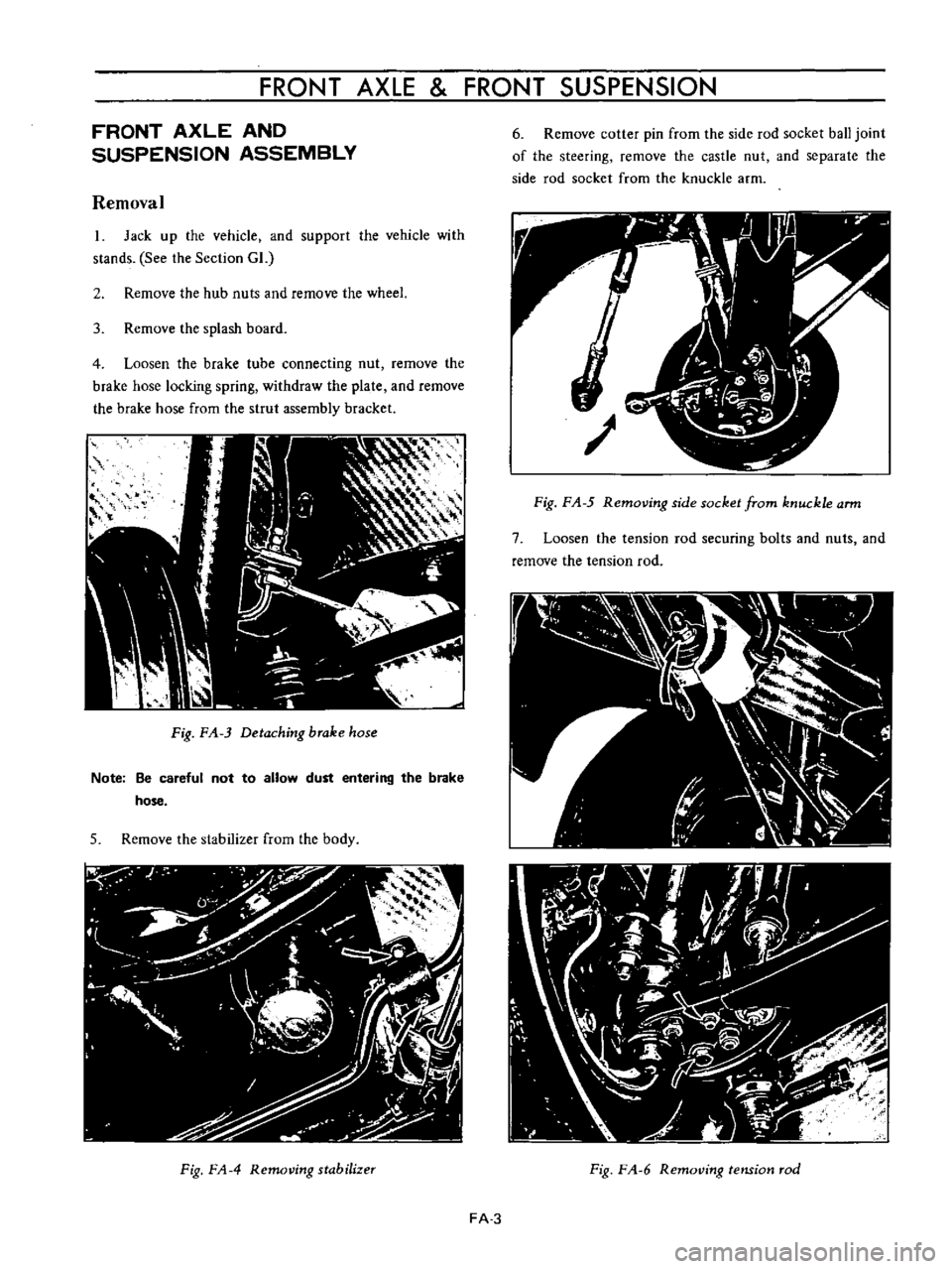

4

Loosen

the

brake

tube

connecting

nut

remove

the

brake

hose

locking

spring

withdraw

the

plate

and

remOve

the

brake

hose

from

the

strul

assembly

bracket

Fig

FA

3

Detaching

brake

hose

Note

Be

careful

not

to

allow

dust

entering

the

brake

hose

5

Remove

the

stabilizer

from

the

body

Fig

FA

4

Removing

stabilizer

6

Remove

cotter

pin

from

the

side

rod

socket

ball

joint

of

the

steering

remove

the

castle

nut

and

separate

the

side

rod

socket

from

the

knuckle

arm

Fig

F

A

5

Removing

side

socket

from

knuckle

arm

7

Loosen

the

tension

rod

securing

bolts

and

nuts

and

remove

the

tension

rod

Fig

F

A

6

RemotJing

tension

rod

FA

3

Page 92 of 513

CHASSIS

Tightening

torque

of

front

suspension

cross

member

and

body

is

3

2

to

4

0

kg

m

23

1

to

28

9

ft

Ib

5

Tightening

torque

of

bolt

used

to

secure

the

upper

portion

of

the

strut

assembly

on

the

body

is

1

6

to

2

1

kg

m

11

6

to

15

2ft

lb

FRONT

AXLE

Removal

I

Jack

up

the

vehicle

remove

the

wheel

and

discon

nect

the

brake

hose

at

the

strut

outer

casing

bracket

unit

For

details

see

Removal

of

front

axle

and

suspension

assembly

2

Remove

the

brake

caliper

installation

bolts

and

remove

the

caliper

