ECU DODGE CARAVAN 2004 4.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: CARAVAN, Model: DODGE CARAVAN 2004 4.GPages: 397, PDF Size: 6.83 MB

Page 274 of 397

Figure out the weight on the front and rear of the vehicle

separately. It is important that you distribute the load

evenly over the front and rear axles.

Overloading can cause potential safety hazards and

shorten useful service life. Heavier axles or suspension

components do not necessarily increase the vehicle's

GVWR.

Loading

To load your vehicle properly, first figure out its empty

weight, axle by axle and side by side. Store heavier items

down low and be sure you distribute their weight as

evenly as possible. Stow all loose items securely before

driving. If weighing the loaded vehicle shows that you

have exceeded either GAWR, but the total load is within

the specified GVWR, you must redistribute the weight.

Improper weight distribution can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.A loaded vehicle is shown in the illustration. Note that

neither the GVWR or the GAWR capacities have been

exceeded.

274 STARTING AND OPERATING

Page 286 of 397

properly engaged in the described location.Do not raise

the vehicle until you are sure the jack is securely

engaged.

5. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

6. Remove the wheel lug nuts, for vehicles with wheel

covers, remove the cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.7. Install the spare wheel, for vehicles with wheel covers,

align the notch in the wheel cover with the valve stem on

the wheel. Install the cover on the wheel by hand only

and install the wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the nuts. To

avoid the risk of forcing the vehicle off the jack, do not

tighten the lug nuts fully until the vehicle has been

lowered.

NOTE:Do not install the wheel cover on the compact

spare.

Do not use a hammer or force to install the wheel covers.

8. Lower the vehicle by turning the jack screw to the left.

9. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N´m (95 ft. lbs). If in doubt

286 WHAT TO DO IN EMERGENCIES

Page 287 of 397

about the correct tightness, have them checked with a

torque wrench by your dealer or at a service station.

10. Lower the jack to its fully closed position.

WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

11. Secure the flat or spare tire as follows:

²If your vehicle is equipped with cast aluminum

wheels, the center cap of the wheel must be re-

moved prior to flat tire stowage. Store the center cap

inside the glove box or other storage compartment.

²Turn the wheel so that the valve-stem is down. Slide

the wheel retainer through the center of the wheel

and position it properly across the wheel opening.

²For convenience in checking the spare tire inflation,

stow with the valve-stem toward the rear of the

vehicle.

²Using the jack-handle, rotate the drive nut to the

right until the wheel is drawn into place against the

underside of the vehicle.

²Continue to rotate the nut until you hear the mecha-

nism click three times. It cannot be overtightened.

Push against the tire several times to be sure it is

securely in place.

12. Stow jack and handle.

13. Check the tire pressure as soon as possible. Correct

pressure as required.

WHAT TO DO IN EMERGENCIES 287

6

Page 323 of 397

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of wear or damage that could cause failure.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Schedules.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering Hoses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, tears, cuts, abrasion, and excessive swelling

indicate deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.

MAINTAINING YOUR VEHICLE 323

7

Page 324 of 397

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:Often, fluid such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to facilitate the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation), should be noted before hose is re-

placed based on leakage.

NOTE:Inspection of brake hoses should be performed

whenever the brake system is serviced and every engine

oil change. Inspect hydraulic brake hoses for surface

cracking, scuffing, or worn spots. If there is any evidence

of cracking, scuffing, or worn spots, the hose should bereplaced immediately! Eventual deterioration of the hose

can take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder Ð ABS Brakes Brake Fluid Level

Check

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the brake system warning light indicates system failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

ªFULLº mark on the side of the master cylinder reservoir.

