width DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 79 of 513

CHASSIS

7

Turn

drive

pinion

in

both

directions

several

times

to

set

bearing

rollers

And

adjust

bearing

preload

to

specifi

cations

Drive

pinion

bearing

preload

with

oil

seal

7

to

9

kg

cm

6

1

to

7

8

in

1b

At

companion

flange

bolt

hole

2

25

to

2

95

kg

4

96

to

6

50

1b

Pinion

nut

tightening

torque

12

to

17

kg

m

86

8

to

122

9

ft

1b

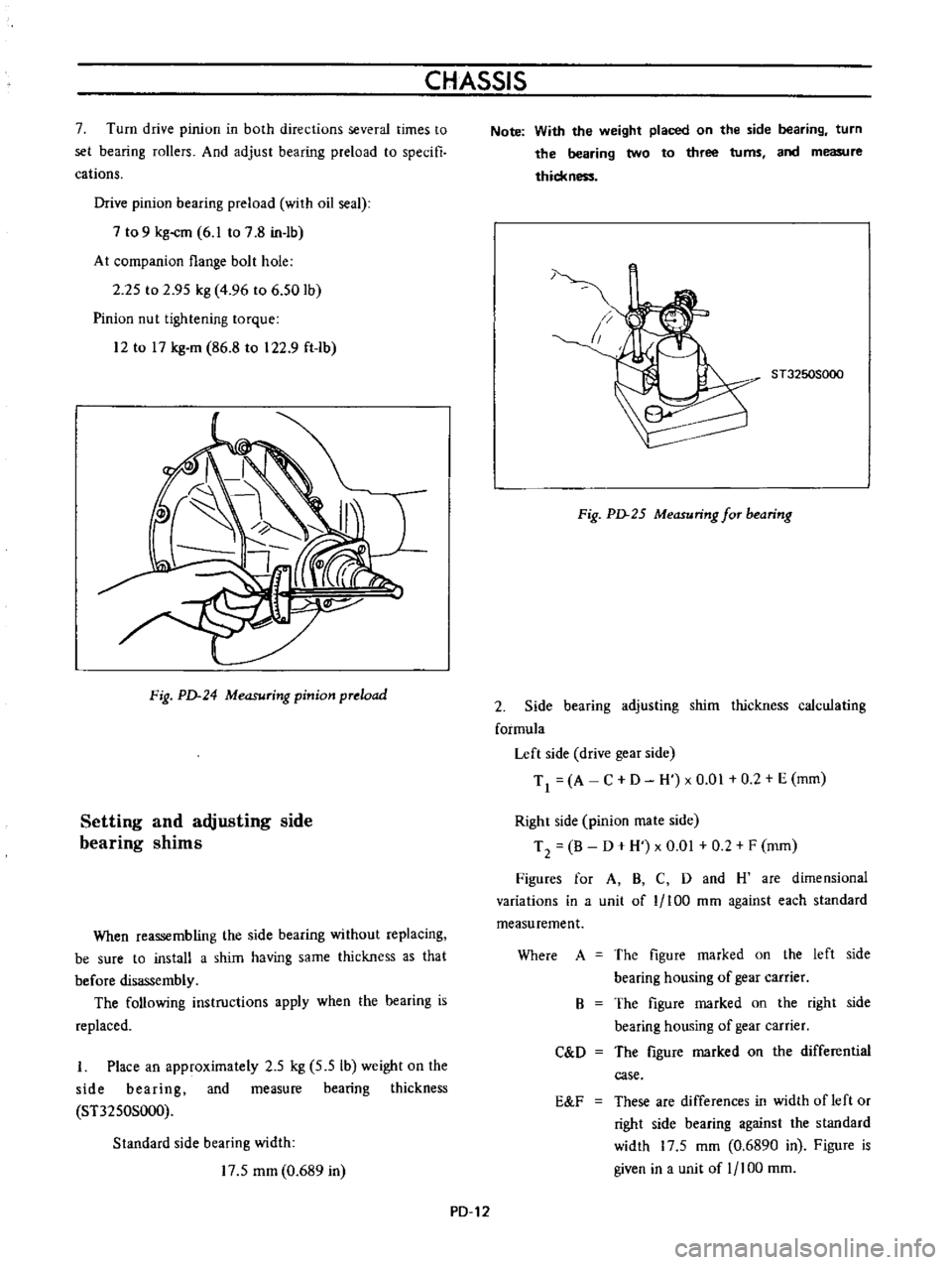

Fig

PD

24

Measuring

pinion

preload

Setting

and

adjusting

side

bearing

shims

When

reassembling

the

side

bearing

without

replacing

be

sure

to

install

a

shim

having

same

thickness

as

that

before

disassembly

The

following

instructions

apply

when

the

hearing

is

replaced

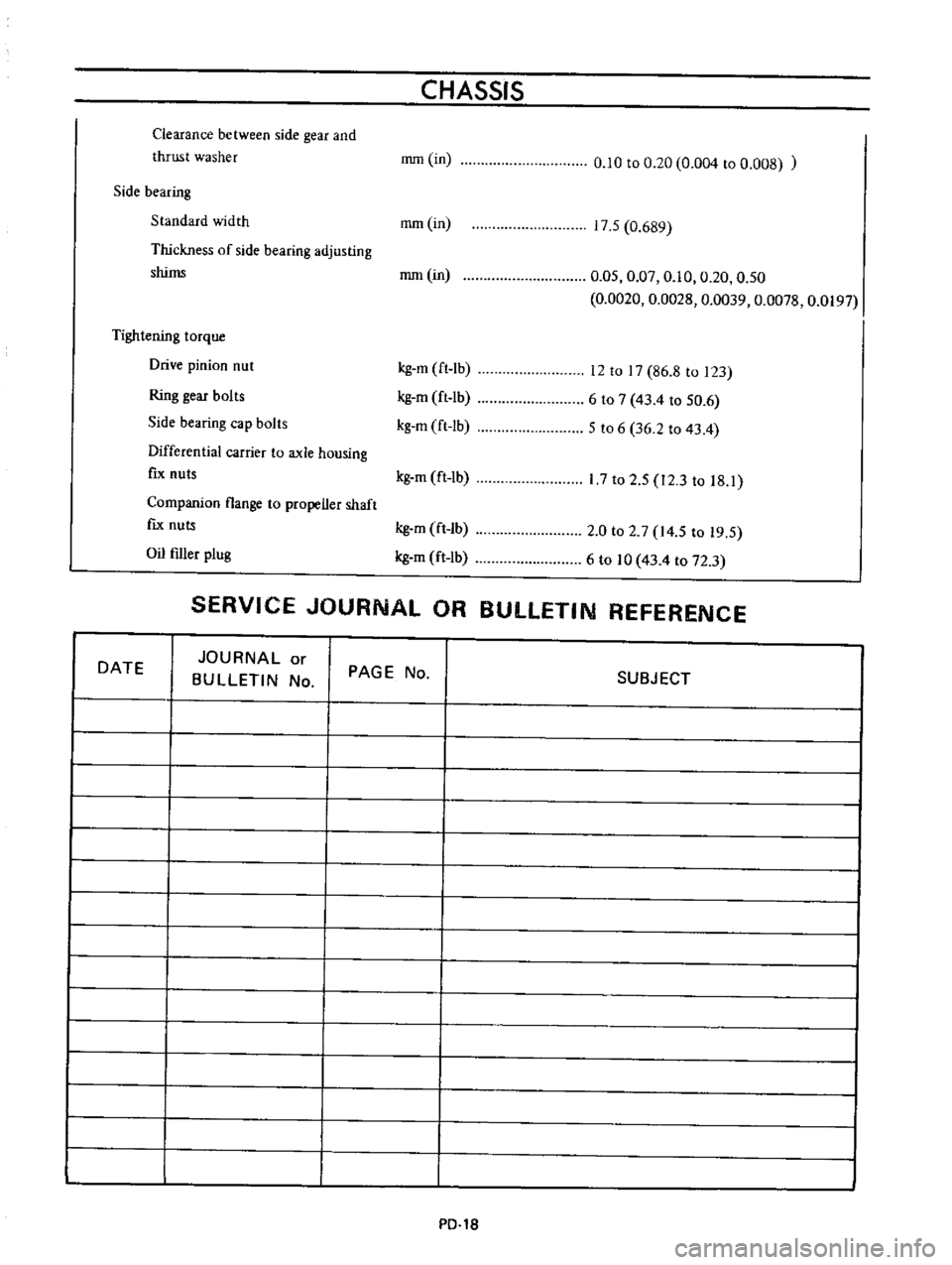

I

Place

an

approximately

2

5

kg

5

5

Ib

weight

on

the

side

bearing

and

measure

bearing

thickness

ST3250S000

Standard

side

bearing

width

17

5

mm

0

689

in

Note

With

the

weight

placed

on

the

side

bearing

turn

the

bearing

two

to

three

turns

and

measure

thickn

1

ST3250S000

Fig

PD

25

Measuring

for

bearing

2

Side

bearing

adjusting

shim

thickness

calculating

formula

Left

side

drive

gear

side

Tl

A

C

D

H

xO

01

0

2

E

mm

Right

side

pinion

mate

side

T

2

B

D

H

x

0

01

0

2

F

mm

Figures

for

A

B

C

D

and

H

are

dimensional

variations

in

a

unit

of

1

100

mm

against

each

standard

measurement

Where

A

The

figure

marked

on

the

left

side

bearing

housing

of

gear

carrier

The

figure

marked

on

the

right

side