assembly

Disc

type

brake

3

Remove

the

brake

druOL

Drum

type

brake

4

Remove

the

hub

cap

with

a

flal

headed

screwdriver

or

other

proper

tool

and

hammer

Be

sure

to

tap

lightly

5

Remove

cotter

pin

from

the

wheel

bearing

lock

nut

and

remove

the

lock

nut

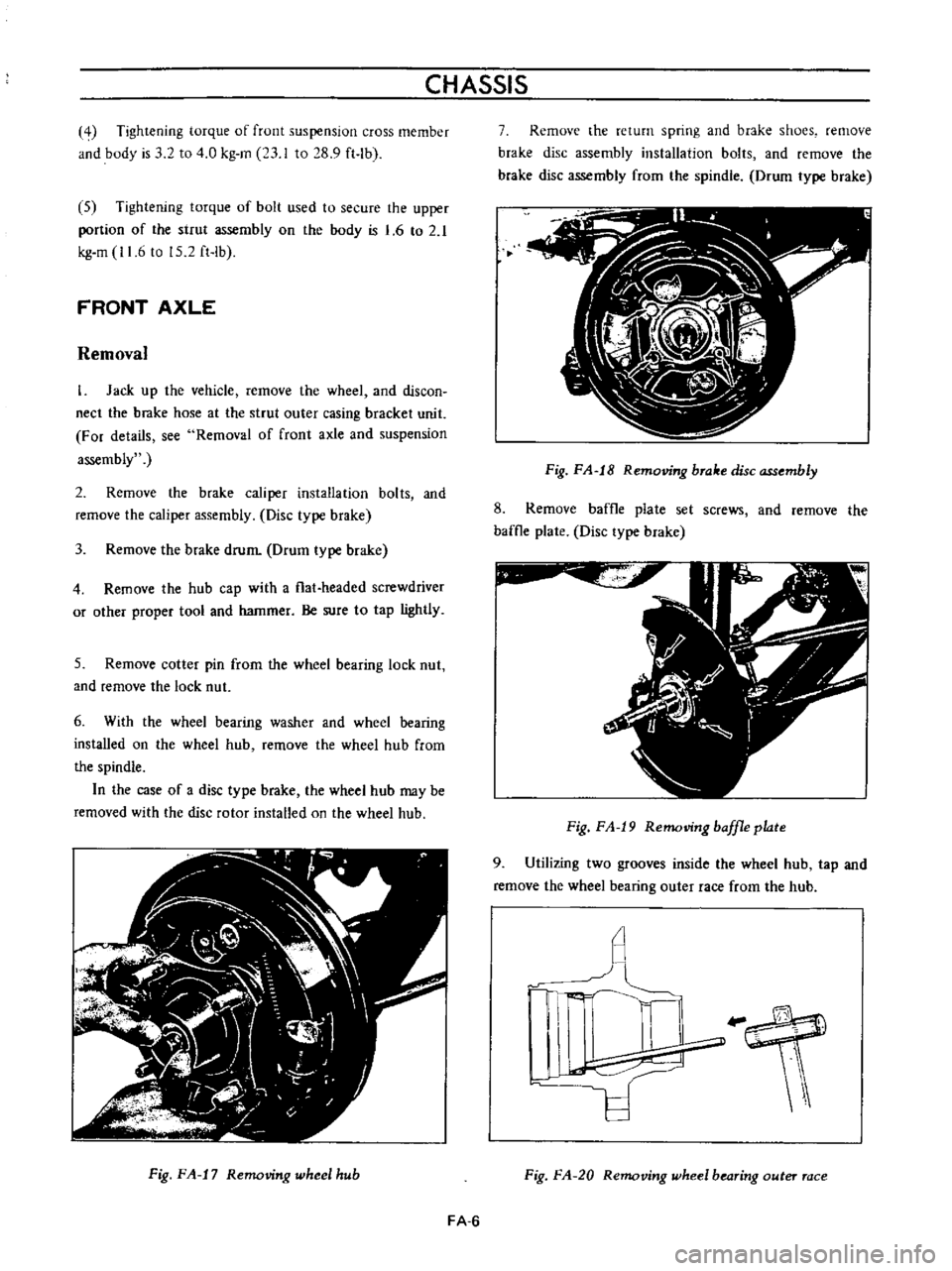

6

With

the

wheel

bearing

washer

and

wheel

bearing

installed

on

the

wheel

hub

remove

the

wheel

hub

from

the

spindle

In

the

case

of

a

disc

type

brake

the

wheel

hub

may

be

removed

with

the

disc

rotor

installed

on

the

wheel

hub

Fig

FA

17

Removing

wheel

hub

7

Remove

the

return

spring

and

brake

shoes

remove

brake

disc

assembly

installation

bolts

and

remove

the

brake

disc

assembly

from

the

spindle

Drum

type

brake

Fig

FA

IS

Removing

brake

disc

a

ssembly

8

Remove

baffle

plate

set

screws

and

remove

the

baffle

plate

Disc

type

brake

Fig

FA

19

Removingbaffleplate

9

Utilizing

two

grooves

inside

the

wheel

hub

tap

and

remove

the

wheel

bearing

outer

race

from

the

hub

Fig

FA

20

Removing

wheel

bearing

outer

race

FA

6

Page 93 of 513

FRONT

AXLE

FRONT

SUSPENSION

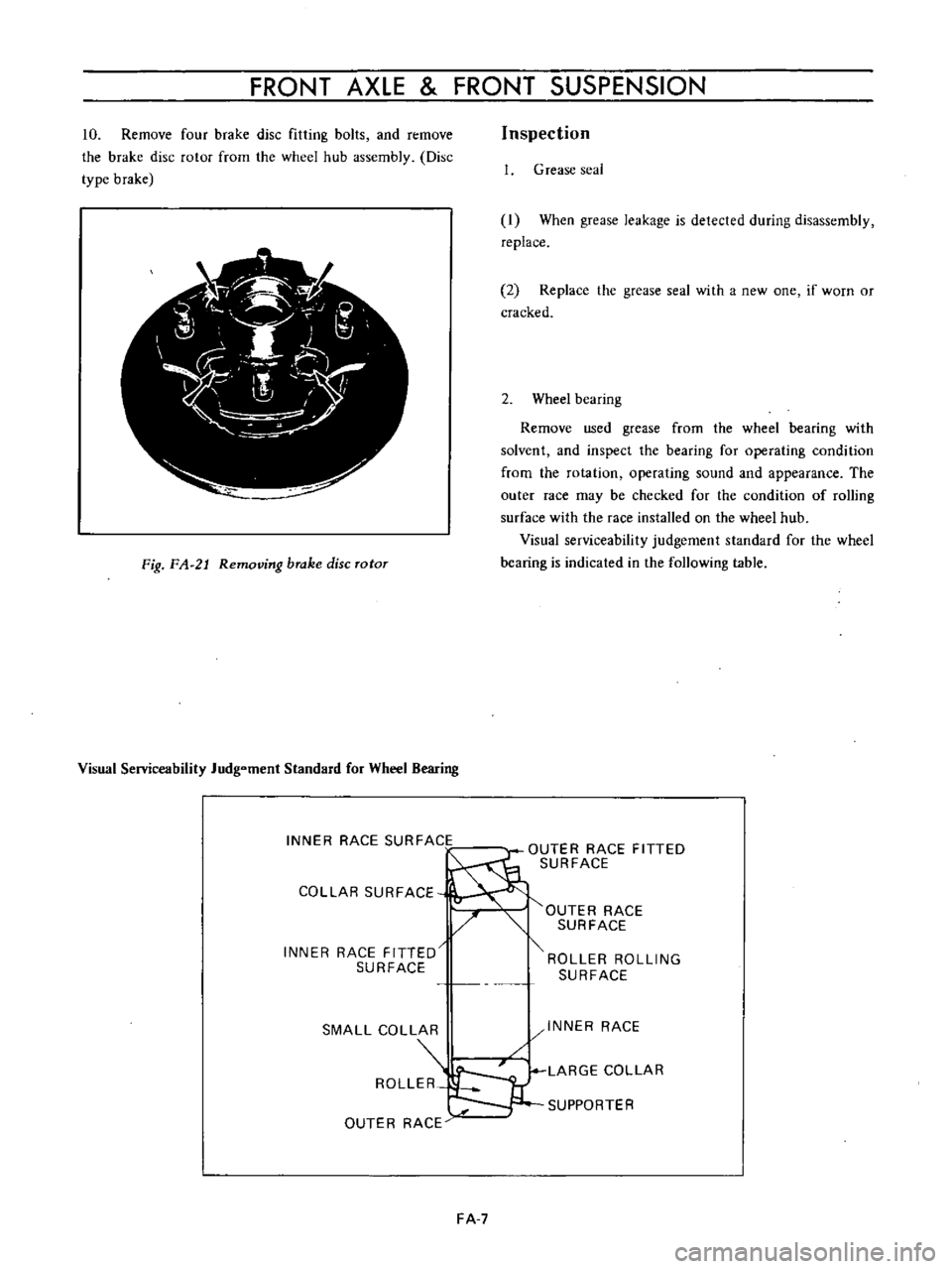

10

Remove

four

brake

disc

fitting

bolts

and

remove

the

brake

disc

rotor

from

the

wheel

hub

assembly

