oil DODGE CHARGER 2013 7.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2013, Model line: CHARGER, Model: DODGE CHARGER 2013 7.GPages: 132, PDF Size: 4.77 MB

Page 90 of 132

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting TIREFIT Sealant Into The Deflated Tire:

• Always start the engine before turning ON the TIREFIT kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

• After pressing the Power Button (4), the sealant (white fluid) will flow from the SealantBottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

• If the sealant (white fluid) does not flow within 0 – 10 seconds through the Sealant

Hose (6):

1. Press the Power Button (4) to turn Off the TIREFIT kit. Disconnect the Sealant Hose (6) from the valve stem. Make sure the valve stem is free of debris. Reconnect the Sealant

Hose (6) to the valve stem. Check that the Mode Select Knob (5) is in the Sealant Mode

position and not Air Mode. Press the Power Button (4) to turn On the TIREFIT kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or another vehicle, if available. Make sure the engine is running before turning ON the TIREFIT kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense from

the Air Pump Hose (7) only, not the Sealant Hose (6).

• If the sealant (white fluid) does flow through the Sealant Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through the hose (typically takes 30 - 70 seconds). As the sealant flows through the Sealant Hose (6), the

Pressure Gauge (3) can read as high as 70 psi (5 kPa). The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (5 kPa) to the actual tire pressure when the

Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is empty. Continue to operate the pump and inflate the tire to the pressure indicated on the

tire pressure label on the driver-side latch pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (3).

• If the tire does not inflate to at least 26 psi (1.8 kPa) pressure within 15 minutes:

• The tire is too badly damaged. Do not attempt to drive the vehicle further. Call for assistance.

WHAT TO DO IN EMERGENCIES

88

Page 91 of 132

NOTE:

If the tire becomes over-inflated, press the Deflation Button to reduce the tire pressure to

the recommended inflation pressure before continuing.

•If the tire inflates to the recommended pressure or is at least 26 psi (1.8 Bar) pressure

within 15 minutes:

1. Press the Power Button (4) to turn off the TIREFIT kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the sticker on the instrument panel.

3. Immediately disconnect the Sealant Hose (6) from the valve stem, reinstall the cap on the fitting at the end of the hose, and place the TIREFIT kit in the vehicle storage

location. Quickly proceed to (D) “Drive Vehicle”.

(D) Drive Vehicle:

• Immediately after injecting sealant and inflating the tire, drive the vehicle 5 miles (8 km)or 10 minutes to ensure distribution of the TIREFIT Sealant within the tire. Do not exceed

55 mph (88 km/h).

(E) After Driving:

• Pull over to a safe location. Refer to “Whenever You Stop to Use TIREFIT” beforecontinuing.

1. Turn the Mode Select Knob (5) to the Air Mode position.

2. Uncoil the Air Pump Hose (7) (black in color) and screw the fitting at the end of hose (7) onto the valve stem.

3. Uncoil the power plug and insert the plug into the vehicles 12 Volt power outlet.

4. Check the pressure in the tire by reading the Pressure Gauge (3).

• If tire pressure is less than 19 psi (1.3 kPa), the tire is too badly damaged. Do not

attempt to drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 kPa) or higher:

1. Press the Power Button (4) to turn on TIREFIT and inflate the tire to the pressure indicated on the tire and loading information label on the driver-side door opening.

2. Disconnect the TIREFIT kit from the valve stem, reinstall the cap on the valve stem and unplug from 12 Volt outlet.

3. Place the TIREFIT kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire service center.

5. Replace the Sealant Bottle (1) and Sealant Hose (6) assembly at your authorized dealer as soon as possible. Refer to “(F) Sealant Bottle and Hose Replacement.”

WHAT TO DO IN EMERGENCIES

89

Page 92 of 132

NOTE:

• If the tire becomes over-inflated, press the Deflation Button to reduce the tire pressure tothe recommended inflation pressure before continuing.

• When having the tire serviced, advise the authorized dealer or service center that the tire has been sealed using the TIREFIT service kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant

bottle.

