service DODGE CHALLENGER 2023 Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: CHALLENGER, Model: DODGE CHALLENGER 2023Pages: 300, PDF Size: 12.82 MB

Page 223 of 300

IN CASE OF EMERGENCY221

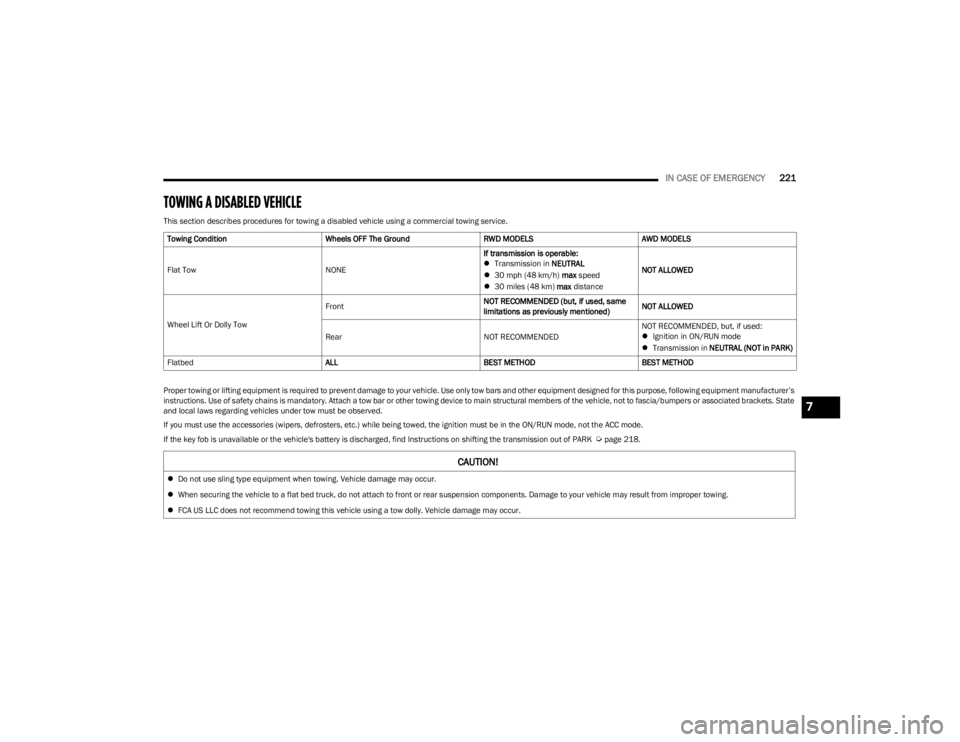

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

Proper towing or lifting equipment is required to prevent damage to your vehicle. Use only tow bars and other equipment designed for this purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory. Attach a tow bar or other towing device to main structural members of the vehicle, not to fascia/bumpers or associated brackets. State

and local laws regarding vehicles under tow must be observed.

If you must use the accessories (wipers, defrosters, etc.) while being towed, the ignition must be in the ON/RUN mode, not the ACC mode.

If the key fob is unavailable or the vehicle's battery is discharged, find Instructions on shifting the transmission out of PARK

Úpage 218.

Towing Condition

Wheels OFF The GroundRWD MODELSAWD MODELS

Flat Tow NONEIf transmission is operable:

Transmission in NEUTRAL

30 mph (48 km/h) max speed

30 miles (48 km) max distance NOT ALLOWED

Wheel Lift Or Dolly Tow Front

NOT RECOMMENDED (but, if used, same

limitations as previously mentioned)NOT ALLOWED

Rear NOT RECOMMENDEDNOT RECOMMENDED, but, if used:

Ignition in ON/RUN mode

Transmission in NEUTRAL (NOT in PARK)

Flatbed ALLBEST METHODBEST METHOD

CAUTION!

Do not use sling type equipment when towing. Vehicle damage may occur.

