Oil filter DODGE CHALLENGER 2021 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2021, Model line: CHALLENGER, Model: DODGE CHALLENGER 2021Pages: 328, PDF Size: 15 MB

Page 8 of 328

6

JUMP STARTING .................................................. 238 Preparations For Jump Start......................... 239Jump Starting Procedure .............................. 240

IF YOUR ENGINE OVERHEATS ........................... 241

MANUAL PARK RELEASE — 8 – SPEED

TRANSMISSION .................................................. 241

FREEING A STUCK VEHICLE ............................... 243

TOWING A DISABLED VEHICLE .......................... 244 Rear-Wheel Drive (RWD) Models.................. 245

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) .................................................................. 245

EVENT DATA RECORDER (EDR) ......................... 245

SERVICING AND MAINTENANCE

SCHEDULED SERVICING .................................... 246

3.6L And 5.7L Engines ................................. 246

ENGINE COMPARTMENT .................................... 251

3.6L Engine ................................................... 2515.7L Engine ................................................... 252Checking Oil Level ......................................... 253

Adding Washer Fluid ..................................... 253

Maintenance-Free Battery ............................ 254

Pressure Washing ......................................... 254 VEHICLE MAINTENANCE..................................... 254

Engine Oil ...................................................... 255

Engine Oil Filter ............................................. 256Engine Air Cleaner Filter .............................. 256Air Conditioner Maintenance ....................... 257

Accessory Drive Belt Inspection ................... 259Body Lubrication ........................................... 260Windshield Wiper Blades.............................. 260Exhaust System ............................................. 261Cooling System .............................................. 262

Brake System ............................................... 265

Clutch Hydraulic System — Manual

Transmission (If Equipped)........................... 266Manual Transmission — If Equipped............ 266

Automatic Transmission — If Equipped ....... 266

All Wheel Drive (AWD) — If Equipped .......... 267

Rear Axle ........................................................ 267Fuses.............................................................. 267

Bulb Replacement ........................................ 276 TIRES ..................................................................... 279

Tire Safety Information ................................ 279Tires — General Information ........................ 288Tire Types....................................................... 291Spare Tires — If Equipped ............................ 292

Wheel And Wheel Trim Care ........................ 294Snow Traction Devices.................................. 295Tire Rotation Recommendations ................. 296

DEPARTMENT OF TRANSPORTATION UNIFORM

TIRE QUALITY GRADES ...................................... 296

Treadwear...................................................... 297

Traction Grades ............................................. 297Temperature Grades..................................... 297

VEHICLE STORAGE .............................................. 298

BODYWORK .......................................................... 298 Protection From Atmospheric Agents .......... 298