Disc

type

b

rake

Inspection

1

Grease

seal

I

ycQ

r

A

1

r

j

t

I

I

i

I

When

grease

leakage

is

delected

during

disassembly

replace

2

Replace

the

grease

seal

with

a

new

one

if

worn

or

cracked

Fig

FA

21

Removing

brake

disc

rotor

2

Wheel

bearing

Remove

used

grease

from

the

wheel

bearing

with

solvent

and

inspect

the

bearing

for

operating

condition

from

the

rotation

operating

sound

and

appearance

The

outer

race

may

be

checked

for

the

condition

of

rolling

surface

with

the

race

installed

on

the

wheel

hub

Visual

serviceability

judgement

standard

for

the

wheel

bearing

is

indicated

in

the

following

table

Visual

Serviceability

Judg

ment

Standard

for

Wheel

Bearing

INNER

RACE

SURFACE

OUTER

RACE

FITTED

SURFACE

COLLAR

SURFACE

OUTER

RACE

SURFACE

INNER

RACE

FITTED

ROLLER

ROLLING

SURFACE

SURFACE

SMALL

COLLAR

INNER

RACE

LARGE

COLLAR

ROLLER

SUPPORTER

OUTER

RACE

FA

7

Page 98 of 513

fl

i

i

I

1

I

I

i

2

4

L

thi7

lrr

I

1

1

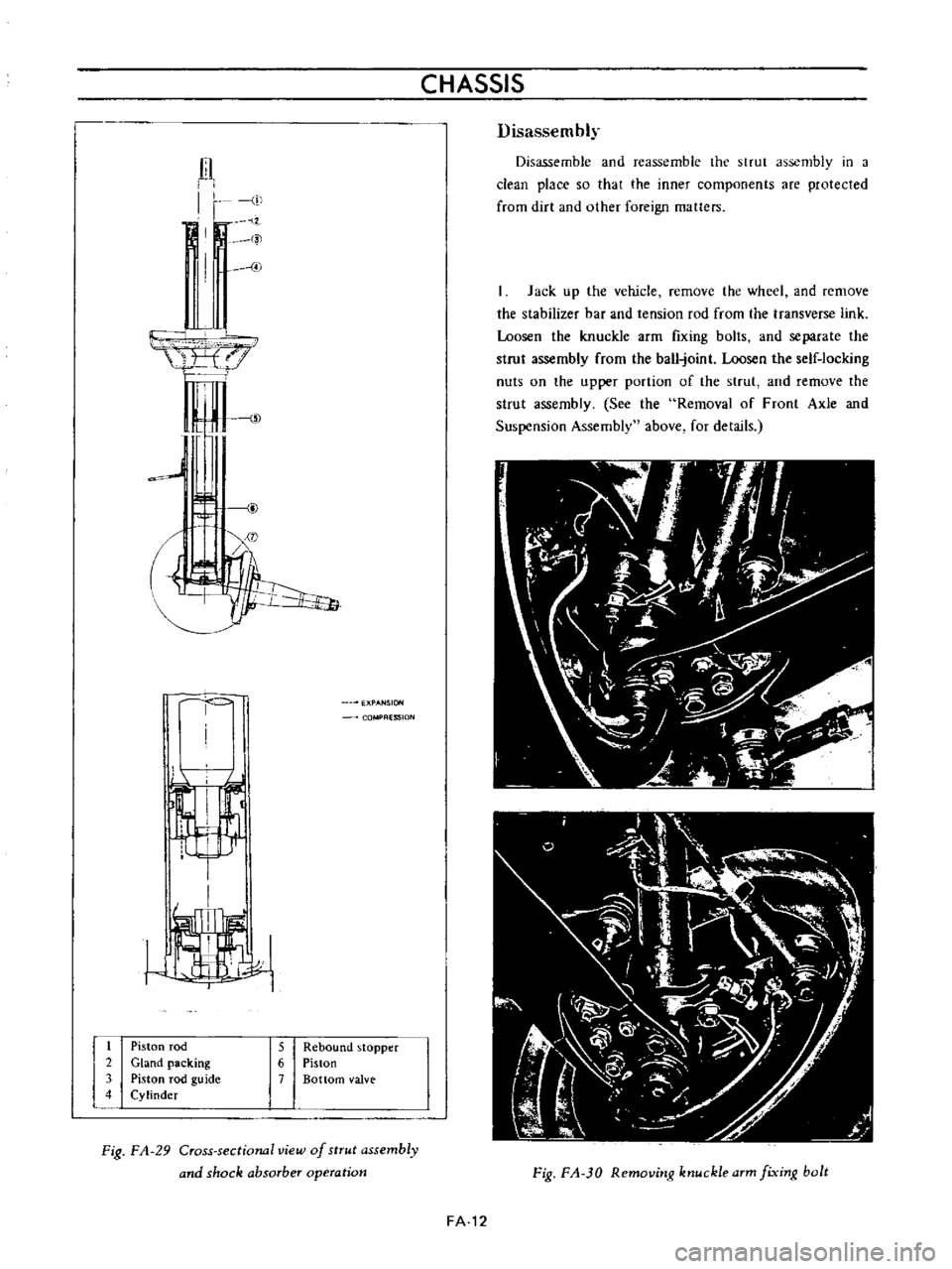

Piston

rod

2

Gland

packing

3

Piston

rod

guide

4

Cylinder

CHASSIS

ESSION

5

Rebound

stopper

6

Piston

7

Bottom

valve

Fig

FA

29

Cross

sectional

view

of

strut

assembly

and

shock

absorber

operation

Disassembly

Disassemble

and

reassemble

the

