light DODGE CHARGER 2008 6.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: CHARGER, Model: DODGE CHARGER 2008 6.GPages: 466, PDF Size: 6.37 MB

Page 353 of 466

6. Raise the vehicle just enough to remove the flat tire

and install the spare tire.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

7. Remove the lug nuts, wheel cover (if equipped), and

tire. Remove the cover by hand. Do not pry it off.

8. Mount the spare tire.

NOTE:For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the compact spare.

However, when reinstalling the road tire, follow the

procedure under ªWheel Cover or Center Cap Installa-

tionº in place of the remaining steps in this procedure.9. Install the lug nuts with the cone shaped end of the

nut toward the wheel. Lightly tighten the lug nuts. To

avoid the risk of forcing the vehicle off the jack, do not

tighten the lug nuts fully until the vehicle is lowered to

the ground.

10. Lower the vehicle to the ground by turning the jack

handle counter-clockwise.

11. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

lug nuts until each nut has been tightened twice. The

correct tightness of each lug nut is 100 ft/lb. (135 N. m).

If in doubt about the correct tightness, have them

checked with a torque wrench by your dealer or at a

service station.

12. Stow the jack, tools, and flat tire. Make sure the base

of the jack faces the rear of the vehicle before tightening

down the fastener.

WHAT TO DO IN EMERGENCIES 353

6

Page 355 of 466

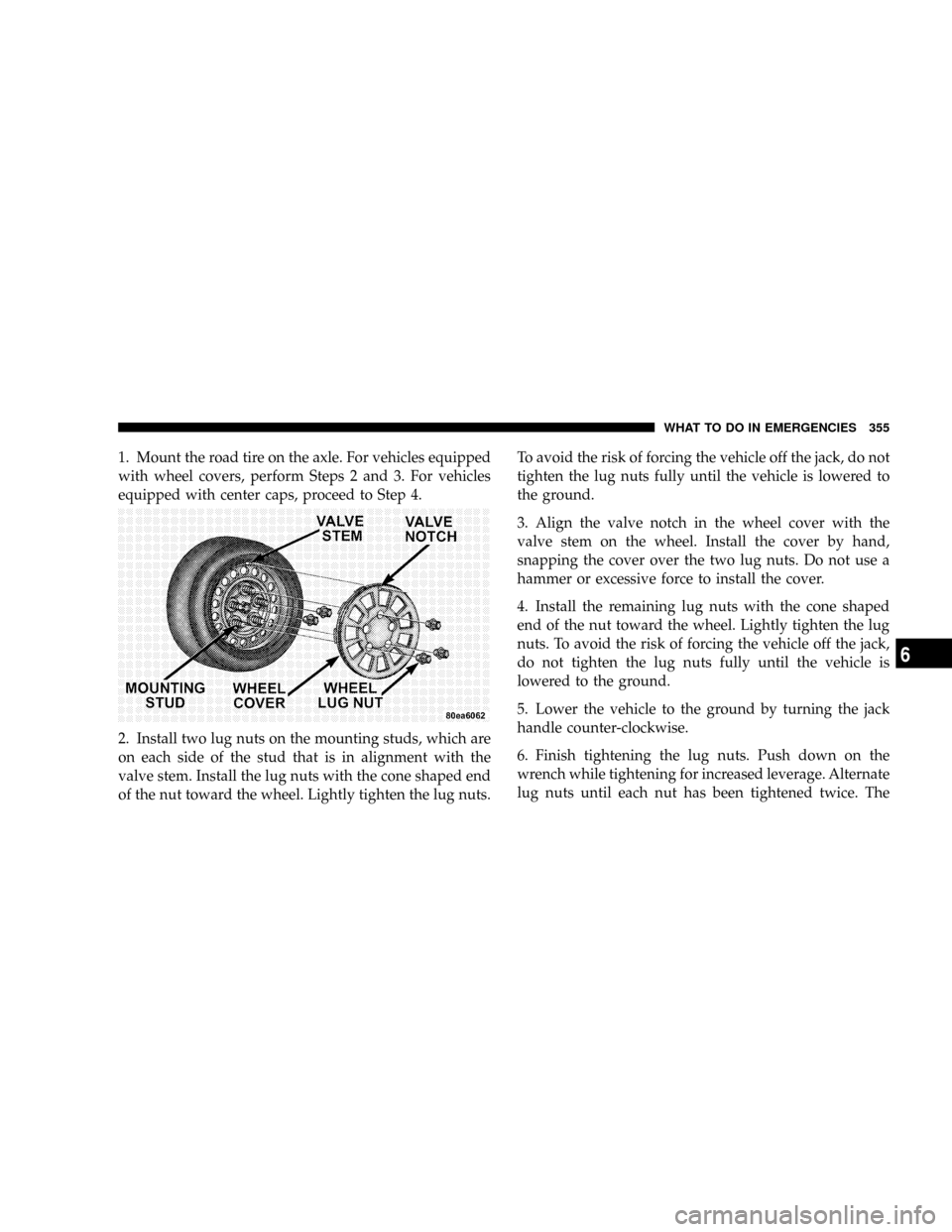

1. Mount the road tire on the axle. For vehicles equipped

with wheel covers, perform Steps 2 and 3. For vehicles

equipped with center caps, proceed to Step 4.

