check engine DODGE CHALLENGER 2023 Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: CHALLENGER, Model: DODGE CHALLENGER 2023Pages: 300, PDF Size: 12.82 MB

Page 158 of 300

156MULTIMEDIA

NOTE:

Launch Control should not be used on public roads.

Always check track conditions and the surrounding

area.

Launch Control is not available for the first 500 miles

(805 km) of the vehicle’s life.

Launch Control should only be used when the engine

and transmission are at operating temperature.

Launch Control is intended to be used on dry, paved

road surfaces only. Use on slippery or loose surfaces

may cause damage to vehicle components and is not

recommended.

Launch Control is not available in ESC Full Off Mode.

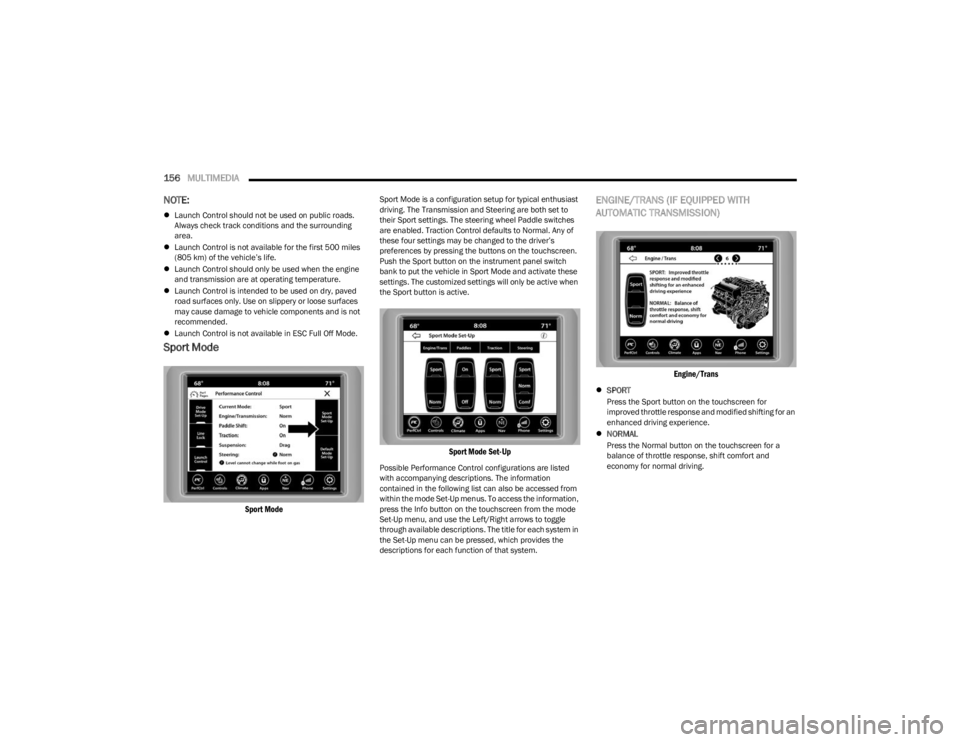

Sport Mode

Sport Mode

Sport Mode is a configuration setup for typical enthusiast

driving. The Transmission and Steering are both set to

their Sport settings. The steering wheel Paddle switches

are enabled. Traction Control defaults to Normal. Any of

these four settings may be changed to the driver’s

preferences by pressing the buttons on the touchscreen.

Push the Sport button on the instrument panel switch

bank to put the vehicle in Sport Mode and activate these

settings. The customized settings will only be active when

the Sport button is active.

