light DODGE CHALLENGER 2023 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: CHALLENGER, Model: DODGE CHALLENGER 2023Pages: 300, PDF Size: 12.82 MB

Page 235 of 300

SERVICING AND MAINTENANCE233

3. Using water and mild detergent, clean the following

locations:

The water drain slot located at the front forward

edge of the Shaker assembly.

The seals attached to the scoop and air box.

Lower water drains located in the lower Shaker

assembly and air box as well as the hood interface

areas for the seals. Apply Mopar® Leather,

Rubber & Vinyl Protectant after cleaning the seals.

4. Reinstall Shaker assembly.

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product and

its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service

station or governmental agency for advice on how and

where used oil and oil filters can be safely discarded in

your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used for

replacement. The quality of replacement filters varies

considerably. Only high quality Mopar® certified filters

should be used. If a Mopar® Engine Oil Filter is

unavailable, only use filters that meet or exceed

SAE/USCAR-36 Filter Performance Requirements.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 224.

NOTE:Be sure to follow the “Severe Duty Conditions” mainte -

nance interval if applicable. Engine Air Cleaner Filter Selection

The quality of replacement filters varies considerably. Only

high quality Mopar® certified filters should be used.

T/A Air Filter Maintenance — If Equipped

Clean Engine Air Filter

T/A air filters are made of a unique, washable material.

Follow the recommended service interval as for non-T/A

air filters, substituting a cleaning for replacement.

Cleaning your engine air filter with the recommended

Mopar® Performance Air Filter Service Kit is not required

if you can still see any part of the wire screen on the entire

air filter regardless of how dirty it may appear. When any

part of the wire screen is no longer visible on the air filter,

that is an indication it is time to clean the air filter.

For cleaning instructions see steps 1-7 from the Shaker

Hood Air Filter Cleaning section

Úpage 232.

Unique for T/A, using the Mopar® Performance Air Filter

Service Kit, spray oil evenly along the crown of each filter

pleat holding the nozzle about 3 inches (76 mm) away

from the air filter. One spray per 2 square inches

(1,290 square mm) of air filter. With one complete coat of

oil, let it wick (saturate) for about 20 minutes, and if

required touch up any light areas on either side of the

filter.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc.) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in serious

personal injury.

8

23_LA_OM_EN_USC_t.book Page 233

Page 242 of 300

240SERVICING AND MAINTENANCE

BRAKE SYSTEM

In order to ensure brake system performance, all brake

system components should be inspected periodically

Úpage 224.

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder immediately if

the Brake System Warning Light indicates system failure.

Check the fluid level in the master cylinder when

performing underhood services.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the requirements

described on the brake fluid reservoir. With disc brakes,

fluid level can be expected to fall as the brake pads wear.

However, low fluid level may be caused by a leak and a

checkup may be needed. Use only brake fluid that has been recommended by the

manufacturer, and has been kept in a tightly closed

container to avoid contamination from foreign matter or

moisture

Úpage 278.

CLUTCH HYDRAULIC SYSTEM — MANUAL

T

RANSMISSION (IF EQUIPPED)

The clutch hydraulic system is fed by a segregated volume

of fluid within the brake system master cylinder reservoir.

In the event of leakage or wear, use only the

manufacturer's recommended brake fluid

Úpage 278.

MANUAL TRANSMISSION — IF EQUIPPED

Fluid Level Check

Check the fluid level by removing the fill plug on the left

side of the transmission. The fluid level should be

1/4 inch (6.4mm) below the bottom of the fill hole.

Add fluid, if necessary, to maintain the proper level

Úpage 278.

Change Transmission Fluid

If contaminated with water, change the fluid immediately.

See an authorized dealer for service.

For the proper maintenance intervals

Úpage 224.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on the

brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

Use only manufacturer's recommended brake fluid Úpage 278. Using the wrong type of brake fluid can

severely damage your brake system and/or impair its

performance. The proper type of brake fluid for your

vehicle is also identified on the original factory

installed hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in a open container absorbs moisture from the

air resulting in a lower boiling point. This may cause

it to boil unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This could

result in a collision.

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

CAUTION!