2. Install two lug nuts on the mounting studs, which are

on each side of the stud that is in alignment with the

valve stem. Install the lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the lug nuts.To avoid the risk of forcing the vehicle off the jack, do not

tighten the lug nuts fully until the vehicle is lowered to

the ground.

3. Align the valve notch in the wheel cover with the

valve stem on the wheel. Install the cover by hand,

snapping the cover over the two lug nuts. Do not use a

hammer or excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped

end of the nut toward the wheel. Lightly tighten the lug

nuts. To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle is

lowered to the ground.

5. Lower the vehicle to the ground by turning the jack

handle counter-clockwise.

6. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

lug nuts until each nut has been tightened twice. The

WHAT TO DO IN EMERGENCIES 355

6

Page 359 of 466

NOTE:For vehicles equipped with ESP, refer to9Syn-

chronizing ESP9under9Electronic Stability Program9in

Section 5 of this manual if the ESP/BAS light (in the

instrument cluster) remains on continuously after start-

ing the engine of the vehicle with the discharged battery.

8. When removing the jumper cables, reverse the above

sequence exactly. Be careful of the moving belts and fan.

WARNING!

Any procedure other than above could result in:

1. Personal injury caused by electrolyte squirting out

the battery vent;

2. Personal injury or property damage due to battery

explosion;

3. Damage to charging system of booster vehicle or

of immobilized vehicle.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow, it

can often be moved by a rocking motion. Turn your

steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between Reverse

and Drive. Usually the least accelerator pedal pressure to

maintain the rocking motion without spinning the

wheels is most effective.

NOTE:Turn off the Electronic Stability Program (ESP)

Ð if equipped, or Traction Control System (TCS) Ð if

equipped before rocking the vehicle. For details, refer to

ªElectronic Stability Programº or ªTraction Control Sys-

temº in this manual.

WHAT TO DO IN EMERGENCIES 359

6

Page 364 of 466

NMaintenance-Free Battery................381

NAir Conditioner Maintenance.............383

NA/C Air Filter Ð If Equipped............384

NPower Steering Ð Fluid Check............384

NFront & Rear Suspension Ball Joints........385

NSteering Linkage......................385

NBody Lubrication.....................385

NWindshield Wiper Blades................386

NWindshield Washers...................386

NExhaust System......................387

NCooling System.......................388

NHoses And Vacuum/Vapor Harnesses.......393

NFuel System.........................393NBrake System........................394

NAutomatic Transmission................396

NAll Wheel Drive (AWD) Ð If Equipped.....398

NFront And Rear Wheel Bearings...........398

NAppearance Care And Protection From

Corrosion...........................398

NCleaning The Center Console Cup Holders . . . 403

mFuses (Power Distribution Centers)..........404

NFuses (Front Power Distribution Center).....404

NFuses (Rear Power Distribution Center)......406

mVehicle Storage........................411

mReplacement Light Bulbs.................412

mBulb Replacement......................413

364 MAINTAINING YOUR VEHICLE

Page 365 of 466

NLow Beam Headlight, High Beam Headlight,

Park/Turn Light, And Front Side Marker

Light..............................413

NBackup Light, Side Marker Light, Tail/Turn

Light, And Tail/Stop Light...............415

NLicense Light........................418mFluids And Capacities...................419

mFluids, Lubricants, And Genuine Parts........421

NEngine.............................421

NChassis............................423

MAINTAINING YOUR VEHICLE 365

7

Page 370 of 466

ONBOARD DIAGNOSTIC SYSTEM Ð OBD II

Your vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the ªMalfunction Indicator Light.º It will

also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your dealer for service as soon as

possible.CAUTION!

Prolonged driving with the ªMalfunction Indicator

Lightº on could cause further damage to the emission

control system. It could also affect fuel economy and

driveability. The vehicle must be serviced before any

emissions tests can be performed.

If the ªMalfunction Indicator Lightº is flashing

while the engine is running, severe catalytic con-

verter damage and power loss will soon occur. Im-

mediate service is required.

