wheel alignment DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 53 of 537

r

Engine

Mechanical

INSPECTION

AND

REPAIR

PREPARATION

FOR

INSPECTION

CYLINDER

HEAD

AND

VALVE

CHECKING

CYLINDER

HEAD

MATING

FACE

VALVE

ASSEMBLY

VALVE

SPRING

ROCKER

ARM

AND

VALVE

ROCKER

PIVOT

VALVE

GUIDE

VALVE

SEAT

INSERTS

CAMSHAFT

AND

CAMSHAFT

BEARING

CAMSHAFT

BEARING

CLEARANCE

VALVE

TIMING

CAMSHAFT

ALIGNMENT

CYLINDER

BLOCK

HOW

TO

MEASURE

CYLINDER

BORE

CYLINDER

BORING

PREPARATION

FOR

INSPECTI

N

I

Before

cleaning

check

for

signs

of

water

and

oil

leaks

in

cylinder

block

and

head

2

Clean

oil

carbon

deposits

and

sealant

from

an

parts

Remove

gasket

3

Clean

all

oil

holes

with

solvent

and

dry

with

compressed

air

Make

sure

that

they

are

not

restricted

CYLINDER

HEAD

AND

VALVE

CHECKING

CYLINDER

HEAD

MATING

FACE

EM407

Fig

EM

34

Cylinder

head

CONTENTS

EM

8

EM

B

EM

8

EM

8

EM

9

EM

lO

EM

l0

EM

11

EM

12

EM

12

EM

12

EM

13

EM

13

EM

13

EM

14

PISTONS

PISTON

PINS

AND

PISTON

RINGS

CONNECTING

ROD

CRANKSHAFT

BUSHING

AND

BEARING

MEASUREMENT

OF

MAIN

BEARING

CLEARANCE

MEASUREMENT

OF

CONNECTING

ROD

BEARING

CLEARANCE

FITTING

BEARINGS

MISCELLANEOUS

COMPONENTS

CRANKSHAFT

AND

CAMSHAFT

SPROCKETS

CHAIN

TENSIONER

AND

CHAIN

GUIDE

FLYWHEEL

FRONT

COVER

AND

REAR

OIL

SEAL

Note

Never

remove

camshaft

bear

ings

unless

you

have

a

Suitable

machine

or

boring

Camshaft

bear

ing

in

line

If

you

once

remove

camshaft

bearings

bearing

centers

will

come

out

o

alignment

reo

conditioning

is

very

difficult

with

out

center

borings

L

Make

a

v

isual

check

for

cracks

and

flaws

2

Measure

the

surface

of

cylinder

head

on

cylinder

block

side

for

warpage

If

it

is

found

to

be

beyond

the

limit

designated

below

regrind

the

affected

surface

with

a

surface

grinder

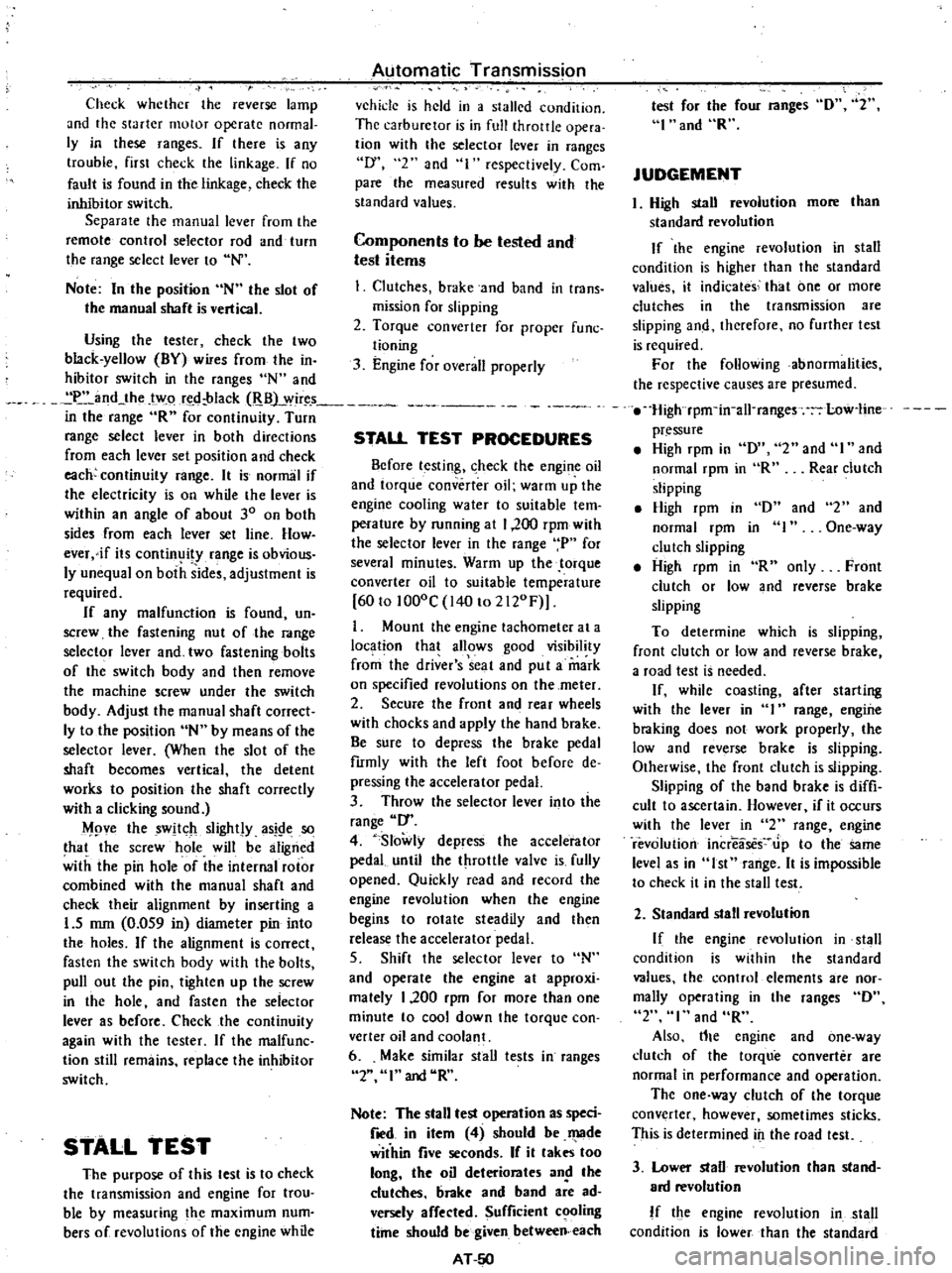

Fig

EM

35

Checking

cylinder

head

8JJrface

EM

8

Head

surface

flatnes

Standard

less

than

0

05

mm

0

0020

in

O

lmm

0

0039

in

EM

15

EM

16

EM

16

EM

17

EM

17

EM

1B

EM

18

EM

19

EM

19

EM

20

EM

20

EM

20

Maximum

VALVE

ASSEMBLY

Check

each

intake

and

exhaust

valve

for

worn

damaged

or

deformed

valve

caps

or

stems

Correct

or

replace

any

valve

that

is

faulty

2

Valve

face

or

valve

stem

end

surface

should

be

refaced

with

a

valve

grinder

10

L

I

I

I

EM109

Fig

EM

36

Intak

and

exhaust

valve

dimensions

