inflation pressure DODGE CHALLENGER 2023 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: CHALLENGER, Model: DODGE CHALLENGER 2023Pages: 300, PDF Size: 12.82 MB

Page 69 of 300

GETTING TO KNOW YOUR INSTRUMENT PANEL67

Loose Fuel Filler Cap Warning Light —

If Equipped

This warning light will illuminate when the fuel

filler cap is loose. Properly close the filler cap to

disengage the light. If the light does not turn

off, please see an authorized dealer.

Engine Check/Malfunction Indicator

Warning Light (MIL)

The Engine Check/Malfunction Indicator Light

(MIL) is a part of an Onboard Diagnostic System

called OBD II that monitors engine and

automatic transmission control systems.

This warning light will illuminate when the ignition is in the

ON/RUN position before engine start. If the bulb does not

come on when turning the ignition switch from OFF to

ON/RUN, have the condition checked promptly.

Certain conditions, such as a loose or missing gas cap,

poor quality fuel, etc., may illuminate the light after engine

start. The vehicle should be serviced if the light stays on

through several typical driving styles. In most situations,

the vehicle will drive normally and will not require towing.

When the engine is running, the MIL may flash to alert

serious conditions that could lead to immediate loss of

power or severe catalytic converter damage. The vehicle

should be serviced by an authorized dealer as soon as

possible if this occurs.

Service AWD Warning Light — If Equipped

This telltale will turn on to indicate the All Wheel

Drive (AWD) system is not functioning properly

and that service is required. Contact an

authorized dealer.

Service Forward Collision Warning (FCW)

Light — If Equipped

This warning light will illuminate to indicate a

fault in the Forward Collision Warning System.

Contact an authorized dealer for service

Úpage 167.

Tire Pressure Monitoring System (TPMS)

Warning Light

The warning light switches on and a message is

displayed to indicate that the tire pressure is

lower than the recommended value and/or

that slow pressure loss is occurring. In these

cases, optimal tire duration and fuel consumption may not

be guaranteed.

Should one or more tires be in the condition mentioned

previously, the display will show the indications

corresponding to each tire.

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer on

the vehicle placard or tire inflation pressure label. If your

vehicle has tires of a different size than the size indicated

on the vehicle placard or tire inflation pressure label, you

should determine the proper tire inflation pressure for

those tires.

WARNING!

A malfunctioning catalytic converter can reach higher

temperatures than in normal operating conditions. This

can cause a fire if you drive slowly or park over

flammable substances such as dry plants, wood,

cardboard, etc. This could result in death or serious

injury to the driver, occupants or others.

CAUTION!

Prolonged driving with the Malfunction Indicator Light

(MIL) on could cause damage to the vehicle control

system. It also could affect fuel economy and

driveability. If the MIL is flashing, severe catalytic

converter damage and power loss will soon occur.

Immediate service is required.CAUTION!

Do not continue driving with one or more flat tires as

handling may be compromised. Stop the vehicle,

avoiding sharp braking and steering. If a tire puncture

occurs, repair immediately using the dedicated tire

repair kit and contact an authorized dealer as soon as

possible.

3

23_LA_OM_EN_USC_t.book Page 67

Page 70 of 300

68GETTING TO KNOW YOUR INSTRUMENT PANEL

As an added safety feature, your vehicle has been

equipped with a TPMS that illuminates a low tire pressure

telltale when one or more of your tires is significantly

underinflated. Accordingly, when the low tire pressure

telltale illuminates, you should stop and check your tires

as soon as possible, and inflate them to the proper

pressure. Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire failure.

Underinflation also reduces fuel efficiency and tire tread

life, and may affect the vehicle’s handling and stopping

ability.

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver’s responsibility to

maintain correct tire pressure, even if underinflation has

not reached the level to trigger illumination of the TPMS

low tire pressure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon subsequent

vehicle start-ups as long as the malfunction exists. When

the malfunction indicator is illuminated, the system may

not be able to detect or signal low tire pressure as

intended. TPMS malfunctions may occur for a variety of

reasons, including the installation of replacement or

alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the TPMS malfunction telltale after

replacing one or more tires or wheels on your vehicle to

ensure that the replacement or alternate tires and wheels

allow the TPMS to continue to function properly.

