steering DODGE CHARGER 2020 Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: CHARGER, Model: DODGE CHARGER 2020Pages: 412, PDF Size: 18.96 MB

Page 226 of 412

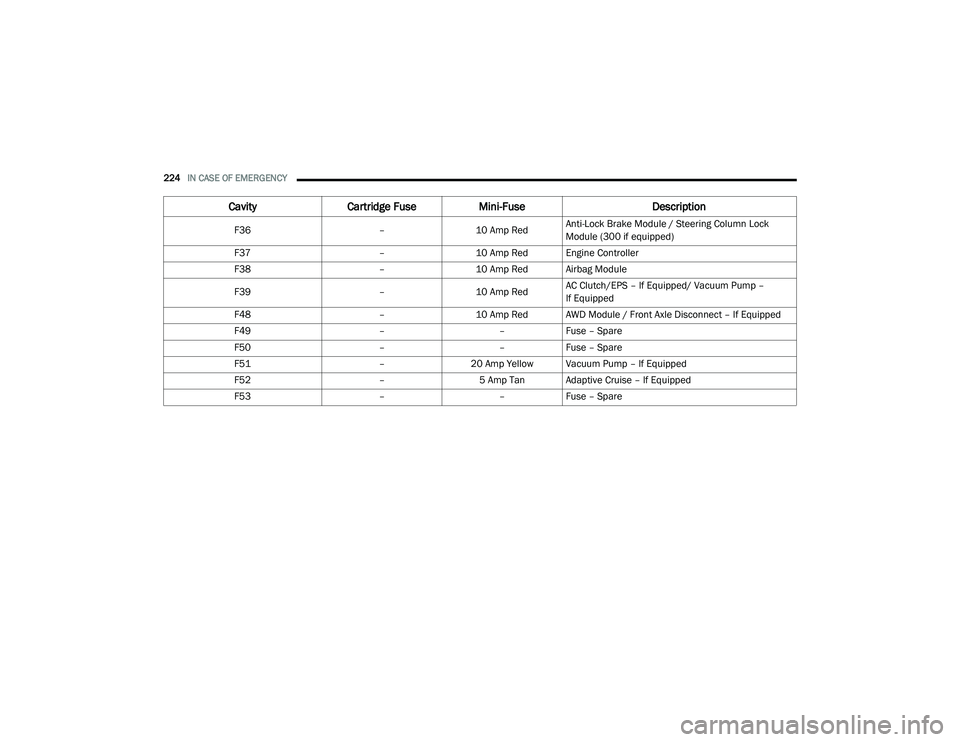

224IN CASE OF EMERGENCY

F36 –10 Amp RedAnti-Lock Brake Module / Steering Column Lock

Module (300 if equipped)