324 MAINTAINING YOUR VEHICLE

Page 339 of 397

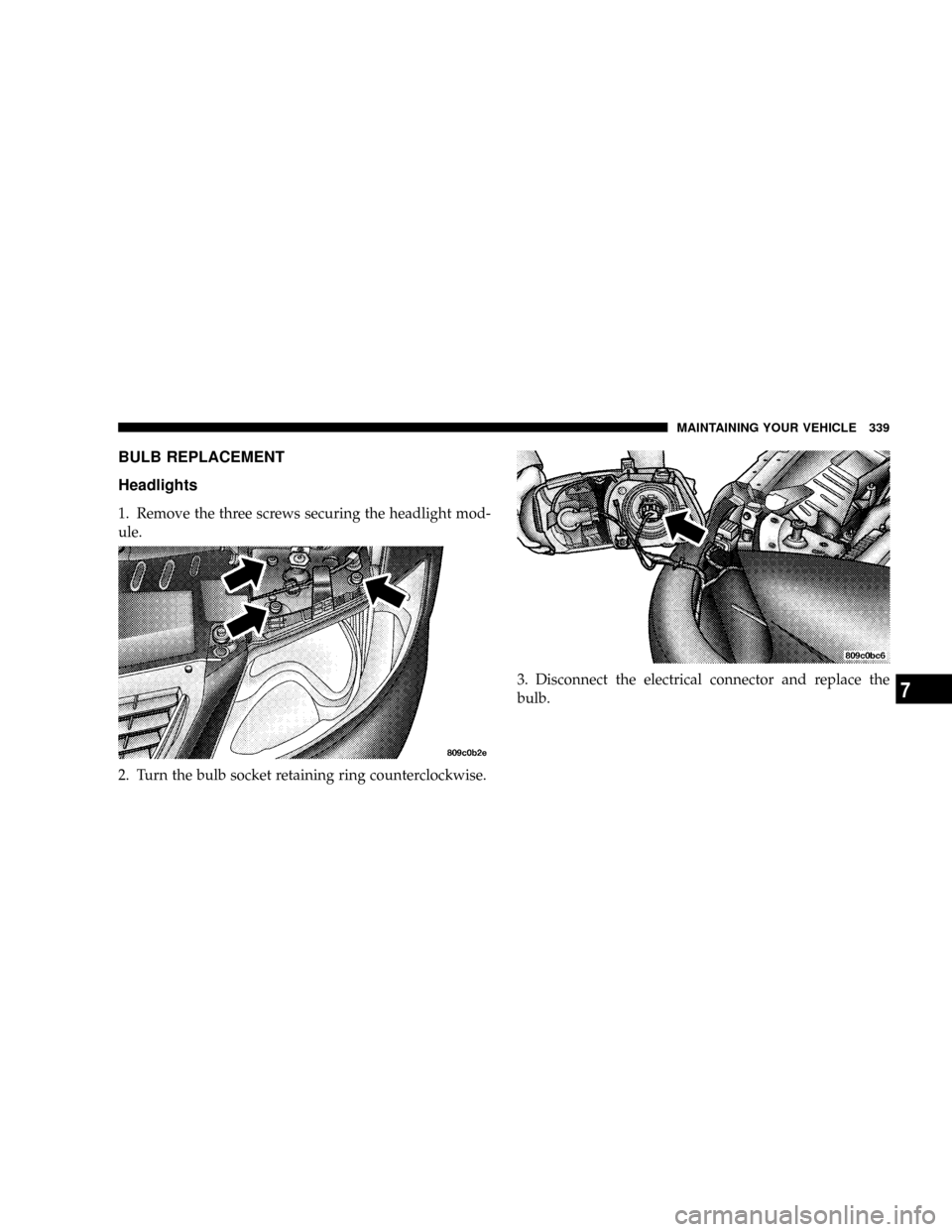

BULB REPLACEMENT

Headlights

1. Remove the three screws securing the headlight mod-

ule.

2. Turn the bulb socket retaining ring counterclockwise.3. Disconnect the electrical connector and replace the

bulb.