Using a transmission fluid other than the

manufacturer's recommended fluid may cause

deterioration in transmission shift quality and/or

damage to the transmission

Úpage 278.

23_LA_OM_EN_USC_t.book Page 240

Page 243 of 300

SERVICING AND MAINTENANCE241

AUTOMATIC TRANSMISSION —

I

F EQUIPPED

Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic

Transmission Fluid (ATF) is an engineered product and its

performance may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the

transmission. Avoid using transmission sealers as they

may adversely affect seals.

Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required; therefore the

transmission has no dipstick. An authorized dealer can

check your transmission fluid level using special service

tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer immediately to

have the transmission fluid level checked. Operating the

vehicle with an improper fluid level can cause severe

transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid installed at

the factory will provide satisfactory lubrication for the life

of the vehicle.

Routine fluid and filter changes are not required. However,

change the fluid and filter if the fluid becomes

contaminated (with water, etc.), or if the transmission is

disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid to

ensure optimum transmission performance and life. Use

only the manufacturer's specified transmission fluid

Úpage 278. It is important to maintain the transmission

fluid at the correct level using the recommended fluid.

NOTE:No chemical flushes should be used in any transmission;

only the approved lubricant should be used.

ALL-WHEEL DRIVE (AWD) —

I

F EQUIPPED

The All-Wheel Drive system consists of a transfer case and

front differential. The exterior surface of these components

should be inspected for evidence of fluid leaks. Confirmed

leaks should be repaired as soon as possible.

The transfer case fluid fill/inspection plug is located in the

middle of the rear housing. To inspect the transfer case fluid

level, remove the fill/inspection plug. The fluid level should

be even with the bottom of the hole. Use this plug to add

fluid as required.

The front differential fill plug is located on the outer cover

near the half shaft attachment. To inspect the differential

fluid level, remove the fill plug. The fluid level should be

even with or slightly below the bottom of the hole.

Fluid Changes

For the proper maintenance intervals Úpage 223.

REAR AXLE

Fluid Level Check

Checking the fluid level while the vehicle is on level ground

and has been stationary for 15 minutes will improve the

accuracy of the fluid level reading.

Check the fluid level by removing the fill plug on the axle.

The fluid level should be 1-2.5 mm below the fill plug. Add

fluid, if necessary, to maintain the proper level

Ú

page 278.

Change Axle Fluid

For the proper maintenance intervals Úpage 223.

CAUTION!

Do not use chemical flushes in your transmission as the

chemicals can damage your transmission components.

Such damage is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an authorized

dealer immediately. Severe transmission damage may

occur. An authorized dealer has the proper tools to

adjust the fluid level accurately.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or torque

converter shudder

Úpage 278.