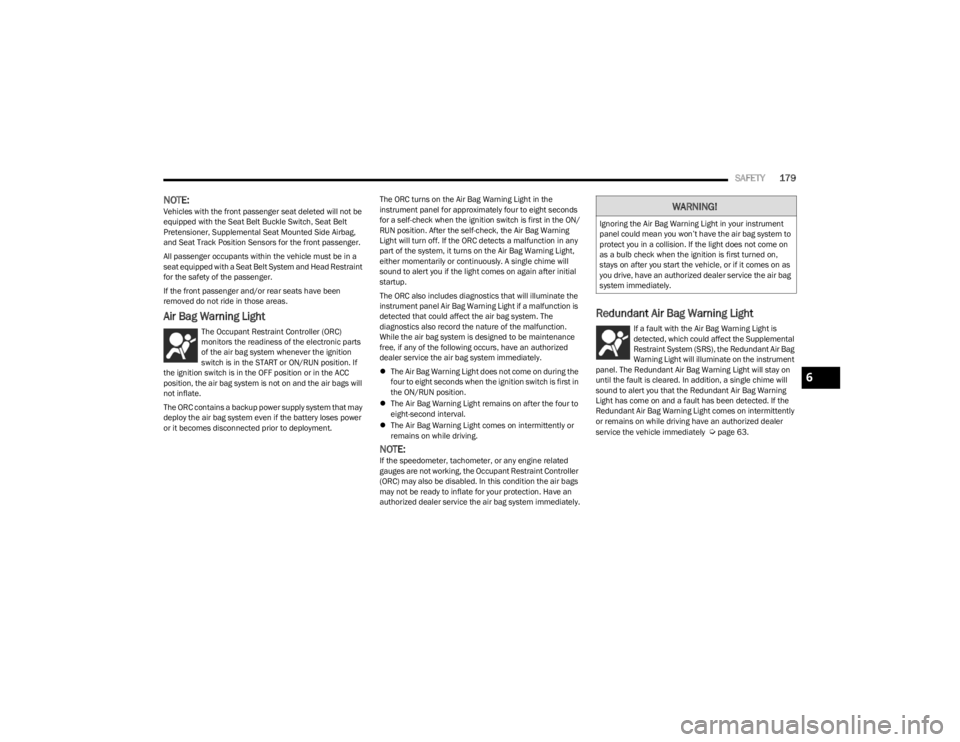

Sport Mode Set-Up

Possible Performance Control configurations are listed

with accompanying descriptions. The information

contained in the following list can also be accessed from

within the mode Set-Up menus. To access the information,

press the Info button on the touchscreen from the mode

Set-Up menu, and use the Left/Right arrows to toggle

through available descriptions. The title for each system in

the Set-Up menu can be pressed, which provides the

descriptions for each function of that system.

ENGINE/TRANS (IF EQUIPPED WITH

AUTOMATIC TRANSMISSION)

Engine/Trans

SPORT

Press the Sport button on the touchscreen for

improved throttle response and modified shifting for an

enhanced driving experience.

NORMAL

Press the Normal button on the touchscreen for a

balance of throttle response, shift comfort and

economy for normal driving.

23_LA_OM_EN_USC_t.book Page 156

Page 181 of 300

SAFETY179

NOTE:Vehicles with the front passenger seat deleted will not be

equipped with the Seat Belt Buckle Switch, Seat Belt

Pretensioner, Supplemental Seat Mounted Side Airbag,

and Seat Track Position Sensors for the front passenger.

All passenger occupants within the vehicle must be in a

seat equipped with a Seat Belt System and Head Restraint

for the safety of the passenger.

If the front passenger and/or rear seats have been

removed do not ride in those areas.

Air Bag Warning Light

The Occupant Restraint Controller (ORC)

monitors the readiness of the electronic parts

of the air bag system whenever the ignition

switch is in the START or ON/RUN position. If

the ignition switch is in the OFF position or in the ACC

position, the air bag system is not on and the air bags will

not inflate.

The ORC contains a backup power supply system that may

deploy the air bag system even if the battery loses power

or it becomes disconnected prior to deployment. The ORC turns on the Air Bag Warning Light in the

instrument panel for approximately four to eight seconds

for a self-check when the ignition switch is first in the ON/

RUN position. After the self-check, the Air Bag Warning

Light will turn off. If the ORC detects a malfunction in any

part of the system, it turns on the Air Bag Warning Light,

either momentarily or continuously. A single chime will

sound to alert you if the light comes on again after initial

startup.