MAINTAINING YOUR VEHICLE 339

7

Page 340 of 397

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

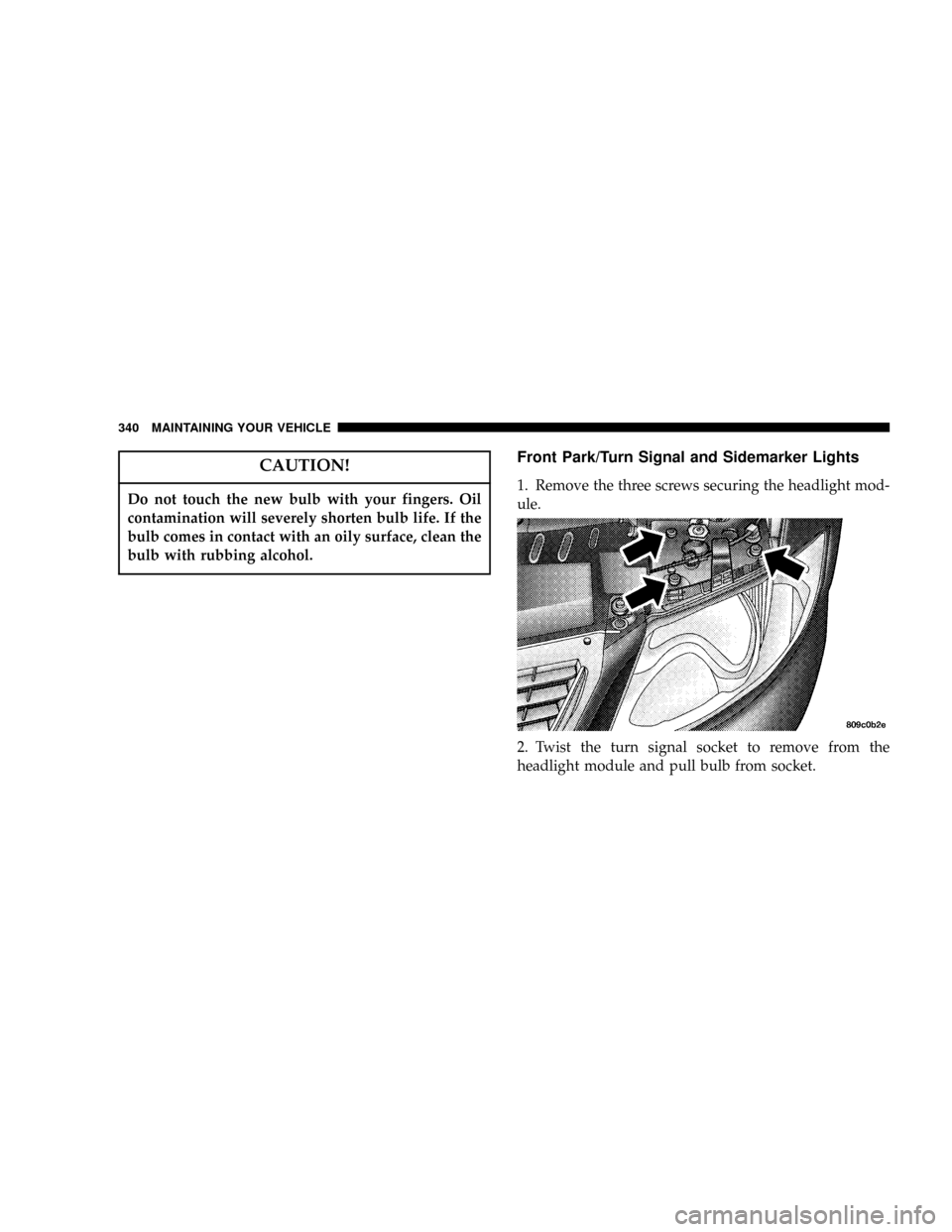

Front Park/Turn Signal and Sidemarker Lights

1. Remove the three screws securing the headlight mod-

ule.