Page 314 of 537

Using

the

tester

check

the

two

black

yellow

BY

wires

from

the

in

hibitor

switch

in

the

ranges

N

and

I

and

the

tw

re

d

black

RBj

wir

s

in

the

range

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continl

ity

range

is

obvious

ly

unequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

of

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

ly

to

the

position

N

by

means

of

the

selector

lever

When

the

slot

of

the

shaft

becomes

vertical

the

detent

works

to

position

the

shaft

correctly

with

a

clicking

sound

MSlVe

the

switch

slightly

asj

Je

so

that

the

screw

hole

will

be

aligned

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

mm

0

059

in

diameter

pin

into

the

holes

If

the

alignment

is

correct

fasten

the

switch

body

with

the

bolts

pull

out

the

pin

tighten

up

the

screw

in

the

hole

and

fasten

the

selector

lever

as

before

Check

the

continuity

again

with

the

tester

If

the

malfunc

tion

still

remains

replace

the

inhibitor

switch

Chcck

whether

the

reverse

lamp

and

the

starter

motor

operate

normal

ly

in

these

ranges

If

Ihere

is

any

lrouble

first

check

the

linkage

If

no

fault

is

found

in

the

linkage

check

the

inhibitor

switch

Separate

the

manual

lever

from

Ihe

remote

control

selector

rod

and

turn

the

range

selcct

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximum

num

bers

of

revolutions

of

the

engine

while

Automatic

Transmission

vehicle

is

held

in

a

stalled

condition

The

carburctor

is

in

full

throttle

opera

tion

with

the

selector

lever

in

ranges

f

2

and

I

respectively

Com

pare

the

measured

results

with

the

slandard

values

Components

to

be

tested

and

test

items

I

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

proper

fune

tioning

3

Engine

for

overall

properly

STALL

TEST

PROCEDURES

Before

Icsting

c

heck

the

engine

oil

and

torque

converter

oil

warm

up

the

engine

cooling

water

to

suitable

tem

perature

by

running

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

several

minutes

Warm

up

the

torque

converter

oil

to

suitable

temperature

6010

1000C

140

to

2l20F

I

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

fro

the

dri

er

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

with

chocks

and

apply

the

hand

brake

Be

sure

to

depress

the

brake

pedal

fumly

with

the

left

foot

before

de

pressing

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