Loose Fuel Filler Cap

If the vehicle diagnostic system determines that the fuel

filler cap is loose, improperly installed, or damaged, a

ªCheck Gascapº message will display in the Electronic

Vehicle Information Center (EVIC) Ð if equipped. If this

occurs, tighten the fuel filler cap properly and press the

370 MAINTAINING YOUR VEHICLE

Page 371 of 466

odometer reset button to turn off the message. If the

problem continues, the message will appear the next time

the vehicle is started.

A loose, improperly installed, or damaged fuel filler cap

may also turn on the Malfunction Indicator Light (MIL).

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass

an inspection of your vehicle's emissions control system.

Failure to pass could prevent vehicle registration.

For states, which have an I/M (Inspection and

Maintenance) requirement, this check verifies the

following: the MIL (Malfunction Indicator Light)

is functioning and is not on when the engine is running,

and that the OBD (On Board Diagnostic) system is ready

for testing.Normally, the OBD system will be ready. The OBD

system maynotbe ready if your vehicle was recently

serviced, if you recently had a dead battery, or a battery

replacement. If the OBD system should be determined

not ready for the I/M test, your vehicle may fail the test.

Your vehicle has a simple ignition key actuated test,

which you can use prior to going to the test station. To

check if your vehicle's OBD system is ready, you must do

the following:

1. Insert your ignition key into the ignition switch.

2. Turn the ignition to the ON position, but do not crank

or start the engine.

3. If you crank or start the engine, you will have to start

this test over.

4. As soon as you turn your key to the ON position, you

will see your MIL symbol come on as part of a normal

bulb check.

MAINTAINING YOUR VEHICLE 371

7

Page 395 of 466

necessarily an indication of leakage. Actual dripping

of hot fluid when systems are under pressure (during

vehicle operation), should be noted before a hose is

replaced based on leakage.

²Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replaced

immediately! Eventual deterioration of the hose can

take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder Ð Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the brake system warning light indicates system fail-

ure.

Check the fluid level in the master cylinder when per-

forming underhood services.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

ªFULLº mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.

MAINTAINING YOUR VEHICLE 395

7

Page 398 of 466

All Wheel Drive (AWD) Ð If Equipped

The all wheel drive system consists of a Transfer Case

and Front Differential. The exterior surface of these

components should be inspected for evidence of fluid

leaks. Confirmed leaks should be repaired as soon as

possible.

The transfer case fluid inspection plug is located in the

middle of the rear housing. To inspect the transfer case

fluid level, remove the inspection plug. The fluid level

should be even with the bottom of the hole. The transfer

case fill plug is located on the rear housing near the

output shaft.

The front differential fill plug is located on the outer

cover near the halfshaft attachment. To inspect the differ-

ential fluid level, remove the fill plug. The fluid level

should be even with or slightly below the bottom of the

hole.

Fluid Changes

Refer to the ªMaintenance Scheduleº in Section 8 of this

manual for the recommended transfer case fluid change

intervals.

Front And Rear Wheel Bearings

Front and rear wheel bearings are permanently sealed.

No regular maintenance is required for these compo-

nents.

Appearance Care and Protection from Corrosion

Protection of Body and Paint from Corrosion

Vehicle body care requirements vary according to geo-

graphic locations and usage. Chemicals that make roads

passable in snow and ice, and chemicals that are sprayed

on trees and road surfaces during other seasons, are

highly corrosive to the metal in your vehicle. Outside

parking, which exposes your vehicle to airborne contami-

nants, road surfaces on which the vehicle is operated,

398 MAINTAINING YOUR VEHICLE

Page 402 of 466

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in

closed areas they may cause respiratory harm.

Cleaning Headlights

Your vehicle has plastic headlights that are lighter and

less susceptible to stone breakage than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution fol-

lowed by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

Glass Surfaces

All glass surfaces should be cleaned on a regular basis

with MopartGlass Cleaner or any commercial

household-type glass cleaner. Never use an abrasive type

cleaner. Use caution when cleaning the inside rear win-

dow equipped with electric defrosters or the right rear

quarter window equipped with the radio antenna. Do

not use scrapers or other sharp instruments, which may

scratch the elements.

When cleaning the rear view mirror, spray cleaner on the

towel or rag that you are using. Do not spray cleaner

directly on the mirror.

Cleaning Plastic Instrument Cluster Lenses

The lenses in front of the instruments in this vehicle are

molded in clear plastic. When cleaning the lenses, care

must be taken to avoid scratching the plastic.

402 MAINTAINING YOUR VEHICLE