bearing

housing

of

gear

carrier

The

figure

marked

on

the

differential

case

B

C

D

E

F

These

are

differences

in

width

of

left

or

right

side

bearing

against

the

standard

width

17

5

mm

0

6890

in

Figure

is

given

in

a

unit

of

1

100

mm

PD

12

Page 85 of 513

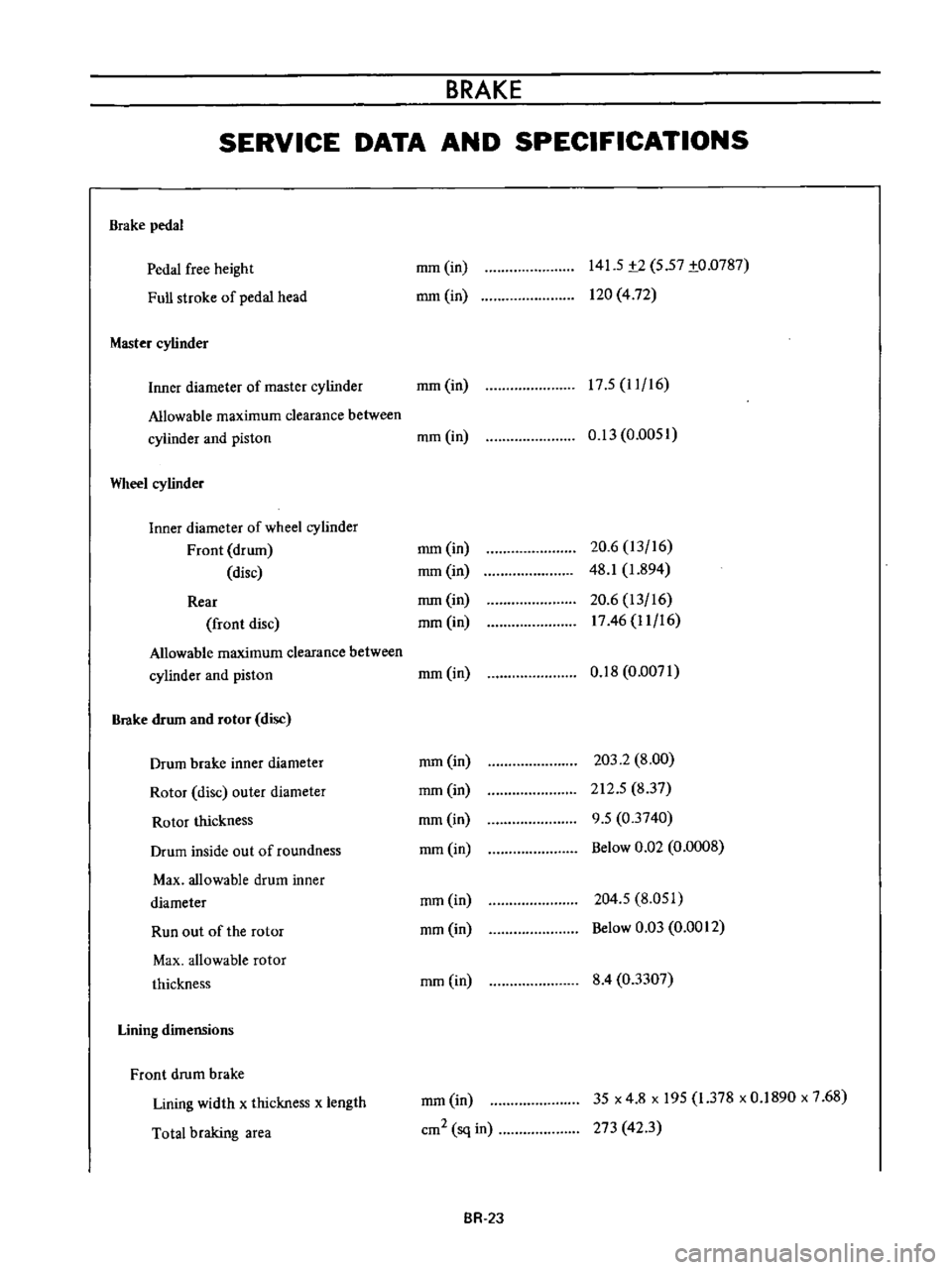

Clearance

between

side

gear

and

thrust

washer

CHASSIS

rrun

in

0

10

to

0

20

0

004

to

0

008

Side

bearing

Standard

width

rom

in

Thickness

of

side

bearing

adjusting

shims

rom

in

Tightening

torque

Drive

pinion

nut

Ring

gear

bolts

Side

bearing

cap

bolts

Differential

carrier

to

axle

housing

fIx

nuts

Companion

flange

to

propeller

shaft

fIx

nuts

Oil

filler

plug

17

5

0

689

0

05

0

07

0

10

0

20

0

50

0

0020

0

0028

0

0039

0

0078

0

0197

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

12

to

17

86

8

to

123

6

to

7

43

4

to

50

6

5

to

6

36

2

to

43

4

kg

m

ft

1b

17

to

2

5

12

3

to

18

1

kg

m

ft

lb

kg

m

ft

lb

2

0

to

2

7

14

5

to

19

5

6

to

10

43

4

to

72

3

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

I

I

I

I

PAGE

No

SUBJECT

PO

1S

Page 147 of 513

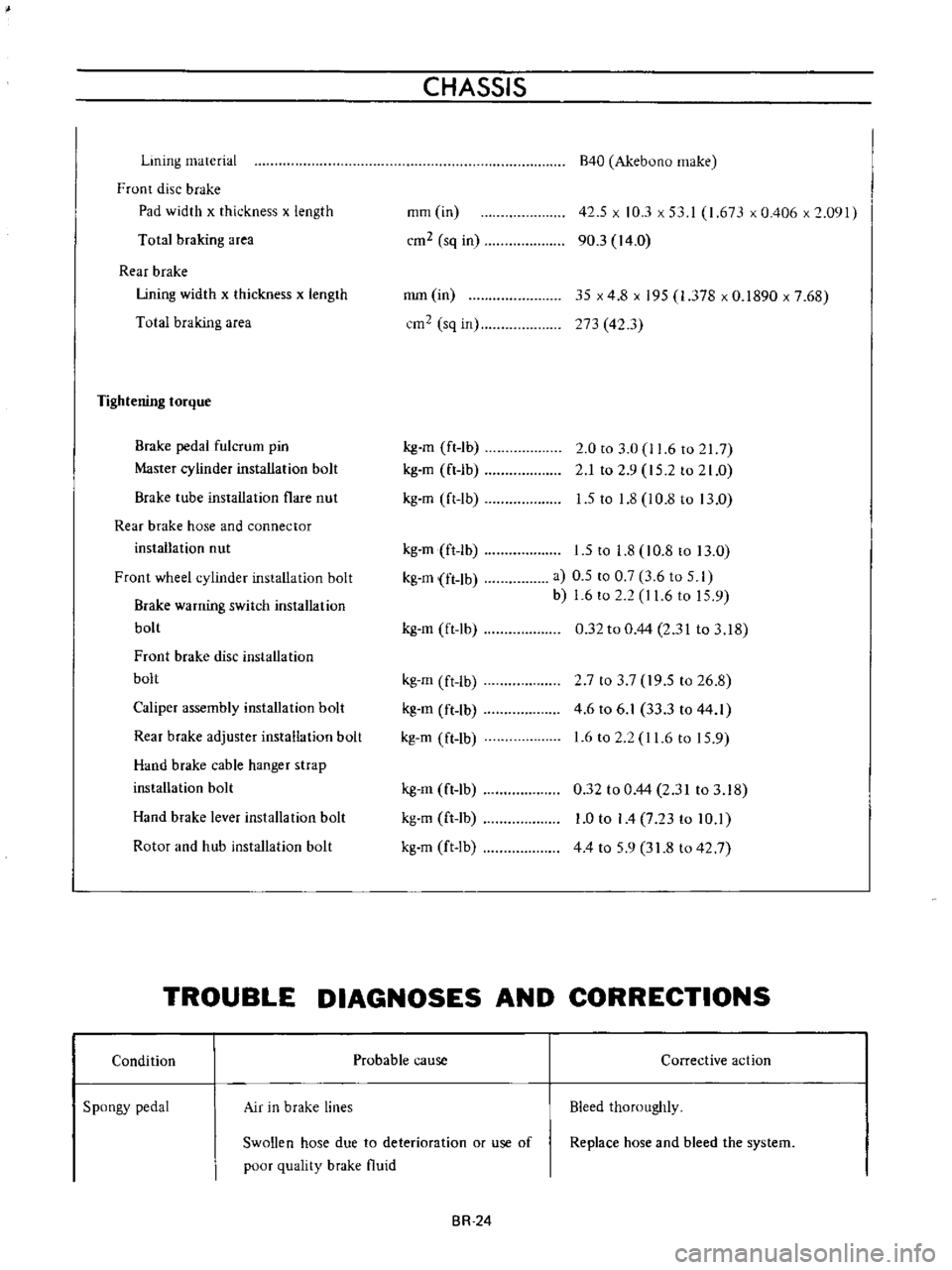

BRAKE

SERVICE

DATA

AND

SPECIFICATIONS

Brake

pedal

Pedal

free

height

Full

stroke

of

pedal

head

Master

cylinder

mm

in

mm

in

141

5

t2

5

57

to

0787

120

4

72

17

5

11

16

Inner

diameter

of

master

cylinder

mm

in

Allowable

maximum

clearance

between

cylinder

and

piston

mm

in

Wheel

cylinder

Inner

diameter

of

wheel

cylinder

Front

drum

disc

Rear

front

disc