The ORC also includes diagnostics that will illuminate the

instrument panel Air Bag Warning Light if a malfunction is

detected that could affect the air bag system. The

diagnostics also record the nature of the malfunction.

While the air bag system is designed to be maintenance

free, if any of the following occurs, have an authorized

dealer service the air bag system immediately.

The Air Bag Warning Light does not come on during the

four to eight seconds when the ignition switch is first in

the ON/RUN position.

The Air Bag Warning Light remains on after the four to

eight-second interval.

The Air Bag Warning Light comes on intermittently or

remains on while driving.

NOTE:If the speedometer, tachometer, or any engine related

gauges are not working, the Occupant Restraint Controller

(ORC) may also be disabled. In this condition the air bags

may not be ready to inflate for your protection. Have an

authorized dealer service the air bag system immediately.

Redundant Air Bag Warning Light

If a fault with the Air Bag Warning Light is

detected, which could affect the Supplemental

Restraint System (SRS), the Redundant Air Bag

Warning Light will illuminate on the instrument

panel. The Redundant Air Bag Warning Light will stay on

until the fault is cleared. In addition, a single chime will

sound to alert you that the Redundant Air Bag Warning

Light has come on and a fault has been detected. If the

Redundant Air Bag Warning Light comes on intermittently

or remains on while driving have an authorized dealer

service the vehicle immediately

Úpage 63.

WARNING!

Ignoring the Air Bag Warning Light in your instrument

panel could mean you won’t have the air bag system to

protect you in a collision. If the light does not come on

as a bulb check when the ignition is first turned on,

stays on after you start the vehicle, or if it comes on as

you drive, have an authorized dealer service the air bag

system immediately.

6

23_LA_OM_EN_USC_t.book Page 179

Page 186 of 300

184SAFETY

(Continued)

Do not drive your vehicle after the air bags have deployed.

If you are involved in another collision, the air bags will not

be in place to protect you.

NOTE:

Air bag covers may not be obvious in the interior trim,

but they will open during air bag deployment.

After any collision, the vehicle should be taken to an

authorized dealer immediately.

Enhanced Accident Response System

In the event of an impact, if the communication network

remains intact, and the power remains intact, depending

on the nature of the event, the Occupant Restraint

Controller (ORC) will determine whether to have the

Enhanced Accident Response System perform the

following functions:

Cut off fuel to the engine (if equipped).

Cut off battery power to the electric motor (if equipped).

Flash hazard lights as long as the battery has power.

Turn on the interior lights, which remain on as long as

the battery has power or for 15 minutes from the inter -

vention of the Enhanced Accident Response System.

Unlock the power door locks. Your vehicle may also be designed to perform any of these

other functions in response to the Enhanced Accident

Response System:

Turn off the Fuel Filter Heater, Turn off the HVAC Blower

Motor, Close the HVAC Circulation Door

Cut off battery power to the:

Engine

Electric Motor (if equipped)

Electric power steering

Brake booster

Electric park brake

Automatic transmission gear selector

Horn

Front wiper

NOTE:After an accident, remember to cycle the ignition to the

STOP (OFF/LOCK) position and remove the key from the

ignition switch to avoid draining the battery. Carefully

check the vehicle for fuel leaks in the engine compartment

and on the ground near the engine compartment and fuel

tank before resetting the system and starting the engine.

If there are no fuel leaks or damage to the vehicle elec -

trical devices (e.g. headlights) after an accident, reset the

system by following the procedure described below. If you

have any doubt, contact an authorized dealer.

Enhanced Accident Response System

Reset Procedure

In order to reset the Enhanced Accident Response System

functions after an event, the ignition switch must be

changed from ignition START or ON/RUN to ignition OFF.

Carefully check the vehicle for fuel leaks in the engine

compartment and on the ground near the engine

compartment and fuel tank before resetting the system

and starting the engine.

After an accident, if the vehicle will not start after

performing the reset procedure, the vehicle must be

towed to an authorized dealer to be inspected and to have

the Enhanced Accident Response System reset.

