oil filter DODGE CHALLENGER 2020 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: CHALLENGER, Model: DODGE CHALLENGER 2020Pages: 396, PDF Size: 16.64 MB

Page 8 of 396

6

DEALER SERVICE .............................................. 252 Engine Oil ...................................................252

Engine Oil Filter .........................................255

Engine Air Cleaner Filter ...........................255

Air Conditioner Maintenance ....................257

Accessory Drive Belt Inspection................258Body Lubrication ........................................259

Windshield Wiper Blades ..........................259

Exhaust System .........................................261

Cooling System ........................................262

Brake System ............................................266

Clutch Hydraulic System — Manual

Transmission (If Equipped) .......................267 Manual Transmission — If Equipped ........267Automatic Transmission — If Equipped ....267

All Wheel Drive (AWD) — If Equipped .......268

Rear Axle ....................................................268

RAISING THE VEHICLE ...................................... 269

TIRES ................................................................... 269

Tire Safety Information .............................. 269

Tires — General Information .....................276Tire Types ...................................................280

Spare Tires — If Equipped .........................281

Wheel And Wheel Trim Care .....................283Tire Chains And Traction Devices —

Non-SRT......................................................284 Tire Chains And Traction Devices —

SRT .............................................................285 Tire Rotation Recommendations —

Non-SRT ..................................................... 285 Tire Rotation Recommendations —

SRT ............................................................ 285 Tire Rotation—Different Tire Size On

Front And Rear Axle ................................... 286

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES ................... 286

Treadwear .................................................. 286

Traction Grades ......................................... 286

Temperature Grades ................................. 287

VEHICLE STORAGE ...........................................287

BODYWORK ........................................................ 287

Protection From Atmospheric Agents ...... 287

Body And Underbody Maintenance .......... 288Preserving The Bodywork .......................... 288

INTERIORS ......................................................... 289

Seats And Fabric Parts .............................. 289

Plastic And Coated Parts ........................... 290

Leather Parts ............................................. 290

Glass Surfaces .......................................... 290

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA .......................................291Vehicle Identification Number .................. 291

BRAKE SYSTEM ................................................. 291 WHEEL AND TIRE TORQUE

SPECIFICATIONS .............................................. 291

Torque Specifications................................ 292

FUEL REQUIREMENTS ....................................... 293

3.6L Engine ................................................ 293

5.7L Engine (With Automatic

Transmission) ............................................ 293 5.7L Engine (With Manual

Transmission) ............................................ 293 6.2L Supercharged Engine ....................... 2946.4L Engine ................................................ 294

Reformulated Gasoline ............................. 294

Materials Added To Fuel ........................... 295

Gasoline/Oxygenate Blends ..................... 295

Do Not Use E-85 In Non-Flex Fuel

Vehicles ...................................................... 295 CNG And LP Fuel System

Modifications ............................................. 295 MMT In Gasoline........................................ 296