Allowable

maximum

clearance

between

cylinder

and

piston

Brake

drum

and

rotor

disc

Drum

brake

inner

diameter

Rotor

disc

outer

diameter

Rotor

thickness

Drum

inside

out

of

roundness

Max

allowable

drum

inner

diameter

Run

out

of

the

rotor

Max

allowable

rotor

thickness

Lining

dimensions

Front

drum

brake

Lining

width

x

thickness

x

length

Total

braking

area

0

13

0

0051

mm

in

mm

in

mm

in

mm

in

20

6

13

16

48

1

1

894

20

6

13

16

1746

11

16

mm

in

0

18

0

0071

mm

in

mm

in

mm

in

mm

in

203

2

8

00

212

5

837

9

5

03740

Below

0

Q2

0

0008

mm

in

mm

in

204

5

8

051

Below

0

03

0

0012

mm

in

8

4

03307

mm

in

cm2

sq

in

35

x

4

8

x

195

1

378

x

0

1890

x

7

68

273

423

BR

2J

Page 148 of 513

Lining

material

Front

disc

brake

Pad

width

x

thickness

x

length

Total

braking

area

Rear

brake

Lining

width

x

thickness

x

length

Total

braking

area

Tightening

torque

Brake

pedal

fulcrum

pin

Master

cylinder

installation

bolt

Brake

tube

installation

flare

nut

Rear

brake

hose

and

connector

installation

nut

Front

wheel

cylinder

installation

bolt

Brake

warning

switch

installation

bolt

Front

brake

disc

installation

bolt

Caliper

assembly

installation

bolt

Rear

brake

adjuster

installation

bolt

Hand

brake

cable

hanger

strap

installation

bolt

Hand

brake

lever

installation

bolt

Rotor

and

hub

installation

bolt

CHASSIS

mm

in

cm2

sq

in

mm

in

cm2

sq

in

kg

m

ft

1b

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

Ib

B40

Akebuno

make

42

5

x

10

3

x

53

I

1

673