Body And Underbody Maintenance ............. 298

Preserving The Bodywork ............................. 298

INTERIORS ........................................................... 299

Seats And Fabric Parts ................................. 299

Plastic And Coated Parts .............................. 299

Leather Surfaces........................................... 300

Glass Surfaces ............................................. 300

21_LA_OM_EN_USC_t.book Page 6

Page 249 of 328

SERVICING AND MAINTENANCE247

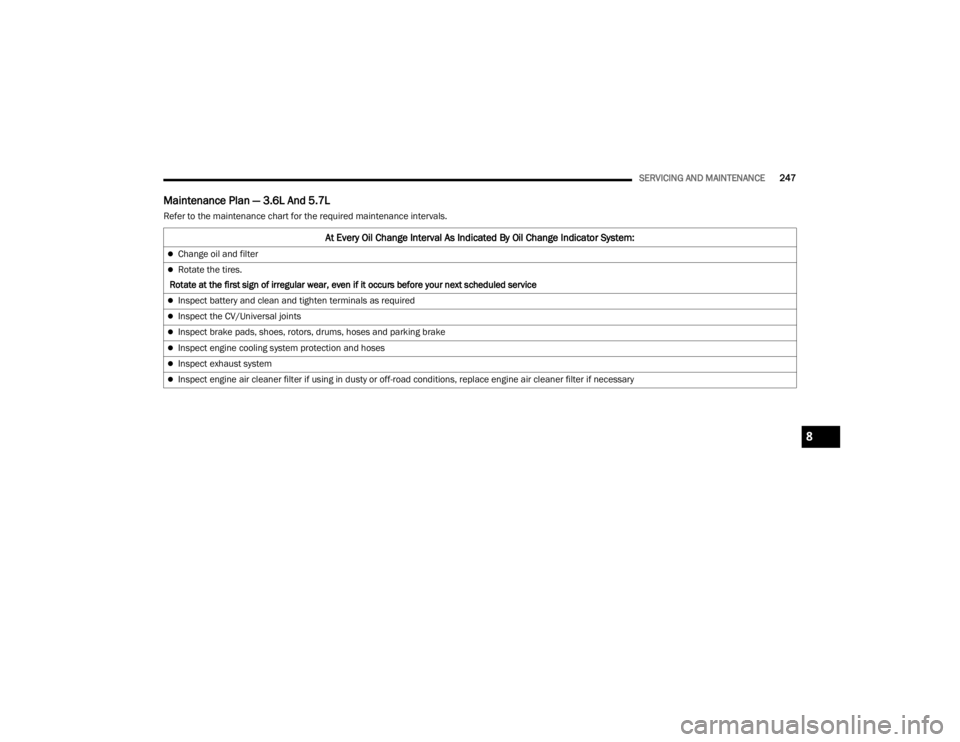

Maintenance Plan — 3.6L And 5.7L

Refer to the maintenance chart for the required maintenance intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter

Rotate the tires.

Rotate at the first sign of irregular wear, even if it occurs before your next scheduled service

Inspect battery and clean and tighten terminals as required

Inspect the CV/Universal joints

Inspect brake pads, shoes, rotors, drums, hoses and parking brake

Inspect engine cooling system protection and hoses

Inspect exhaust system

Inspect engine air cleaner filter if using in dusty or off-road conditions, replace engine air cleaner filter if necessary