3. Press the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the bottle and dispose of it accordingly.

4. Clean any remaining sealant from the TIREFIT housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (6) aligns with the hose slot in the front of the housing. Press the bottle into the housing. An audible

click will be heard indicating the bottle is locked into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (6) and return the hose to its storage area (located on the bottom of the air pump).

7. Return the TIREFIT kit to its storage location in the vehicle.

CAUTION!

• The metal end fitting from Power Plug (8) may get hot after use, so it should be handled carefully.

• Failure to reinstall the cap on the fitting at the end of the Sealant Hose (6) can result

in sealant contacting your skin, clothing, and the vehicle’s interior. It can also result in

sealant contacting internal TIREFIT kit components which may cause permanent

damage to the kit.

WHAT TO DO IN EMERGENCIES

90

Page 107 of 132

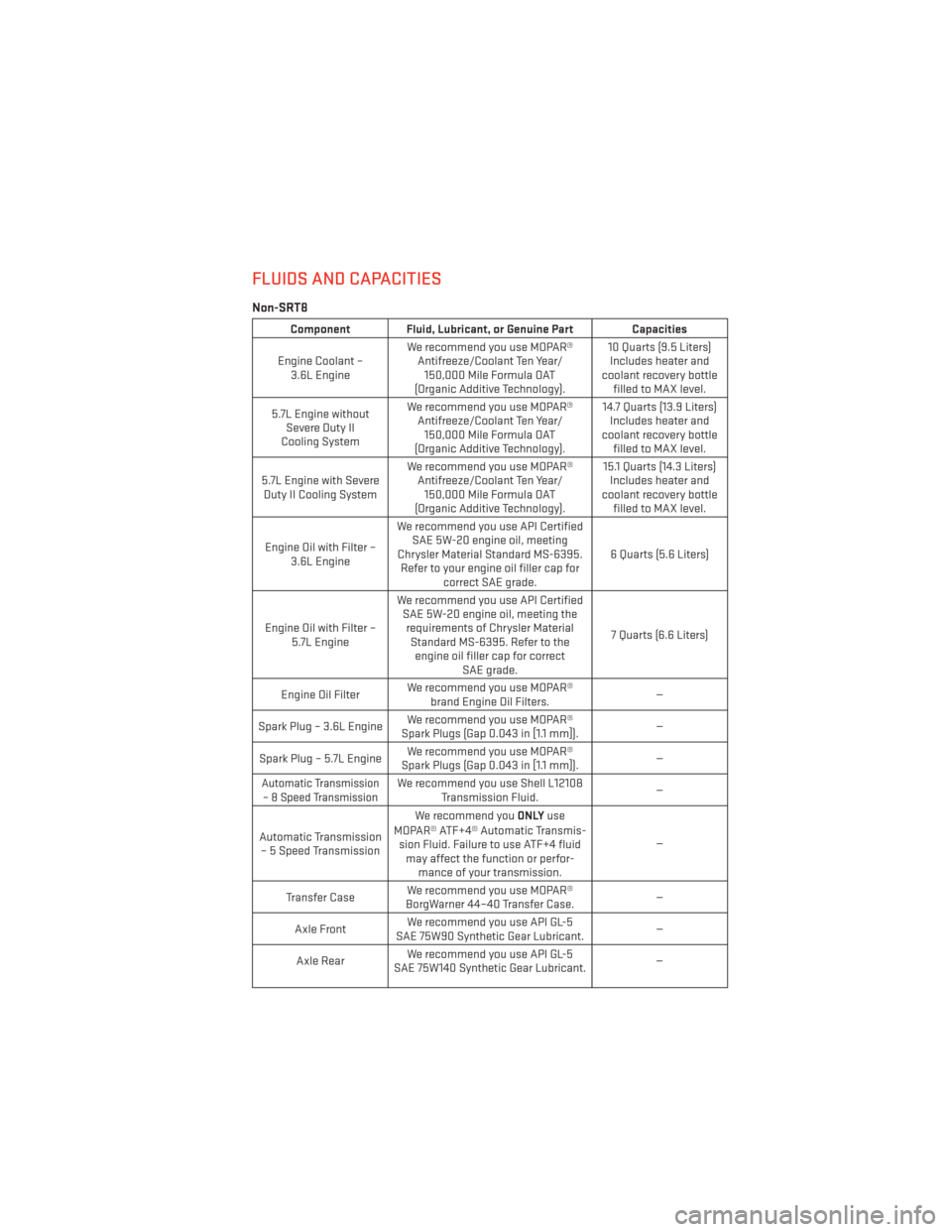

FLUIDS AND CAPACITIES

Non-SRT8

Component Fluid, Lubricant, or Genuine Part Capacities

Engine Coolant – 3.6L Engine We recommend you use MOPAR®

Antifreeze/Coolant Ten Year/150,000 Mile Formula OAT

(Organic Additive Technology). 10 Quarts (9.5 Liters)

Includes heater and

coolant recovery bottle filled to MAX level.

5.7L Engine without Severe Duty II

Cooling System We recommend you use MOPAR®