x

0

406

x

2

091

90

3

14

0

35

x

4

8

x

195

1

378

x

0

1890

x

7

68

273

42

3

2

0

to

3

0

11

6

to

217

2

1

to

2

9

15

2

to

21

0

1

5

to

1

8

l

0

8

to

13

0

1

5

to

1

8

10

8

to

13

0

a

0

5

to

0

7

3

6

to

5

I

b

1

6

to

2

2

I

1

6

to

15

9

0

32

to

0

44

2

31

to

3

18

2

7

to

3

7

19

5

to

26

8

4

6

to

6

1

33

3

to

44

1

1

6

to

2

2

11

6

to

15

9

0

32

to

0

44

2

31

to

3

18

1

0

to

I

4

7

23

to

10

1

44

to

59

31

8

to

42

7

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Spongy

pedal

Air

in

brake

lines

Probable

cause

Swollen

hose

due

to

deterioration

or

use

of

poor

quality

brake

fluid

BR

24

Corrective

action

Bleed

thoroughly

Replace

hose

and

bleed

the

system

Page 224 of 513

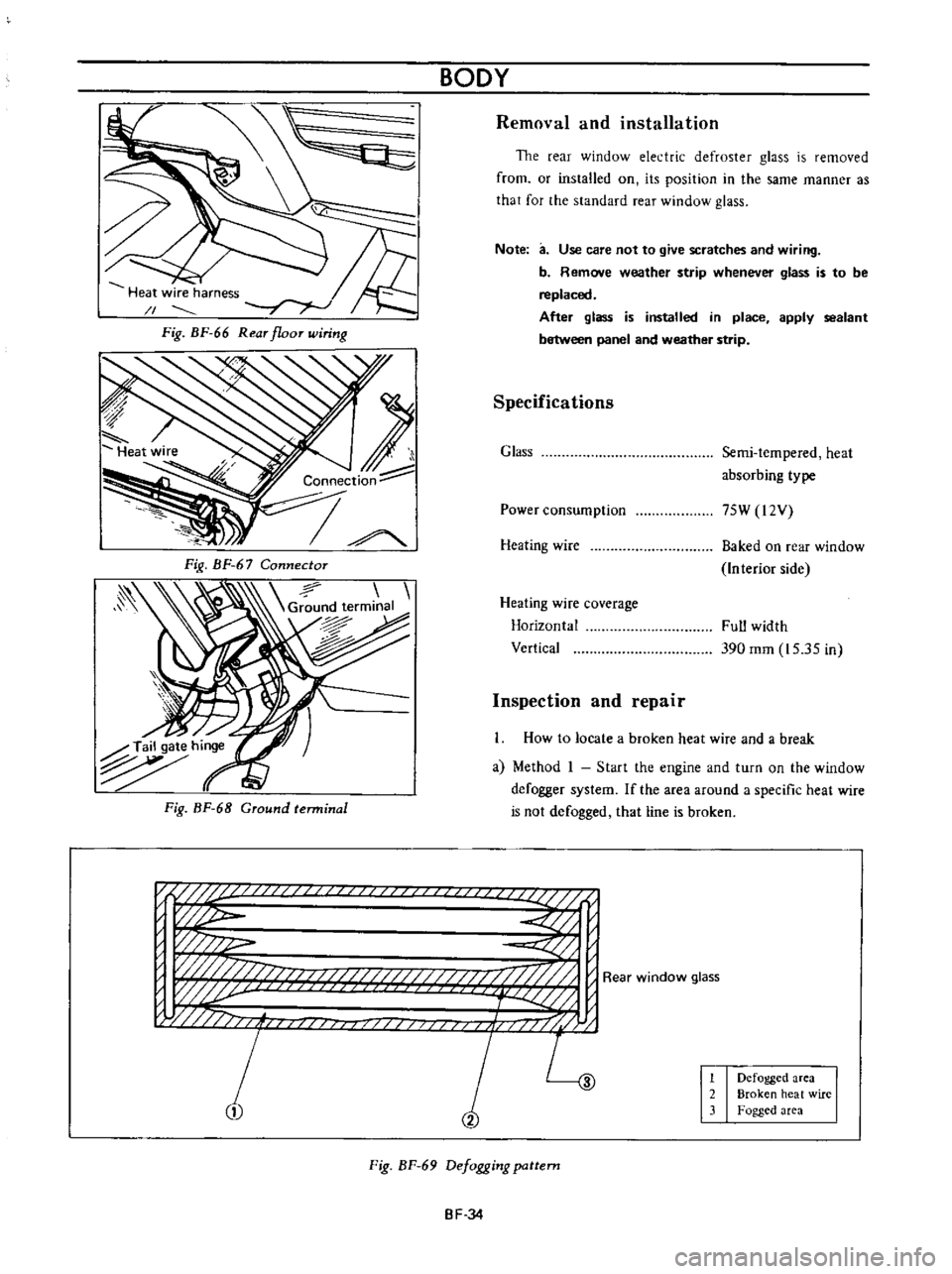

BODY

Removal

and

installation

The

rear

window

electric

defroster

glass

is

removed

from

or

installed

on

its

position

in

the

same

manner

as

that

for

the

standard

rear

window

glass

Heat

wire

harness

1

Fig

BF

66

Rear

floor

wiring

Note

a

Use

care

not

to

give

scratches

and

wiring

b

Remove

weather

strip

whenever

glass

is

to

be

replaced

After

glass

is

installed

in

place

apply

sealant

between

panel

and

weather

strip

1

Connection

Specifications

Glass

Semi

tempered

heat

absorbing

type

Power

consumption

75W

l2V

Heating

wire

Baked

on

rear

window

Interior

side

Heating

wire

coverage

Horizontal

Vertical

Full

width

390

mm

15

35

in

Inspection

and

repair

Ground

terminal

How

to

locate

a

broken

heat

wire