8

21_LA_OM_EN_USC_t.book Page 247

Page 253 of 328

SERVICING AND MAINTENANCE251

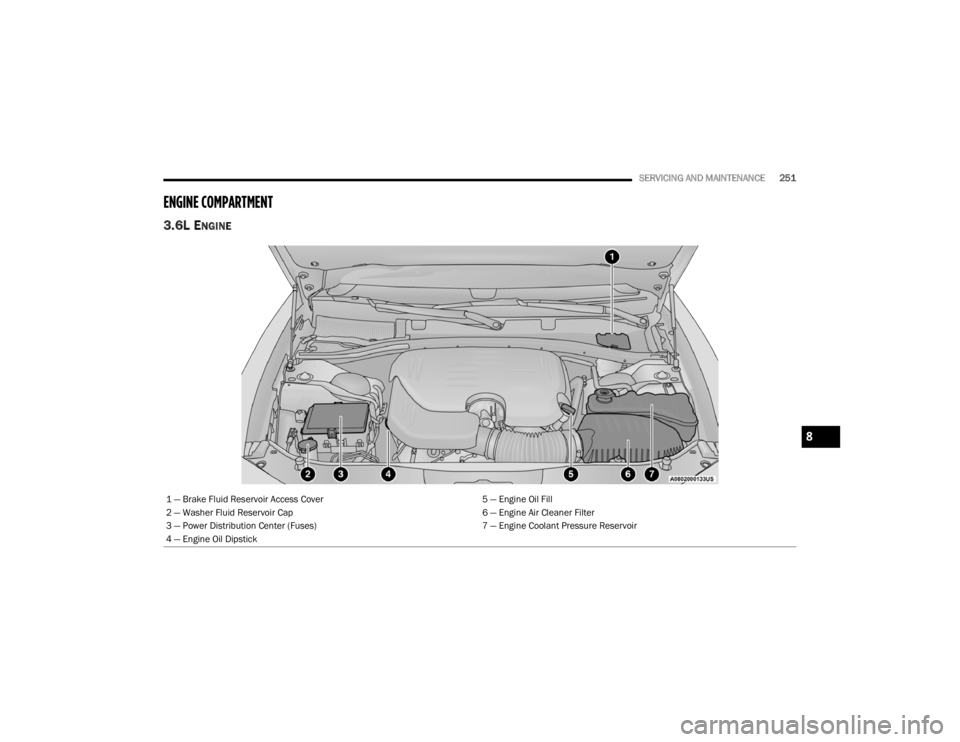

ENGINE COMPARTMENT

3.6L ENGINE

1 — Brake Fluid Reservoir Access Cover 5 — Engine Oil Fill

2 — Washer Fluid Reservoir Cap 6 — Engine Air Cleaner Filter

3 — Power Distribution Center (Fuses) 7 — Engine Coolant Pressure Reservoir

4 — Engine Oil Dipstick

8

21_LA_OM_EN_USC_t.book Page 251

Page 254 of 328

252SERVICING AND MAINTENANCE

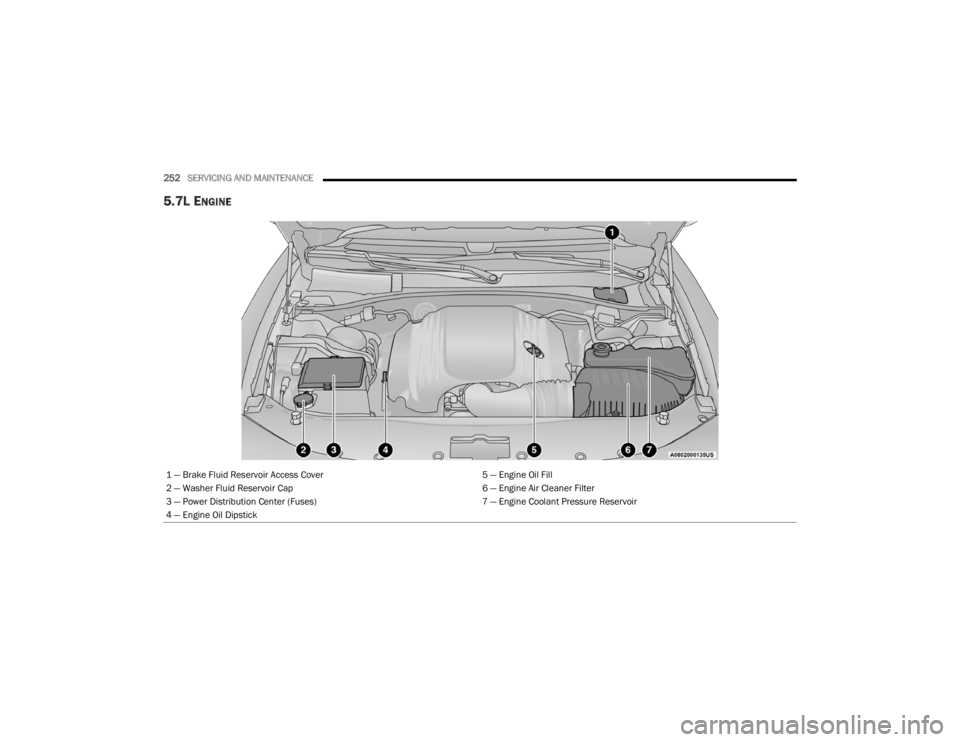

5.7L ENGINE

1 — Brake Fluid Reservoir Access Cover 5 — Engine Oil Fill

2 — Washer Fluid Reservoir Cap 6 — Engine Air Cleaner Filter

3 — Power Distribution Center (Fuses) 7 — Engine Coolant Pressure Reservoir

4 — Engine Oil Dipstick

21_LA_OM_EN_USC_t.book Page 252

Page 257 of 328

SERVICING AND MAINTENANCE255

NOTE:Intentional tampering with emissions control

systems may void your warranty and could result in

civil penalties being assessed against you.

ENGINE OIL

Engine Oil Selection — 3.6L And 5.7L

Engine

For best performance and maximum protection

under all types of operating conditions, the

manufacturer only recommends engine oils that

are API Certified and meet the requirements of the

manufacturer Material Standard MS-6395.

NOTE:Hemi engines (5.7L) at times can tick right after

startup and then quiet down after approximately

30 seconds. This is normal and will not harm the

engine. This characteristic can be caused by short

drive cycles: for example, if the vehicle is started

then shut off after driving a short distance. Upon

restarting, you may experience a ticking sound. Other causes could be if the vehicle is unused for

an extended period of time, incorrect oil, extended

oil changes or extended idling. If the engine

continues to tick or if the Malfunction Indicator

Light (MIL) comes on, see the nearest authorized

dealer.

American Petroleum Institute (API) Engine

Oil Identification Symbol

This symbol means that the oil has been

certified by the American Petroleum

Institute (API). The manufacturer only

recommends API Certified engine oils.