strut

assembly

in

a

clean

place

so

that

the

inner

components

are

protected

from

dirt

and

other

foreign

matters

Jack

up

the

vehicle

remove

the

wheel

and

remove

the

stabilizer

bar

and

tension

rod

from

the

transverse

link

Loosen

the

knuckle

arm

fIxing

bolts

and

separate

the

strut

assembly

from

the

ball

joint

Loosen

the

self

locking

nuts

on

the

upper

portion

of

the

strut

and

remove

the

strut

assembly

See

the

Removal

of

Front

Axle

and

Suspension

Assembly

above

for

details

Fig

FA

JO

Removitlg

ktluckle

arm

fixitlg

bolt

FA

12

Page 104 of 513

CHASSIS

r

I

El

0

3

to

1

0

mm

0

0118

to

0

0394

in

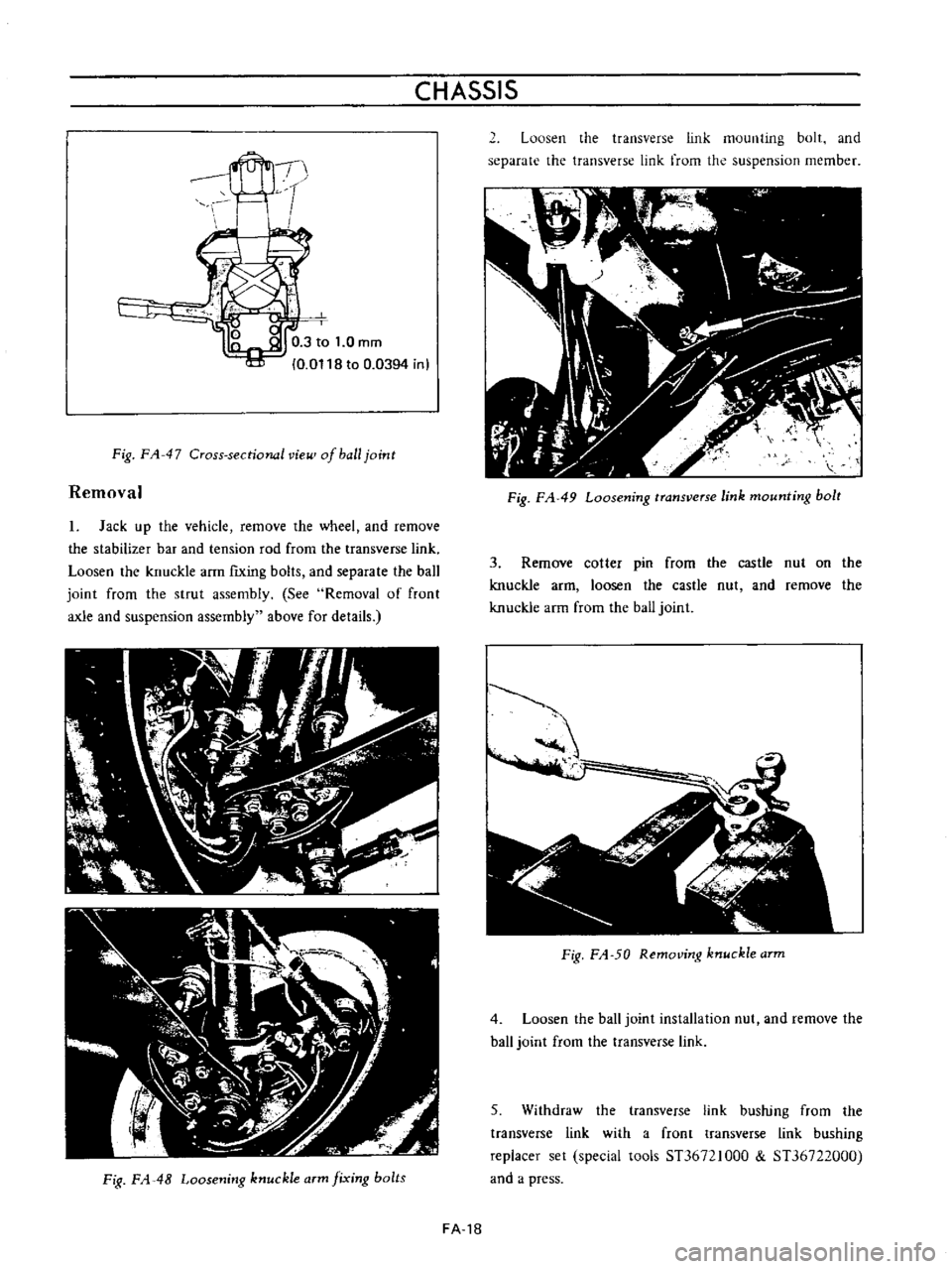

Fig

FA

47

Cross

sectional

vie

of

ball

joint

Removal

1

Jack

up

the

vehicle

remove

the

wheel

and

remove

the

stabilizer

bar

and

tension

rod

from

the

transverse

link

Loosen

the

knuckle

arm

fiXing

bolts

and

separate

the

ball

joint

from

the

strut

assembly

See

Removal

of

front

axle

and

suspension

assembly

above

for

details

Fig

FA

48

Loosening

knuckle

arm

fixing

bolts

2

Loosen

the

transverse

link

mounting

bolt

and

separate

the

transverse

link

from

the

suspension

member

Fig

FA

49

Loosening

transverse

link

mounting

bolt

3

Remove

cotter

pin

from

the

castle