8

23_LA_OM_EN_USC_t.book Page 241

Page 248 of 300

246SERVICING AND MAINTENANCE

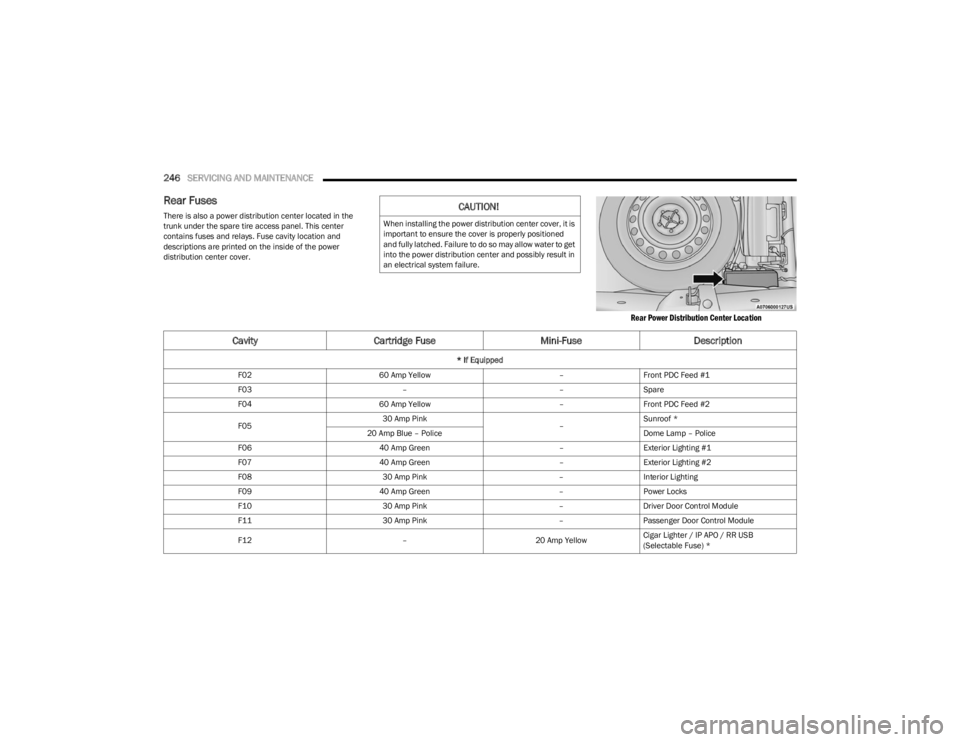

Rear Fuses

There is also a power distribution center located in the

trunk under the spare tire access panel. This center

contains fuses and relays. Fuse cavity location and

descriptions are printed on the inside of the power

distribution center cover.

Rear Power Distribution Center Location

CAUTION!

When installing the power distribution center cover, it is

important to ensure the cover is properly positioned

and fully latched. Failure to do so may allow water to get

into the power distribution center and possibly result in

an electrical system failure.