This symbol certifies 0W-20, 5W-20, 0W-30,

5W-30 and 10W-30 engine oils.

Synthetic Engine Oils

You may use synthetic engine oils provided the

recommended oil quality requirements are met,

and the recommended maintenance intervals for

oil and filter changes are followed.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Shaker Hood — If Equipped

Shaker Hood Oil Filler

For vehicles equipped with a “Shaker Hood”, the

upper scoop will need to be removed so that oil can

be properly added to the engine.

To do this, use the following procedure:

1. Remove the four nuts with the Shaker tool located in the glove compartment.

2. Lift off the upper scoop.

NOTE:Be sure to clean off all debris around or inside of

the Shaker assembly.

3. Locate the oil fill cover in base assembly to expose the oil fill cap.

4. Remove oil fill cap to add oil.

5. Reinstall Shaker assembly.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which

you have the knowledge and the proper

equipment. If you have any doubt about your

ability to perform a service job, take your vehicle

to a competent mechanic.

CAUTION!

Do not use chemical flushes in your engine oil as

the chemicals can damage your engine. Such

damage is not covered by the New Vehicle

Limited Warranty.

8

21_LA_OM_EN_USC_t.book Page 255

Page 258 of 328

256SERVICING AND MAINTENANCE

Shaker Hood Air Filter Cleaning

1. Remove the air filter from the intake and set the filter clamp aside.

2. Measure the length of the filter media.

3. Fill a bucket with warm clean water to the depth matching the filter media measurement

and add a mild household detergent or air

filter cleaning solution.

4. Without allowing the solution to flow back into the inside of the air filter, submerge the filter media in

to the water and let it soak for ten minutes.

5. Empty the bucket filled with dirty water and repeat steps 3 and 4.

6. Refill the bucket with clean warm water and rinse the filter by rotating the filter.

NOTE:The water should be clean with no signs of dirt in

the bucket.

7. Allow the filter to air dry. Reinstall the filter on the intake system once it is dry.

Shaker Hood Removal And Cleaning

1. Remove the four nuts with the Shaker tool located in glove compartment.

2. Lift off the upper scoop.

NOTE:Be sure to clean off all debris around or inside of

the Shaker assembly. 3. Using a water and mild detergent clean the

following locations:

The water drain slot located at the front

forward edge of the Shaker assembly.

The seals attached to the scoop and air box.

Lower water drains located in the lower

Shaker assembly and air box as well as the

hood interface areas for the seals. Apply

Mopar® Leather, Rubber & Vinyl Protectant

after cleaning the seals.

4. Reinstall Shaker assembly.

Materials Added To Engine Oil

The manufacturer strongly recommends against

the addition of any additives (other than leak

detection dyes) to the engine oil. Engine oil is an

engineered product and its performance may be

impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine

oil and oil filters from your vehicle. Used oil and oil

filters, indiscriminately discarded, can present a

problem to the environment. Contact an

authorized dealer, service station or governmental

agency for advice on how and where used oil and

oil filters can be safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new

filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used

for replacement. The quality of replacement filters

varies considerably. Only high quality Mopar®

certified filters should be used.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 247.

Engine Air Cleaner Filter Selection

The quality of replacement filters varies

considerably. Only high quality Mopar® certified

filters should be used.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in the

case of engine backfire. Do not remove the air

induction system (air cleaner, hoses, etc.) unless

such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle

with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in

serious personal injury.

21_LA_OM_EN_USC_t.book Page 256

Page 259 of 328

SERVICING AND MAINTENANCE257

T/A Air Filter Maintenance — If Equipped

Clean Engine Air Filter

The scheduled air filter cleaning interval is

30,000 miles (48,280 km), or if in a dusty

environment the engine air filter should be

checked periodically to ensure optimal air flow.

Cleaning your engine air filter with the

recommended Mopar® Performance Air Filter

Service Kit is not required if you can still see any

part the wire screen on the entire air filter

regardless of how dirty it may appear. When any

part of the wire screen is no longer visible on the air

filter, that is an indication it is time to clean the air

filter.

1. Spray the air filter with the recommended

Mopar® air filter cleaner and let sit for at

least 10 minutes to loosen dirt, before

rinsing.

NOTE:Never use strong detergents, high pressure, or

gasoline on air filter.