nut

on

the

knuckle

arm

loosen

the

castle

nut

and

remove

the

knuckle

arm

from

the

ball

joint

J

iIP

A

i

Fig

FA

50

Removing

knuckle

arm

4

Loosen

the

ball

joint

installation

nut

and

remove

the

haJJ

joint

from

the

transverse

Jink

5

Withdraw

the

transverse

link

bushing

from

the

transverse

link

with

a

front

transverse

link

bushing

replacer

set

special

tools

ST36721000

ST36722000

and

a

press

FA

18

Page 108 of 513

CHASSIS

For

high

speed

Over

100

km

h

or

60

MPH

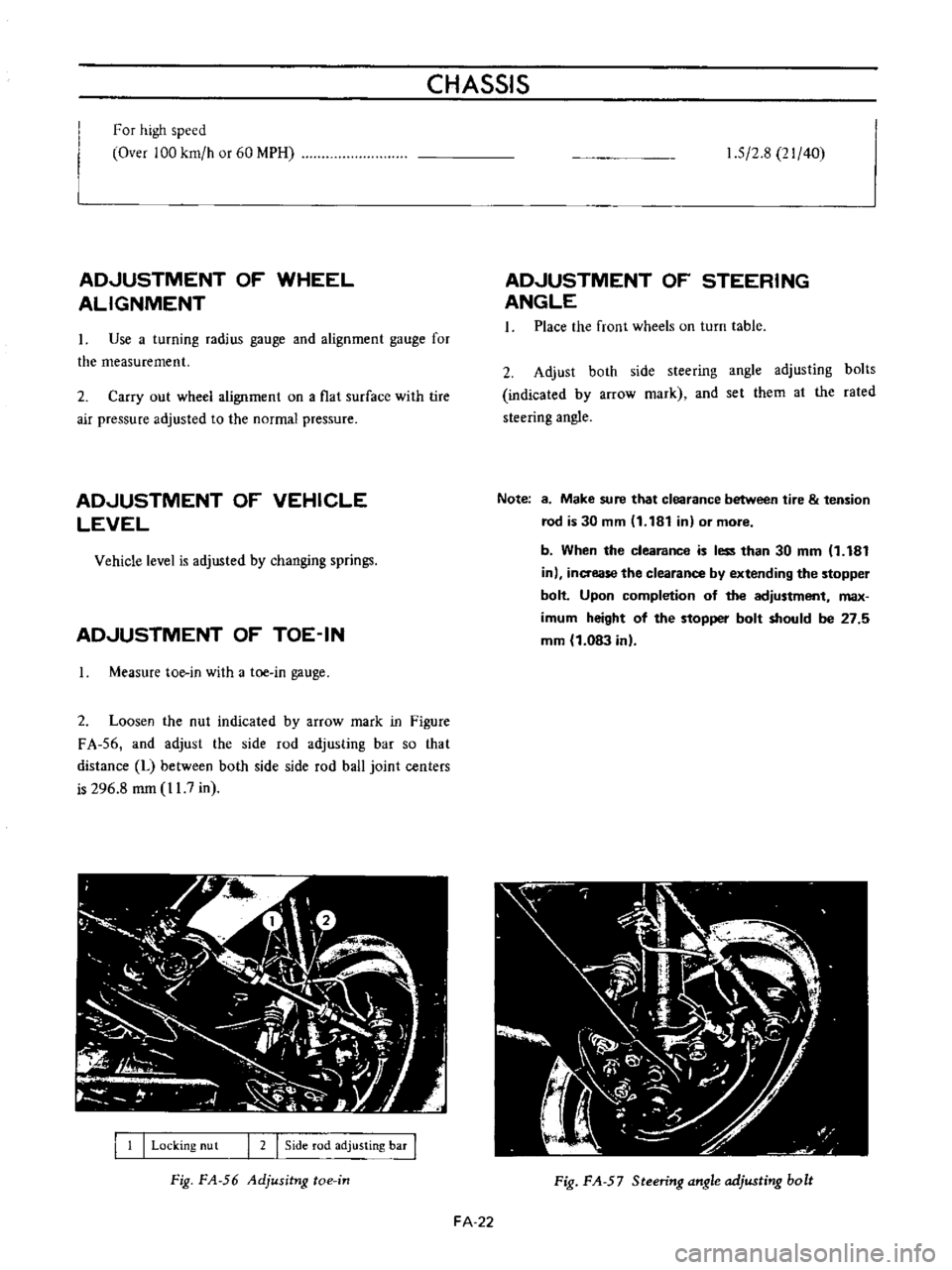

ADJUSTMENT

OF

WHEEL

ALIGNMENT

Use

a

turning

radius

gauge

and

alignment

gauge

for

the

measurement

2

Carry

out

wheel

alignment

on

a

flat

surface

with

tire

air

pressure

adjusted

to

the

normal

pressure

ADJUSTMENT

OF

VEHICLE

LEVEL

Vehicle

level

is

adjusted

by

changing

springs

ADJUSTMENT

OF

TOE

IN

Measure

toe

in

with

a

toe

in

gauge

2

Loosen

the

nut

indicated

by

arrow

mark

in

Figure

FA

56

and

adjust

the

side

rod

adjusting

bar

so

that

distance

L

between

both

side

side

rod

ball

joint

centers

is

296

8

mm

11

7

in

I

1

I

Locking

nu

t

I

2

I

Side

rod

adjusting

bar

I

Fig

FA

56

Adjusitng

toe

in

1

5

2

8

21

40

ADJUSTMENT

OF

STEERING

ANGLE

1

Place

the

front

wheels

on

turn

table

2

Adjust