YELLOW INDICATOR LIGHTS

Forward Collision Warning (FCW) OFF

Indicator Light — If Equipped

This indicator light illuminates to indicate that

Forward Collision Warning is off.

GREEN INDICATOR LIGHTS

Adaptive Cruise Control (ACC) Set Without

Target Vehicle Indicator Light —

If Equipped

This will display the distance setting for the ACC

system when the system is engaged

Úpage 85.

Adaptive Cruise Control (ACC) Set With

Target Vehicle Indicator Light —

If Equipped

This will display when the ACC is set and the

vehicle in front is detected Úpage 85.

Parking/Headlights On Indicator Light

This indicator light will illuminate when the

parking lights or headlights are turned on

Úpage 39.

Front Fog Indicator Light — If Equipped

This indicator light will illuminate when the

front fog lights are on Úpage 39.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system

operation or sensor damage may result when using

replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Using aftermarket tire sealants may

cause the Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended that you

take your vehicle to an authorized dealer to have your

sensor function checked.

23_LA_OM_EN_USC_t.book Page 68

Page 104 of 300

102STARTING AND OPERATING

Perform the maintenance listed in the “Scheduled

Servicing” Úpage 223. When towing a trailer, never

exceed the GAWR or GCWR ratings.

Towing Requirements — Tires

Do not attempt to tow a trailer while using a compact

spare tire.

Do not drive more than 50 mph (80 km/h) when towing

while using a full size spare tire.

Proper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle. For proper

tire inflation procedures.

Check the trailer tires for proper tire inflation pressures

before trailer usage.

Check for signs of tire wear or visible tire damage

before towing a trailer.

Replacing tires with a higher load carrying capacity will

not increase the vehicle's GVWR and GAWR limits.

For further information

Úpage 253.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury.

An electronically actuated trailer brake controller is

required when towing a trailer with electronically actu -

ated brakes. When towing a trailer equipped with a

hydraulic surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers over

1,000 lb (453 kg) and required for trailers in excess of

2,000 lb (907 kg).

Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-pin

wiring harness. Use a factory approved trailer harness and

connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

CAUTION!

Do not tow a trailer at all during the first 500 miles

(805 km) the new vehicle is driven. The engine, axle

or other parts could be damaged.

Then, during the first 500 miles (805 km) that a

trailer is towed, do not drive over 50 mph (80 km/h)

and do not make starts at full throttle. This helps the

engine and other parts of the vehicle wear in at the

heavier loads.

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your brake

system and cause it to fail. You might not have

brakes when you need them and could have an acci -

dent.

Towing any trailer will increase your stopping

distance. When towing, you should allow for addi -

tional space between your vehicle and the vehicle in

front of you. Failure to do so could result in an

accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

23_LA_OM_EN_USC_t.book Page 102

Page 171 of 300

SAFETY169

(Continued)

The tire pressure will vary with temperature by about 1 psi

(7 kPa) for every 12°F (6.5°C). This means that when the

outside temperature decreases, the tire pressure will

decrease. Tire pressure should always be set based on

cold inflation tire pressure. This is defined as the tire

pressure after the vehicle has not been driven for at least

three hours, or driven less than 1 mile (1.6 km) after a

three hour period. The cold tire inflation pressure must not

exceed the maximum inflation pressure molded into the

tire sidewall. The tire pressure will also increase as the

vehicle is driven — this is normal and there should be no

adjustment for this increased pressure.

See

Úpage 253 on how to properly inflate the

vehicle’s tires.

The TPMS will warn the driver of a low tire pressure if the

tire pressure falls below the low-pressure warning limit for

any reason, including low temperature effects and natural

pressure loss through the tire.