and

a

break

a

Method

I

Start

the

engine

and

turn

on

the

window

defogger

system

If

the

area

around

a

specific

heat

wire

is

not

defogged

that

line

is

broken

n

if

U

i

p

w

w

j

w

j

fj

f

i

j

L

1

2

Defogged

area

Broken

heat

wire

Fogged

area

Fig

BF

69

Defogging

pattern

BF

34

Page 280 of 513

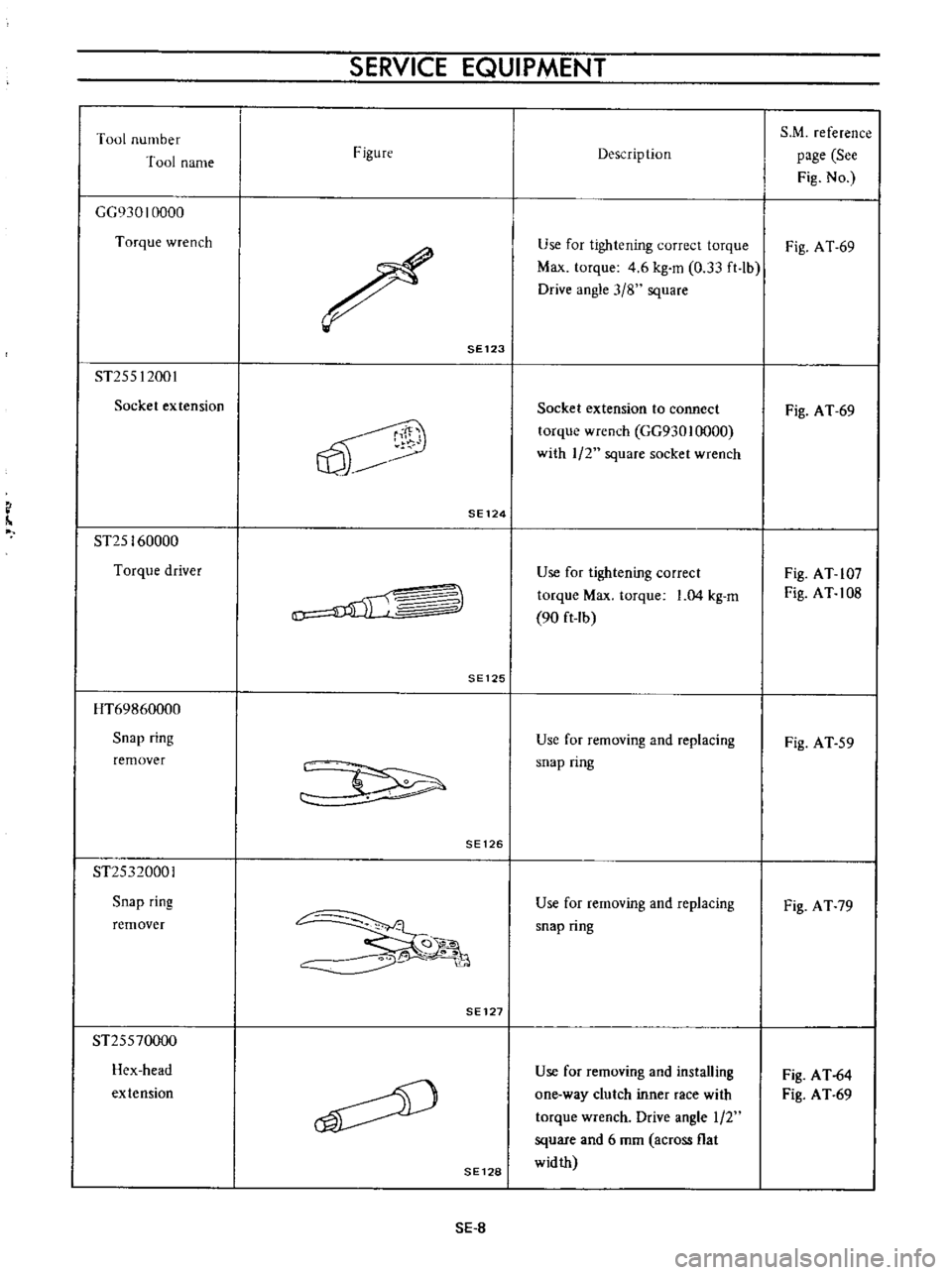

SERVICE

EQUIPMENT

Tool

number

S

M

reference

Tool

name

Figure

Description

page

See

Fig

No

GG930

10000

Torque

wrench

Use

for

tightening

correct

torque

Fig

A

T

69

Max

torque

4

6

kg

m

0

33

ft

lb

Drive

angle

3

8

square

SE123

ST255

12001

Socket

extension

Socket

extension

to

connect

Fig

A

T

69

0

torque

wrench

GG930

I

000

with

1

2

square

socket

wrench

SE124

ST25

160000

Torque

driver

Use

for

tightening

correct

Fig

AT

107

torque

Max

torque

1

04

kg

m

Fig

AT

108

u

90

ft

Ib

SE125

HT69860000

Snap

ring

Use

for

removing

and

replacing

Fig

AT

59

remover

snap

ring

SE126

ST25320001

Snap

ring

Use

for

removing

and

replacing

Fig

AT

79

snap

ring

remover

Go

O

SE127

ST25570000

Hex

head

Use

for

removing

and

installing

Fig

AT

64

extension

one

way

clutch

inner

race

with

Fig

AT

69

torque

wrench

Drive

angle

1

2

square

and

6

mm

across

flat

SE128

width

sE

8

Page 284 of 513

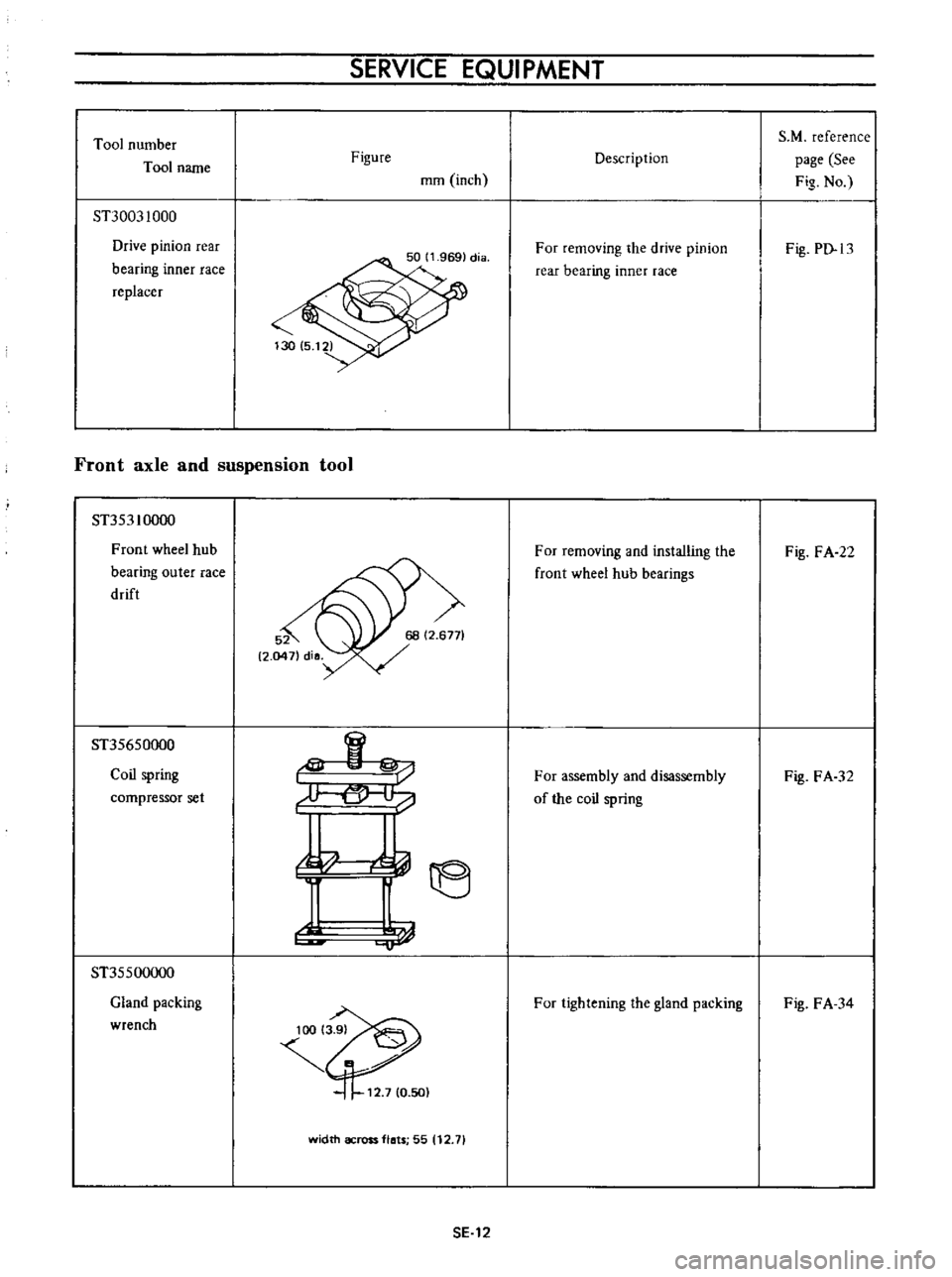

Tool

number

Tool

name

ST30031000

Drive

pinion

rear

bearing

inner

race

replacer

SERVICE

EQUIPMENT

Figure

mm

inch

Front

axle

and

suspension

tool

ST353

10000

Front

wheel

hub

bearing

outer

race

drift

ST35650000

Coil