2. Rinse the air filter with cool low-pressure water applied from the inside (clean side) out in

order to flush the dirt out of the filter. Continue

to rinse the filter until all traces of the cleaner

have been removed.

NOTE:It may be necessary to repeat steps 1 and 2 if the

air filter is not completely clean.

3. After rinsing the air filter, gently shake off the excess water and allow air filter to dry

naturally. Do not apply oil until air filter is

completely dry.

NOTE:Do not use forced air pressure as it may damage

the filtering capabilities of the filter’s microfibers

and also void its warranty.

4. Using the Mopar® Performance Air Filter Service Kit, spray oil evenly along the crown of

each filter pleat holding the nozzle about

3 inches (76 mm) away from the air filter. One

spray per 2 square inches (1,290 square mm)

of air filter. With one complete coat of oil, let it

wick (saturate) for about 20 minutes, and if

required touch up any light areas on either

side of the filter.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner

should be checked and serviced by an authorized

dealer at the start of each warm season. This

service should include cleaning of the condenser

fins and a performance test. Drive belt tension

should also be checked at this time.

WARNING!

Use only refrigerants and compressor lubri -

cants approved by the manufacturer for your

air conditioning system. Some unapproved

refrigerants are flammable and can explode,

injuring you. Other unapproved refrigerants or

lubricants can cause the system to fail,

requiring costly repairs. Refer to Warranty

Information Book, for further warranty infor -

mation.

The air conditioning system contains refrig -

erant under high pressure. To avoid risk of

personal injury or damage to the system,

adding refrigerant or any repair requiring lines

to be disconnected should be done by an

experienced technician.

CAUTION!

Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning components. Such

damage is not covered by the New Vehicle

Limited Warranty.8

21_LA_OM_EN_USC_t.book Page 257

Page 260 of 328

258SERVICING AND MAINTENANCE

Refrigerant Recovery And Recycling

R-134a — If Equipped

R-134a Air Conditioning Refrigerant is a hydrofluo -

rocarbon (HFC) that is an ozone-friendly

substance. The manufacturer recommends that

air conditioning service be performed by an

authorized dealer or other service facilities using

recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil and refrigerants.

Refrigerant Recovery And Recycling

R-1234yf — If Equipped

R–1234yf Air Conditioning Refrigerant is a

hydrofluoroolefin (HFO) that is endorsed by the

Environmental Protection Agency and is an

ozone-friendly substance with a low

global-warming potential. The manufacturer

recommends that air conditioning service be

performed by an authorized dealer using recovery

and recycling equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil, and refrigerants.