The TPMS will continue to warn the driver of low tire

pressure as long as the condition exists, and will not turn

off until the tire pressure is at or above the recommended

cold placard pressure. Once the low tire pressure warning

(TPMS Warning Light) illuminates, you must increase the

tire pressure to the recommended cold placard pressure

in order for the TPMS Warning Light to turn off. The system

will automatically update and the TPMS Warning Light will

turn off once the system receives the updated tire

pressures. The vehicle may need to be driven for up to

20 minutes above 15 mph (24 km/h) in order for the TPMS to receive this information.

NOTE:When filling warm tires, the tire pressure may need to be

increased up to an additional 4 psi (28 kPa) above the

recommended cold placard pressure in order to turn the

TPMS Warning Light off.

For example, your vehicle may have a recommended cold

(parked for more than three hours) placard pressure of

30 psi (207 kPa). If the ambient temperature is 68°F

(20°C) and the measured tire pressure is 27 psi

(186 kPa), a temperature drop to 20°F (-7°C) will

decrease the tire pressure to approximately 23 psi

(158 kPa). This tire pressure is sufficiently low enough to

turn on the TPMS Warning Light. Driving the vehicle may

cause the tire pressure to rise to approximately 27 psi

(186 kPa), but the TPMS Warning Light will still be on.

In this situation, the TPMS Warning Light will turn off only

after the tires are inflated to the vehicle’s recommended

cold placard pressure value

Úpage 284.

NOTE:

The TPMS is not intended to replace normal tire care

and maintenance or to provide warning of a tire failure

or condition.

The TPMS should not be used as a tire pressure gauge

while adjusting your tire pressure, unless your vehicle

is equipped with a Tire Fill Alert (TFA) system.

Driving on a significantly underinflated tire causes the

tire to overheat and can lead to tire failure. Underinfla -

tion also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire mainte -

nance, and it is the driver’s responsibility to maintain

correct tire pressure using an accurate tire pressure

gauge, even if underinflation has not reached the level

to trigger illumination of the TPMS Warning Light.

Seasonal temperature changes will affect tire pres -

sure, and the TPMS will monitor the actual tire pres -

sure in the tire.

CAUTION!

The TPMS has been optimized for the original equip -

ment tires and wheels. TPMS pressures and warning

have been established for the tire size equipped on

your vehicle. Undesirable system operation or sensor

damage may result when using replacement equip -

ment that is not of the same size, type, and/or style.

The TPMS sensor is not designed for use on after -

market wheels and may contribute to a poor overall

system performance or sensor damage. Customers

are encouraged to use Original Equipment Manufac -

turer (OEM) wheels to ensure proper TPMS feature

operation.

Using aftermarket tire sealants may cause the Tire

Pressure Monitoring System (TPMS) sensor to

become inoperable. After using an aftermarket tire

sealant it is recommended that you take your vehicle

to an authorized dealer to have your sensor function

checked.

After inspecting or adjusting the tire pressure always

reinstall the valve stem cap. This will prevent mois -

ture and dirt from entering the valve stem, which

could damage the TPMS sensor.

CAUTION!

6

23_LA_OM_EN_USC_t.book Page 169

Page 172 of 300

170SAFETY

Premium System

The Tire Pressure Monitoring System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire pressure

readings to the receiver module.

NOTE:It is particularly important for you to check the tire

pressure in all of the tires on your vehicle monthly and to

maintain the proper pressure.

The TPMS consists of the following components:

Receiver module

Four Tire Pressure Monitoring System sensors

Various Tire Pressure Monitoring System messages,

which display in the instrument cluster

Tire Pressure Monitoring System Warning Light

Tire Pressure Monitoring System Low

Pressure Warnings

The TPMS Warning Light will illuminate in the

instrument cluster and a chime will sound

when tire pressure is low in one or more of the

four active road tires. In addition, the

instrument cluster will display an “Inflate to XX” message

and a graphic showing the pressure values of each tire

with the low tire pressure values shown in a different color.