spring

compressor

set

ST35500000

Gland

packing

wrench

rU

jb

1118

1

1

width

across

flats

55

12

71

SE

12

Descrip

tion

For

removing

the

drive

pinion

rear

bearing

inner

race

For

removing

and

installing

the

front

wheel

hub

bearings

For

assembly

and

disassembly

of

the

coil

spring

For

tightening

the

gland

packing

S

M

reference

page

See

Fig

No

Fig

PD

13

Fig

FA

22

Fig

FA

32

Fig

FA

34

Page 361 of 513

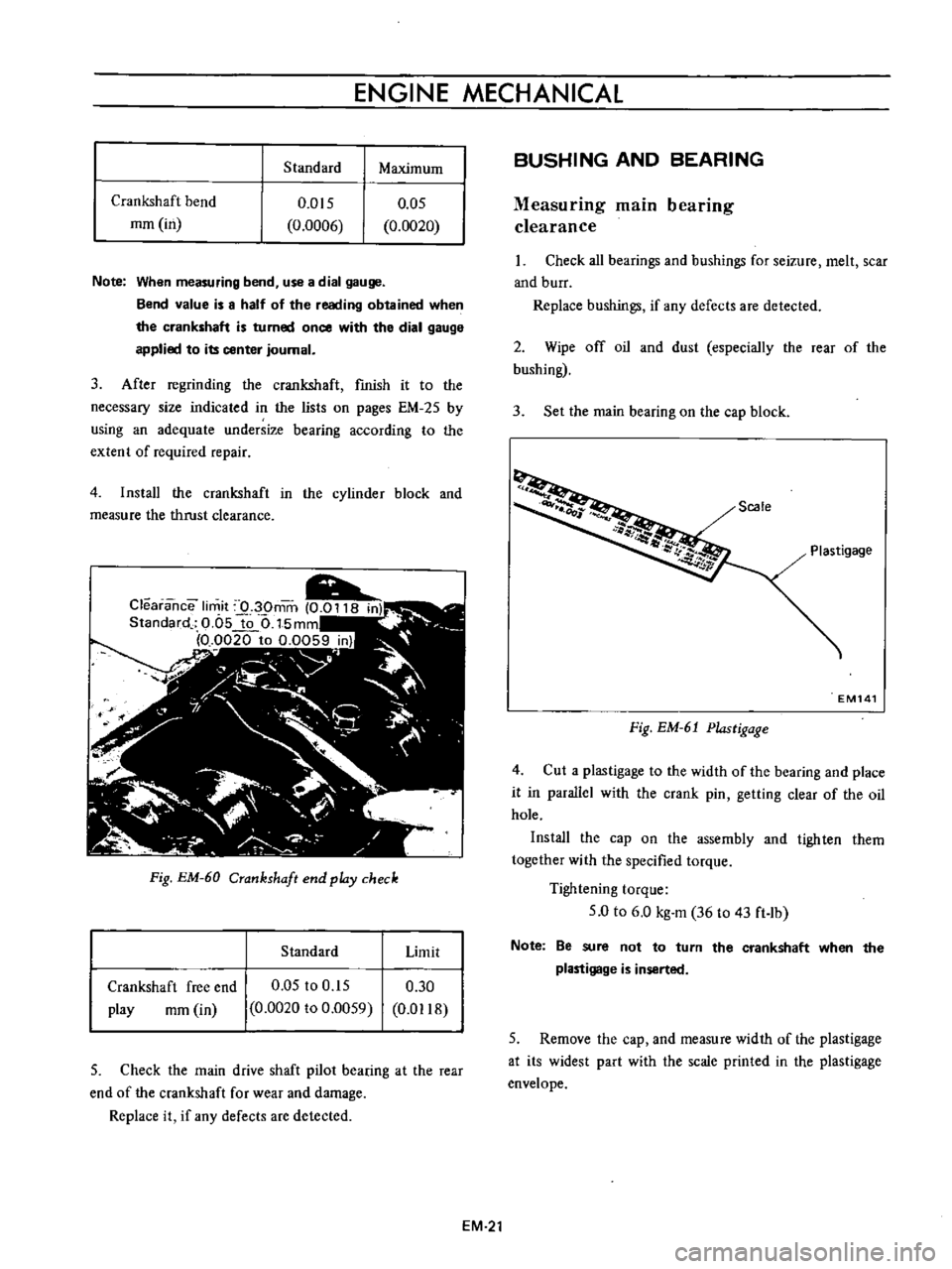

ENGINE

MECHANICAL

Standard

Maximum

Crankshaft

bend

mm

in

0

05

0

0020

0

015

0

0006

Note

When

measuring

bend

use

a

dial

gauge

Bend

value

is

a

half

of

the

reading

obtained

when

the

crankshaft

is

turned

once

with

the

dial

gauge

applied

to

its

center

journal

3

After

regrinding

the

crankshaft

fmish

it

to

the

necessary

size

indicated

in

the

lists

on

pages

EM

25

by

using

an

adequate

undersize

bearing

according

to

the

extent

of

required

repair

4

Install

the

crankshaft

in

the

cylinder

block

and

measure

the

thrust

clearance

Fig

EM

60

Crankshaft

end

pldy

check

Standard

Limit

Crankshaft

free

end

play

rom

in

0

05

to

0

15

0

0020

to

0

0059

0

30

0

D118

5

Check

the

main

drive

shaft

pilot

bearing

at

the

rear

end

of

the

crankshaft

for

wear

and

damage

Replace

it

if

any

defects

are

detected

BUSHING

AND

BEARING

Measuring

main

bearing

clearance

Check

all

bearings

and

bushings

for

seizure

melt

scar

and

burr

Replace

bushings

if

any

defects

are

detected

2

Wipe

off

oil

and

dust

especially

the

rear

of

the

bushing

