brakes DODGE AVENGER 2008 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: AVENGER, Model: DODGE AVENGER 2008Pages: 467, PDF Size: 7.16 MB

Page 335 of 467

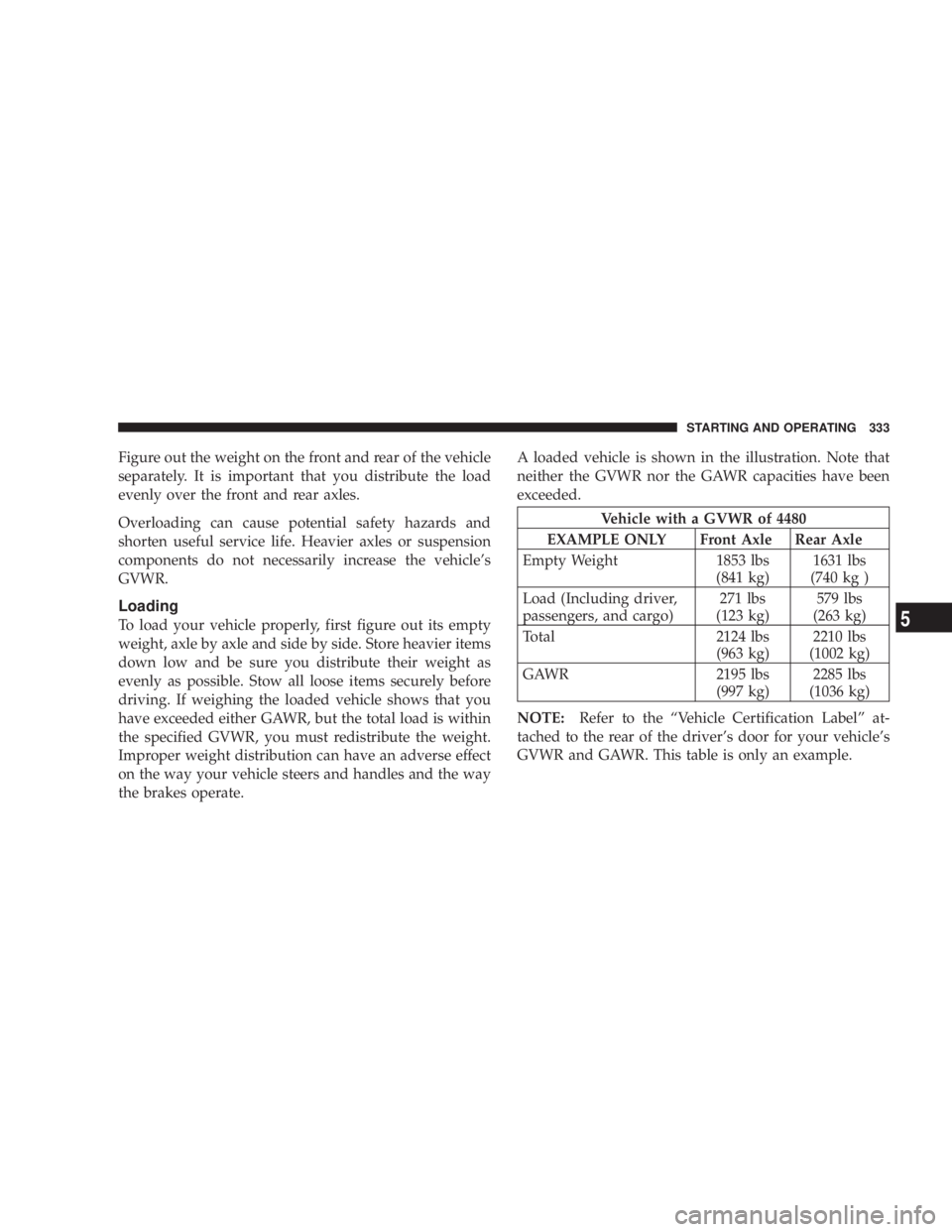

Figure out the weight on the front and rear of the vehicle

separately. It is important that you distribute the load

evenly over the front and rear axles.