both

side

steering

angle

adjusting

bolts

indicated

by

arrow

mark

and

set

them

al

the

rated

steering

angle

Note

8

Make

sure

that

clearance

between

tire

tension

rod

is

30

mm

11

181

in

or

more

b

When

the

clearance

is

less

than

30

mm

1

181

in

inaease

the

clearance

by

extending

the

stopper

bolt

Upon

completion

of

the

adjustment

max

imum

height

of

the

stopper

bolt

should

be

27

5

mm

1

083

in

Fig

FA

57

Steering

angle

adjusting

bolt

FA

22

Page 110 of 513

CHASSIS

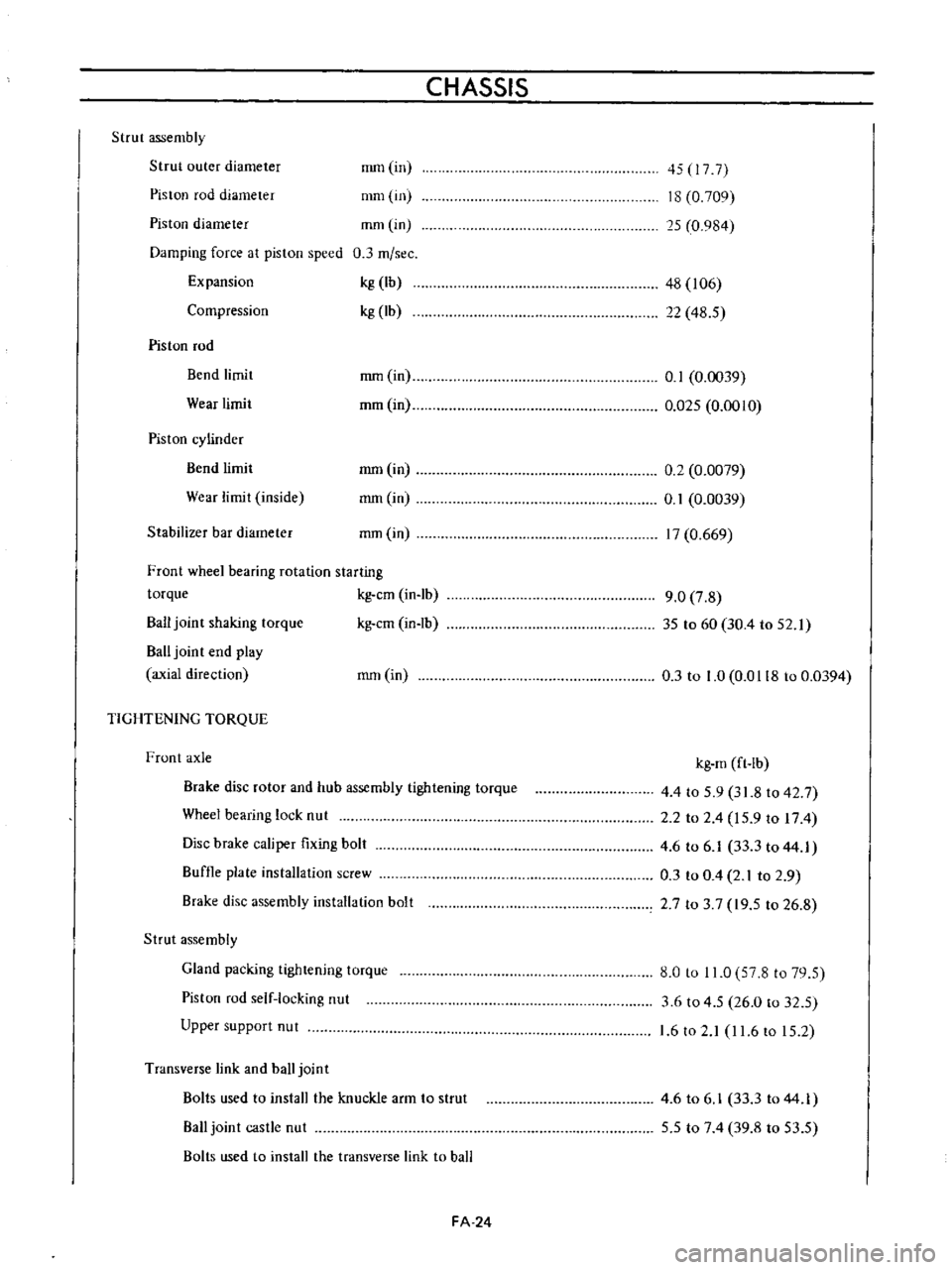

Strut

assembly

Strut

outer

diameter

Piston

rod

diameter

mmlin

nml

in

45

17

7

18

0

709

15

0

984

Piston

diameter

mmlin

Damping

force

at

piston

speed

0

3

m

sec

Expansion

kg

Ib

Compression

kg

lb

48

106

22

48

5

Piston

rod

Bend

limit

Wear

limit

mm

in

0

1

0

0039

mm

in

0

025

0

0010

Piston

cylinder

Bend

limit

Wear

limit

inside

mm

in

mm

in

0

2

0

0079

0

1

0

0039

17

0

669

Stabilizer

bar

diameter

mm

in

Front

wheel

bearing

rotation

starting

torque

kg

cm

in

lb

Ball

joint

shaking

torque

kg

cm

in

lb

Ball

joint

end

play

axial

direction

mm

in

9

0

7

8

35

to

60

30

4

to

52

1

0

3

to

1

0

0

0118

to

0

0394

TIGHTENING

TORQUE

Front

axle

Brake

disc

rotor

and

hub

assembly