3

Set

the

main

bearing

on

the

cap

block

Scale

Plastigage

EM141

Fig

EM

61

Plastigage

4

Cut

a

plastigage

to

the

width

of

the

bearing

and

place

it

in

parallel

with

the

crank

pin

getting

clear

of

the

oil

hole

Install

the

cap

on

the

assembly

and

tighten

them

together

with

the

specified

torque

Tightening

torque

5

0

to

6

0

kg

m

36

to

43

ft

lb

Note

Be

sure

not

to

turn

the

crankshaft

when

the

plastigage

is

inserted

5

Remove

the

cap

and

measure

width

of

the

plastigage

at

its

widest

part

with

the

scale

printed

in

the

plastigage

envelope

EM

21

Page 375 of 513

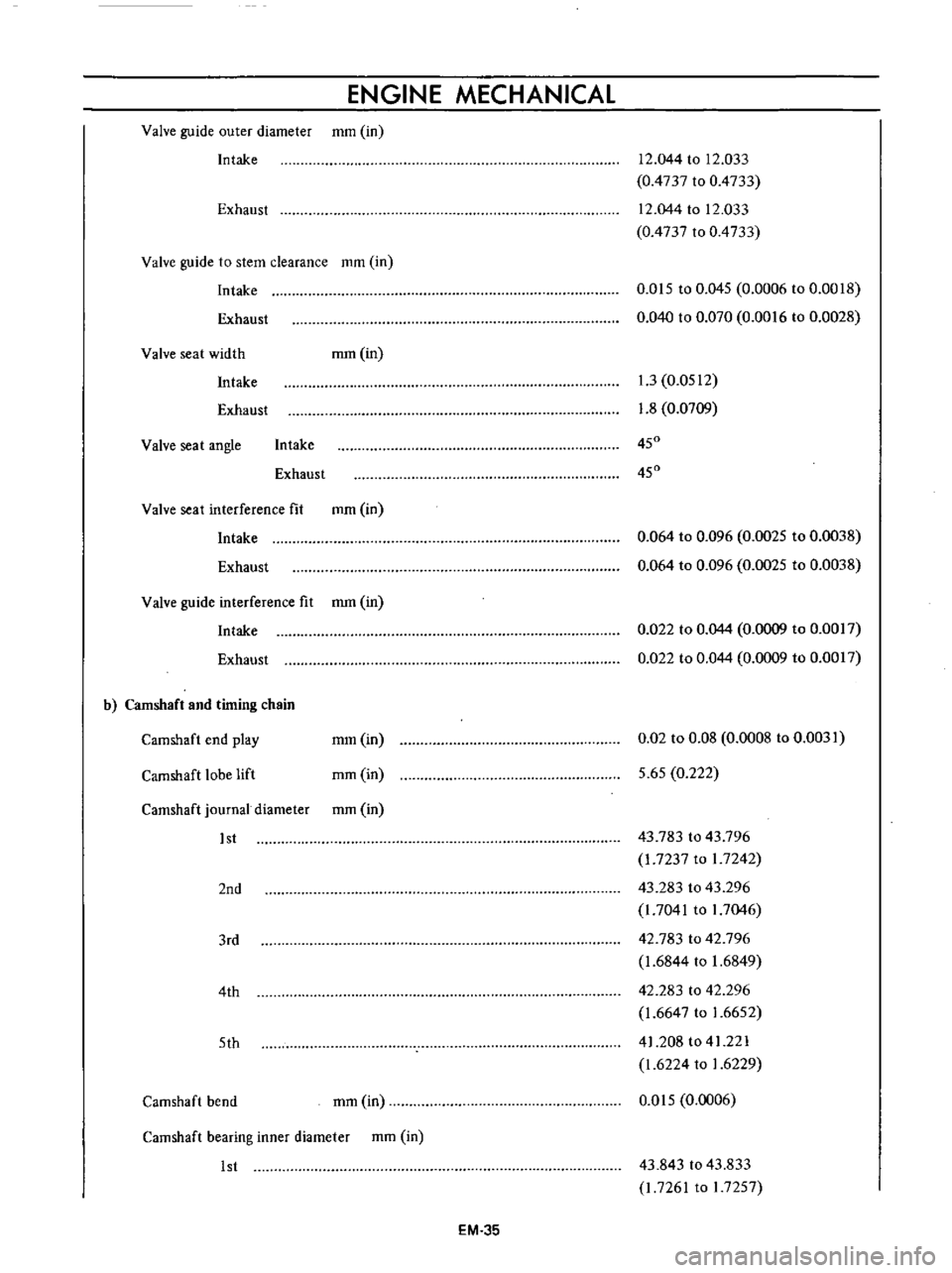

ENGINE

MECHANICAL

Valve

guide

outer

diameter

mm

in

Intake

12

044

to

12

033

0

4737

to

0

4733

Exhaust

12

044

to

12

033

0

4737

to

0

4733

Valve

guide

to

stem

clearance

mm

in

Exhaust

O

oJ5

to

0

045

0

0006

to

0

0018

0

040

to

0

070

0

0016

to

0

0028

Intake

Valve

seat

width

Intake

Exhaust

mm

in

1

3

0

0512

1

8

0

0709

Valve

sea

tangle

Intake

450

Exhaust

450

Valve

seat

interference

fit

mm

in

Intake

0

064

to

0

096

0

0025

to

0

0038

Exhaust

0

064

to

0

096

0

0025

to

0

0038

Valve

guide

interference

fit

rom

in

Intake

Exhaust

0

022

to

0

044

0

0009

to

0

0017

0

022

to

0

044

0

0009

to

0

0017

b

Camshaft

and

timing

chain

Camshaft

lobe

lift

mm

in

mm

in

0

02

to

0

08

0

0008

to

0

0031

Camshaft

end

play

5

65

0

222

Camshaft

journal

diameter

mm

in

1st

43

783

to

43

796

I

7237

to

I

7242

2nd

43

283

to

43

296

1

7041

to

1