CavityCartridge Fuse Mini-FuseDescription

* If Equipped

F02 60 Amp Yellow –Front PDC Feed #1

F03 ––Spare

F04 60 Amp Yellow –Front PDC Feed #2

F05 30 Amp Pink

–Sunroof *

20 Amp Blue – Police Dome Lamp – Police

F06 40 Amp Green –Exterior Lighting #1

F07 40 Amp Green –Exterior Lighting #2

F08 30 Amp Pink –Interior Lighting

F09 40 Amp Green –Power Locks

F10 30 Amp Pink –Driver Door Control Module

F11 30 Amp Pink –Passenger Door Control Module

F12 –20 Amp YellowCigar Lighter / IP APO / RR USB

(Selectable Fuse) *

23_LA_OM_EN_USC_t.book Page 246

Page 250 of 300

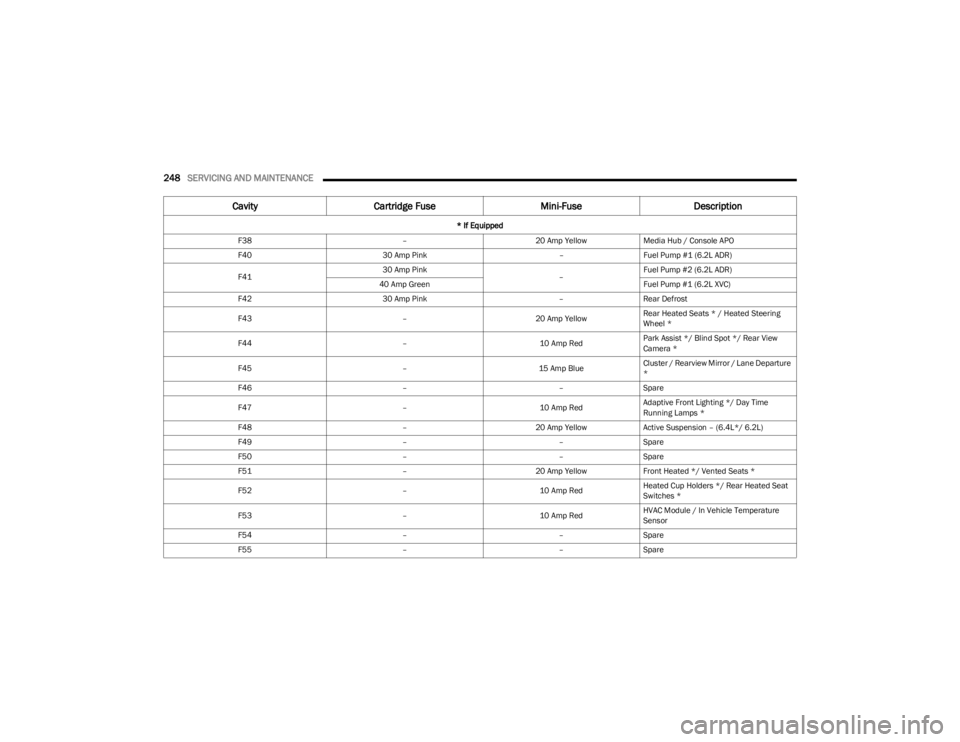

248SERVICING AND MAINTENANCE

F38 –20 Amp YellowMedia Hub / Console APO

F40 30 Amp Pink –Fuel Pump #1 (6.2L ADR)

F41 30 Amp Pink

–Fuel Pump #2 (6.2L ADR)

40 Amp Green Fuel Pump #1 (6.2L XVC)

F42 30 Amp Pink –Rear Defrost

F43 –20 Amp YellowRear Heated Seats * / Heated Steering

Wheel *

F44 –10 Amp RedPark Assist */ Blind Spot */ Rear View

Camera *

F45 –15 Amp BlueCluster / Rearview Mirror / Lane Departure

*

F46 ––Spare

F47 –10 Amp RedAdaptive Front Lighting */ Day Time

Running Lamps *

F48 –20 Amp YellowActive Suspension – (6.4L*/ 6.2L)

F49 ––Spare

F50 ––Spare

F51 –20 Amp YellowFront Heated */ Vented Seats *

F52 –10 Amp RedHeated Cup Holders */ Rear Heated Seat

Switches *

F53 –10 Amp RedHVAC Module / In Vehicle Temperature

Sensor

F54 ––Spare

F55 ––Spare

Cavity Cartridge Fuse Mini-FuseDescription

* If Equipped

23_LA_OM_EN_USC_t.book Page 248

Page 251 of 300

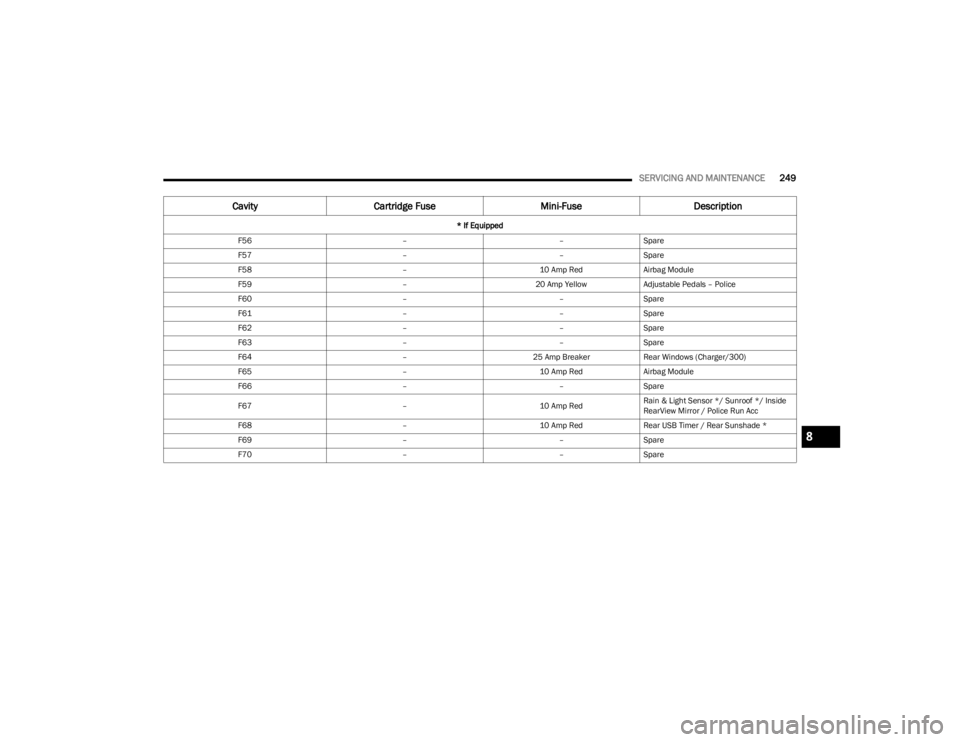

SERVICING AND MAINTENANCE249

F56 ––Spare

F57 ––Spare

F58 –10 Amp RedAirbag Module

F59 –20 Amp YellowAdjustable Pedals – Police

F60 ––Spare

F61 ––Spare

F62 ––Spare

F63 ––Spare

F64 –25 Amp BreakerRear Windows (Charger/300)