1

4

Slowly

depress

the

accelerator

pedal

until

the

throttle

valvc

is

fully

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Shift

the

selector

lever

to

N

and

operate

the

engine

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

ver

ter

oil

and

coolant

6

Make

similar

stall

tests

in

ranges

2

I

and

RIO

Note

The

stall

test

operation

as

speci

f

d

in

item

4

should

be

I

l3de

wiihin

five

seconds

If

it

takes

too

long

the

oil

deteriorates

an

the

clutches

brake

and

band

are

ad

versely

affected

Sufficient

cooling

time

should

be

given

between

each

AT

5O

test

for

the

four

ranges

0

2

I

and

R

JUDGEMENT

High

stall

revolution

more

than

standard

revolution

If

the

engine

revolution

in

stall

condition

is

higher

than

the

standard

values

it

indicates

that

one

or

more

clutches

in

the

transmission

are

slipping

and

therefore

no

further

test

is

required

For

the

following

abnormalities

the

respective

causes

are

presumed

High

rpm

in

all

ranges

low

Iine

pressure

High

rpm

in

D

2

and

I

and

normal

rpm

in

R

Rear

clutch

slipping

High

rpm

in

0

and

normal

rpm

in

I

clutch

slipping

High

rpm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

front

clutch

or

low

and

reverse

brake

a

road

test

is

nceded

If

whilc

coasting

after

starting

with

the

lever

in

1

range

engine

braking

does

not

work

properly

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

Slipping

of

the

band

brake

is

diffi

cult

to

ascertain

However

if

it

occurs

with

the

lever

in

2

range

engine

revolution

increases

Jp

to

thesarne

level

as

in

I

strange

It

is

impossible

to

check

it

in

the

stall

test

2

and

One

way

2

Standard

stall

revolution

If

the

engine

revolution

in

stall

condition

is

within

the

standard

values

the

control

elements

are

nor

mally

operating

in

the

ranges

0

2

I

and

R

Also

tIle

engine

and

one

way

clutch

of

the

torque

converter

are

normal

in

performance

and

operation

The

one

way

clutch

of

the

torque

converter

however

sometimes

sticks

This

is

determined

in

the

road

test

3

Lower

stall

revolution

than

stand

ard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

Page 351 of 537

Front

Axle

Front

Suspension

FRONT

AXLE

AND

FRONT

SUSPENSION

CONTENTS

GENERAL

DESCRIPTION

FRONT

AXLE

REMOVAL

AND

INSTALLATION

WHEEL

BEARING

ADJUSTMENT

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