Antifreeze/Coolant Ten Year/150,000 Mile Formula OAT

(Organic Additive Technology). 14.7 Quarts (13.9 Liters)

Includes heater and

coolant recovery bottle filled to MAX level.

5.7L Engine with Severe Duty II Cooling System We recommend you use MOPAR®

Antifreeze/Coolant Ten Year/150,000 Mile Formula OAT

(Organic Additive Technology). 15.1 Quarts (14.3 Liters)

Includes heater and

coolant recovery bottle filled to MAX level.

Engine Oil with Filter – 3.6L Engine We recommend you use API Certified

SAE 5W-20 engine oil, meeting

Chrysler Material Standard MS-6395. Refer to your engine oil filler cap for correct SAE grade. 6 Quarts (5.6 Liters)

Engine Oil with Filter – 5.7L Engine We recommend you use API Certified

SAE 5W-20 engine oil, meeting therequirements of Chrysler Material Standard MS-6395. Refer to the engine oil filler cap for correct SAE grade. 7 Quarts (6.6 Liters)

Engine Oil Filter We recommend you use MOPAR®

brand Engine Oil Filters. —

Spark Plug – 3.6L Engine We recommend you use MOPAR®

Spark Plugs (Gap 0.043 in [1.1 mm]). —

Spark Plug – 5.7L Engine We recommend you use MOPAR®

Spark Plugs (Gap 0.043 in [1.1 mm]). —

Automatic Transmission

– 8 Speed TransmissionWe recommend you use Shell L12108 Transmission Fluid. —

Automatic Transmission – 5 Speed Transmission We recommend you

ONLYuse

MOPAR® ATF+4® Automatic Transmis- sion Fluid. Failure to use ATF+4 fluid may affect the function or perfor- mance of your transmission. —