F37 –10 Amp Red Engine Controller

F38 –10 Amp Red Airbag Module

F39 –10 Amp RedAC Clutch/EPS – If Equipped/ Vacuum Pump –

If Equipped

F48 –10 Amp Red AWD Module / Front Axle Disconnect – If Equipped

F49 ––Fuse – Spare

F50 ––Fuse – Spare

F51 –20 Amp Yellow Vacuum Pump – If Equipped

F52 –5 Amp Tan Adaptive Cruise – If Equipped

F53 ––Fuse – Spare

Cavity Cartridge Fuse Mini-Fuse Description

20_LD_OM_EN_USC_t.book Page 224

Page 229 of 412

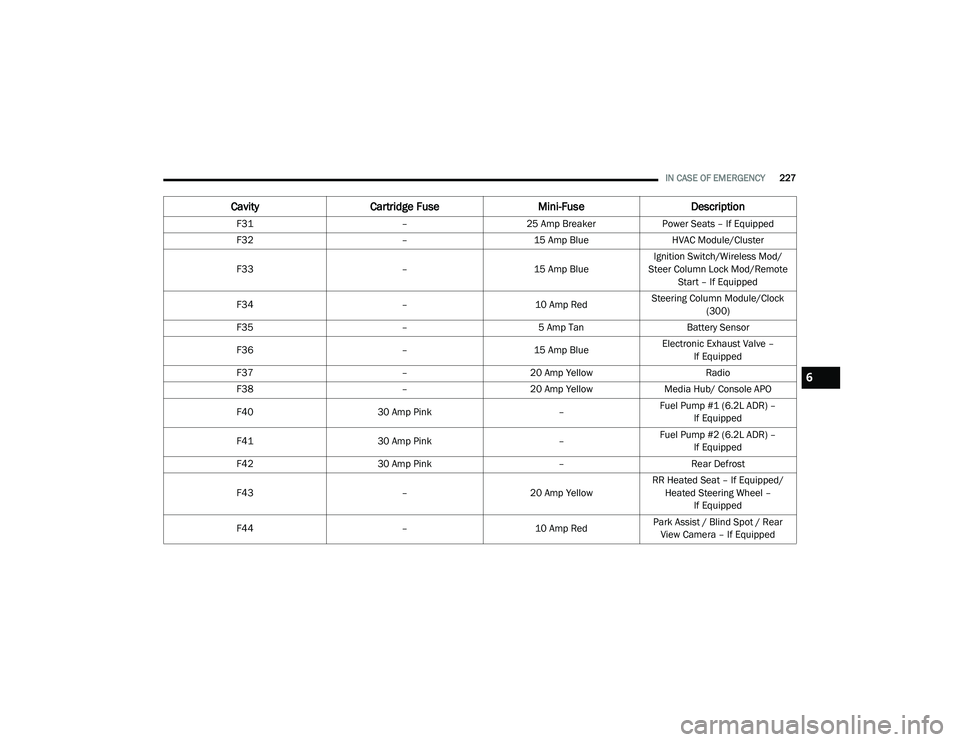

IN CASE OF EMERGENCY227

F31 –25 Amp Breaker Power Seats – If Equipped

F32 –15 Amp Blue HVAC Module/Cluster

F33 –15 Amp BlueIgnition Switch/Wireless Mod/

Steer Column Lock Mod/Remote Start – If Equipped

F34 –10 Amp RedSteering Column Module/Clock

(300)

F35 –5 Amp Tan Battery Sensor

F36 –15 Amp BlueElectronic Exhaust Valve –

If Equipped

F37 –20 Amp Yellow Radio

F38 –20 Amp Yellow Media Hub/ Console APO

F40 30 Amp Pink –Fuel Pump #1 (6.2L ADR) –

If Equipped

F41 30 Amp Pink –Fuel Pump #2 (6.2L ADR) –

If Equipped

F42 30 Amp Pink –Rear Defrost

F43 –20 Amp YellowRR Heated Seat – If Equipped/

Heated Steering Wheel – If Equipped

F44 –10 Amp RedPark Assist / Blind Spot / Rear

View Camera – If Equipped

Cavity Cartridge Fuse Mini-FuseDescription

6

20_LD_OM_EN_USC_t.book Page 227

Page 246 of 412

244IN CASE OF EMERGENCY

To Reset The Manual Park Release:

1. Push the latch (at the base of the lever, on

the rear side) rearward (away from the

lever) to unlatch the lever.

Disengaging The Lever

2. Rotate the Manual Park Release lever forward and down, to its original position,

until the locking tab snaps into place to

secure the lever. 3. Pull up gently on the tether strap to confirm

that the lever is locked in its stowed

position.

4. Tuck the tether strap into the base of the console. Reinstall the Manual Park Release

cover and the console storage bin.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Push

and hold the lock button on the gear selector.

Then, shift back and forth between DRIVE and

REVERSE while gently pressing the accelerator.

Use the least amount of accelerator pedal

pressure that will maintain the rocking motion,

without spinning the wheels or racing the

engine. NOTE:

Shifts between DRIVE and REVERSE can only

be achieved at wheel speeds of 5 mph

(8 km/h) or less. Whenever the transmission

remains in NEUTRAL for more than two

seconds, you must press the brake pedal to

engage DRIVE or REVERSE.