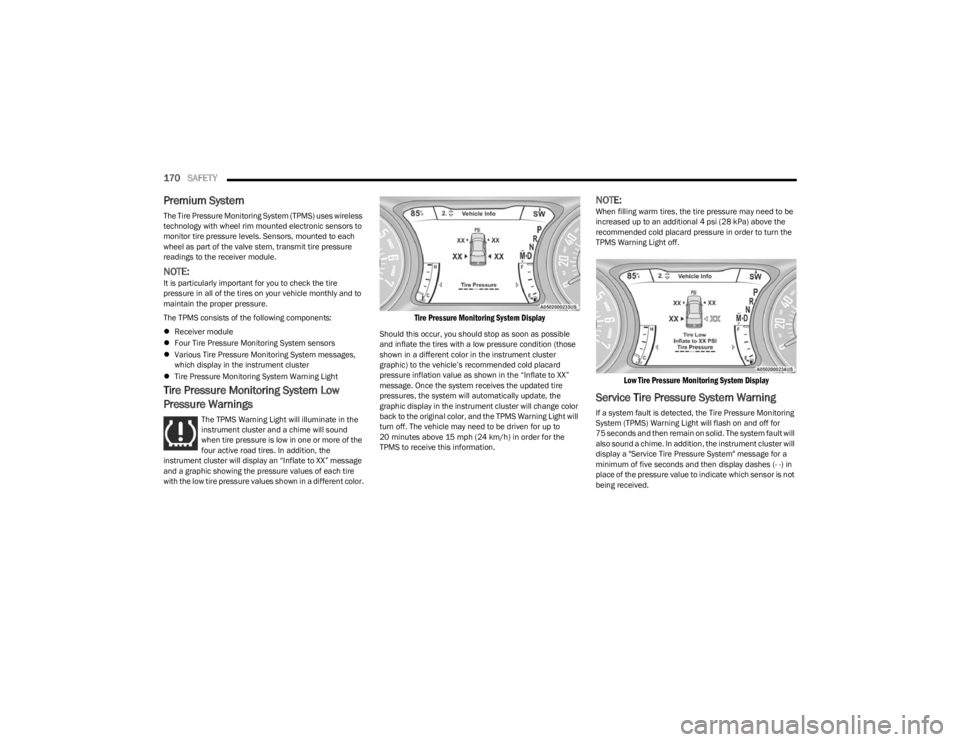

Tire Pressure Monitoring System Display

Should this occur, you should stop as soon as possible

and inflate the tires with a low pressure condition (those

shown in a different color in the instrument cluster

graphic) to the vehicle’s recommended cold placard

pressure inflation value as shown in the “Inflate to XX”

message. Once the system receives the updated tire

pressures, the system will automatically update, the

graphic display in the instrument cluster will change color

back to the original color, and the TPMS Warning Light will

turn off. The vehicle may need to be driven for up to

20 minutes above 15 mph (24 km/h) in order for the TPMS to receive this information.