2. Twist the turn signal socket to remove from the

headlight module and pull bulb from socket.

340 MAINTAINING YOUR VEHICLE

Page 343 of 397

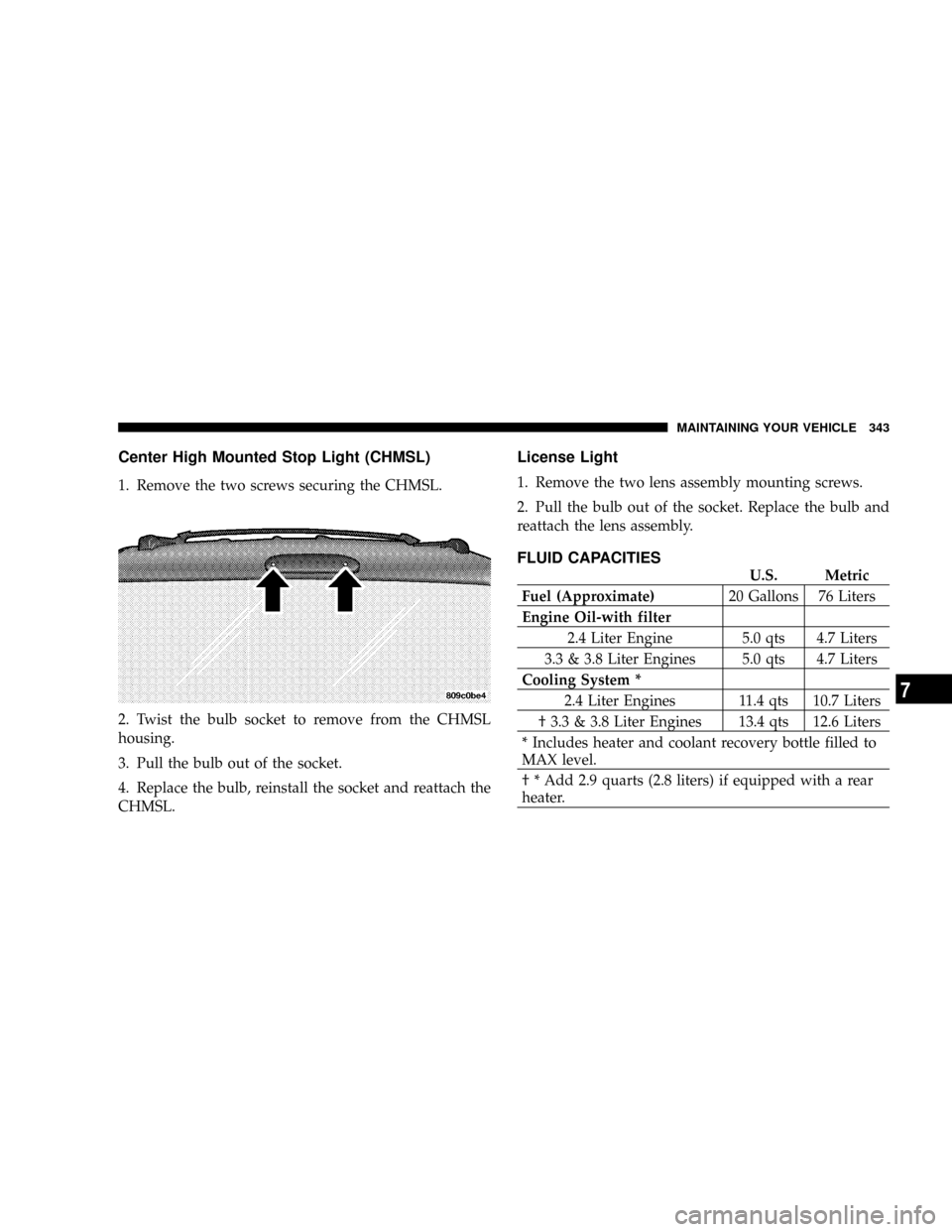

Center High Mounted Stop Light (CHMSL)

1. Remove the two screws securing the CHMSL.

2. Twist the bulb socket to remove from the CHMSL

housing.