SHOCK

ABSORBER

REMOVAL

AND

INSTALLATION

INSPECTION

STABILIZER

REMOVAL

AND

INSTALLATION

INSPECTION

TENSION

ROD

FA

2

FA

3

FA

3

FA

4

FA

4

FA

5

FA

8

FA

8

FA

8

FA

8

FA

8

FA

8

FA

8

REMOVAL

AND

INSTALLATION

INSPECTION

TORSION

BAR

SPRING

REMOVAL

AND

INSTALLATION

INSPECTION

UPPER

AND

LOWER

LINKS

FjEMOVAL

AND

INSTALLATION

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

ADJUSTMENT

VEHICLE

POSTURE

WHEEL

ALIGNMENT

STEERING

ANGLE

GENERAL

DESCRIPTION

uUl

FA

8

FA

9

FA

9

FA

9

FA

9

FA

10

FA

l0

FA

ll

FA

ll

FA

Il

FA

ll

FA

12

FA

12

FA224

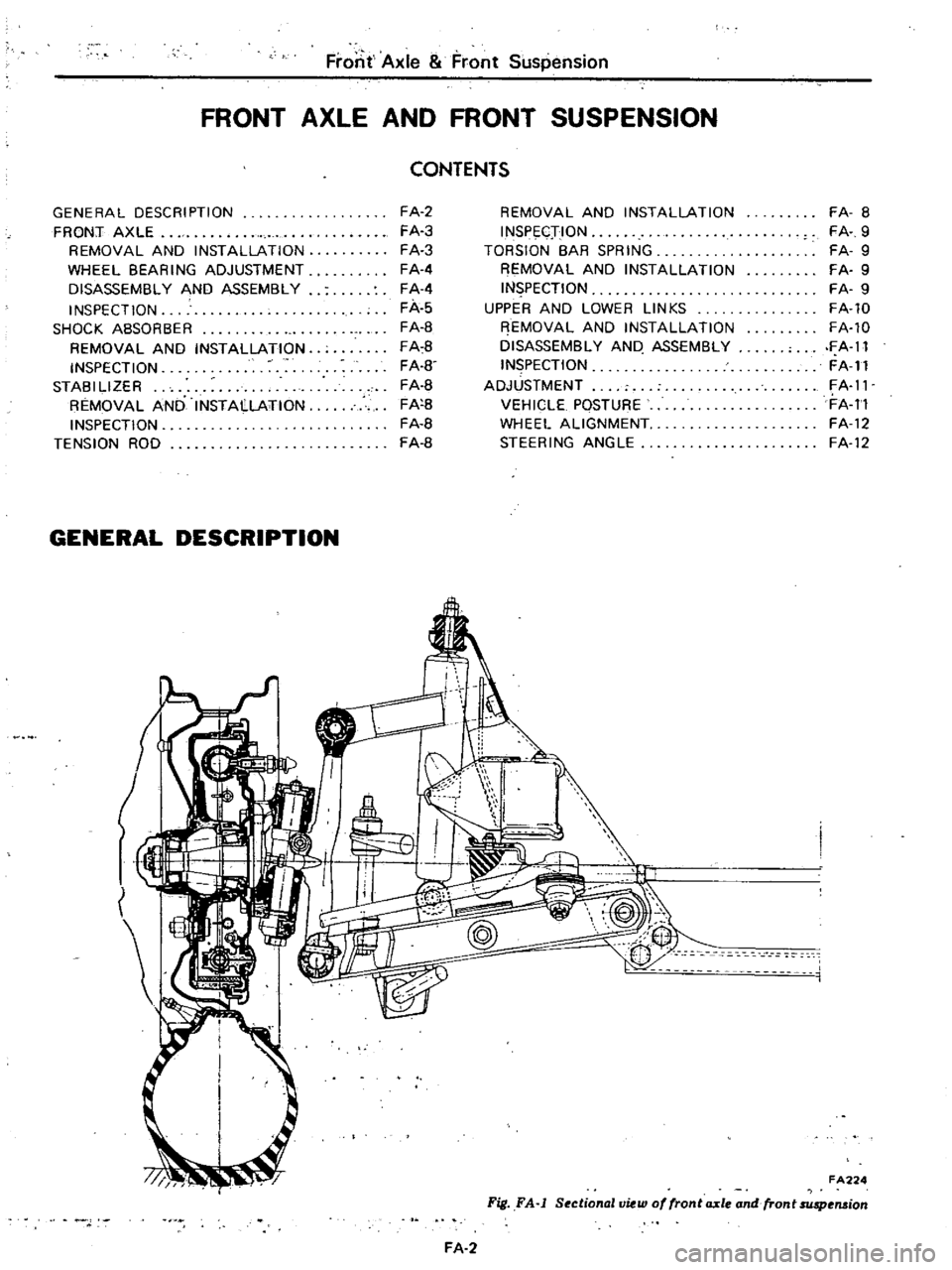

Fig

FA

j

SectionallJiew

of

fronta

xle

and

fron

t

suspension

FA

2

Page 361 of 537

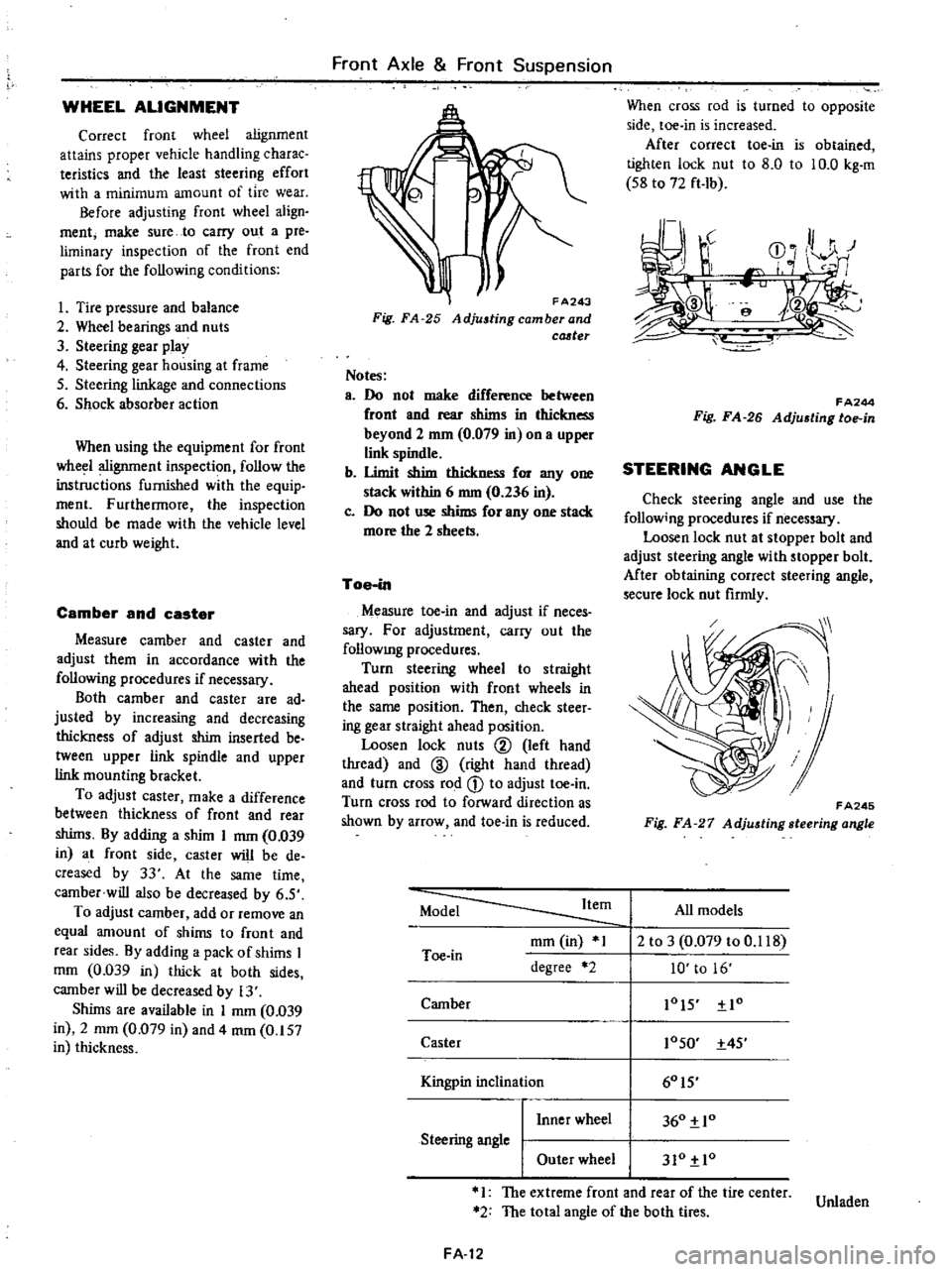

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

attains

proper

vehicle

handling

charac

teristics

and

the

least

steering

effort

with

a

minimum

amount

of

tire

wear

Before

adjusting

front

wheel

align

ment

make

sure

to

carry

out

a

pre

liminary

inspection

of

the

front

end

parts

for

the

following

conditions

1

Tire

pressure

and

balance

2

Wheel

bearings

and

nuts

3

Steering

gear

play

4

Steering

gear

housing

at

frame

S

Steering

linkage

and

connections

6

Shock

absorber

action

When

using

the

equipment

for

front

wheel

alignment

inspection

follow

the

inst

c

tions

furnished

with

the

equip

ment

Furthennore

the

inspection

should

be

made

with

the

vehicle

level

and

at

curb

weight

Camber

and

caster

Measure

camber

and

caster

and

adjust

them

in

accordance

with

the

following

procedures

if

necessary

Both

camber

and

caster

are

ad

justed

by

increasing

and

decreasing

thickness

of

adjust

shim

inserted

be

tween

upper

link

spindle

and

upper

link

mounting

bracket

To

adjust

caster

make

a

difference

between

thickness

of

front

and

rear

shims

By

adding

a

shim

I

mm

0

039

in

at

front

side

caster

will

be

de

creased

by

33

At

the

same

time

camber

will

also

be

decreased

by

6

S

To

adjust

camber

add

or

remove

an

equal

amount

of

shims

to

front

and

rear

sides

By

adding

a

pack

of

shims

I

mOl

0

039

in

thick

at

both

sides

camber

will

be

decreased

by

13

Shims

are

available

in

I

mm

0

039

in

2

mOl

0

079

in

and

4

mOl

0

157

in

thickness

Front

Axle

Front

Suspension

FA243

Fig

FA

25

Adjustingcamberand

cCJ

ter

Notes

a

Do

not

make

difference

between

front

and