When securing the vehicle to a flat bed truck, do not attach to front or rear suspension components. Damage to your vehicle may result from improper towing.

FCA US LLC does not recommend towing this vehicle using a tow dolly. Vehicle damage may occur.

7

23_LA_OM_EN_USC_t.book Page 221

Page 225 of 300

223

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

3.6L AND 5.7L ENGINES

These engines are equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for the vehicle. Operating conditions such as

frequent short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the “Change

Oil” or “Oil Change Required” message is displayed. Have

your vehicle serviced as soon as possible, within the next

500 miles (805 km).

The “Oil Change Required” message will be displayed in

the instrument cluster and a single chime will sound,

indicating that an oil change is necessary.

An authorized dealer will reset the oil change indicator

message after completing the scheduled oil change.

NOTE:Under no circumstances should oil change intervals

exceed 10,000 miles (16,000 km), 12 months or

350 hours of engine run time, whichever comes first.

The 350 hours of engine run or idle time is generally only

a concern for fleet customers.Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear or

damage. Rotate tires at the first sign of irregular wear,

even if it occurs before your next scheduled service.

Check the fluid levels of the coolant reservoir, brake

master cylinder, and power steering (if equipped) and

fill as needed.

Check function of all interior and exterior lights.

8

23_LA_OM_EN_USC_t.book Page 223

Page 226 of 300

224SERVICING AND MAINTENANCE

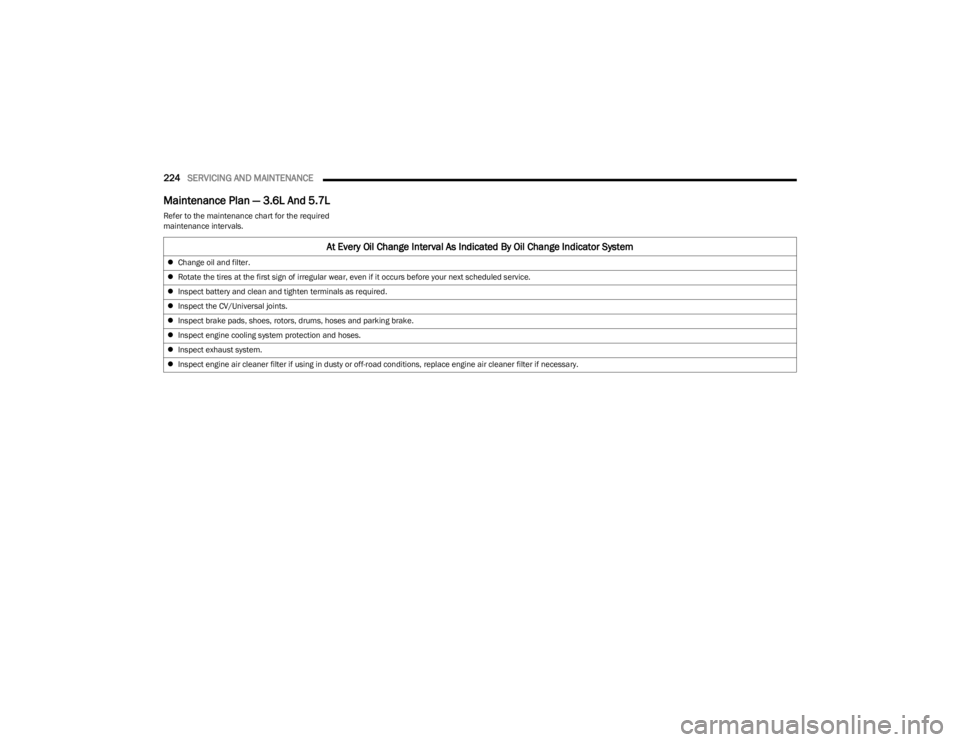

Maintenance Plan — 3.6L And 5.7L

Refer to the maintenance chart for the required

maintenance intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System

Change oil and filter.