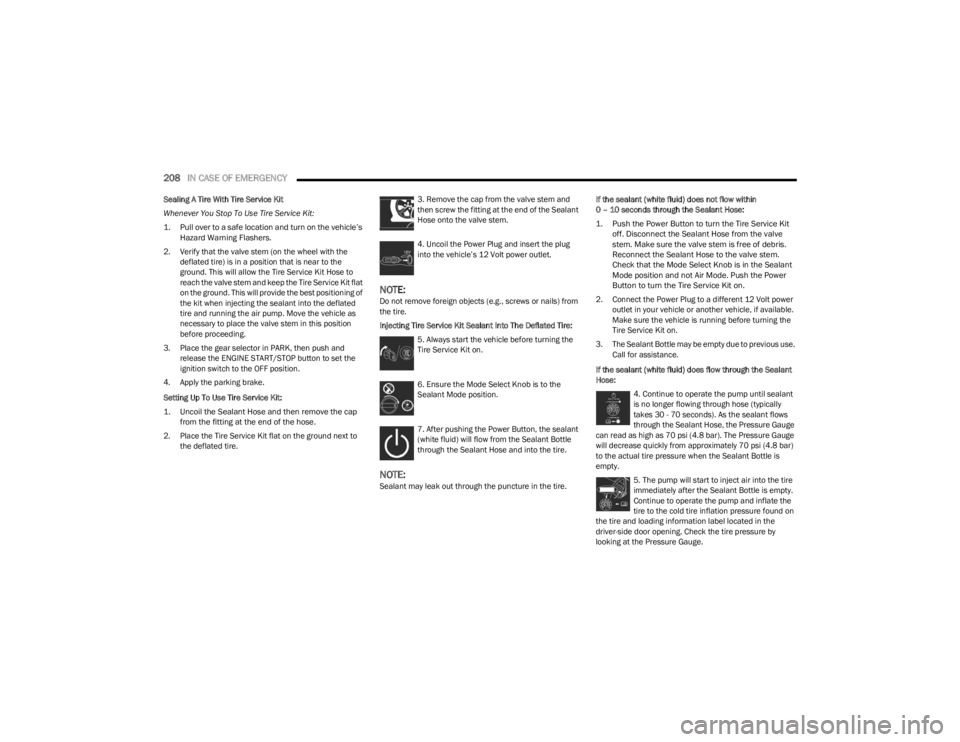

NOTE:When filling warm tires, the tire pressure may need to be

increased up to an additional 4 psi (28 kPa) above the

recommended cold placard pressure in order to turn the

TPMS Warning Light off.

Low Tire Pressure Monitoring System Display

Service Tire Pressure System Warning

If a system fault is detected, the Tire Pressure Monitoring

System (TPMS) Warning Light will flash on and off for

75 seconds and then remain on solid. The system fault will

also sound a chime. In addition, the instrument cluster will

display a "Service Tire Pressure System" message for a

minimum of five seconds and then display dashes (- -) in

place of the pressure value to indicate which sensor is not

being received.

23_LA_OM_EN_USC_t.book Page 170

Page 200 of 300

198SAFETY

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nuts/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn

signal and high beam indicator lights on the instrument

panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight parking for

fuel, coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel or brake fluid leaks are

suspected, the cause should be located and corrected

immediately.

EXHAUST GAS

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system. Whenever a change is noticed in the sound of the exhaust

system, when exhaust fumes can be detected inside the

vehicle, or when the underside or rear of the vehicle is

damaged, have an authorized dealer inspect the complete

exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

CARBON MONOXIDE WARNINGS

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing (CO), follow

these safety tips:

Do not run the engine in a closed garage or in

confined areas any longer than needed to move your

vehicle in or out of the area.

If you are required to drive with the trunk/liftgate/

rear doors open, make sure that all windows are

closed and the climate control BLOWER switch is set

at high speed. DO NOT use the recirculation mode.

If it is necessary to sit in a parked vehicle with the

engine running, adjust your heating or cooling

controls to force outside air into the vehicle. Set the

blower at high speed.

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly.

Follow the precautions below to prevent carbon

monoxide poisoning:

Do not inhale exhaust gases. They contain carbon

monoxide, a colorless and odorless gas, which can

kill. Never run the engine in a closed area, such as a

garage, and never sit in a parked vehicle with the

engine running for an extended period. If the vehicle

is stopped in an open area with the engine running

for more than a short period, adjust the ventilation

system to force fresh, outside air into the vehicle.

Guard against carbon monoxide with proper mainte -

nance. Have the exhaust system inspected every

time the vehicle is raised. Have any abnormal condi -

tions repaired promptly. Until repaired, drive with all

side windows fully open.