tightening

torque

Wheel

bearing

lock

nut

Disc

brake

caliper

fixing

bolt

Buffle

plate

installation

screw

Brake

disc

assembly

installation

bolt

kg

m

ft

lb

4

4

to

5

9

31

8

to

42

7

2

2

to

2

4

15

9

to

174

4

6

to

6

1

33

3

to

44

1

0

3

to

0

4

2

1

to

2

9

2

7

to

3

7

19

5

to

26

8

Strut

assembly

Gland

packing

tightening

torque

Piston

rod

self

locking

nut

Upper

support

nut

8

0

to

11

0

57

8

to

79

5

3

6

to

4

5

26

0

to

32

5

1

6

to

2

1

I

1

6

to

15

2

Transverse

link

and

ball

joint

Bolts

used

to

install

the

knuckle

arm

to

strut

Ball

joint

castle

nut

Bolts

used

to

install

the

transverse

link

to

ball

4

6

to

6

1

33

3

to

44

1

5

5

to

7

4

39

8

to

53

5

FA

24

Page 112 of 513

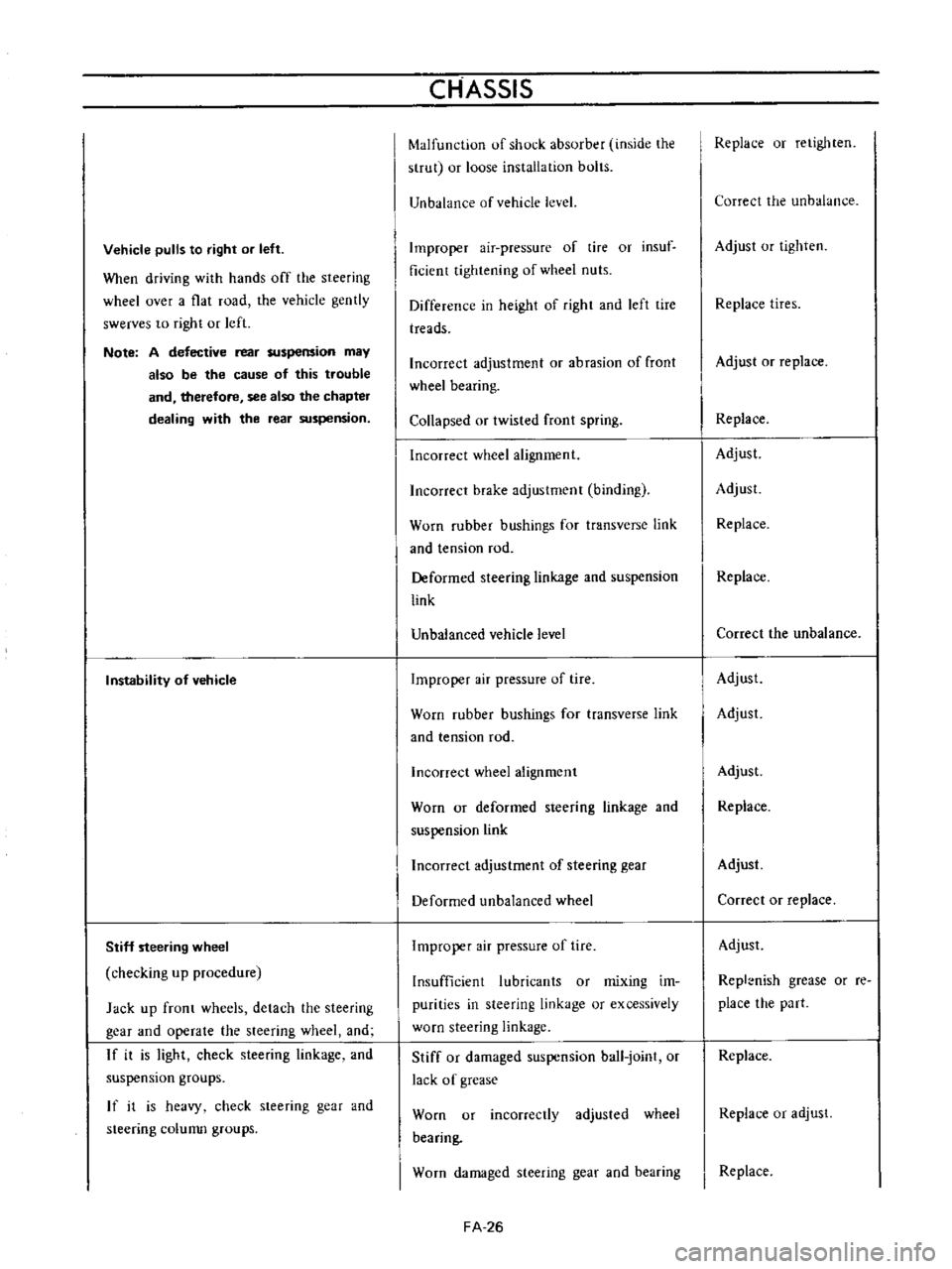

Vehicle

pulls

to

right

or

left

When

driving

with

hands

off

the

steering

wheel

over

a

flat

road

the

vehicle

gently

swerves

to

right

or

left

Note

A

defective

rear

suspension

may

also

be

the

cause

of

this

trouble

and

therefore

see

also

the

chapter

dealing

with

the

rear

suspension

Instability

of

vehicle

Stiff

steering

wheel

checking

up

procedure

Jack

up

front

wheels

detach

the

steering

gear

and

operate

the

steering

wheel

and

If

it

is

light

check

steering

linkage

and

suspension

groups

If

it

is

heavy

check

steering

gear

and

steering

colunm

groups

CHASSIS

Malfunction

of

shock

absorber

inside

the

strut

or

loose

installation

bolts

Unbalance

of

vehicle

level

Improper

air

pressure

of

tire

or

insuf

ficient

tightening

of

wheel

nuts

Difference

in

height

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Collapsed

or

twisted

front

spring

Incorrect

wheel

alignment

Incorrect

brake

adjustment

binding

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Deformed

steering

linkage

and

suspension

link

Unbalanced

vehicle

level

Improper

air

pressure

of

tire

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

unbalanced

wheel

Improper

air

pressure

of

tire

Insufficient

lubricants

or

mixing

im

purities

in

steering

linkage

or

excessively

worn

steering

linkage

Stiff

or

damaged

suspension

ball

joint

or

lack

of

grease

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

damaged

steering

gear

and

bearing

FA

26

Replace

or

retighten

Correct

the

unbalance

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Adjust

Adjust

Replace

Replace

Correct

the

unbalance

Adjust

Adjust

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Repl

nish

grease

or

re

place

the

part

Replace

Replace

or

adjust

Replace