Rotate the tires at the first sign of irregular wear, even if it occurs before your next scheduled service.

Inspect battery and clean and tighten terminals as required.

Inspect the CV/Universal joints.

Inspect brake pads, shoes, rotors, drums, hoses and parking brake.

Inspect engine cooling system protection and hoses.

Inspect exhaust system.

Inspect engine air cleaner filter if using in dusty or off-road conditions, replace engine air cleaner filter if necessary.

23_LA_OM_EN_USC_t.book Page 224

Page 229 of 300

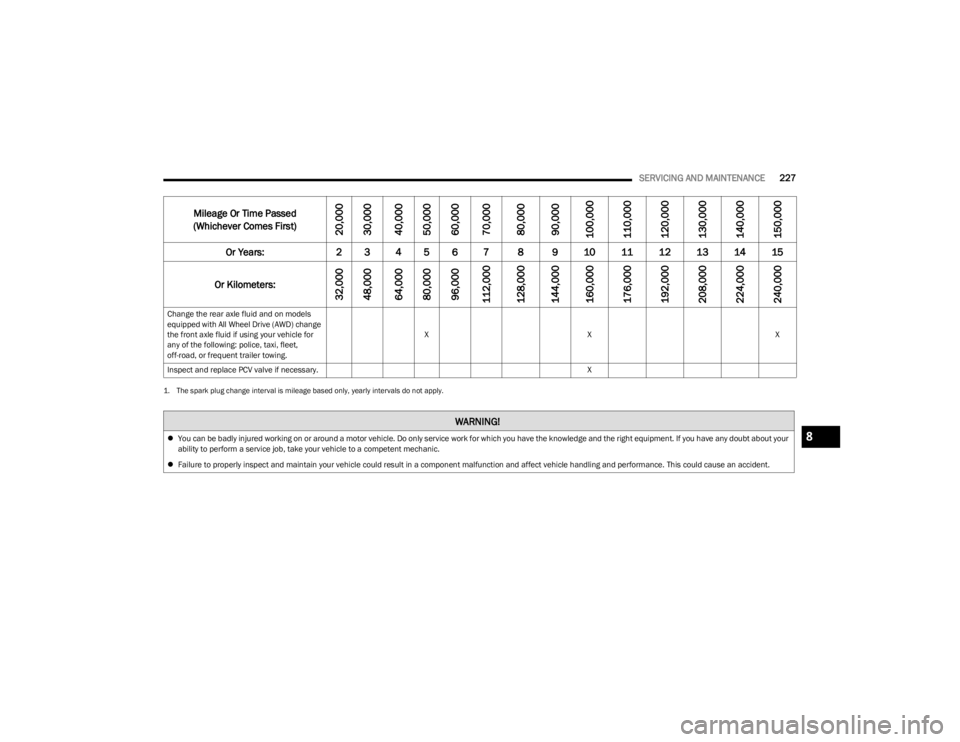

SERVICING AND MAINTENANCE227

Change the rear axle fluid and on models

equipped with All Wheel Drive (AWD) change

the front axle fluid if using your vehicle for

any of the following: police, taxi, fleet,

off-road, or frequent trailer towing. X

X X

Inspect and replace PCV valve if necessary. X

1. The spark plug change interval is mileage based only, yearly intervals do not apply.

Mileage Or Time Passed

(Whichever Comes First)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

WARNING!

You can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have any doubt about your

ability to perform a service job, take your vehicle to a competent mechanic.

Failure to properly inspect and maintain your vehicle could result in a component malfunction and affect vehicle handling and performance. This could cause an accident.8

23_LA_OM_EN_USC_t.book Page 227

Page 233 of 300

SERVICING AND MAINTENANCE231

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free battery.

Water will never have to be added, and periodic

maintenance is not required.

NOTE:The battery is stored under an access cover in the trunk.

Remote battery terminals are located in the engine

compartment for jump starting

Úpage 216.