23_LA_OM_EN_USC_t.book Page 198

Page 210 of 300

208IN CASE OF EMERGENCY

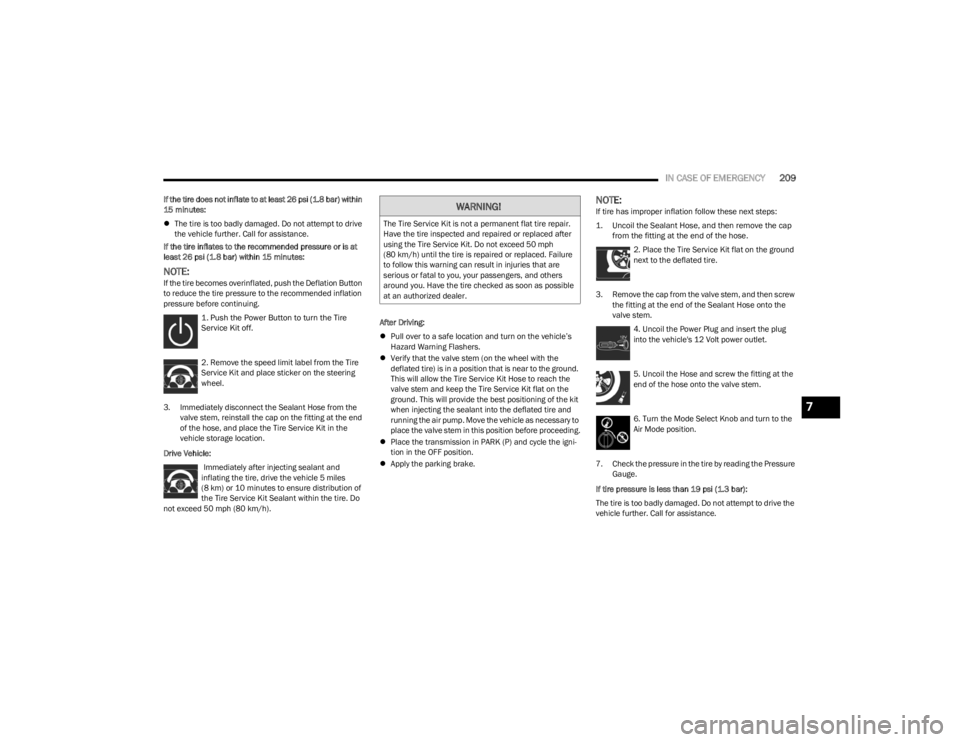

Sealing A Tire With Tire Service Kit

Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hose to

reach the valve stem and keep the Tire Service Kit flat

on the ground. This will provide the best positioning of

the kit when injecting the sealant into the deflated

tire and running the air pump. Move the vehicle as

necessary to place the valve stem in this position

before proceeding.

3. Place the gear selector in PARK, then push and release the ENGINE START/STOP button to set the

ignition switch to the OFF position.

4. Apply the parking brake.

Setting Up To Use Tire Service Kit:

1. Uncoil the Sealant Hose and then remove the cap from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on the ground next to the deflated tire. 3. Remove the cap from the valve stem and

then screw the fitting at the end of the Sealant

Hose onto the valve stem.

4. Uncoil the Power Plug and insert the plug

into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or nails) from

the tire.

Injecting Tire Service Kit Sealant Into The Deflated Tire:

5. Always start the vehicle before turning the

Tire Service Kit on.

6. Ensure the Mode Select Knob is to the

Sealant Mode position.

7. After pushing the Power Button, the sealant

(white fluid) will flow from the Sealant Bottle

through the Sealant Hose and into the tire.

NOTE:Sealant may leak out through the puncture in the tire. If the sealant (white fluid) does not flow within

0 – 10 seconds through the Sealant Hose:

1. Push the Power Button to turn the Tire Service Kit

off. Disconnect the Sealant Hose from the valve

stem. Make sure the valve stem is free of debris.

Reconnect the Sealant Hose to the valve stem.

Check that the Mode Select Knob is in the Sealant

Mode position and not Air Mode. Push the Power

Button to turn the Tire Service Kit on.

2. Connect the Power Plug to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the vehicle is running before turning the

Tire Service Kit on.