Fuel System Cautions................................ 296

Carbon Monoxide Warnings...................... 296

FLUID CAPACITIES — NON-SRT ........................ 297

FLUID CAPACITIES — SRT ................................. 298

FLUIDS AND LUBRICANTS — NON-SRT .......... 299

Engine ....................................................... 299

Chassis ................................................... 301

FLUIDS AND LUBRICANTS — SRT .................... 302

Engine ........................................................ 302

Chassis ....................................................... 304

20_LA_OM_EN_USC_t.book Page 6

Page 208 of 396

206IN CASE OF EMERGENCY

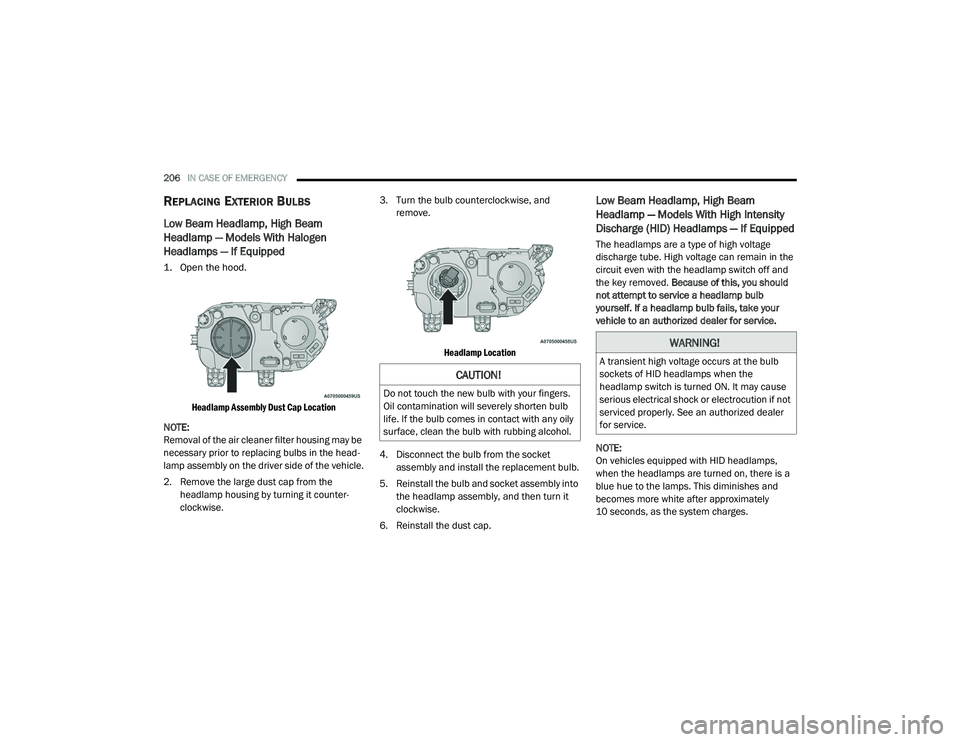

REPLACING EXTERIOR BULBS

Low Beam Headlamp, High Beam

Headlamp — Models With Halogen

Headlamps — If Equipped

1. Open the hood.

Headlamp Assembly Dust Cap Location

NOTE:

Removal of the air cleaner filter housing may be

necessary prior to replacing bulbs in the head -

lamp assembly on the driver side of the vehicle.

2. Remove the large dust cap from the headlamp housing by turning it counter -

clockwise. 3. Turn the bulb counterclockwise, and

remove.

Headlamp Location

4. Disconnect the bulb from the socket assembly and install the replacement bulb.

5. Reinstall the bulb and socket assembly into the headlamp assembly, and then turn it

clockwise.

6. Reinstall the dust cap.

Low Beam Headlamp, High Beam

Headlamp — Models With High Intensity

Discharge (HID) Headlamps — If Equipped

The headlamps are a type of high voltage

discharge tube. High voltage can remain in the

circuit even with the headlamp switch off and

the key removed. Because of this, you should

not attempt to service a headlamp bulb

yourself. If a headlamp bulb fails, take your

vehicle to an authorized dealer for service.

NOTE:

On vehicles equipped with HID headlamps,

when the headlamps are turned on, there is a

blue hue to the lamps. This diminishes and

becomes more white after approximately

10 seconds, as the system charges.

CAUTION!

Do not touch the new bulb with your fingers.

Oil contamination will severely shorten bulb

life. If the bulb comes in contact with any oily

surface, clean the bulb with rubbing alcohol.

WARNING!

A transient high voltage occurs at the bulb

sockets of HID headlamps when the

headlamp switch is turned ON. It may cause

serious electrical shock or electrocution if not

serviced properly. See an authorized dealer

for service.