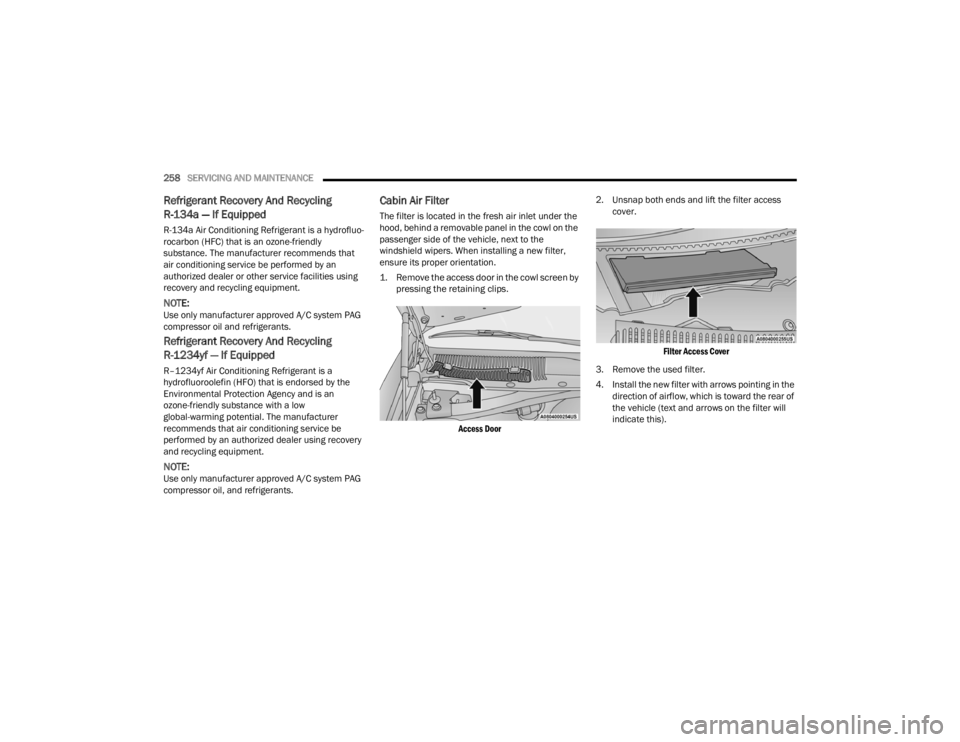

Cabin Air Filter

The filter is located in the fresh air inlet under the

hood, behind a removable panel in the cowl on the

passenger side of the vehicle, next to the

windshield wipers. When installing a new filter,

ensure its proper orientation.

1. Remove the access door in the cowl screen by pressing the retaining clips.

Access Door

2. Unsnap both ends and lift the filter access

cover.

Filter Access Cover

3. Remove the used filter.

4. Install the new filter with arrows pointing in the direction of airflow, which is toward the rear of

the vehicle (text and arrows on the filter will

indicate this).

21_LA_OM_EN_USC_t.book Page 258

Page 280 of 328

278SERVICING AND MAINTENANCE

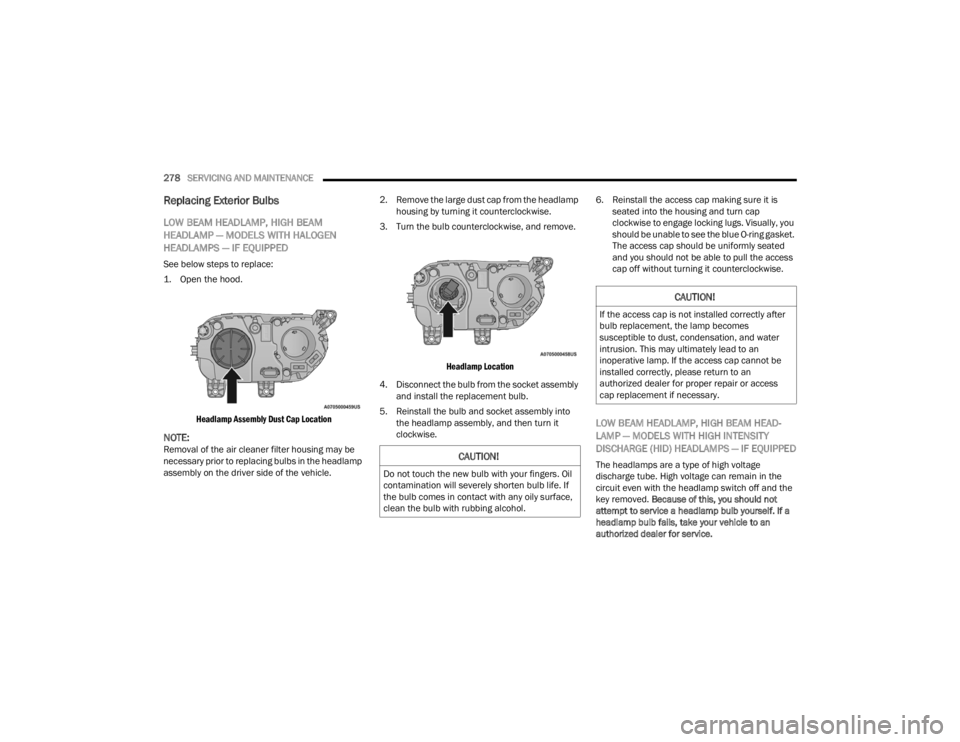

Replacing Exterior Bulbs

LOW BEAM HEADLAMP, HIGH BEAM

HEADLAMP — MODELS WITH HALOGEN

HEADLAMPS — IF EQUIPPED

See below steps to replace:

1. Open the hood.

Headlamp Assembly Dust Cap Location

NOTE:Removal of the air cleaner filter housing may be

necessary prior to replacing bulbs in the headlamp

assembly on the driver side of the vehicle. 2. Remove the large dust cap from the headlamp

housing by turning it counterclockwise.