rear

shims

in

thickness

beyond

2

mm

0

079

in

on

a

upper

link

spindle

b

Umit

shim

thickness

for

anyone

stack

within

6

nun

0

236

in

c

Do

not

use

shims

for

anyone

stack

more

the

2

sheets

Toe

in

Measure

toe

in

and

adjust

if

neces

sary

For

adjustment

carry

out

the

follOWIng

procedures

Turn

steering

wheel

to

straight

ahead

position

with

front

wheels

in

the

same

position

Then

check

steer

ing

gear

straight

ahead

position

Loosen

lock

nuts

@

left

hand

thread

and

ID

right

hand

thread

and

turn

cross

rod

CD

to

adjust

toe

in

Turn

cross

rod

to

forward

direction

as

shown

by

arrow

and

toe

in

is

reduced

When

cross

rod

is

turned

to

opposite

side

toe

in

is

increased

After

correct

toe

in

is

obtained

tighten

lock

nut

to

8

0

to

10

0

kg

m

S8

to

72

ft

Ib

r

J

r

CD

0

HI

r

I

e

f

FA244

Fig

FA

26

Adju6ting

toe

in

STEERING

ANGLE

Check

steering

angle

and

use

the

follow

ng

procedures

if

necessary

Loosen

lock

nut

at

stopper

bolt

and

adjust

steering

angle

with

stopper

bolt

Mter

obtaining

correct

steering

angle

secure

lock

nut

firmly

FA245

Fig

FA

27

Adjusting

steering

angle

Model

Item

All

models

mOl

in

1

2

to

3

0

079

to

0

118

Toe

in

degree

2

10

to

16

Camber

lOIS

Io

Caster

10SO

4S

I

60IS

Kingpin

inc

inal10n

I

Inner

wheel

360

10

Steering

angle

I

Outer

wheel

310

10

1

The

extreme

front

and

rear

of

the

tire

center

Unladen

2

The

total

angle

of

the

both

tires

FA

12

Page 363 of 537

Front

Axle

Front

Suspension

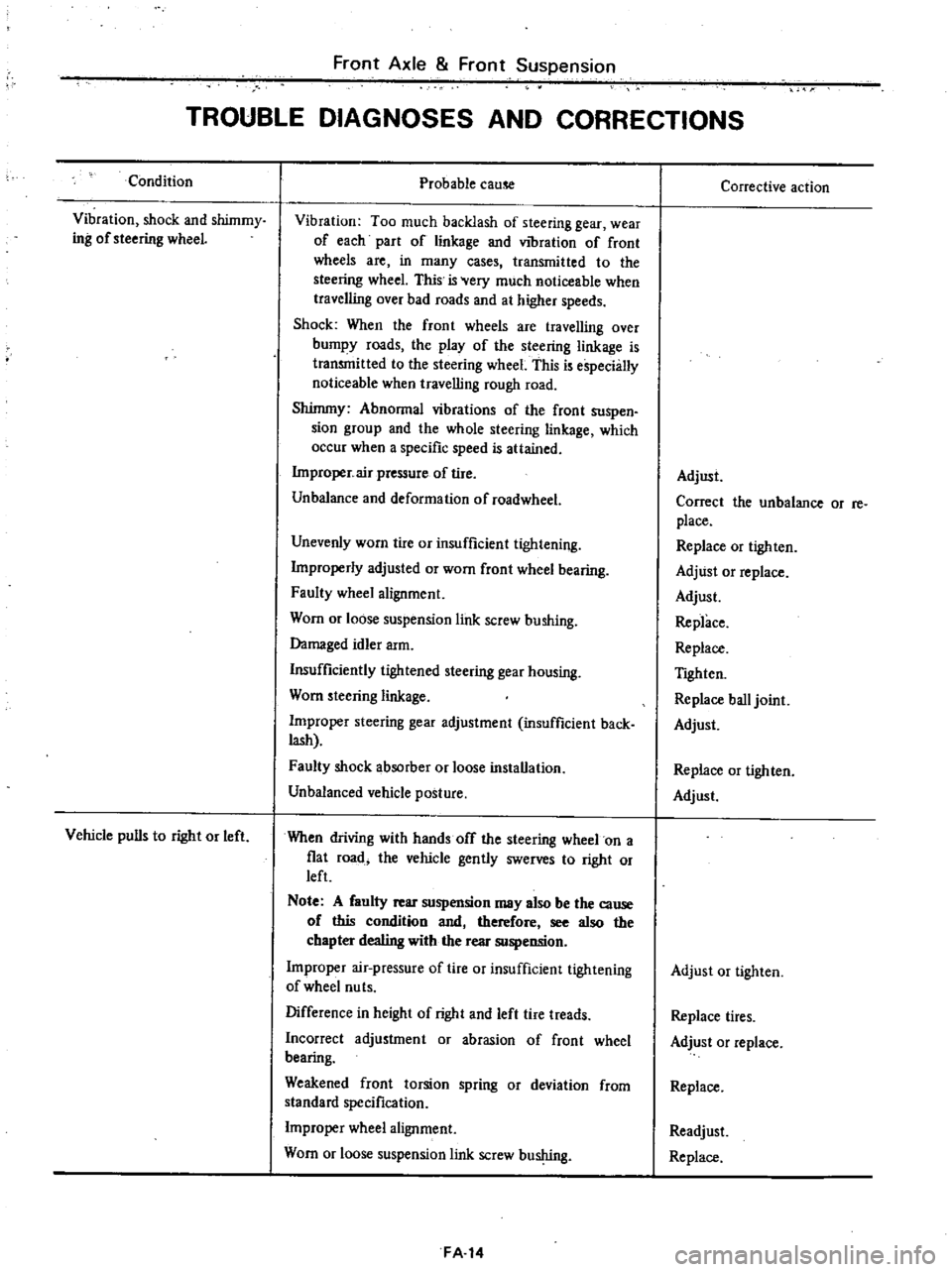

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Vibration

shock

and

shimmy

ing

of

steering

wheeL

Vehicle

pulls

to

right

or

left

Probable

cause

Vibration

Too

much

backlash

of

steering

gear

wear

of

each

part

of

linkage

and

vibration

of

front

wheels

are

in

many

cases

transmitted

to

the

steering

wheel

This

is

Very

much

noticeable

when

traveJling

over

bad

roads

and

at

higher

speeds

Shock

When

the

front

wheels

are

travelling

over

bumpy

roads

the

play

of

the

steering

linkage

is

transmitted

to

the

steering

wheel

This

is

especially

noticeable

when

travelling

rough

road

Shimmy

Abnormal

vibrations

of

the

front

suspen

sion

group

and

the

whole

steering

linkage

which

occur

when

a

specific

speed

is

attained

Improper

air

pressure

of

tire

Unbalance

and

deformation

of

roadwheel

Unevenly

worn