Transfer Case We recommend you use MOPAR®

BorgWarner 44–40 Transfer Case. —

Axle Front We recommend you use API GL-5

SAE 75W90 Synthetic Gear Lubricant. —

Axle Rear We recommend you use API GL-5

SAE 75W140 Synthetic Gear Lubricant. —

MAINTAINING YOUR VEHICLE

105

Page 108 of 132

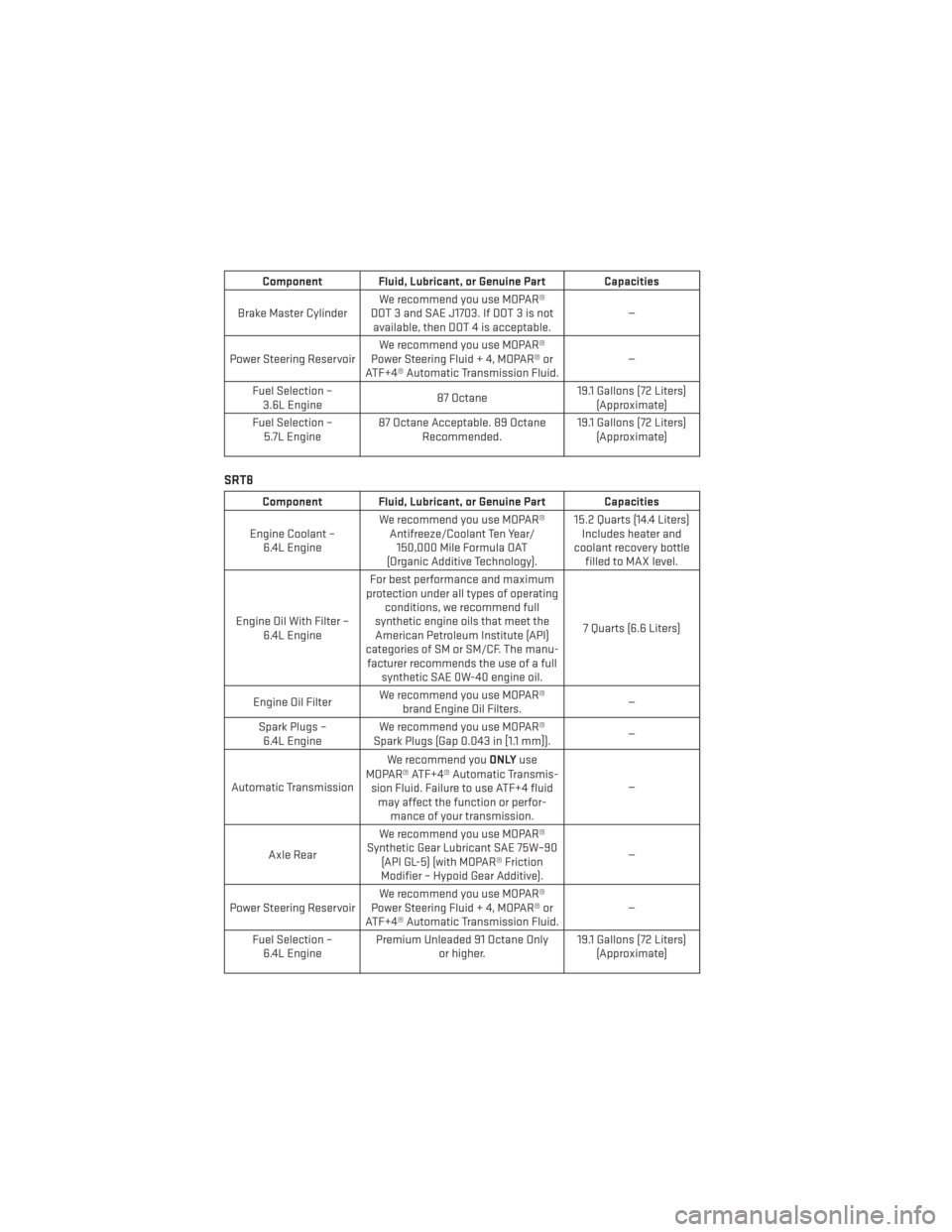

Component Fluid, Lubricant, or Genuine Part Capacities

Brake Master Cylinder We recommend you use MOPAR®

DOT 3 and SAE J1703. If DOT 3 is not available, then DOT 4 is acceptable. —

Power Steering Reservoir We recommend you use MOPAR®

Power Steering Fluid + 4, MOPAR® or

ATF+4® Automatic Transmission Fluid. —

Fuel Selection – 3.6L Engine 87 Octane19.1 Gallons (72 Liters)

(Approximate)

Fuel Selection – 5.7L Engine 87 Octane Acceptable. 89 Octane

Recommended. 19.1 Gallons (72 Liters)

(Approximate)

SRT8

Component Fluid, Lubricant, or Genuine Part Capacities

Engine Coolant – 6.4L Engine We recommend you use MOPAR®

Antifreeze/Coolant Ten Year/150,000 Mile Formula OAT

(Organic Additive Technology). 15.2 Quarts (14.4 Liters)

Includes heater and

coolant recovery bottle filled to MAX level.