PRESSURE WASHING

Cleaning the engine compartment with a high pressure

washer is not recommended.

VEHICLE MAINTENANCE

An authorized dealer has the qualified service personnel,

special tools, and equipment to perform all service

operations in an expert manner. Service Manuals are available which include detailed

service information for your vehicle. Refer to these Service

Manuals before attempting any procedure yourself.

NOTE:Intentional tampering with emissions control systems may

void your warranty and could result in civil penalties being

assessed against you.

ENGINE OIL

Engine Oil Selection

Use only the manufacturer's recommended fluids Úpage 278.

NOTE:Hemi engines at times can tick right after startup and then

quiet down after approximately 30 seconds. This is normal

and will not harm the engine. This characteristic can be

caused by short drive cycles: for example, if the vehicle is

started then shut off after driving a short distance. Upon

restarting, you may experience a ticking sound. Other

causes could be if the vehicle is unused for an extended

period of time, incorrect oil, extended oil changes or

extended idling. If the engine continues to tick or if the

Malfunction Indicator Light (MIL) comes on, see the

nearest authorized dealer.

WARNING!

Battery fluid is a corrosive acid solution and can burn

or even blind you. Do not allow battery fluid to

contact your eyes, skin, or clothing. Do not lean over

a battery when attaching clamps. If acid splashes in

eyes or on skin, flush the area immediately with large

amounts of water

Úpage 216.

Battery gas is flammable and explosive. Keep flame

or sparks away from the battery. Do not use a

booster battery or any other booster source with an

output greater than 12 Volts. Do not allow cable

clamps to touch each other.

Battery posts, terminals, and related accessories

contain lead and lead compounds. Wash hands after

handling.

The battery in this vehicle has a vent hose that

should not be disconnected and should only be

replaced with a battery of the same type (vented).

CAUTION!

It is essential when replacing the cables on the

battery that the positive cable is attached to the posi -

tive post and the negative cable is attached to the

negative post. Battery posts are marked positive (+)

and negative (-) and are identified on the battery

case. Cable clamps should be tight on the terminal

posts and free of corrosion.

If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables

before connecting the charger to the battery. Do not

use a “fast charger” to provide starting voltage.

CAUTION!

Precautions have been taken to safeguard all parts and

connections however, the pressures generated by these

machines is such that complete protection against

water ingress cannot be guaranteed.

WARNING!

You can be badly injured working on or around a motor

vehicle. Only do service work for which you have the

knowledge and the proper equipment. If you have any

doubt about your ability to perform a service job, take

your vehicle to a competent mechanic.

8

23_LA_OM_EN_USC_t.book Page 231

Page 234 of 300

232SERVICING AND MAINTENANCE

American Petroleum Institute (API)

Approved Engine Oil

These symbols mean that the oil has been certified by the

API. The manufacturer only recommends API trademark

oils.

The API Starburst trademark certifies 0W-20,

0W-30 and 5W-30 engine oils.

The API Donut trademark certifies 0W-40 and

5W-40 engine oil.

Synthetic Engine Oils

Your engine was designed for synthetic engine oils, only

use synthetic API approved engine oils.

Synthetic engine oils which do not have both the correct

API trademark and the correct SAE viscosity grade

numbers should not be used.

Shaker Hood — If Equipped

Shaker Hood Oil Filler

For vehicles equipped with a Shaker Hood, the upper

scoop will need to be removed so that oil can be properly

added to the engine.

To do this, see the following procedure:

1. Remove the four nuts with the Shaker tool located in glove compartment.

2. Lift off the upper scoop.

NOTE:Be sure to clean off all debris around or inside the Shaker

assembly.

3. Locate the oil fill cover in the base assembly and expose the oil fill cap.

4. Remove oil fill cap to add oil.

5. Reinstall Shaker assembly.

Shaker Hood Air Filter Cleaning

Shaker air filters are made of a unique, washable

synthetic material. Base program air filters with paper

media cannot be washed. All filters follow the same

service interval, though Shaker systems substitute a

cleaning while paper air filter elements are to be replaced.