3. The Sealant Bottle may be empty due to previous use. Call for assistance.

If the sealant (white fluid) does flow through the Sealant

Hose: 4. Continue to operate the pump until sealant

is no longer flowing through hose (typically

takes 30 - 70 seconds). As the sealant flows

through the Sealant Hose, the Pressure Gauge

can read as high as 70 psi (4.8 bar). The Pressure Gauge

will decrease quickly from approximately 70 psi (4.8 bar)

to the actual tire pressure when the Sealant Bottle is

empty.

5. The pump will start to inject air into the tire

immediately after the Sealant Bottle is empty.

Continue to operate the pump and inflate the

tire to the cold tire inflation pressure found on

the tire and loading information label located in the

driver-side door opening. Check the tire pressure by

looking at the Pressure Gauge.

23_LA_OM_EN_USC_t.book Page 208

Page 211 of 300

IN CASE OF EMERGENCY209

If the tire does not inflate to at least 26 psi (1.8 bar) within

15 minutes:

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 bar) within 15 minutes:

NOTE:If the tire becomes overinflated, push the Deflation Button

to reduce the tire pressure to the recommended inflation

pressure before continuing.

1. Push the Power Button to turn the Tire

Service Kit off.

2. Remove the speed limit label from the Tire

Service Kit and place sticker on the steering

wheel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the fitting at the end

of the hose, and place the Tire Service Kit in the

vehicle storage location.

Drive Vehicle: Immediately after injecting sealant and

inflating the tire, drive the vehicle 5 miles

(8 km) or 10 minutes to ensure distribution of

the Tire Service Kit Sealant within the tire. Do

not exceed 50 mph (80 km/h). After Driving:

Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hose to reach the

valve stem and keep the Tire Service Kit flat on the

ground. This will provide the best positioning of the kit

when injecting the sealant into the deflated tire and

running the air pump. Move the vehicle as necessary to

place the valve stem in this position before proceeding.

Place the transmission in PARK (P) and cycle the igni -

tion in the OFF position.

Apply the parking brake.

NOTE:If tire has improper inflation follow these next steps:

1. Uncoil the Sealant Hose, and then remove the cap

from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on the ground

next to the deflated tire.

3. Remove the cap from the valve stem, and then screw the fitting at the end of the Sealant Hose onto the

valve stem.

4. Uncoil the Power Plug and insert the plug

into the vehicle's 12 Volt power outlet.

5. Uncoil the Hose and screw the fitting at the

end of the hose onto the valve stem.

6. Turn the Mode Select Knob and turn to the

Air Mode position.

7. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 bar):

The tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.WARNING!

The Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced after

using the Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced. Failure

to follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others

around you. Have the tire checked as soon as possible

at an authorized dealer.

7

23_LA_OM_EN_USC_t.book Page 209

Page 212 of 300

210IN CASE OF EMERGENCY

If the tire pressure is 19 psi (1.3 bar) or higher:

1. Push the Power Button to turn on Tire

Service Kit and inflate the tire to the cold tire

inflation pressure found on the tire and

loading information label located in the

driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation Button

to reduce the tire pressure to the recommended inflation

pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and unplug from

12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the steering wheel after the tire has been repaired.