Push the "ESC OFF" switch, to place the Elec

-

tronic Stability Control (ESC) system in

"Partial Off" mode, before rocking the vehicle.

Refer to “Electronic Brake Control System” in

“Safety” for further information. Once the

vehicle has been freed, push the "ESC OFF"

switch again to restore "ESC On" mode.

20_LD_OM_EN_USC_t.book Page 244

Page 252 of 412

250

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

3.6L AND 5.7L ENGINES

These vehicles are equipped with an automatic

oil change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the

“Change Oil” or “Oil Change Required” message

is displayed. Severe Operating Conditions can

cause the change oil message to illuminate as

early as 3,500 miles (5,600 km) since last

reset. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).

The “Oil Change Required” message will be

displayed in the instrument cluster and a single

chime will sound, indicating that an oil change

is necessary.An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset by

referring to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

further information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off-road environment,

or is operated predominantly at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before your

next scheduled service.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering

(if equipped) and fill as needed.

Check function of all interior and exterior

lights.

Maintenance Plan — 3.6L And 5.7L

Required Maintenance Intervals:

Refer to the maintenance schedules on the

following page for the required maintenance

intervals. More frequent maintenance may be

needed in severe conditions, such as dusty

areas and very short trip driving. In some

extreme conditions, additional maintenance

not specified in the maintenance schedule may

be required.

20_LD_OM_EN_USC_t.book Page 250

Page 257 of 412

SERVICING AND MAINTENANCE255

An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset by

referring to the steps described under

“Instrument Cluster Display” in “Getting To

Know Your Instrument Panel” for further

information.

At Each Stop For Fuel

Check the engine oil level. Refer to “Engine

Compartment” in this chapter for further

information.

Check the windshield washer solvent and

add if required. Once A Month

Check tire pressure and look for unusual

wear or damage.

Inspect the battery, and clean and tighten the

terminals as required.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering

(6.2L only), and add as needed.

Check all lights and other electrical items for

correct operation.

At Each Oil Change

Change the engine oil filter.

Inspect the brake hoses and lines.

Inspect the CV/Universal joints.

CAUTION!

Failure to perform the required maintenance

items may result in damage to the vehicle.