Maintaining Your Air Bag System

WARNING!

Deployed air bags and seat belt pretensioners cannot

protect you in another collision. Have the air bags, seat

belt pretensioners, and the seat belt retractor

assemblies replaced by an authorized dealer

immediately. Also, have the Occupant Restraint

Controller System serviced as well.

WARNING!

Modifications to any part of the air bag system could

cause it to fail when you need it. You could be injured

if the air bag system is not there to protect you. Do

not modify the components or wiring, including

adding any kind of badges or stickers to the steering

wheel hub trim cover or the upper passenger side of

the instrument panel. Do not modify the front fascia/

bumper, vehicle body structure, or add aftermarket

side steps or running boards.

It is dangerous to try to repair any part of the air bag

system yourself. Be sure to tell anyone who works on

your vehicle that it has an air bag system.

23_LA_OM_EN_USC_t.book Page 184

Page 199 of 300

SAFETY197

(Continued)

(Continued)

After the bulb check, this light will illuminate with a single

chime when a fault with the Air Bag System has been

detected. It will stay on until the fault is removed. If the

light comes on intermittently or remains on while driving,

have an authorized dealer service the vehicle immediately

Úpage 172.

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield. See an

authorized dealer for service if your defroster is

inoperable.

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle. Only use

a floor mat that does not interfere with the operation of the

accelerator, brake or clutch pedals. Only use a floor mat

that is securely attached using the floor mat fasteners so

it cannot slip out of position and interfere with the

accelerator, brake or clutch pedals or impair safe

operation of your vehicle in other ways.

WARNING!

An improperly attached, damaged, folded, or stacked

floor mat, or damaged floor mat fasteners may cause

your floor mat to interfere with the accelerator, brake, or

clutch pedals and cause a loss of vehicle control. To

prevent SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor mat

using the floor mat fasteners. DO NOT

install your floor mat upside down or turn

your floor mat over. Lightly pull to confirm

mat is secured using the floor mat fasteners on a

regular basis.

ALWAYS REMOVE THE EXISTING FLOOR

MAT FROM THE VEHICLE before installing

any other floor mat. NEVER install or stack

an additional floor mat on top of an

existing floor mat.

ONLY install floor mats designed to fit your vehicle.

NEVER install a floor mat that cannot be properly

attached and secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA approved floor

mat for the specific make, model, and year of your

vehicle.

ONLY use the driver’s side floor mat on the driver’s

side floor area. To check for interference, with the

vehicle properly parked with the engine off, fully

depress the accelerator, the brake, and the clutch

pedal (if present) to check for interference. If your

floor mat interferes with the operation of any pedal,

or is not secure to the floor, remove the floor mat

from the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on the

passenger’s side floor area.

WARNING!

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could change

the position of the floor mat and may cause interfer-

ence with the accelerator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

6

23_LA_OM_EN_USC_t.book Page 197

Page 200 of 300

198SAFETY

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nuts/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn

signal and high beam indicator lights on the instrument

panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight parking for

fuel, coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel or brake fluid leaks are

suspected, the cause should be located and corrected

immediately.

EXHAUST GAS

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system. Whenever a change is noticed in the sound of the exhaust

system, when exhaust fumes can be detected inside the

vehicle, or when the underside or rear of the vehicle is

damaged, have an authorized dealer inspect the complete

exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

CARBON MONOXIDE WARNINGS

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing (CO), follow

these safety tips:

Do not run the engine in a closed garage or in

confined areas any longer than needed to move your

vehicle in or out of the area.

If you are required to drive with the trunk/liftgate/

rear doors open, make sure that all windows are

closed and the climate control BLOWER switch is set

at high speed. DO NOT use the recirculation mode.

If it is necessary to sit in a parked vehicle with the

engine running, adjust your heating or cooling

controls to force outside air into the vehicle. Set the

blower at high speed.

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly.

