light DODGE CHALLENGER 2013 3.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2013, Model line: CHALLENGER, Model: DODGE CHALLENGER 2013 3.GPages: 543, PDF Size: 3.04 MB

Page 384 of 543

Materials Added To Fuel

All gasoline sold in the United States is required to

contain effective detergent additives. Use of additional

detergents or other additives is not needed under normal

conditions and they would result in additional cost.

Therefore, you should not have to add anything to the

fuel.

Fuel System Cautions

CAUTION!

Follow these guidelines to maintain your vehicle’s

performance:

•The use of leaded gas is prohibited by Federal law.

Using leaded gasoline can impair engine perfor-

mance and damage the emissions control system.

(Continued)

CAUTION! (Continued)

•An out-of-tune engine or certain fuel or ignition

malfunctions can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune

or malfunctioning and may require immediate ser-

vice. Contact your authorized dealer for service

assistance.

• The use of fuel additives, which are now being

sold as octane enhancers, is not recommended.

Most of these products contain high concentrations

of methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such

fuels or additives is not the responsibility of the

manufacturer.

NOTE: Intentional tampering with the emissions control

system can result in civil penalties being assessed against

you.

382 STARTING AND OPERATING

Page 386 of 543

NOTE:When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler door.

CAUTION!

• Damage to the fuel system or emissions control

system could result from using an improper fuel

tank filler tube cap (gas cap).

• A poorly fitting gas cap could let impurities into

the fuel system.

• A poorly fitting gas cap may cause the “Malfunc-

tion Indicator Light (MIL)” to turn on.

• To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling. When the fuel

nozzle “clicks” or shuts off, the fuel tank is full.

WARNING!

• Never have any smoking materials lit in or near the

vehicle when the gas cap is removed or the tank is

being filled.

(Continued)

Fuel Filler Cap

384 STARTING AND OPERATING

Page 394 of 543

WARNING!

•An improperly adjusted Weight Distributing Hitch

system may reduce handling, stability, braking

performance, and could result in a collision.

•

Weight Distributing Systems may not be compatible

with Surge Brake Couplers. Consult with your hitch

and trailer manufacturer or a reputable Recreational

Vehicle dealer for additional information.

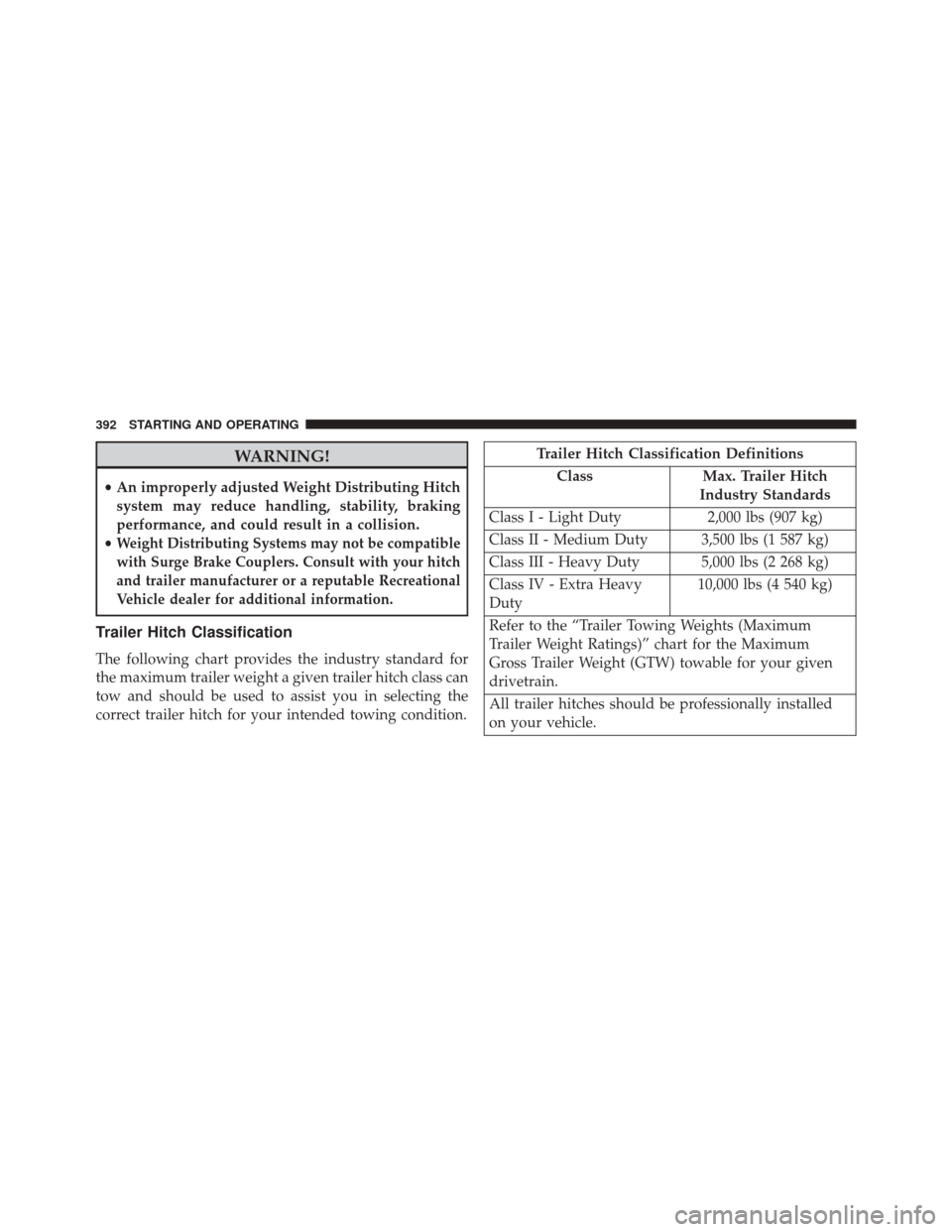

Trailer Hitch Classification

The following chart provides the industry standard for

the maximum trailer weight a given trailer hitch class can

tow and should be used to assist you in selecting the

correct trailer hitch for your intended towing condition.