Engine Oil With Filter – 6.4L Engine For best performance and maximum

protection under all types of operating conditions, we recommend full

synthetic engine oils that meet the American Petroleum Institute (API)

categories of SM or SM/CF. The manu- facturer recommends the use of a full synthetic SAE 0W-40 engine oil. 7 Quarts (6.6 Liters)

Engine Oil Filter We recommend you use MOPAR®

brand Engine Oil Filters. —

Spark Plugs – 6.4L Engine We recommend you use MOPAR®

Spark Plugs (Gap 0.043 in [1.1 mm]). —

Automatic Transmission We recommend you

ONLYuse

MOPAR® ATF+4® Automatic Transmis- sion Fluid. Failure to use ATF+4 fluid may affect the function or perfor- mance of your transmission. —

Axle Rear We recommend you use MOPAR®

Synthetic Gear Lubricant SAE 75W–90 (API GL-5) (with MOPAR® Friction

Modifier – Hypoid Gear Additive). —

Power Steering Reservoir We recommend you use MOPAR®

Power Steering Fluid + 4, MOPAR® or

ATF+4® Automatic Transmission Fluid. —

Fuel Selection – 6.4L Engine Premium Unleaded 91 Octane Only

or higher. 19.1 Gallons (72 Liters)

(Approximate)

MAINTAINING YOUR VEHICLE

106

Page 110 of 132

MAINTENANCE SCHEDULE

Your vehicle is equipped with an automatic oil change indicator system. The oil change

indicator system will remind you that it is time to take your vehicle in for scheduled

maintenance.

Based on engine operation conditions, the oil change indicator message will illuminate.

This means that service is required for your vehicle. Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold ambient temperatures, and E85 fuel usage

will influence when the “Change Oil” or “Oil Change Required” message is displayed.

Severe Operating Conditions can cause the change oil message to illuminate as early as

3,500 miles (5,600 km) since last reset. Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

On Electronic Vehicle Information Center (EVIC) equipped vehicles, “Oil Change Required”

will be displayed in the EVIC and a single chime will sound, indicating that an oil change is

necessary.

On Non-EVIC equipped vehicles, “Change Oil” will flash in the instrument cluster odometer

and a single chime will sound, indicating that an oil change is necessary.

Your authorized dealer will reset the oil change indicator message after completing the

scheduled oil change. If a scheduled oil change is performed by someone other than your

authorized dealer, the message can be reset by referring to the steps described under

“Electronic Vehicle Information Center (EVIC)/Oil Change Required” in “Understanding Your

Instrument Panel” or under “Instrument Cluster Description/Odometer/Trip Odometer” in

“Understanding Your Instrument Panel” for further information.

NOTE:

Under no circumstances should oil change intervals exceed 10,000 miles (16,000 km) or

twelve months, whichever comes first.

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual wear or damage

• Check the fluid levels of the coolant reservoir, brake master cylinder, power steering andtransmission as needed

• Check function of all interior and exterior lights

MAINTAINING YOUR VEHICLE

108

Page 111 of 132

Required Maintenance Intervals.

Refer to the maintenance schedules on the following page for the required maintenance

intervals.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

• Change oil and filter

• Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil

indicator system turns on.