6. Replace the Sealant Bottle at an authorized dealer as soon as possible.

NOTE:When having the tire serviced, advise the authorized

dealer or service center that the tire has been sealed

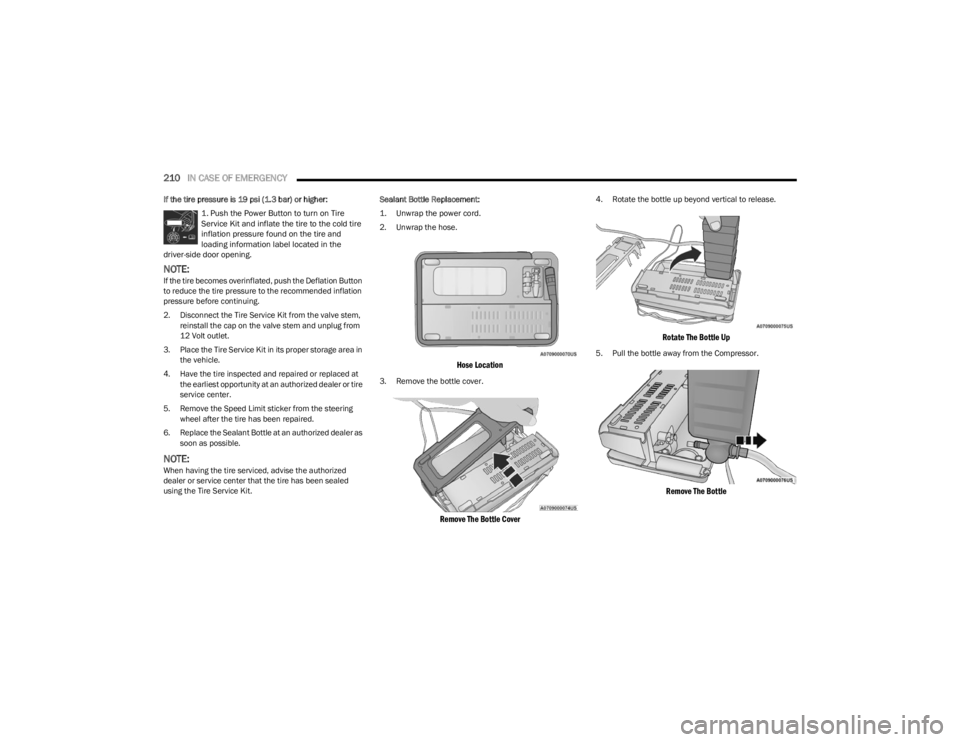

using the Tire Service Kit. Sealant Bottle Replacement:

1. Unwrap the power cord.

2. Unwrap the hose.

Hose Location

3. Remove the bottle cover.

Remove The Bottle Cover

4. Rotate the bottle up beyond vertical to release.

Rotate The Bottle Up

5. Pull the bottle away from the Compressor.

Remove The Bottle

23_LA_OM_EN_USC_t.book Page 210

Page 216 of 300

214IN CASE OF EMERGENCY

(B) SETTING UP TO USE TIRE SERVICE KIT:

1. Push in the Mode Select Knob (6) and turn to the

Sealant Mode position.

2. Uncoil the Sealant Hose (4) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (4) onto the

valve stem.

5. Uncoil the Power Plug (7) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or nails) from

the tire.

(C) INJECTING TIRE SERVICE KIT SEALANT

INTO THE DEFLATED TIRE:

Always start the engine before turning ON the Tire

Service Kit.

NOTE:Manual transmission vehicles must have the parking

brake engaged and the gear selector in NEUTRAL.

After pushing the Power Button (3), the sealant (white

fluid) will flow from the Sealant Bottle (1) through the

Sealant Hose (4) and into the tire.

NOTE:Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within 0 – 10

seconds through the Sealant Hose :

1. Push the Power Button (3) to turn Off the Tire

Service Kit. Disconnect the Sealant Hose (4) from

the valve stem. Make sure the valve stem is free of

debris. Reconnect the Sealant Hose (4) to the valve

stem. Check that the Mode Select Knob (6) is in the

Sealant Mode position and not Air Mode. Push the

Power Button (3) to turn On the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another vehicle, if

available. Make sure the engine is running before

turning ON the Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob (6) is on Air Mode and the pump

is operating, air will dispense from the Air Pump Hose (8)

only, not the Sealant Hose (4). If the sealant (white fluid) does flow through the Sealant

Hose :

1. Continue to operate the pump until sealant is no

longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through the

Sealant Hose (4), the Pressure Gauge (5) can read

as high as 70 psi (4.8 Bar). The Pressure Gauge (5)

will decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when the

Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is empty.

Continue to operate the pump and inflate the tire to

the pressure indicated on the tire pressure label on

the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure

Gauge (5).

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.NOTE:If the tire becomes overinflated, push the Deflation Button

(2) to reduce the tire pressure to the recommended

inflation pressure before continuing.

23_LA_OM_EN_USC_t.book Page 214