tire

or

insufficient

tightening

Improperly

adjusted

or

worn

front

wheel

bearing

Faulty

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

Damaged

idler

arm

Insufficiently

tightened

steering

gear

housing

Worn

steering

linkage

Improper

steering

gear

adjustment

insufficient

back

lash

Faulty

shock

absorber

or

loose

installation

Unbalanced

vehicle

posture

When

driving

with

hands

off

the

steering

wheel

on

a

fiat

road

the

vehicle

gently

swerves

to

right

or

left

Note

A

faulty

rear

suspension

may

also

be

the

cause

of

this

condition

and

therefore

see

also

the

chapter

dealing

with

the

rear

suspension

Improper

air

pressure

of

tire

or

insufficient

tightening

of

wheel

nu

ts

Difference

in

height

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Weakened

front

torsion

spring

or

deviation

from

standard

specification

Improper

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

FA

14

Corrective

action

Adjust

Correct

the

unbalance

or

re

place

Replace

or

tighten

Adjust

or

replace

Adjust

Replace

Replace

TIghten

Replace

ball

joint

Adjust

Replace

or

tighten

Adjust

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Readjust

Replace

Page 364 of 537

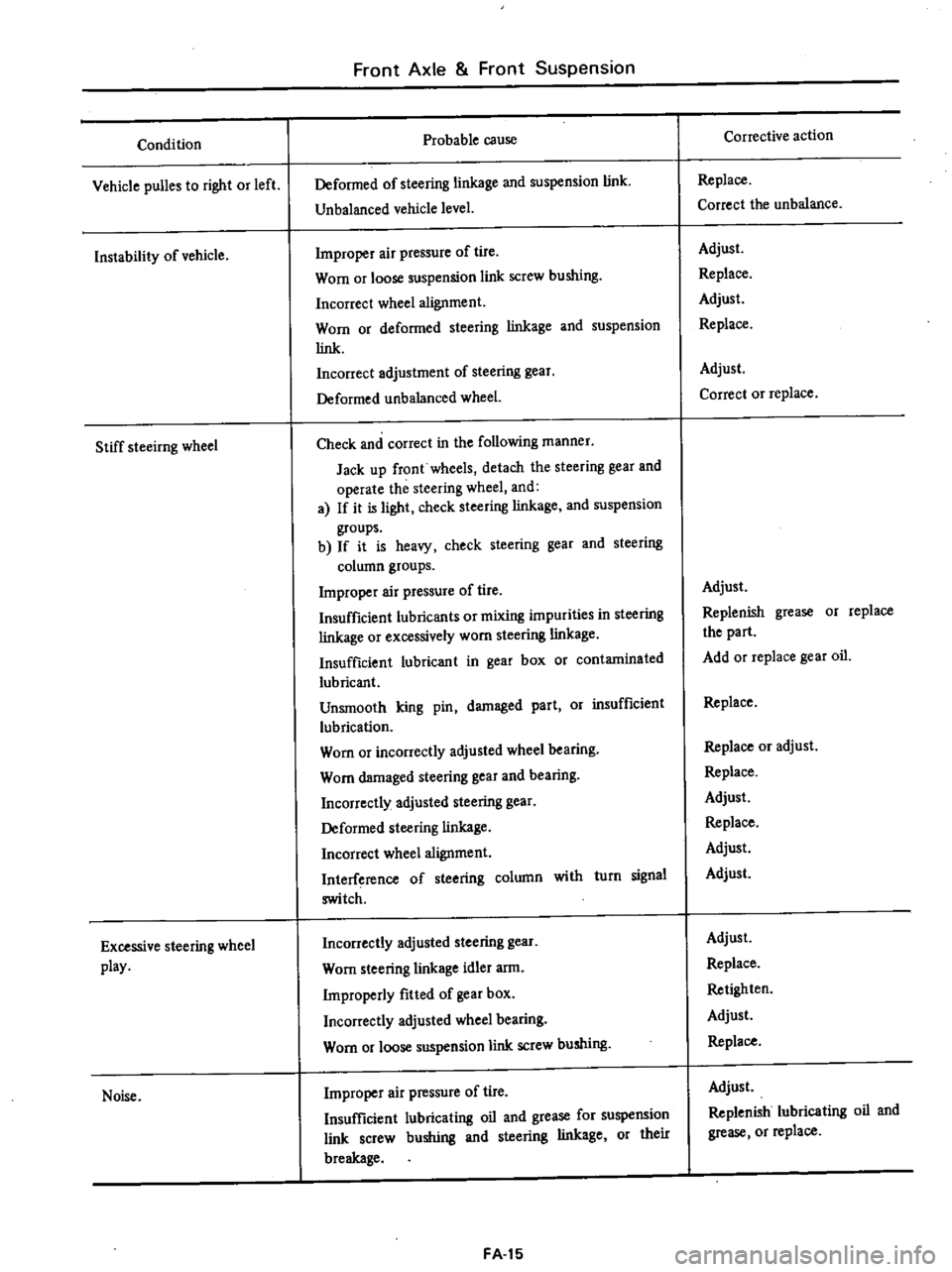

Condition

Vehicle

puBes

to

right

or

left

Instability

of

vehicle

Stiff

steeirng

wheel

Excessive

steering

wheel

play

Noise

Front

Axle

Front

Suspension

Probable

cause

Deformed

of

steering

linkage

and

suspension

link

Unbalanced

vehicle

level

Improper

air

pressure

of

tire

Worn

or

loose

suspension

link

screw

bushing

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

unbalanced

wheel

Check

and

correct

in

the

following

manner

Jack

up

front

wheels

detach

the

steering

gear

and

operate

the

steering

wheel

and

a

If

it

is

light

check

steering

linkage

and

suspension

groups

b

If

it

is

heavy

check

steering

gear

and

steering

column

groups

Improper

air

pressure

of

tire

Insufficient

lubricants

or

mixing

impurities

in

steering

linkage

or

excessively

worn

steering

linkage

Insufficient

lubricant

in

gear

box

or

contaminated

lubricant

Unsmooth

king

pin

damaged

part

Or

insufficient

lubrication

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

linkage

Incorrect

wheel

alignment

Interference

of

steering

column

with

turn

signal

switch

Incorrectly

adjusted

steering

gear

Worn

steering

linkage

idler

arm

Improperly

fitted

of

gear

box