Follow the precautions below to prevent carbon

monoxide poisoning:

Do not inhale exhaust gases. They contain carbon

monoxide, a colorless and odorless gas, which can

kill. Never run the engine in a closed area, such as a

garage, and never sit in a parked vehicle with the

engine running for an extended period. If the vehicle

is stopped in an open area with the engine running

for more than a short period, adjust the ventilation

system to force fresh, outside air into the vehicle.

Guard against carbon monoxide with proper mainte -

nance. Have the exhaust system inspected every

time the vehicle is raised. Have any abnormal condi -

tions repaired promptly. Until repaired, drive with all

side windows fully open.

23_LA_OM_EN_USC_t.book Page 198

Page 210 of 300

208IN CASE OF EMERGENCY

Sealing A Tire With Tire Service Kit

Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hose to

reach the valve stem and keep the Tire Service Kit flat

on the ground. This will provide the best positioning of

the kit when injecting the sealant into the deflated

tire and running the air pump. Move the vehicle as

necessary to place the valve stem in this position

before proceeding.

3. Place the gear selector in PARK, then push and release the ENGINE START/STOP button to set the

ignition switch to the OFF position.

4. Apply the parking brake.

Setting Up To Use Tire Service Kit:

1. Uncoil the Sealant Hose and then remove the cap from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on the ground next to the deflated tire. 3. Remove the cap from the valve stem and

then screw the fitting at the end of the Sealant

Hose onto the valve stem.

4. Uncoil the Power Plug and insert the plug

into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or nails) from

the tire.

Injecting Tire Service Kit Sealant Into The Deflated Tire:

5. Always start the vehicle before turning the

Tire Service Kit on.

6. Ensure the Mode Select Knob is to the

Sealant Mode position.

7. After pushing the Power Button, the sealant

(white fluid) will flow from the Sealant Bottle

through the Sealant Hose and into the tire.

NOTE:Sealant may leak out through the puncture in the tire. If the sealant (white fluid) does not flow within

0 – 10 seconds through the Sealant Hose:

1. Push the Power Button to turn the Tire Service Kit

off. Disconnect the Sealant Hose from the valve

stem. Make sure the valve stem is free of debris.

Reconnect the Sealant Hose to the valve stem.

Check that the Mode Select Knob is in the Sealant

Mode position and not Air Mode. Push the Power

Button to turn the Tire Service Kit on.

2. Connect the Power Plug to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the vehicle is running before turning the

Tire Service Kit on.

3. The Sealant Bottle may be empty due to previous use. Call for assistance.

If the sealant (white fluid) does flow through the Sealant

Hose: 4. Continue to operate the pump until sealant

is no longer flowing through hose (typically

takes 30 - 70 seconds). As the sealant flows

through the Sealant Hose, the Pressure Gauge

can read as high as 70 psi (4.8 bar). The Pressure Gauge

will decrease quickly from approximately 70 psi (4.8 bar)

to the actual tire pressure when the Sealant Bottle is

empty.

5. The pump will start to inject air into the tire

immediately after the Sealant Bottle is empty.

Continue to operate the pump and inflate the

tire to the cold tire inflation pressure found on

the tire and loading information label located in the

driver-side door opening. Check the tire pressure by

looking at the Pressure Gauge.

23_LA_OM_EN_USC_t.book Page 208

Page 216 of 300

214IN CASE OF EMERGENCY

(B) SETTING UP TO USE TIRE SERVICE KIT:

1. Push in the Mode Select Knob (6) and turn to the

Sealant Mode position.

2. Uncoil the Sealant Hose (4) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (4) onto the

valve stem.

5. Uncoil the Power Plug (7) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or nails) from

the tire.

(C) INJECTING TIRE SERVICE KIT SEALANT

INTO THE DEFLATED TIRE:

Always start the engine before turning ON the Tire

Service Kit.

NOTE:Manual transmission vehicles must have the parking

brake engaged and the gear selector in NEUTRAL.

After pushing the Power Button (3), the sealant (white

fluid) will flow from the Sealant Bottle (1) through the

Sealant Hose (4) and into the tire.