1. Remove the air filter from the intake and set the filter clamp aside.

2. Measure the length of the filter media.

3. Fill a bucket with warm clean water to the depth matching the filter media measurement and add a

mild household detergent or air filter cleaning

solution.

NOTE:Never use strong detergents, high pressure, or gasoline on

air filters.

4. Without allowing the solution to flow back into the inside of the air filter, submerge the filter media into

the water and let it soak for ten minutes.

5. Empty the bucket filled with dirty water and repeat steps 3 and 4.

6. Refill the bucket with clean warm water and rinse the filter by rotating the filter.

NOTE:The water should be clean with no signs of dirt in the

bucket.

7. Allow the filter to air dry. Reinstall the filter on the intake system once it is dry.

NOTE:Do not use forced air pressure to dry the air filter as

damage may occur and void the warranty.

Shaker Hood Removal And Cleaning

1. Remove the four nuts with the Shaker tool located in the glove compartment.

2. Lift off the upper scoop.

NOTE:Be sure to clean off all debris around or inside of the

Shaker assembly.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is

not covered by the New Vehicle Limited Warranty.

23_LA_OM_EN_USC_t.book Page 232

Page 235 of 300

SERVICING AND MAINTENANCE233

3. Using water and mild detergent, clean the following

locations:

The water drain slot located at the front forward

edge of the Shaker assembly.

The seals attached to the scoop and air box.

Lower water drains located in the lower Shaker

assembly and air box as well as the hood interface

areas for the seals. Apply Mopar® Leather,

Rubber & Vinyl Protectant after cleaning the seals.

4. Reinstall Shaker assembly.

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product and

its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service

station or governmental agency for advice on how and

where used oil and oil filters can be safely discarded in

your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used for

replacement. The quality of replacement filters varies

considerably. Only high quality Mopar® certified filters

should be used. If a Mopar® Engine Oil Filter is

unavailable, only use filters that meet or exceed

SAE/USCAR-36 Filter Performance Requirements.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 224.

NOTE:Be sure to follow the “Severe Duty Conditions” mainte -

nance interval if applicable. Engine Air Cleaner Filter Selection

The quality of replacement filters varies considerably. Only

high quality Mopar® certified filters should be used.

T/A Air Filter Maintenance — If Equipped

Clean Engine Air Filter

T/A air filters are made of a unique, washable material.

Follow the recommended service interval as for non-T/A

air filters, substituting a cleaning for replacement.

Cleaning your engine air filter with the recommended

Mopar® Performance Air Filter Service Kit is not required

if you can still see any part of the wire screen on the entire

air filter regardless of how dirty it may appear. When any

part of the wire screen is no longer visible on the air filter,

that is an indication it is time to clean the air filter.

For cleaning instructions see steps 1-7 from the Shaker

Hood Air Filter Cleaning section

Úpage 232.

Unique for T/A, using the Mopar® Performance Air Filter

Service Kit, spray oil evenly along the crown of each filter

pleat holding the nozzle about 3 inches (76 mm) away

from the air filter. One spray per 2 square inches

(1,290 square mm) of air filter. With one complete coat of

oil, let it wick (saturate) for about 20 minutes, and if

required touch up any light areas on either side of the

filter.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc.) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in serious

personal injury.

8

23_LA_OM_EN_USC_t.book Page 233

Page 236 of 300

234SERVICING AND MAINTENANCE

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner should

be checked and serviced by an authorized dealer at the

start of each warm season. This service should include

cleaning of the condenser fins and a performance test.

Drive belt tension should also be checked at this time.

Refrigerant Recovery And Recycling

R-134a — If Equipped

R-134a Air Conditioning Refrigerant is a hydrofluo -

rocarbon (HFC) that is an ozone-friendly substance. The

manufacturer recommends that air conditioning service

be performed by an authorized dealer or other service

facilities using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil and refrigerants.