20_LA_OM_EN_USC_t.book Page 206

Page 237 of 396

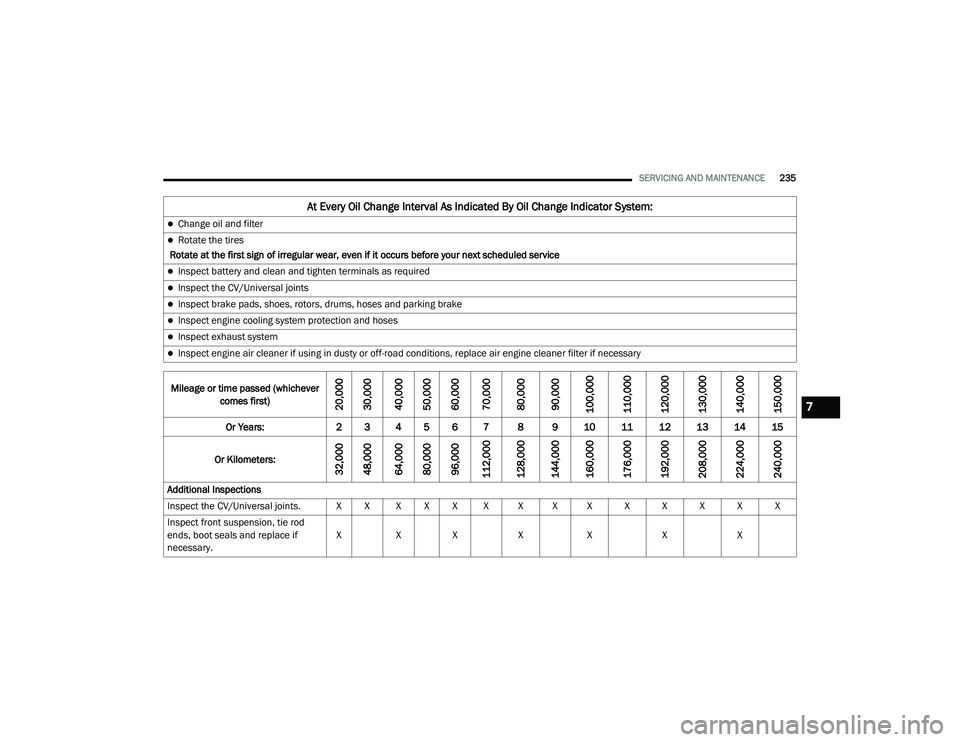

SERVICING AND MAINTENANCE235

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter

Rotate the tires

Rotate at the first sign of irregular wear, even if it occurs before your next scheduled service

Inspect battery and clean and tighten terminals as required

Inspect the CV/Universal joints

Inspect brake pads, shoes, rotors, drums, hoses and parking brake

Inspect engine cooling system protection and hoses

Inspect exhaust system

Inspect engine air cleaner if using in dusty or off-road conditions, replace air engine cleaner filter if necessary

Mileage or time passed (whichever comes first)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X

Inspect front suspension, tie rod

ends, boot seals and replace if

necessary. X

XX X X XX

7

20_LA_OM_EN_USC_t.book Page 235

Page 241 of 396

SERVICING AND MAINTENANCE239

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

6.2L SUPERCHARGED AND 6.4L

E

NGINES

The scheduled maintenance services listed in

this manual must be done at the times or

mileages specified to protect your vehicle

warranty and ensure the best vehicle

performance and reliability. More frequent

maintenance may be needed for vehicles in

severe operating conditions, such as dusty

areas and very short trip driving. Inspection and

service should also be done anytime a

malfunction is suspected.

The oil change indicator system will remind you

that it is time to take your vehicle in for

scheduled maintenance.

An “Oil Change Required” message will be

displayed in the instrument cluster and a single

chime will sound, indicating that an oil change

is necessary. Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

NOTE:

The oil change indicator message will not

monitor the time since the last oil change.

Change your vehicle's oil if it has been six

months since your last oil change, even if the

oil change indicator message is NOT illumi-

nated.

Change your engine oil more often if you drive

your vehicle off-road/track usage for an

extended period of time.