7

20_LD_OM_EN_USC_t.book Page 255

Page 270 of 412

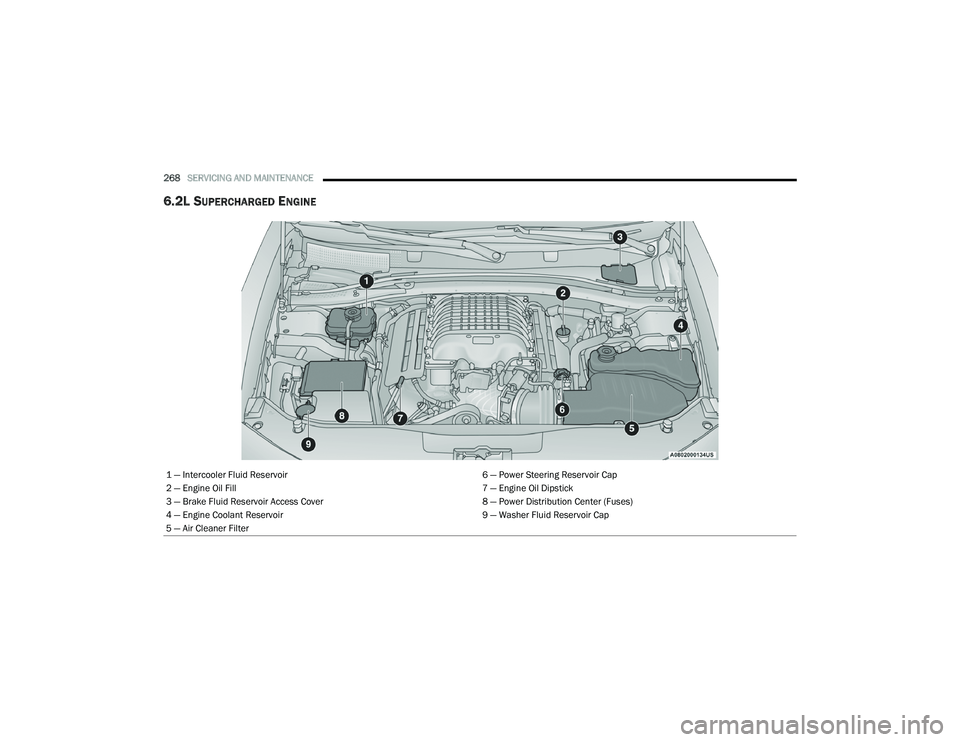

268SERVICING AND MAINTENANCE

6.2L SUPERCHARGED ENGINE

1 — Intercooler Fluid Reservoir 6 — Power Steering Reservoir Cap

2 — Engine Oil Fill 7 — Engine Oil Dipstick

3 — Brake Fluid Reservoir Access Cover 8 — Power Distribution Center (Fuses)

4 — Engine Coolant Reservoir 9 — Washer Fluid Reservoir Cap

5 — Air Cleaner Filter

20_LD_OM_EN_USC_t.book Page 268

Page 296 of 412

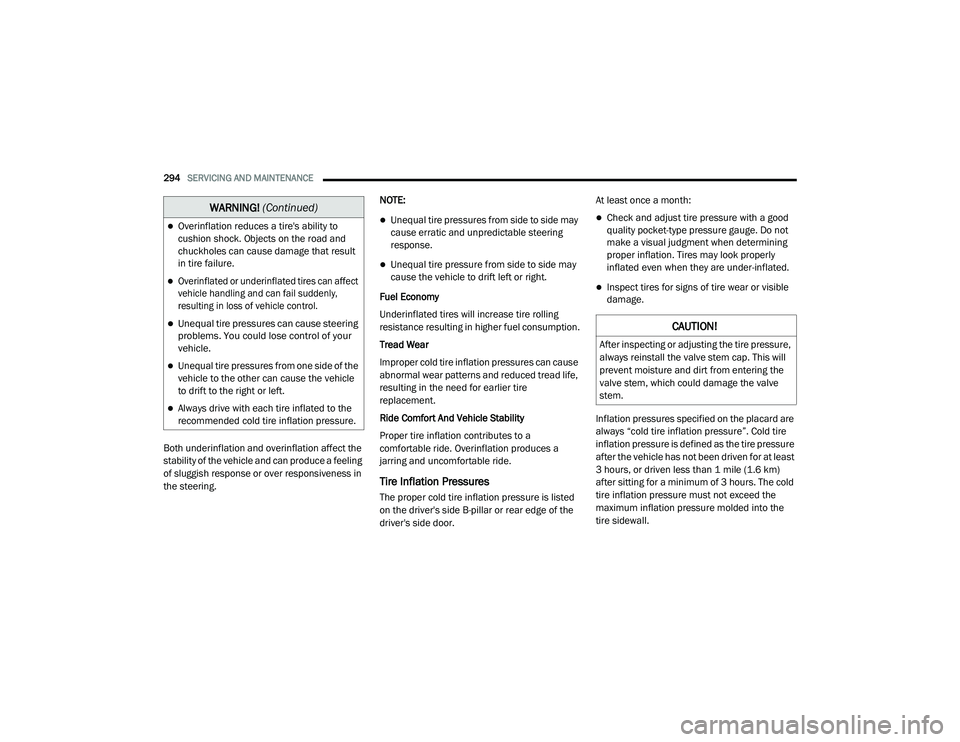

294SERVICING AND MAINTENANCE

Both underinflation and overinflation affect the

stability of the vehicle and can produce a feeling

of sluggish response or over responsiveness in

the steering. NOTE:

Unequal tire pressures from side to side may

cause erratic and unpredictable steering

response.