F65 –10 Amp RedAirbag Module

F66 ––Spare

F67 –10 Amp RedRain & Light Sensor */ Sunroof */ Inside

RearView Mirror / Police Run Acc

F68 –10 Amp RedRear USB Timer / Rear Sunshade *

F69 ––Spare

F70 ––Spare

Cavity Cartridge Fuse Mini-FuseDescription

* If Equipped

8

23_LA_OM_EN_USC_t.book Page 249

Page 252 of 300

250SERVICING AND MAINTENANCE

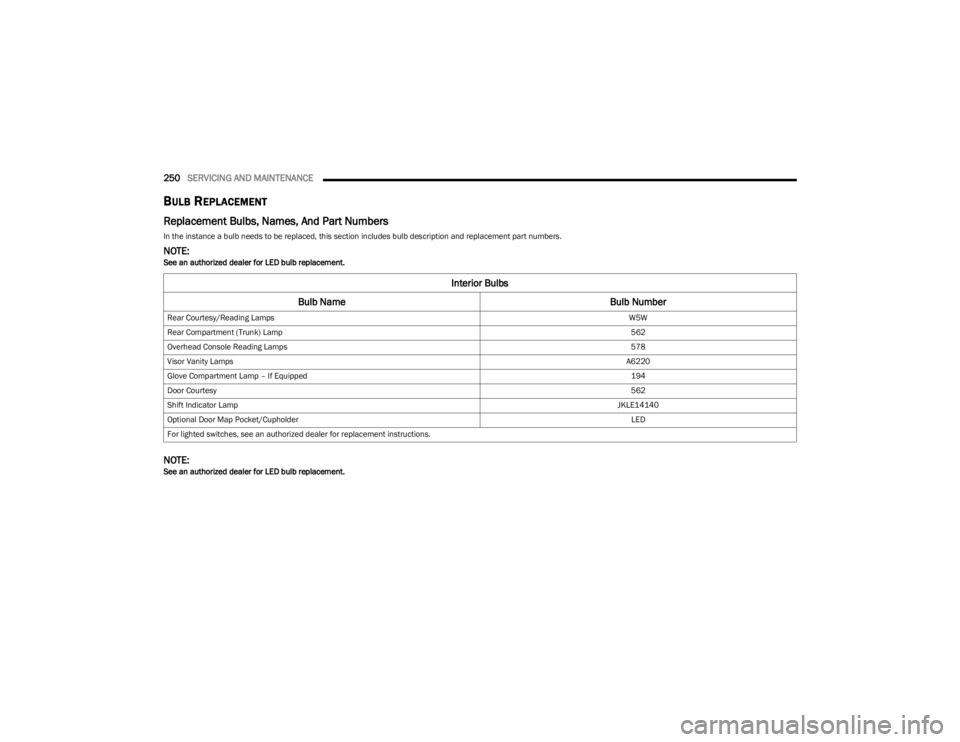

BULB REPLACEMENT

Replacement Bulbs, Names, And Part Numbers

In the instance a bulb needs to be replaced, this section includes bulb description and replacement part numbers.

NOTE:See an authorized dealer for LED bulb replacement.

NOTE:See an authorized dealer for LED bulb replacement.

Interior Bulbs

Bulb Name Bulb Number

Rear Courtesy/Reading Lamps W5W

Rear Compartment (Trunk) Lamp 562

Overhead Console Reading Lamps 578

Visor Vanity Lamps A6220

Glove Compartment Lamp – If Equipped 194

Door Courtesy 562

Shift Indicator Lamp JKLE14140

Optional Door Map Pocket/Cupholder LED

For lighted switches, see an authorized dealer for replacement instructions.