Under no circumstances should oil change

intervals exceed 6,000 miles (10,000 km) or

6 months, whichever comes first.

An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset by

referring to the steps described under

“Instrument Cluster Display” in “Getting To

Know Your Instrument Panel” for further

information. At Each Stop For Fuel

Check the engine oil level. Refer to “Engine

Compartment” in this chapter for further

information.

Check the windshield washer solvent and

add if required.

Once A Month

Check tire pressure and look for unusual

wear or damage.

Inspect the battery, and clean and tighten the

terminals as required.

Check the fluid levels of the coolant reservoir,

brake master cylinder and add as needed.

Check all lights and other electrical items for

correct operation.

At Each Oil Change

Change the engine oil filter.

Inspect the brake hoses and lines.

Inspect the CV/Universal joints.

CAUTION!

Failure to perform the required maintenance

items may result in damage to the vehicle.

7

20_LA_OM_EN_USC_t.book Page 239

Page 242 of 396

240SERVICING AND MAINTENANCE

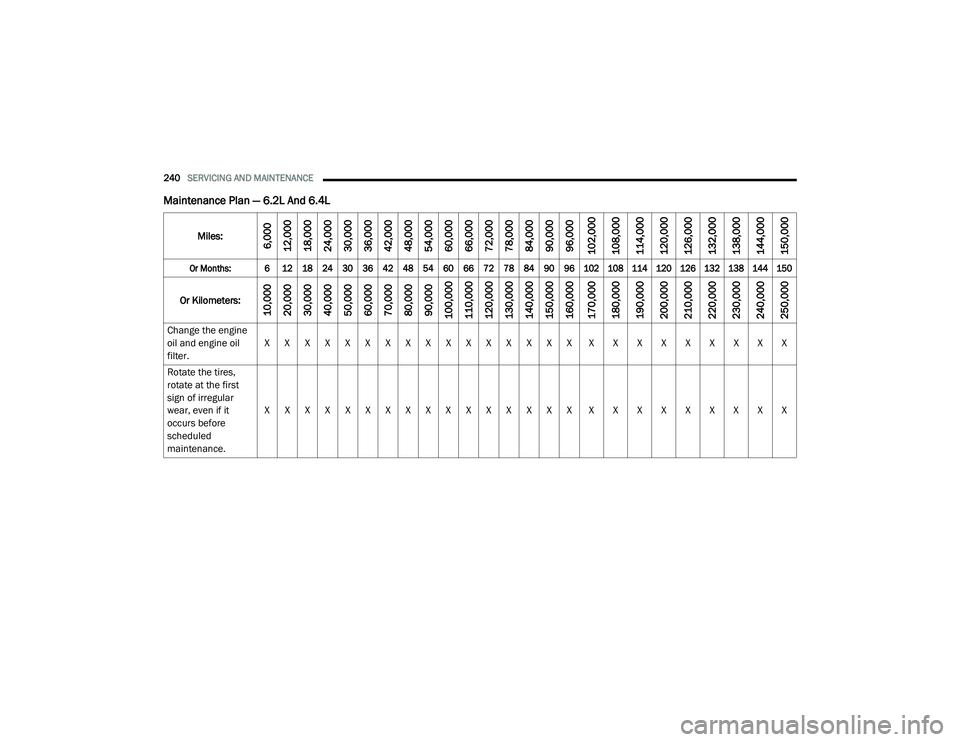

Maintenance Plan — 6.2L And 6.4L

Miles:6,000

12,000

18,000

24,000

30,000

36,000

42,000

48,000

54,000

60,000

66,000

72,000

78,000

84,000

90,000

96,000

102,000

108,000

114,000

120,000

126,000

132,000

138,000

144,000

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120 126 132 138 144 150

Or Kilometers:

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

160,000

170,000

180,000

190,000

200,000

210,000

220,000

230,000

240,000

250,000

Change the engine

oil and engine oil

filter. X X X X X X X X X X X X X X X X X X X X X X X X X

Rotate the tires,

rotate at the first

sign of irregular

wear, even if it

occurs before

scheduled

maintenance. X X X X X X X X

X X X X X X X X X X X X X X X X X

20_LA_OM_EN_USC_t.book Page 240

Page 248 of 396

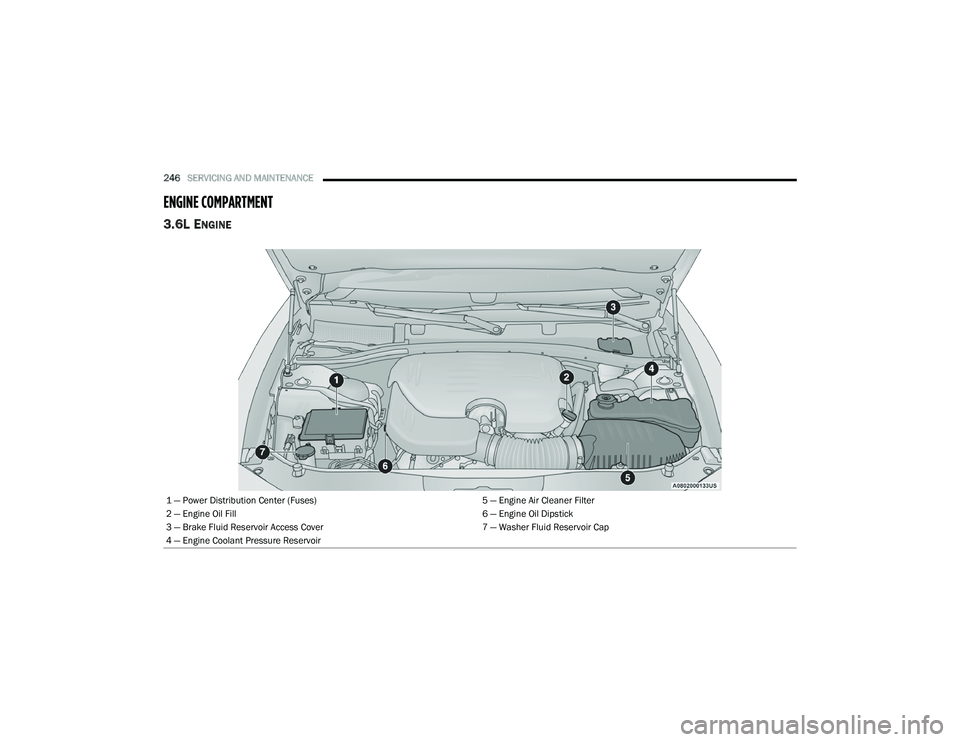

246SERVICING AND MAINTENANCE

ENGINE COMPARTMENT

3.6L ENGINE

1 — Power Distribution Center (Fuses) 5 — Engine Air Cleaner Filter

2 — Engine Oil Fill 6 — Engine Oil Dipstick

3 — Brake Fluid Reservoir Access Cover 7 — Washer Fluid Reservoir Cap

4 — Engine Coolant Pressure Reservoir

20_LA_OM_EN_USC_t.book Page 246

Page 249 of 396

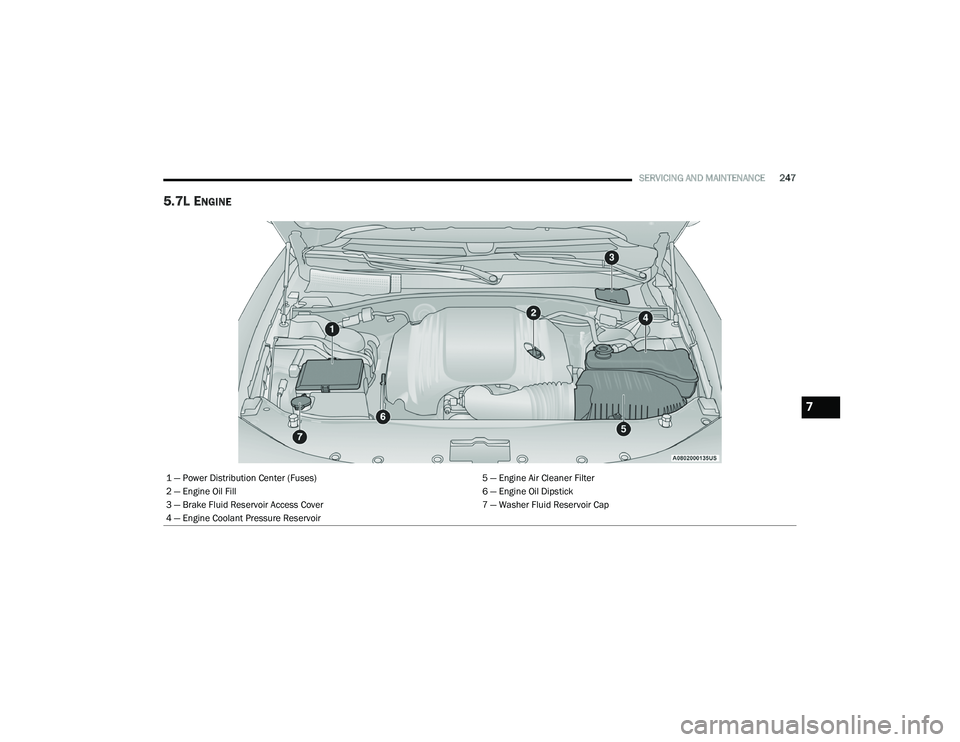

SERVICING AND MAINTENANCE247

5.7L ENGINE

1 — Power Distribution Center (Fuses) 5 — Engine Air Cleaner Filter

2 — Engine Oil Fill 6 — Engine Oil Dipstick

3 — Brake Fluid Reservoir Access Cover 7 — Washer Fluid Reservoir Cap

4 — Engine Coolant Pressure Reservoir

7

20_LA_OM_EN_USC_t.book Page 247

Page 250 of 396

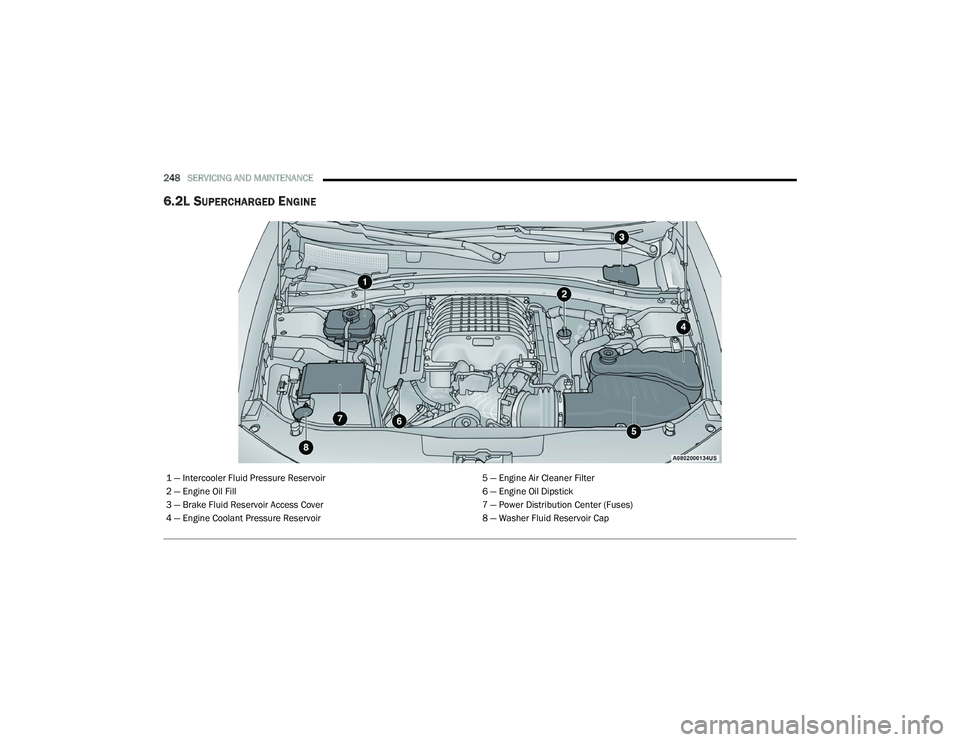

248SERVICING AND MAINTENANCE

6.2L SUPERCHARGED ENGINE

1 — Intercooler Fluid Pressure Reservoir 5 — Engine Air Cleaner Filter

2 — Engine Oil Fill 6 — Engine Oil Dipstick

3 — Brake Fluid Reservoir Access Cover 7 — Power Distribution Center (Fuses)