NOTE:Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within 0 – 10

seconds through the Sealant Hose :

1. Push the Power Button (3) to turn Off the Tire

Service Kit. Disconnect the Sealant Hose (4) from

the valve stem. Make sure the valve stem is free of

debris. Reconnect the Sealant Hose (4) to the valve

stem. Check that the Mode Select Knob (6) is in the

Sealant Mode position and not Air Mode. Push the

Power Button (3) to turn On the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another vehicle, if

available. Make sure the engine is running before

turning ON the Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob (6) is on Air Mode and the pump

is operating, air will dispense from the Air Pump Hose (8)

only, not the Sealant Hose (4). If the sealant (white fluid) does flow through the Sealant

Hose :

1. Continue to operate the pump until sealant is no

longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through the

Sealant Hose (4), the Pressure Gauge (5) can read

as high as 70 psi (4.8 Bar). The Pressure Gauge (5)

will decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when the

Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is empty.

Continue to operate the pump and inflate the tire to

the pressure indicated on the tire pressure label on

the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure

Gauge (5).

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.NOTE:If the tire becomes overinflated, push the Deflation Button

(2) to reduce the tire pressure to the recommended

inflation pressure before continuing.

23_LA_OM_EN_USC_t.book Page 214

Page 225 of 300

223

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

3.6L AND 5.7L ENGINES

These engines are equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for the vehicle. Operating conditions such as

frequent short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the “Change

Oil” or “Oil Change Required” message is displayed. Have

your vehicle serviced as soon as possible, within the next

500 miles (805 km).

The “Oil Change Required” message will be displayed in

the instrument cluster and a single chime will sound,

indicating that an oil change is necessary.

An authorized dealer will reset the oil change indicator

message after completing the scheduled oil change.

NOTE:Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km), 12 months or

350 hours of engine run time, whichever comes first.

The 350 hours of engine run or idle time is generally only

a concern for fleet customers.Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before your next scheduled service.

Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering (if equipped) and

fill as needed.

Check function of all interior and exterior lights.

8

23_LA_OM_EN_USC_t.book Page 223

Page 232 of 300

230SERVICING AND MAINTENANCE

CHECKING OIL LEVELTo ensure proper engine lubrication, the engine oil must

be maintained at the correct level. Check the oil level at

regular intervals, such as every fuel stop. The best time to

check the engine oil level is about ten minutes after a fully

warmed up engine is shut off.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the low end of

the range and MAX at the high end of the range.

Crosshatched zone marked with dimples at the MIN

and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick.

Adding 1 qt (1 L) of oil when the reading is at the low end

of the dipstick range will raise the oil level to the high end

of the range marking.

ADDING WASHER FLUID

The windshield washer fluid reservoir is located in the

front of the engine compartment. Be sure to check the

fluid level at regular intervals. Fill the reservoir with

windshield washer solvent (not radiator antifreeze) and

operate the system for a few seconds to flush out the

residual water.

When refilling the washer fluid reservoir, apply some

washer fluid to a cloth or towel and wipe the wiper blades

clean. This will help blade performance.

To prevent freeze-up of your windshield washer system in

cold weather, select a solution or mixture that meets or

exceeds the temperature range of your climate. This rating

information can be found on most washer fluid containers.

The fluid reservoir will hold nearly 1 Gallon (4 Liters) of

washer fluid when the message “Low Washer Fluid”

appears in the instrument cluster.WARNING!

Never smoke while working in the engine compart -

ment: gas and flammable vapors may be present,

with the risk of fire.

Be very careful when working in the engine compart -

ment when the engine is hot: you may get burned. Do

not get too close to the radiator cooling fan: the elec -

tric fan may start; danger of injury. Scarves, ties and

other loose clothing might be pulled by moving parts.

CAUTION!

Be careful not to confuse the various types of fluids

while topping up: they are not compatible with each

other! Topping up with an unsuitable fluid could

severely damage your car.

The oil level must never exceed the MAX mark.

Always top up using engine oil of the same specifica -

tions as what is already in the engine.