7046

3rd

42

783

to

42

796

1

6844

to

1

6849

4th

42

283

to

42

296

1

6647

to

1

6652

5th

41

208

to

41

221

1

6224

to

1

6229

Camshaft

bend

mm

in

0

015

0

0006

Camshaft

bearing

inner

diameter

mm

in

1st

43

843

to

43

833

I

7261

to

1

7257

EM

35

Page 377 of 513

ENGINE

MECHANICAL

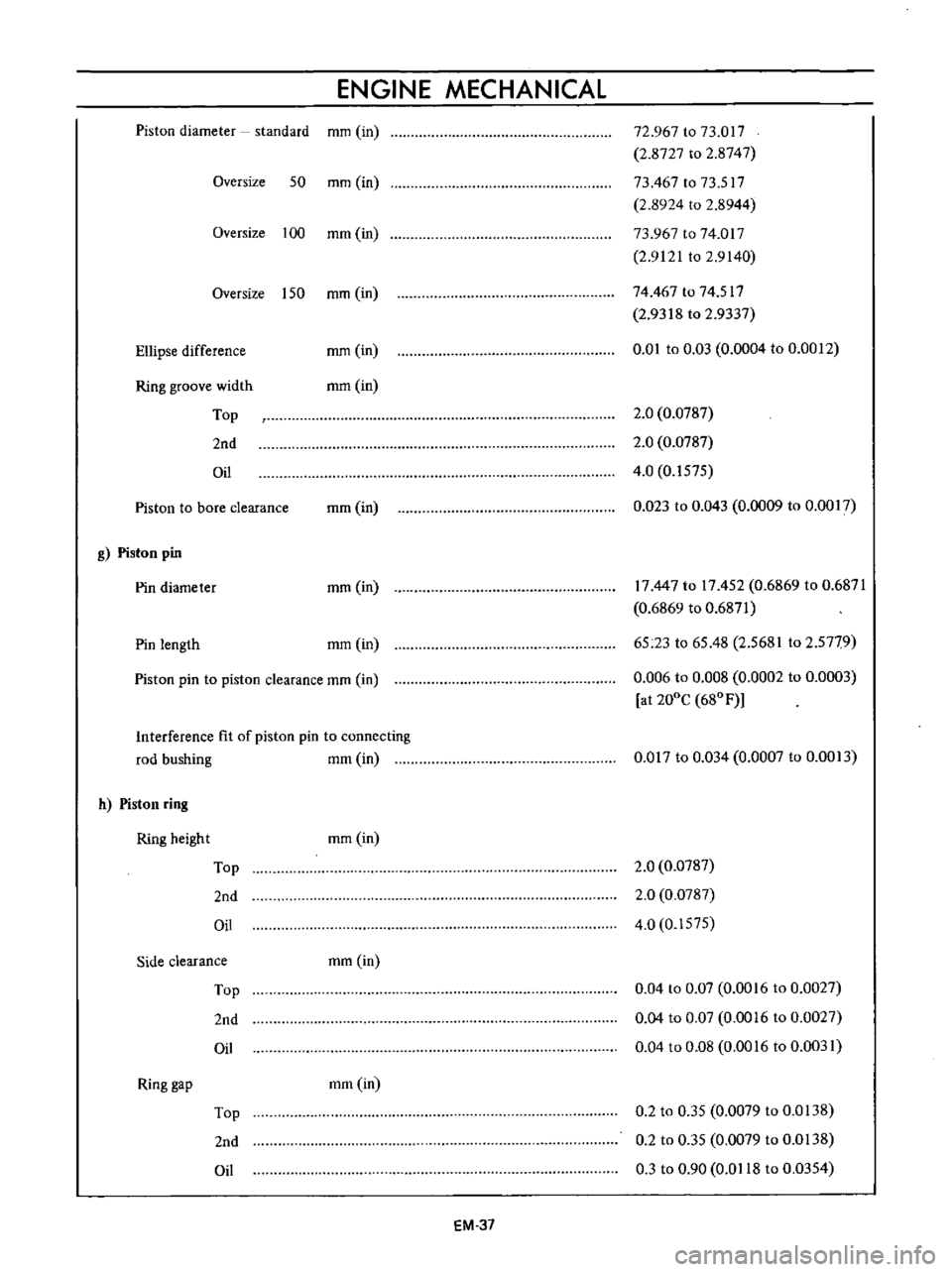

Piston

diameter

standard

mm

in

Oversize

50

mm

in

Oversize

100

mm

in

Oversize

150

mm

in

Ellipse

difference

mm

in

Ring

groove

width

Top

2nd

Oil

mm

in

Piston

to

bore

clearance

mm

in

g

Piston

pin

Pin

diameter

mm

in

Pin

length

mm

in

Piston

pin

to

piston

clearance

mm

in

Interference

fit

of

piston

pin

to

connecting

rod

bushing

mm

in

h

Piston

ring

Ring

height

Top

2nd

Oil

mm

in

Side

clearance

mm

in

Top

2nd

Oil

Ring

gap

mm

in

Top

2nd

Oil

EM

37

72

967

to

73

017

2

8727

to

2

8747

73

467

to

73

517

2

8924

to

2

8944

73

967

to

74

017

2

9121

to

2

9140

74

467

to

74

517

2

9318

to

2

9337

0

01

to

0

03

0

0004

to

0

0012

2

0

0

0787

2

0

0

0787

4

0

0

1575

0

023

to

0

043

0

0009

to

0

0017

17

447

to

17

452

0

6869

to

0

6871

0

6869

to

0

6871

65

23

to

65

48

2

5681

to

2

5779

0

006

to

0

008

0

0002

to

0

0003

at

200e

680

F

0

017

to

0

034

0

0007

to

0

0013

2

0

0

0787

2

0

0

0787

4

0

0

1575

0

04

to

0

07

0

0016

to

0

0027

0

04

to

0

07

0

0016

to

0

0027

0

04

to

0

08

0

0016

to

0

0031

0

2

to

0

35

0

0079

to

0

0138

0

2

to

0

35

0

0079

to

0

0138

0

3

to

0

90

0

0118

to

0

0354