3. Turn the bulb counterclockwise, and remove.

Headlamp Location

4. Disconnect the bulb from the socket assembly and install the replacement bulb.

5. Reinstall the bulb and socket assembly into the headlamp assembly, and then turn it

clockwise. 6. Reinstall the access cap making sure it is

seated into the housing and turn cap

clockwise to engage locking lugs. Visually, you

should be unable to see the blue O-ring gasket.

The access cap should be uniformly seated

and you should not be able to pull the access

cap off without turning it counterclockwise.

LOW BEAM HEADLAMP, HIGH BEAM HEAD -

LAMP — MODELS WITH HIGH INTENSITY

DISCHARGE (HID) HEADLAMPS — IF EQUIPPED

The headlamps are a type of high voltage

discharge tube. High voltage can remain in the

circuit even with the headlamp switch off and the

key removed. Because of this, you should not

attempt to service a headlamp bulb yourself. If a

headlamp bulb fails, take your vehicle to an

authorized dealer for service.CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If

the bulb comes in contact with any oily surface,

clean the bulb with rubbing alcohol.

CAUTION!

If the access cap is not installed correctly after

bulb replacement, the lamp becomes

susceptible to dust, condensation, and water

intrusion. This may ultimately lead to an

inoperative lamp. If the access cap cannot be

installed correctly, please return to an

authorized dealer for proper repair or access

cap replacement if necessary.

21_LA_OM_EN_USC_t.book Page 278

Page 307 of 328

TECHNICAL SPECIFICATIONS305

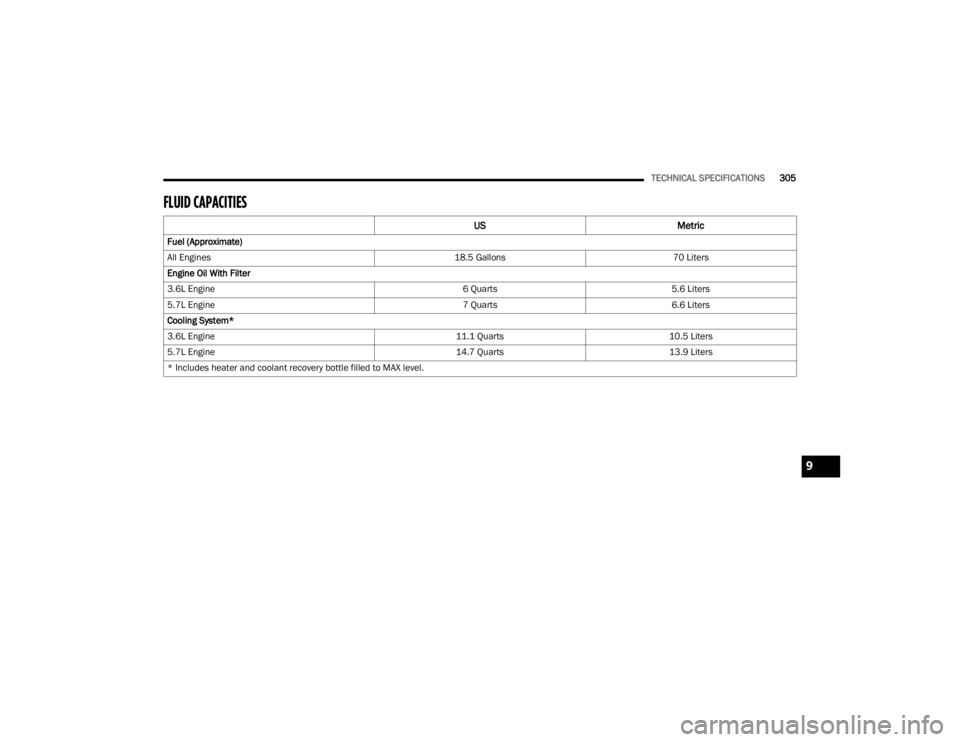

FLUID CAPACITIES

US Metric

Fuel (Approximate)

All Engines 18.5 Gallons70 Liters

Engine Oil With Filter

3.6L Engine 6 Quarts5.6 Liters

5.7L Engine 7 Quarts6.6 Liters

Cooling System*

3.6L Engine 11.1 Quarts10.5 Liters

5.7L Engine 14.7 Quarts13.9 Liters

* Includes heater and coolant recovery bottle filled to MAX level.

9

21_LA_OM_EN_USC_t.book Page 305