• Inspect battery and clean and tighten terminals as required

• Inspect automatic transmission fluid if equipped with dipstick

• Inspect brake pads, shoes, rotors, drums, hoses and park brake

• Inspect engine cooling system protection and hoses

• Inspect exhaust system

• Inspect engine air cleaner if using in dusty or off-road conditions

MAINTAINING YOUR VEHICLE

109

Page 115 of 132

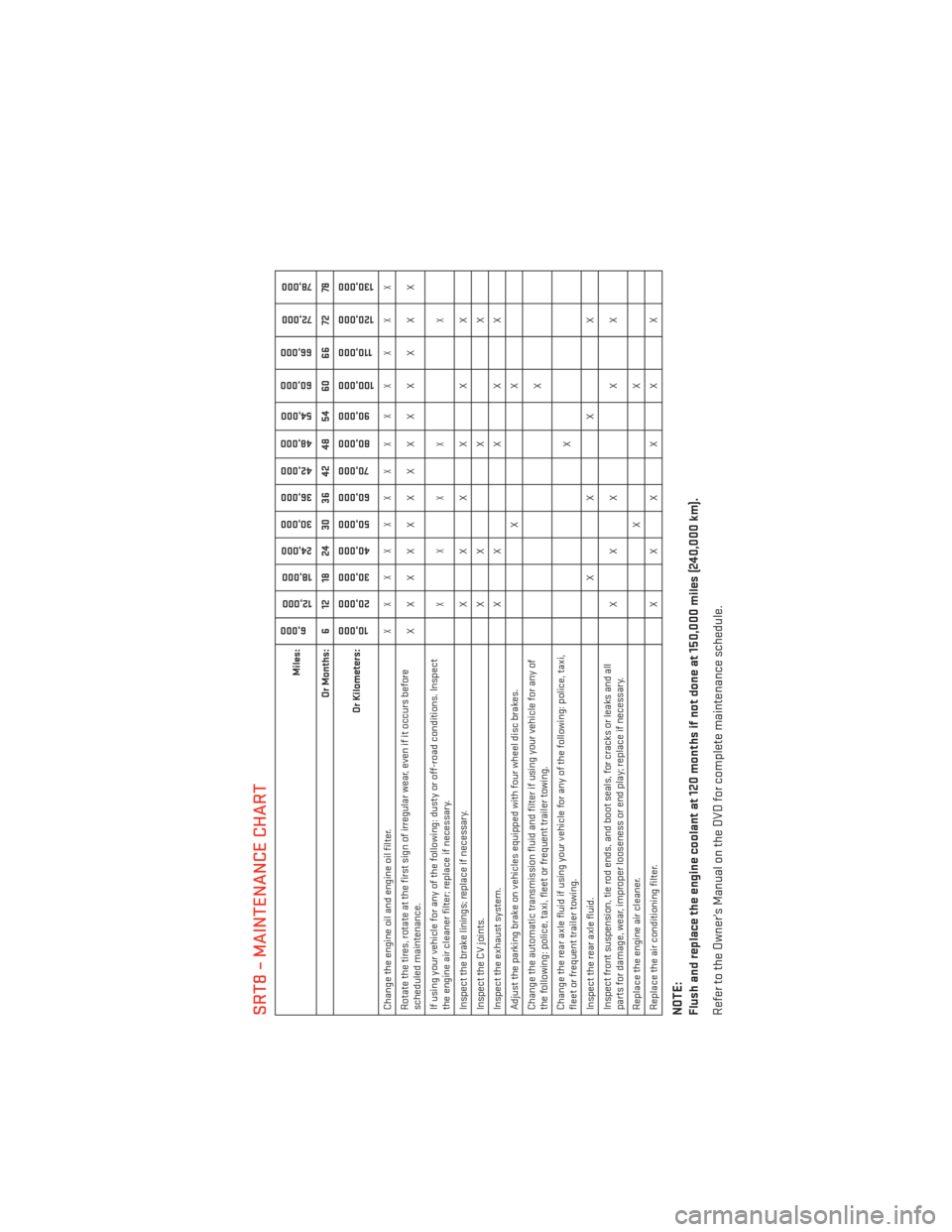

SRT8 – MAINTENANCE CHART

Miles:

6,000

12,000

18,000

24,000

30,000

36,000

42,000

48,000

54,000

60,000

66,000

72,000

78,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78

Or Kilometers:

10,000

20,000 30,000

40,000

50,000

60,000 70,000

80,000

90,000

100,000

110,000

120,000 130,000

Change the engine oil and engine oil filter.

XXXXXXX X X X X X X

Rotate the tires, rotate at the first sign of irregular wear, even if it occurs before

scheduled maintenance. XXXXXXX X X X X X X

If using your vehicle for any of the following: dusty or off-road conditions. Inspect

the engine air cleaner filter; replace if necessary.