If the engine oil is being topped up, wait for the

engine to cool down before loosening the filler cap,

particularly for vehicles with aluminum caps (if

equipped). WARNING: risk of burns!

Overfilling or underfilling the crankcase will cause

aeration or loss of oil pressure. This could damage

your engine.

CAUTION!

Overfilling or underfilling the crankcase will cause

aeration or loss of oil pressure. This could damage your

engine.

WARNING!

Commercially available windshield washer solvents are

flammable. They could ignite and burn you. Care must

be exercised when filling or working around the washer

solution.

23_LA_OM_EN_USC_t.book Page 230

Page 240 of 300

238SERVICING AND MAINTENANCE

Coolant Checks

Check engine coolant (antifreeze) protection every

12 months (before the onset of freezing weather, where

applicable). If the engine coolant is dirty, the system

should be drained, flushed, and refilled with fresh Organic

Additive Technology (OAT) coolant (conforming to

MS.90032) by an authorized dealer. Check the front of the

radiator for any accumulation of bugs, leaves, etc. If dirty,

clean by gently spraying water from a garden hose

vertically down the face of the condenser.

Check the coolant recovery bottle tubing for brittle rubber,

cracking, tears, cuts, and tightness of the connection at

the bottle and radiator. Inspect the entire system for

leaks. DO NOT REMOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could lead

to severe internal engine damage. If any coolant is needed

to be added to the system please contact an authorized

dealer.

If the engine coolant (antifreeze) is dirty or contains visible

sediment, have an authorized dealer clean and flush with

Organic Additive Technology (OAT) coolant (conforming to

MS.90032).

For the proper maintenance intervals

Úpage 224.

Selection Of Coolant

For further information Úpage 278.

NOTE:

Mixing of engine coolant (antifreeze) other than speci-

fied Organic Additive Technology (OAT) engine coolant,

may result in engine damage and may decrease corro -

sion protection. OAT engine coolant is different and

should not be mixed with Hybrid Organic Additive Tech -

nology (HOAT) engine coolant or any “globally compat -

ible” coolant. If a non-OAT engine coolant is introduced

into the cooling system in an emergency, the cooling

system will need to be drained, flushed, and refilled

with fresh OAT coolant (conforming to MS.90032), by

an authorized dealer as soon as possible.

Do not use water alone or alcohol-based engine

coolant products. Do not use additional rust inhibitors

or antirust products, as they may not be compatible

with the radiator engine coolant and may plug the radi -

ator.

This vehicle has not been designed for use with

propylene glycol-based engine coolant. Use of

propylene glycol-based engine coolant is not recom -

mended.

Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could

lead to severe internal engine damage. If any coolant is

needed to be added to the system please contact an

authorized dealer.

Adding Coolant

Your vehicle has been built with an improved engine

coolant (OAT coolant conforming to MS.90032) that

allows extended maintenance intervals. This engine

coolant (antifreeze) can be used up to 10 years or

150,000 miles (240,000 km) before replacement. To

prevent reducing this extended maintenance period, it is

important to use the same engine coolant (OAT coolant

conforming to MS.90032) throughout the life of your

vehicle.

Please review these recommendations for using Organic

Additive Technology (OAT) engine coolant that meets the

requirements of the manufacturer Material Standard

MS.90032. When adding engine coolant:

We recommend using Mopar® Antifreeze/Coolant

10 Year/150,000 Mile (240,000 km) Formula OAT

that meets the requirements of the manufacturer

Material Standard MS.90032.

Mix a minimum solution of 50% OAT engine coolant

that meets the requirements of the manufacturer

Material Standard MS.90032 and distilled water.

Use higher concentrations (not to exceed 70%) if

temperatures below −34°F (−37°C) are anticipated.

Please contact an authorized dealer for assistance.

Use only high purity water such as distilled or deionized

water when mixing the water/engine coolant solution.

The use of lower quality water will reduce the amount

of corrosion protection in the engine cooling system.

23_LA_OM_EN_USC_t.book Page 238