Refrigerant Recovery And Recycling

R-1234yf — If Equipped

R–1234yf Air Conditioning Refrigerant is a hydrofluo -

roolefin (HFO) that is endorsed by the Environmental

Protection Agency and is an ozone-friendly substance with

a low global-warming potential. The manufacturer

recommends that air conditioning service be performed by

an authorized dealer using recovery and recycling

equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil, and refrigerants.

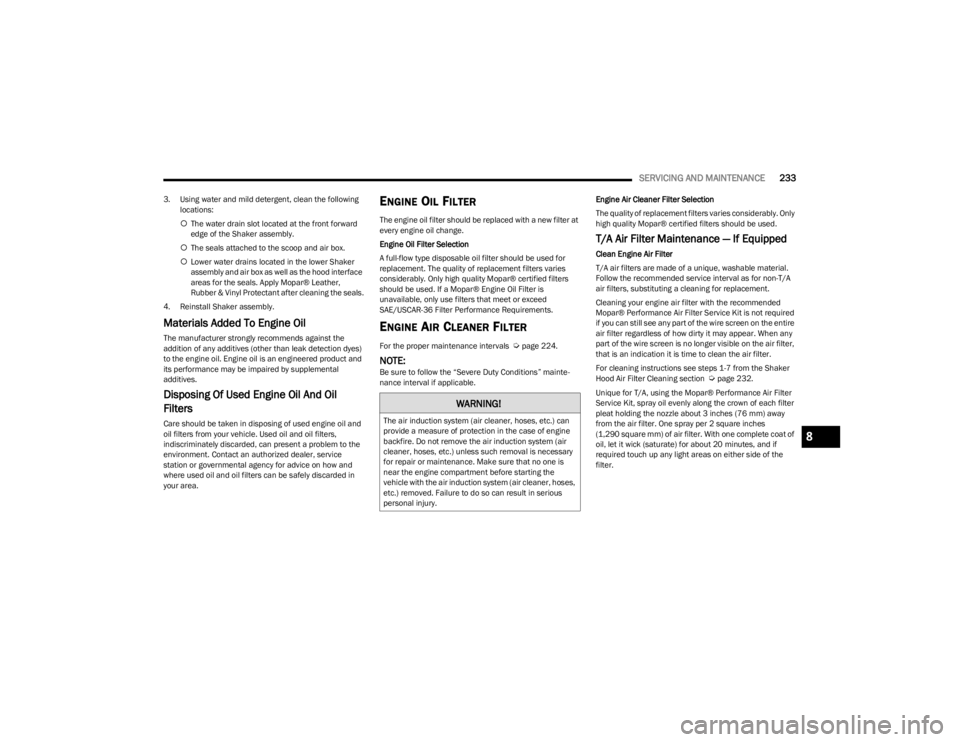

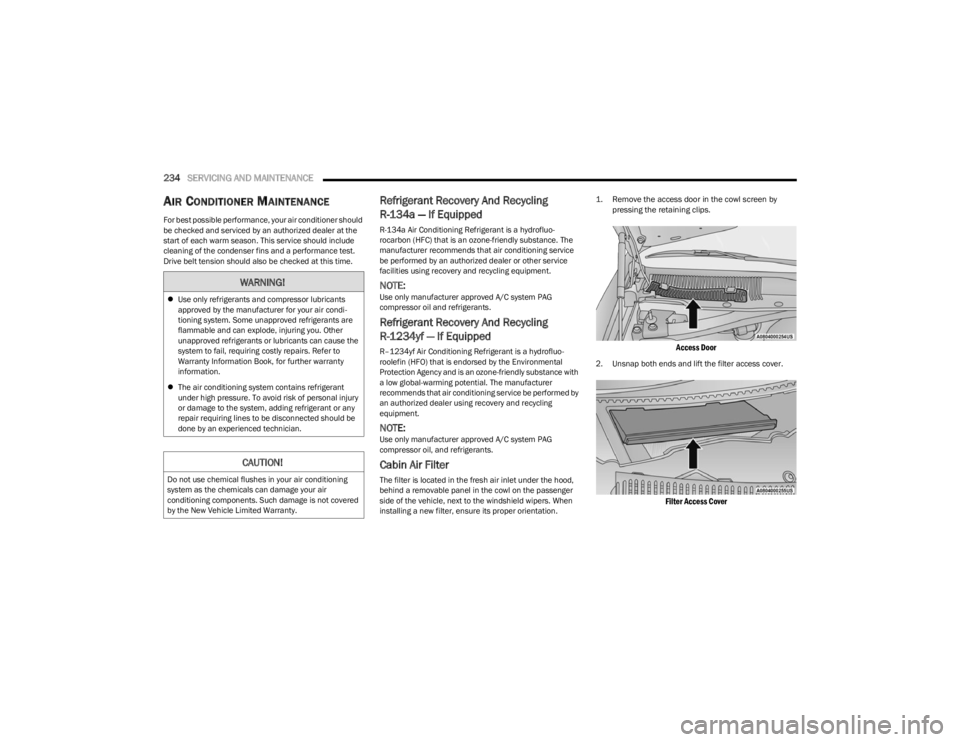

Cabin Air Filter

The filter is located in the fresh air inlet under the hood,

behind a removable panel in the cowl on the passenger

side of the vehicle, next to the windshield wipers. When

installing a new filter, ensure its proper orientation.

1. Remove the access door in the cowl screen by

pressing the retaining clips.

Access Door

2. Unsnap both ends and lift the filter access cover.

Filter Access Cover

WARNING!

Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi -

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause the

system to fail, requiring costly repairs. Refer to

Warranty Information Book, for further warranty

information.

The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal injury

or damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced technician.

CAUTION!

Do not use chemical flushes in your air conditioning

system as the chemicals can damage your air

conditioning components. Such damage is not covered

by the New Vehicle Limited Warranty.

23_LA_OM_EN_USC_t.book Page 234

Page 237 of 300

SERVICING AND MAINTENANCE235

(Continued)