23_LA_OM_EN_USC_t.book Page 250

Page 256 of 300

254SERVICING AND MAINTENANCE

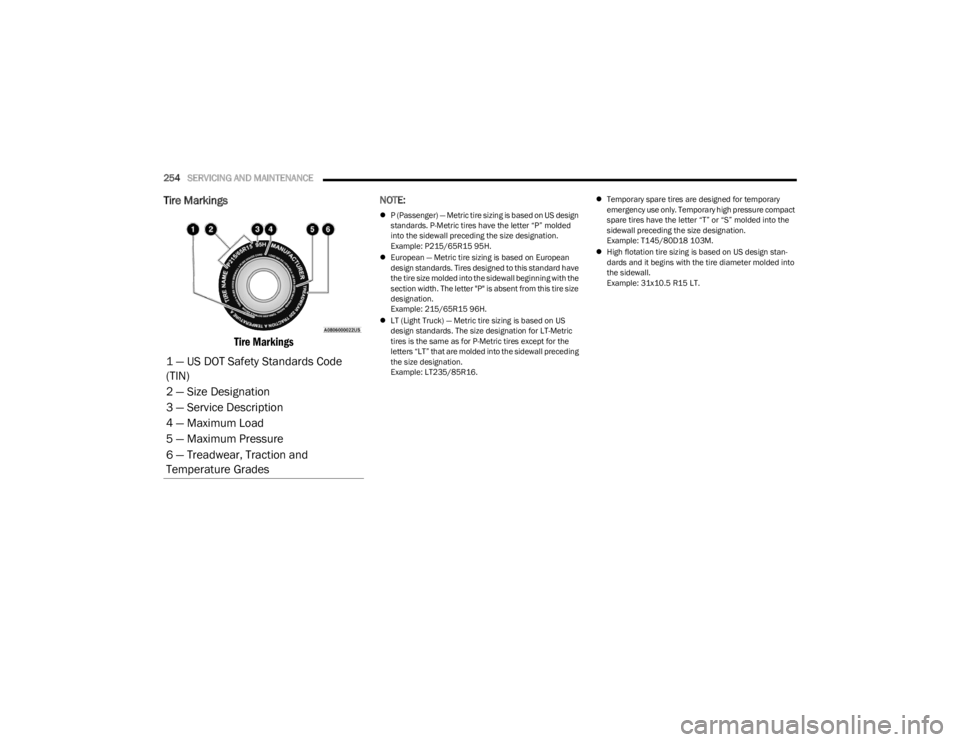

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US design

standards. P-Metric tires have the letter “P” molded

into the sidewall preceding the size designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with the

section width. The letter "P" is absent from this tire size

designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on US

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters “LT” that are molded into the sidewall preceding

the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for temporary

emergency use only. Temporary high pressure compact

spare tires have the letter “T” or “S” molded into the

sidewall preceding the size designation.

Example: T145/80D18 103M.

High flotation tire sizing is based on US design stan -

dards and it begins with the tire diameter molded into

the sidewall.

Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards Code

(TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

23_LA_OM_EN_USC_t.book Page 254

Page 257 of 300

SERVICING AND MAINTENANCE255

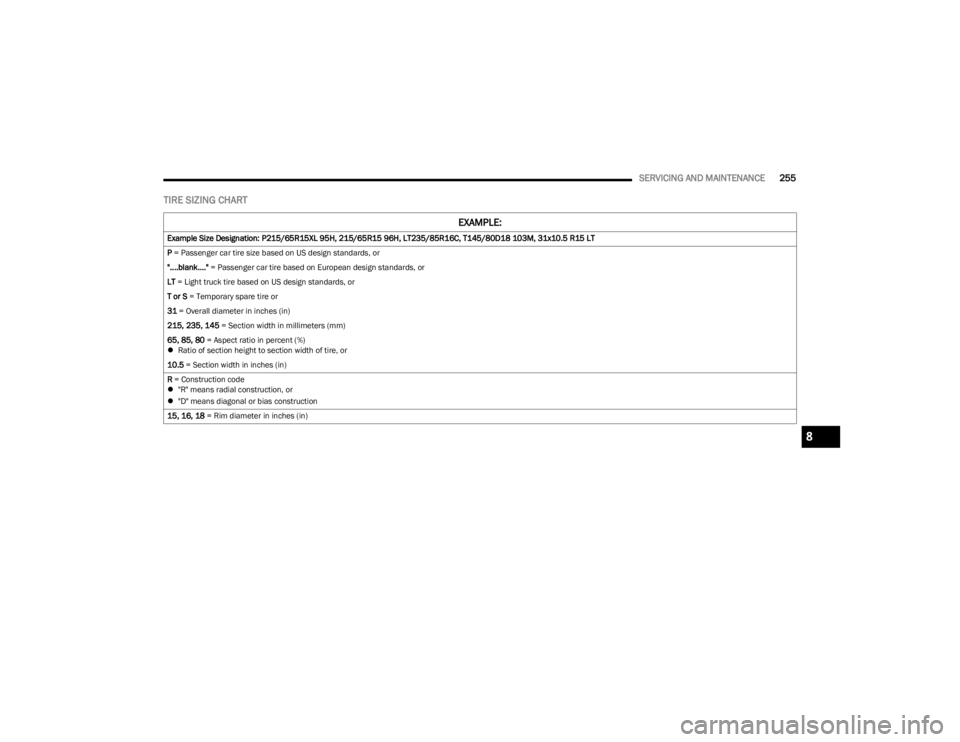

TIRE SIZING CHART

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

8

23_LA_OM_EN_USC_t.book Page 255

Page 258 of 300

256SERVICING AND MAINTENANCE

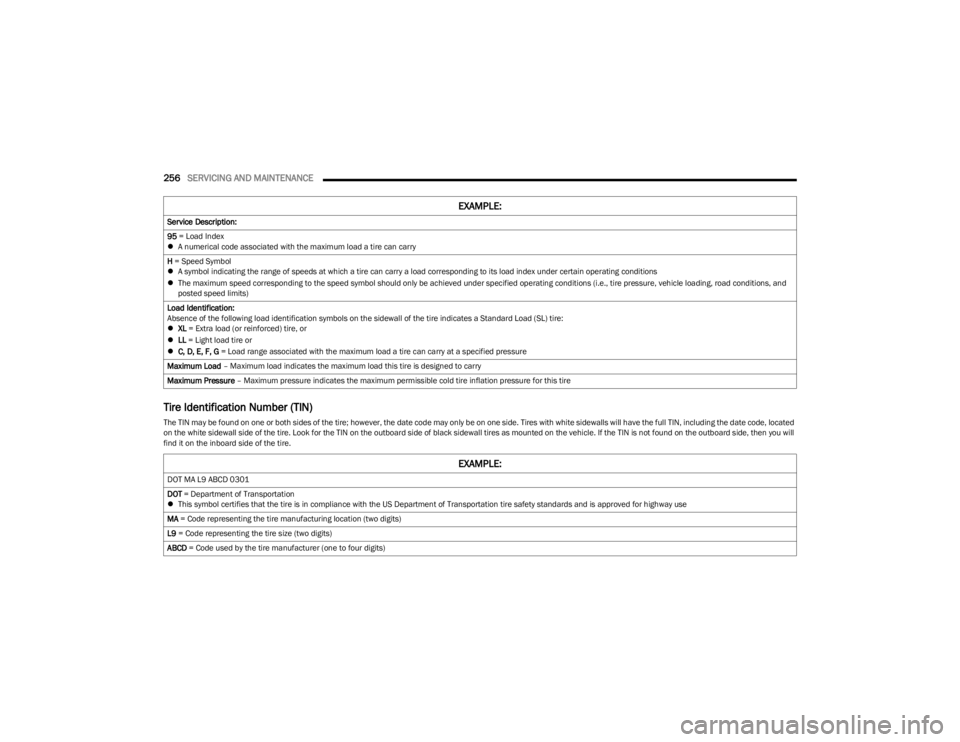

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls will have the full TIN, including the date code, located

on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as mounted on the vehicle. If the TIN is not found on the outboard side, then you will

find it on the inboard side of the tire.Service Description:

95

= Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and

posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

23_LA_OM_EN_USC_t.book Page 256