Trailer Hitch Classification Definitions

Class Max. Trailer Hitch

Industry Standards

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium Duty 3,500 lbs (1 587 kg)

Class III - Heavy Duty 5,000 lbs (2 268 kg)

Class IV - Extra Heavy

Duty 10,000 lbs (4 540 kg)

Refer to the “Trailer Towing Weights (Maximum

Trailer Weight Ratings)” chart for the Maximum

Gross Trailer Weight (GTW) towable for your given

drivetrain.

All trailer hitches should be professionally installed

on your vehicle.

392 STARTING AND OPERATING

Page 401 of 543

Towing Requirements – Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-

pin wiring harness. Use a factory approved trailer har-

ness and connector.

NOTE:Do not cut or splice wiring into the vehicles

wiring harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following illustrations.

Four-Pin Connector

1 — Female Pins 4 — Park

2 — Male Pin 5 — Left Stop/Turn

3 — Ground 6 — Right Stop/Turn

5

STARTING AND OPERATING 399

Page 403 of 543

fluid and filter as specified for “police, taxi, fleet, or

frequent trailer towing.” Refer to the “Maintenance Sched-

ule” for the proper maintenance intervals.

Electronic Speed Control – If Equipped

•Do not use in hilly terrain or with heavy loads.

• When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

• Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

AutoStick®

• When using the AutoStick® shift control, select the

highest gear that allows for adequate performance and

avoids frequent downshifts. For example, choose “4” if

the desired speed can be maintained. Choose “3” or

“2” if needed to maintain the desired speed. •

To prevent excess heat generation, avoid continuous

driving at high RPM. Reduce vehicle speed as neces-

sary to avoid extended driving at high RPM. Return to

a higher gear or vehicle speed when grade and road

conditions allow.

Cooling System

To reduce potential for engine and transmission over-

heating, take the following actions:

City Driving

When stopped for short periods, shift the transmission

into NEUTRAL and increase engine idle speed.

Highway Driving

Reduce speed.

Air Conditioning

Turn off temporarily.

5

STARTING AND OPERATING 401

Page 428 of 543

•Refer to “Compact Spare Tire” and to “Limited-Use

Spare” under “Tires—General Information” in “Start-

ing and Operating” for additional warnings, cautions,

and information about the spare tire, its use, and

operation.

8. Install the lug nuts with the cone shaped end of the lug nut toward the wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

9. Lower the vehicle to the ground by turning the jack handle counterclockwise. 10. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. The correct tight-

ness of each lug nut is 110 ft-lb. (150 N·m). If in doubt

about the correct tightness, have them checked with

a torque wrench by your authorized dealer or at a

service station.

11. Stow the jack, tools and flat tire. Make sure the base of the jack faces the front of the vehicle before

tightening down the fastener.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

426 WHAT TO DO IN EMERGENCIES

Page 429 of 543

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shapedend of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise. 4. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. The correct tight-

ness of each lug nut is 110 ft-lbs (150 N·m). If in doubt

about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service

station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery it can be jump-

started using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump-starting can be dangerous if done improperly

so please follow the procedures in this section carefully.

6

WHAT TO DO IN EMERGENCIES 427

Page 446 of 543

ONBOARD DIAGNOSTIC SYSTEM — OBD II

Your vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the “Malfunction Indicator Light” (MIL). It

will also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your authorized dealer for service as

soon as possible.

CAUTION!

•Prolonged driving with the MIL on could cause

further damage to the emission control system. It

could also affect fuel economy and drivability. The

vehicle must be serviced before any emissions tests

can be performed.

• If the MIL is flashing while the engine is running,

severe catalytic converter damage and power loss

will soon occur. Immediate service is required.

444 MAINTAINING YOUR VEHICLE

Page 447 of 543

Loose Fuel Filler Cap

If the vehicle diagnostic system determines that the fuel

filler cap is loose, improperly installed, or damaged, a

”gASCAP” message will display in the odometer or a

“Check Gascap” message will display in the Electronic

Vehicle Information Center (EVIC) (if equipped). If this

occurs, tighten the fuel filler cap properly and press the

Trip Odometer button to turn off the message. If the

problem continues, the message will appear the next time

the vehicle is started.

A loose, improperly installed, or damaged fuel filler cap

may also turn on the MIL.

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass

an inspection of your vehicle’s emissions control system.

Failure to pass could prevent vehicle registration.For states that require an Inspection and Mainte-

nance (I/M), this check verifies the “Malfunction

Indicator Light (MIL)” is functioning and is not

on when the engine is running, and that the OBD II

system is ready for testing.

7

MAINTAINING YOUR VEHICLE 445

Page 471 of 543

•Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine coolant (antifreeze)

performance, poor gas mileage, and increased emis-

sions.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting or

riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You would not have your full

braking capacity in an emergency.

Master Cylinder – Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the brake system warning light indicates system fail-

ure.

Check the fluid level in the master cylinder when per-

forming underhood services.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the “MAX”

mark on the side of the master cylinder reservoir.

7

MAINTAINING YOUR VEHICLE 469