XXX X X

Inspect the brake linings; replace if necessary. X X X X XX

Inspect the CV joints. X XXX

Inspect the exhaust system. X XX XX

Adjust the parking brake on vehicles equipped with four wheel disc brakes. XX

Change the automatic transmission fluid and filter if using your vehicle for any of

the following: police, taxi, fleet or frequent trailer towing. X

Change the rear axle fluid if using your vehicle for any of the following: police, taxi,

fleet or frequent trailer towing. X

Inspect the rear axle fluid. XX X X

Inspect front suspension, tie rod ends, and boot seals, for cracks or leaks and all

parts for damage, wear, improper looseness or end play; replace if necessary. XXX

X X

Replace the engine air cleaner. XX

Replace the air conditioning filter. X X X X XXNOTE:

Flush and replace the engine coolant at 120 months if not done at 150,000 miles (240,000 km).

Refer to the Owner's Manual on the DVD for complete maintenance schedule.

MAINTAINING YOUR VEHICLE

113

Page 121 of 132

TIRE PRESSURES

• Check the inflation pressure of each tire, including the spare tire, at least monthly andinflate to the recommended pressure for your vehicle.

• The tire pressures recommended for your vehicle are found on the “Tire and Loading Information” label located on the driver’s side door opening.

NOTE:

Refer to the Owner's Manual on the DVD for

more information regarding tire warnings

and instructions.

WARNING!

•Overloading of your tires is dangerous. Overloading can cause tire failure, affect vehicle

handling, and increase your stopping distance. Use tires of the recommended load

capacity for your vehicle. Never overload them.

• Improperly inflated tires are dangerous and can cause collisions. Under-inflation is the leading cause of tire failure and may result in severe cracking, component

separation, or “blow out”. Over-inflation reduces a tire’s ability to cushion shock.

Objects on the road and chuck holes can cause damage that results in tire failure.

Unequal tire pressures can cause steering problems. You could lose control of your

vehicle. Over-inflated or under-inflated tires can affect vehicle handling and can fail

suddenly, resulting in loss of vehicle control.

WHEEL AND WHEEL TRIM CARE

• All wheels and wheel trim, especially aluminum and chrome plated wheels, should be

cleaned regularly with a mild soap and water to prevent corrosion.

• To remove heavy soil and/or excessive brake dust, use MOPAR® Wheel Cleaner or equivalent or select a non-abrasive, non-acidic cleaner.

CAUTION!

Do not use scouring pads, steel wool, a bristle brush, or metal polishes. Do not use oven

cleaner. These products may damage the wheel's protective finish. Avoid automatic car

washes that use acidic solutions or harsh brushes that may damage the wheel's protec-

tive finish. Only MOPAR® Wheel Cleaner or equivalent is recommended.

MAINTAINING YOUR VEHICLE

119

Page 125 of 132

AUTHENTIC ACCESSORIES BY MOPAR®

• The following highlights just some of the many Authentic Dodge Accessories by Moparfeaturing a fit, finish, and functionality specifically for your Dodge Charger.

• In choosing Authentic Accessories you gain far more than expressive style, premium protection, or extreme entertainment, you also benefit from enhancing your vehicle with

accessories that have been thoroughly tested and factory-approved.

• For the full line of Authentic Dodge Accessories by Mopar, visit your local Dodge dealer- ship or online at mopar.com.

EXTERIOR:

• Rear Spoiler • Chrome Grill Insert • Fog Lights

• Molded Splash Guards • Lower Front Fascia Air Dam • Front End Cover

• Custom Wheels • Graphics Packages

INTERIOR:

• Premium Carpet Floor Mats • Katzkin Leather Seats • Bright Pedal Kit

• Door Sill Guards • Premium Carpet Cargo Mat • T-Handle Shifter

• Instrument Panel Bezel Kits

CARRIERS:

• Cargo Carriers • Sport Utility Bars• Bike Carriers

• Water Sports Carriers

ELECTRONICS:

• Portable Navigation Systems • Uconnect® Web (WiFi) • Remote Start

• iPod® Adapter • Radio Upgrades

• DVD Rear Seat Video™

• Kicker® Sound System • Uconnect® Phone • Electronic Vehicle Tracking

System

• Ecometer

• iPod® is a registered trademark of Apple, Inc.

• Kicker® is a registered trademark of Stillwater Designs and Audio, Inc.

MOPAR ACCESSORIES

123