Overloading can cause potential safety hazards and

shorten useful service life. Heavier axles or suspension

components do not necessarily increase the vehicle's

GVWR.

Loading

To load your vehicle properly, first figure out its empty

weight, axle by axle and side by side. Store heavier items

down low and be sure you distribute their weight as

evenly as possible. Stow all loose items securely before

driving. If weighing the loaded vehicle shows that you

have exceeded either GAWR, but the total load is within

the specified GVWR, you must redistribute the weight.

Improper weight distribution can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate. A loaded vehicle is shown in the illustration. Note that

neither the GVWR nor the GAWR capacities have been

exceeded.

Vehicle with a GVWR of 4480

EXAMPLE ONLY Front Axle Rear Axle

Empty Weight 1853 lbs

(841 kg) 1631 lbs

(740 kg )

Load (Including driver,

passengers, and cargo) 271 lbs

(123 kg) 579 lbs

(263 kg)

Total 2124 lbs

(963 kg) 2210 lbs

(1002 kg)

GAWR 2195 lbs

(997 kg) 2285 lbs

(1036 kg)

NOTE: Refer to the ªVehicle Certification Labelº at-

tached to the rear of the driver's door for your vehicle's

GVWR and GAWR. This table is only an example. STARTING AND OPERATING 333

5

Page 342 of 467

WARNING!Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and that it will not shift during travel. When traile-

ring cargo that is not fully secured, dynamic load

shifts can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

² When hauling cargo, or towing a trailer, do not

overload your vehicle or trailer. Overloading can cause

a loss of control, poor performance, or damage to

brakes, axle, engine, transaxle, steering, suspension,

chassis structure, or tires. ² Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

frame or hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

² Vehicles with trailers should not be parked on a grade.

When parking, apply the parking brake on the tow

vehicle. Put the tow vehicle automatic transaxle in

PARK. Always, block or 9 chock 9 the trailer wheels.

² GCWR must not be exceeded.

² Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded:

1. GVWR

2. GTW

3. GAWR340 STARTING AND OPERATING

Page 343 of 467

4. Trailer tongue weight rating for the trailer hitch

utilized (This requirement may limit the ability to

always achieve 10% of trailer tongue weight as a

percentage of total trailer weight).

Towing Requirements Ð Tires

² Do not attempt to tow a trailer while using a compact

spare tire.

² Proper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle. Refer to the

ªTires Ð General Informationº in this section for

information on tire pressures and for proper tire

inflation procedures.

² Also, check the trailer tires for proper tire inflation

pressures before trailer usage.

² Check for signs of tire wear or visible tire damage

before towing a trailer. Refer to ªTires Ð General Informationº in this section for information on tread

wear indicators and for proper inspection procedure.

² When replacing tires, refer to ªTires Ð General Infor-

mationº in this section for information on replacement

tires and for proper tire replacement procedures. Re-

placing tires with a higher load carrying capacity will

not increase the vehicle's GVWR and GAWR limits.

Towing Requirements Ð Trailer Brakes

² Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury.

² An electronically actuated trailer brake controller is

required when towing a trailer with electronically

actuated brakes. When towing a trailer equipped with

a hydraulic surge actuated brake system, an electronic

brake controller is not required. STARTING AND OPERATING 341

5

Page 344 of 467

² Trailer brakes are recommended for trailers over 1,000

lbs (450 kg) and required for trailers in excess of 2,000

lbs (907 kg).

CAUTION!If the trailer weighs more than 1,000 lbs (450 kg)

loaded, it should have its own brakes with adequate

braking capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances. WARNING!Do not connect trailer brakes to your vehicle's hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping dis-

tance. When towing, you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

Towing Requirements Ð Trailer Lights and Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

Use a factory approved trailer harness and connector.342 STARTING AND OPERATING

Page 397 of 467

WARNING!Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering Hoses

When servicing the vehicle for scheduled maintenance,

inspect the surface of the hoses and nylon tubing for

evidence of heat and mechanical damage. Hard and

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling suggest deterioration of the rubber. Particu-

lar attention should be made to examining those hose

surfaces nearest to high heat sources, such as the exhaust

manifold. Ensure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:

² Often, fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations

to ease the assembly of hoses to couplings. Therefore,

oil wetness at the hose-coupling area is not necessarily

an indication of leakage. Actual dripping of hot fluid

when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

² Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replaced MAINTAINING YOUR VEHICLE 395

7

Page 412 of 467

Cavity Car-

tridge

Fuse Mini

Fuse Description

33 Ð 10 Amp

Red Battery Feed Ð

Switch Bank/

Diagnostic Link

Connector/

Powertrain Control

Module (PCM)

34 30 Amp

Pink Ð Battery Feed Ð Anti-

Lock Brakes (ABS)

Module - if

equipped/Electronic

Stability Program

(ESP) Module - If

Equipped Cavity Car-

tridge

Fuse Mini

Fuse Description

35 40 Amp

Green Ð Battery Feed Ð Anti-

Lock Brakes (ABS)

Module - If

Equipped/Electronic

Stability Program

(ESP) Module - If

Equipped

36 30 Amp

Pink Ð Battery Feed Ð Pas-

senger Door Module

(PDM)/Driver Door

Module (DDM)

37 Ð 25 Amp

Clear Ð410 MAINTAINING YOUR VEHICLE

Page 447 of 467

Automatic Door Locks ..................... 32

Automatic Oil Change Indicator ........ 173,184,426

Automatic Temperature Control (ATC) ......... 246

Automatic Transaxle .............. 12,261,267,397

Adding Fluid ................... 397,398,424

Filter ............................... 399

Fluid and Filter Changes ................. 399

Fluid Level Check ................... 397,398

Interlock System ....................... 269

Reset Mode .......................... 273

Selection Of Lubricant ................... 424

Shifting ............................. 270

Special Additives ...................... 399

Autostick ............................. 274

Ball Joints ............................. 385

Battery ............................... 381

Gas Caution .......................... 381

Keyless Transmitter Replacement (RKE) ....... 26 Location ............................ 381

Bearings .............................. 400

Belts, Drive ............................ 378

Beverage Cooler ........................ 161

Body Mechanism Lubrication ............... 386

B-Pillar Location ........................ 295

Brake Assist System ...................... 282

Brake, Parking .......................... 276

Brake System ........................ 278,394

Anti-Lock (ABS) ....................... 279

Fluid Check ....................... 396,424

Hoses .............................. 395

Master Cylinder ....................... 396

Parking ............................. 276

Warning Light ........................ 179

Brakes ............................. 278,394

Brake/Transmission Interlock ............... 269

Break-In Recommendations, New Vehicle ........ 78

Bulb Replacement ..................... 41 1,412 INDEX 445

10

Page 456 of 467

Security Alarm (Theft Alarm) .............. 18

Theft Alarm (Security Alarm) .............. 171

Tire Pressure Monitoring (TPMS) ........... 310

Traction Control ....................... 284

Turn Signal .................. 130,133,176,416

Voltage ............................. 171

Warning (Instrument Cluster Description) ..... 170

Loading Vehicle ...................... 331,333

Capacities ........................... 333

Tires ............................... 295

Locks

Auto Unlock .......................... 32

Child Protection ........................ 34

Door ................................ 30

Power Door ........................... 32

Low Tire Pressure System .................. 310

Lower Anchors and Tether for CHildren (LATCH) .. 73

Lubrication, Body ....................... 386

Lumbar Support ........................ 122 Maintenance Free Battery .................. 381

Maintenance, General ..................... 374

Maintenance Procedures ................... 374

Maintenance Schedule .................... 426

Malfunction Indicator Light (Check Engine) . . 178,372

Manual, Service ......................... 440

Map/Reading Lights ..................... 129

Master Cylinder (Brakes) .................. 396

Methanol ............................. 321

Mini-Trip Computer ...................... 184

Mirrors ................................ 85

Automatic Dimming ..................... 86

Electric Powered ....................... 86

Outside .............................. 87

Rearview ............................. 85

Vanity ............................... 88

Modifications/Alterations, Vehicle ............. 7

Monitor, Tire Pressure System ............... 310

Mopar Parts ......................... 373,439454 INDEX