Incorrectly

adjusted

wheel

bearing

Worn

or

loose

suspension

link

screw

bushing

Improper

air

pressure

of

tire

Insufficient

lubricating

oil

and

grease

for

suspension

link

screw

bushing

and

steering

linkage

or

their

breakage

FA

15

Corrective

action

Replace

Correct

the

unbalance

Adjust

Replace

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Replenish

grease

or

replace

the

part

Add

or

replace

gear

oil

Replace

Replace

or

adjust

Replace

Adjust

Replace

Adjust

Adjust

Adjust

Replace

Retighten

Adjust

Replace

Adjust

Replenish

lubricating

oil

and

grease

or

replace

Page 365 of 537

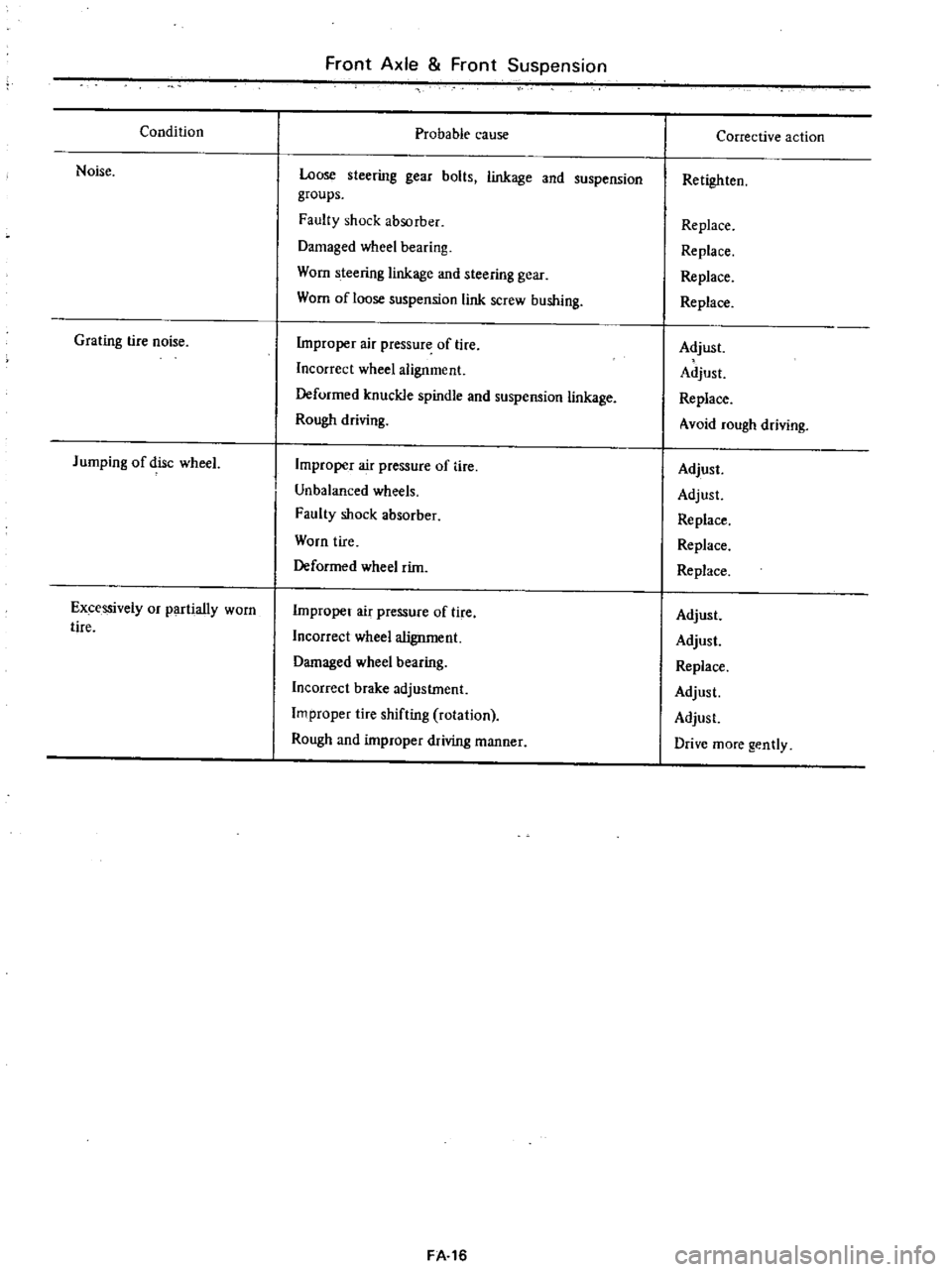

Condition

Noise

Grating

tire

noise

Jumping

of

disc

wheeL

Excessively

or

partially

worn

tire

Front

Axle

Front

Suspension

Probable

cause

Loose

steering

gear

bolts

linkage

and

suspension

groups

Faulty

shock

absorber

Damaged

wheel

bearing

Worn

steering

linkage

and

steering

gear

Worn

of

loose

suspension

link

screw

bushing

Improper

air

pressure

of

lire

Incorrect

wheel

alignment

Deformed

knuckle

spindle

and

suspension

linkage

Rough

driving

Improper

air

pressure

of

tire

Unbalanced

wheels

Faulty

shock

absorber

Worn

tire

Deformed

wheel

rim

Improper

air

pressure

of

tire

Incorrect

wheel

alignment

Damaged

wheel

bearing

Incorrect

brake

adjustment

Improper

tire

shifting

rotation

Rough

and

improper

wiving

manner

FA

16

Corrective

action

Retighten

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Avoid

rough

driving

Adjust

Adjust

Replace

Replace

Replace

Adjust

Adjust

Replace

Adjust

Adjust

Drive

more

gently

Page 399 of 537

Condition

Pedal

yields

under

slight

pressure

Brake

System

Probable

cause

Wheel

cylinder

in

poor

condition

Poor

sliding

condition

of

brake

shoe

Looseness

of

cylinder

body

or

back

plate

securing

bolts

Scored

or

out

of

round

drums

Sticking

wheel

cylinder

cups

Deformation

of

back

plate

Incorrect

adjustment

of

wheel

bearings

Incorrect

adjustment

of

wheel

alignment

Looseness

of

leaf

spring

securing

U

bolts

Faulty

N

L

S

V

Deteriorated

check

valve

Ex

ternalleaks

Leakage

on

master

cylinder

BR

24

Corrective

action

Repair

or

replace

Adjust

Fasten

or

replace

Recondition

or

replace

brake

drum

as

reo

quired

Check

for

improper

lining

contact

with

drum

and

grind

lining

if

necessary

Recondition

or

replace

cylinder

Replace

Adjust

or

replace

Adjust

Tighten

or

replace

Replace