4 — Engine Coolant Pressure Reservoir 8 — Washer Fluid Reservoir Cap

20_LA_OM_EN_USC_t.book Page 248

Page 251 of 396

SERVICING AND MAINTENANCE249

6.4L ENGINE

1 — Power Distribution Center (Fuses) 5 — Engine Air Cleaner Filter

2 — Engine Oil Fill 6 — Engine Oil Dipstick

3 — Brake Fluid Reservoir Access Cover 7 — Washer Fluid Reservoir Cap

4 — Engine Coolant Pressure Reservoir

7

20_LA_OM_EN_USC_t.book Page 249

Page 256 of 396

254SERVICING AND MAINTENANCE

Engine Oil Viscosity (SAE Grade) — 5.7L

Engine

Mopar SAE 5W-20 engine oil approved to FCA

Material Standard MS-6395 such as Pennzoil,

Shell Helix Ultra or equivalent is recommended

for all operating temperatures. This engine oil

improves low temperature starting and vehicle

fuel economy.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to the “Engine Compartment”

illustration in this section.

NOTE:

Vehicles equipped with a 5.7L engine must use

SAE 5W-20 oil. Failure to do so may result in

improper operation of the Fuel Saver Tech -

nology. Refer to “Fuel Saver Technology – If

Equipped” in “Starting And Operating” for

further information.

Lubricants which do not have both the engine

oil certification mark and the correct SAE

viscosity grade number should not be used.

Engine Oil Viscosity — 6.2L And 6.4L

Engine

Use Pennzoil Ultra Platinum 0W-40 engine or

equivalent Mopar oil meeting the FCA Material

Standard MS-12633 for use in all operating

temperatures.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to “Engine Compartment” in this

section for further information.

Synthetic Engine Oils

You may use synthetic engine oils provided the

recommended oil quality requirements are met,

and the recommended maintenance intervals

for oil and filter changes are followed.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Shaker Hood — If Equipped

Shaker Hood Oil Filler

For vehicles equipped with a “Shaker Hood”,

the upper scoop will need to be removed so that

oil can be properly added to the engine. To do this, you will need follow the procedure

below:

1. Remove the four nuts with the Shaker tool

located in glove compartment.

2. Lift off the upper scoop.

NOTE:

Be sure to clean off all debris around or inside

for the Shaker assembly.

3. Locate the oil fill cover in base assembly to expose the oil fill cap.

4. Remove oil fill cap to add oil.

5. Re-install Shaker assembly.

Shaker Hood Air Filter Cleaning

1. Remove the air filter from the intake and set the filter clamp a side.

2. Measure the length of the filter media.

3. Fill a bucket with warm clean water to the depth matching the filter media

measurement and add a mild household

detergent or air filter cleaning solution.

4. Without allowing the solution to flow back into the inside of the air filter, submerge the

filter media in to the water and let it soak for

ten minutes.

20_LA_OM_EN_USC_t.book Page 254