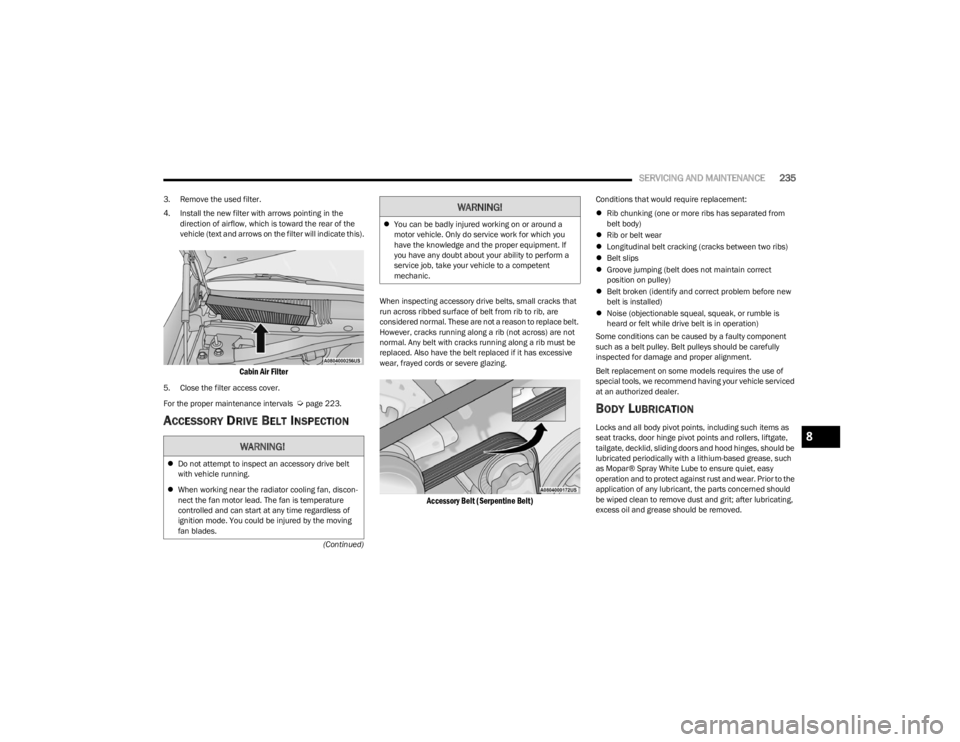

3. Remove the used filter.

4. Install the new filter with arrows pointing in the

direction of airflow, which is toward the rear of the

vehicle (text and arrows on the filter will indicate this).

Cabin Air Filter

5. Close the filter access cover.

For the proper maintenance intervals

Úpage 223.

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts, small cracks that

run across ribbed surface of belt from rib to rib, are

considered normal. These are not a reason to replace belt.

However, cracks running along a rib (not across) are not

normal. Any belt with cracks running along a rib must be

replaced. Also have the belt replaced if it has excessive

wear, frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated from

belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two ribs)

Belt slips

Groove jumping (belt does not maintain correct

position on pulley)

Belt broken (identify and correct problem before new

belt is installed)

Noise (objectionable squeal, squeak, or rumble is

heard or felt while drive belt is in operation)

Some conditions can be caused by a faulty component

such as a belt pulley. Belt pulleys should be carefully

inspected for damage and proper alignment.

Belt replacement on some models requires the use of

special tools, we recommend having your vehicle serviced

at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically with a lithium-based grease, such

as Mopar® Spray White Lube to ensure quiet, easy

operation and to protect against rust and wear. Prior to the

application of any lubricant, the parts concerned should

be wiped clean to remove dust and grit; after lubricating,

excess oil and grease should be removed.

WARNING!

Do not attempt to inspect an accessory drive belt

with vehicle running.

When working near the radiator cooling fan, discon -

nect the fan motor lead. The fan is temperature

controlled and can start at any time regardless of

ignition mode. You could be injured by the moving

fan blades.

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent

mechanic.

WARNING!

8

23_LA_OM_EN_USC_t.book Page 235

Page 238 of 300

236SERVICING AND MAINTENANCE

Particular attention should also be given to hood latching

components to ensure proper function. When performing

other underhood services, the hood latch, release

mechanism and safety catch should be cleaned and

lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Autumn and Spring. Apply a small

amount of a high quality lubricant, such as Mopar® Lock

Cylinder Lubricant directly into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending on

geographical area and frequency of use. Poor perfor -

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary.

Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off of the glass, until the wiper arm is in the full up position.

2. To disengage the wiper blade from the wiper arm, press the release tab on the wiper blade and while

holding the wiper arm with one hand, slide the wiper

blade down towards the base of the wiper arm.

Wiper Blade With Release Tab In Unlocked Position

3. With the wiper blade disengaged, remove the wiper blade from the wiper arm.

Wiper Blade Removed From Wiper Arm

4. Gently lower the wiper arm onto the glass.

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the wiper arm is in the full up position.

2. Position the wiper blade near the hook on the tip of the wiper arm.

3. Insert the hook on the tip of the arm through the opening in the wiper blade.

4. Slide the wiper blade up into the hook on the wiper arm, latch engagement will be accompanied by an

audible click.

5. Gently lower the wiper blade onto the glass.

CAUTION!

Do not allow the wiper arm to spring back against the

glass without the wiper blade in place or the glass may

be damaged.

1 — Wiper Blade

2 — Wiper Arm

3 — Release Tab

1 — Wiper Blade

2 — Wiper Arm

3 — Release Tab

23_LA_OM_EN_USC_t.book Page 236