Replace

check

valve

and

bleed

system

Check

master

cylinder

piping

and

wheel

cylinder

for

leaks

and

repair

Overhaul

master

cylinder

Page 405 of 537

Condition

Wheel

wobbles

Unevenly

or

excessively

worn

tire

Tire

squeals

Wheel

and

Tire

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Improper

tire

pressure

Damaged

tire

or

distorted

wheel

rim

Unbalanced

wheel

Loose

wheel

nuts

Worn

or

damaged

wheel

bearing

or

excessive

play

of

wheel

bearing

Improper

front

wheel

alignment

Worn

or

damaged

ball

joint

Excessive

steering

linkage

play

or

worn

steering

linkage

Loose

steering

linkage

connection

Broken

suspension

spring

Damaged

shock

absorber

Improper

tire

rotation

Improper

tire

pressure

Unbalanced

wheel

Improperly

adjusted

brake

Improper

wheel

alignment

Excessively

distorted

or

improperly

installed

suspension

link

High

speed

on

curves

Sudden

start

and

improper

speed

due

to

rapid

acceleration

or

improper

brake

ap

plication

Improper

tire

pressure

Improper

front

wheel

alignment

Distorted

knuckle

or

suspension

link

WT

5

Corrective

action

Measure

and

adjust

Repair

or

replace

Balance

Tighten

Correct

play

or

replace

wheel

bearing

Align

Replace

Adjust

Or

replace

Tighten

nuts

to

rated

torque

or

replace

worn

parts

if

any

Replace

Replace

Conduct

tire

rotation

periodically

Measure

and

adjust

Balance

or

replace

Adjust

Align

Repair

replace

or

if

necessary

reinstall

Reduce

speed

Follow

correct

and

proper

driving

manner

Measure

and

adjust

Align

Repair

or

replace

Page 414 of 537

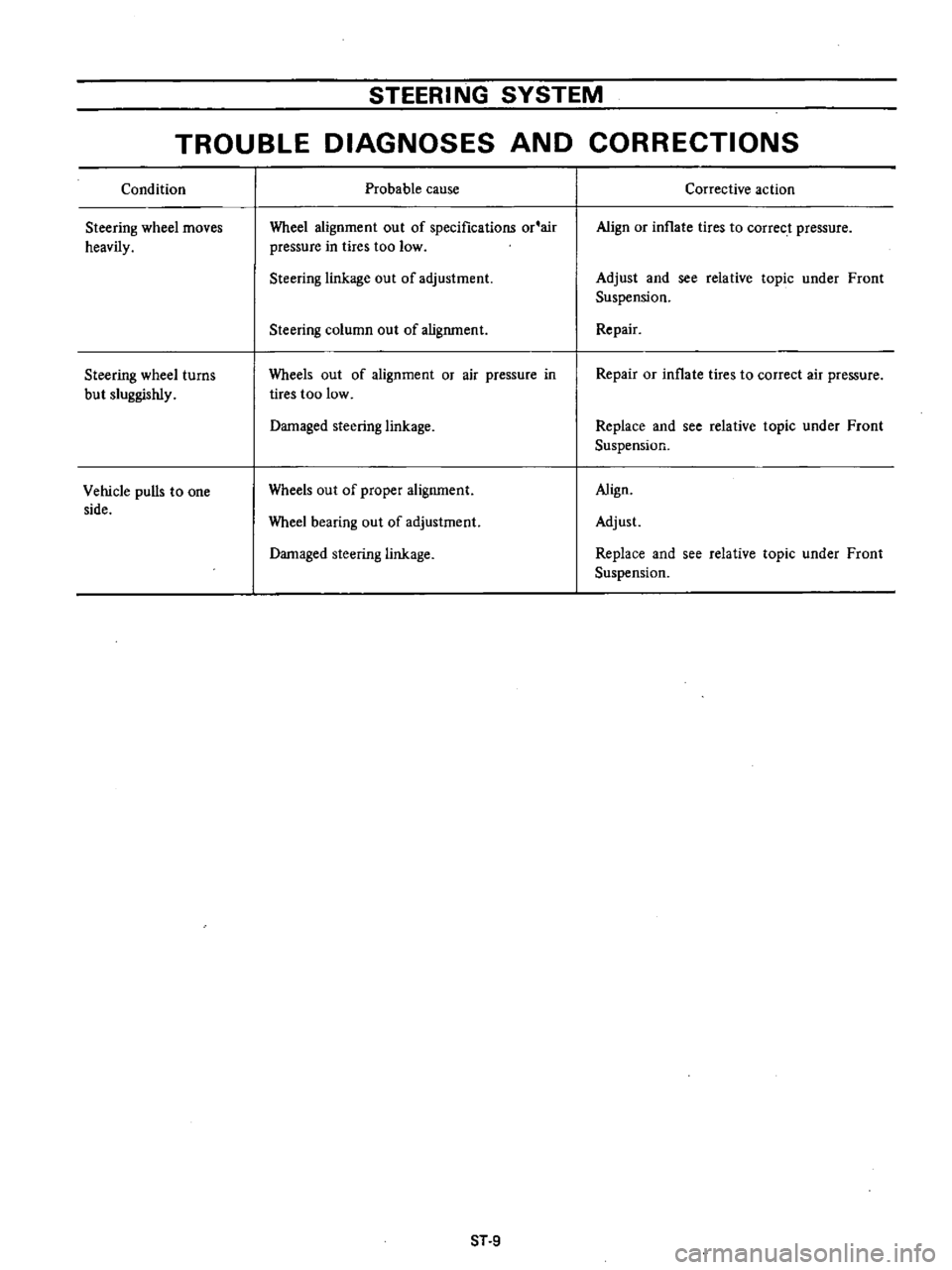

STEERING

SYSTEM

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Steering

wheel

moves

heavily

Steering

wheel

turns

but

sluggishly

Vehicle

pulls

to

one

side

Probable

cause

Wheel

alignment

out

of

specifications

or

air

pressure

in

tires

too

low

Steering

linkage

out

of

adjustment

Steering

column

out

of

alignment

Wheels

out

of

alignment

or

air

pressure

in

tires

too

low

Damaged

steering

linkage

Wheels

out

of

proper

alignment

Wheel

bearing

out

of

adjustment

Damaged

steering

linkage

ST

9

Corrective

action

Align

or

inflate

tires

to

correct

pressure

Adjust

and

see

relative

topic

under

Front

Suspension

Repair

Repair

or

inflate

tires

to

correct

air

pressure

Replace

and

see

relative

topic

under

Front

Suspension

Align

Adjust

Replace

and

see

relative

topic

under

Front

Suspension