3. Pull the bulb out of the socket.

4. Replace the bulb, reinstall the socket and reattach the

CHMSL.

License Light

1. Remove the two lens assembly mounting screws.

2. Pull the bulb out of the socket. Replace the bulb and

reattach the lens assembly.

FLUID CAPACITIES

U.S. Metric

Fuel (Approximate)20 Gallons 76 Liters

Engine Oil-with filter

2.4 Liter Engine 5.0 qts 4.7 Liters

3.3 & 3.8 Liter Engines 5.0 qts 4.7 Liters

Cooling System *

2.4 Liter Engines 11.4 qts 10.7 Liters

² 3.3 & 3.8 Liter Engines 13.4 qts 12.6 Liters

* Includes heater and coolant recovery bottle filled to

MAX level.

² * Add 2.9 quarts (2.8 liters) if equipped with a rear

heater.

MAINTAINING YOUR VEHICLE 343

7

Page 382 of 397

Adding Fuel........................... 270

Adding Washer Fluid..................221,316

Additives, Fuel......................... 268

Adjustable Pedals....................... 106

Air Conditioner Maintenance............... 312

Air Conditioning.....................199,203

Air Conditioning Controls................. 199

Air Conditioning Filter.................219,313

Air Conditioning, Operating Tips............ 218

Air Conditioning, Rear Zone.............206,214

Air Conditioning Refrigerant............... 312

Air Conditioning System..........199,203,208,312

Air Conditioning System, Zone Control........ 200

Air Pressure, Tires....................... 252

Airbag................................ 48

Airbag Deployment....................... 55

Airbag Light.....................52,57,72,152

Airbag Maintenance....................... 57

Airbag, Side............................ 54Alarm Light........................... 154

Alarm System........................... 26

Alignment and Balance................... 258

All Wheel Drive...................235,259,329

Alterations/Modifications, Vehicle............. 7

Antifreeze Disposal...................... 321

Antifreeze (Engine Coolant)..............319,320

Anti-Lock Brake System................... 237

Anti-Lock Warning Light.................. 153

Anti-Theft Security Alarm.................. 26

Appearance Care........................ 330

Ashtray............................... 130

Auto Down Power Windows................ 37

Automatic Dimming Mirror................. 77

Automatic Door Locks..................... 19

Automatic Headlights.................... 100

Automatic Temperature Control............. 208

Automatic Transaxle...................231,326

Adding Fluid......................... 345

382 INDEX

Page 390 of 397

Malfunction Indicator................... 155

Oil Pressure.......................... 155

Park.............................99,340

Passing............................. 103

Reading............................. 110

Rear Servicing........................ 342

Rear Tail............................ 342

Seat Belt Reminder..................... 153

Security Alarm........................ 154

Service...........................338,339

Service Engine Soon.................... 155

Side Marker.......................... 342

Theft Alarm.......................... 154

Turn Signal.....................102,340,342

Voltage............................. 153

Washer Fluid......................... 155

Load Leveling System.................... 141

Loading Vehicle...................135,272,274

Capacities........................... 274Tires ............................... 247

Locks

Door................................ 17

Lower Anchors and Tether for CHildren (LATCH) . 62

Lubrication, Body....................... 315

Luggage Rack.......................... 139

Lumbar Support......................... 84

Maintenance Free Battery.................. 311

Maintenance Procedures................... 303

Maintenance Schedule.................... 348

Light Duty Schedule9A9................. 363

Light Duty Schedule9B9................. 351

Schedule9A9......................... 363

Schedule9B9.......................... 351

Malfunction Indicator Light..............155,301

Manual, Service......................... 376

Mini-Trip Computer...................... 114

Mirrors................................ 77

390 INDEX