Unequal tire pressure from side to side may

cause the vehicle to drift left or right.

Fuel Economy

Underinflated tires will increase tire rolling

resistance resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause

abnormal wear patterns and reduced tread life,

resulting in the need for earlier tire

replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a

comfortable ride. Overinflation produces a

jarring and uncomfortable ride.

Tire Inflation Pressures

The proper cold tire inflation pressure is listed

on the driver's side B-pillar or rear edge of the

driver's side door. At least once a month:

Check and adjust tire pressure with a good

quality pocket-type pressure gauge. Do not

make a visual judgment when determining

proper inflation. Tires may look properly

inflated even when they are under-inflated.

Inspect tires for signs of tire wear or visible

damage.

Inflation pressures specified on the placard are

always “cold tire inflation pressure”. Cold tire

inflation pressure is defined as the tire pressure

after the vehicle has not been driven for at least

3 hours, or driven less than 1 mile (1.6 km)

after sitting for a minimum of 3 hours. The cold

tire inflation pressure must not exceed the

maximum inflation pressure molded into the

tire sidewall.

Overinflation reduces a tire's ability to

cushion shock. Objects on the road and

chuckholes can cause damage that result

in tire failure.

Overinflated or underinflated tires can affect

vehicle handling and can fail suddenly,

resulting in loss of vehicle control.

Unequal tire pressures can cause steering

problems. You could lose control of your

vehicle.

Unequal tire pressures from one side of the

vehicle to the other can cause the vehicle

to drift to the right or left.

Always drive with each tire inflated to the

recommended cold tire inflation pressure.

WARNING! (Continued)

CAUTION!

After inspecting or adjusting the tire pressure,

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the valve

stem.

20_LD_OM_EN_USC_t.book Page 294

Page 299 of 412

SERVICING AND MAINTENANCE297

NOTE:

Wheel valve stem must be replaced as well

when installing new tires due to wear and tear

in existing tires.

Keep dismounted tires in a cool, dry place with

as little exposure to light as possible. Protect

tires from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance

of many characteristics. They should be

inspected regularly for wear and correct cold

tire inflation pressures. The manufacturer

strongly recommends that you use tires

equivalent to the originals in size, quality and

performance when replacement is needed. Refer to the paragraph on “Tread Wear

Indicators” in this section. Refer to the Tire and

Loading Information placard or the Vehicle

Certification Label for the size designation of

your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

See the Tire Sizing Chart example found in the

“Tire Safety Information” section of this manual

for more information relating to the Load Index

and Speed Symbol of a tire.

It is recommended to replace the two front tires

or two rear tires as a pair. Replacing just one tire

can seriously affect your vehicle’s handling. If

you ever replace a wheel, make sure that the

wheel’s specifications match those of the

original wheels.

It is recommended you contact an authorized

tire dealer or original equipment dealer with any

questions you may have on tire specifications or

capability. Failure to use equivalent

replacement tires may adversely affect the

safety, handling, and ride of your vehicle.

WARNING!

Tires and the spare tire should be replaced

after six years, regardless of the remaining

tread. Failure to follow this warning can result

in sudden tire failure. You could lose control

and have a collision resulting in serious injury

or death.

WARNING!

Do not use a tire, wheel size, load rating, or

speed rating other than that specified for

your vehicle. Some combinations of unap

-

proved tires and wheels may change suspen -

sion dimensions and performance

characteristics, resulting in changes to

steering, handling, and braking of your

vehicle. This can cause unpredictable

handling and stress to steering and suspen -

sion components. You could lose control and

have a collision resulting in serious injury or

death. Use only the tire and wheel sizes with

load ratings approved for your vehicle.

Never use a tire with a smaller load index or

capacity, other than what was originally

equipped on your vehicle. Using a tire with

a smaller load index could result in tire

overloading and failure. You could lose

control and have a collision.

Failure to equip your vehicle with tires

having adequate speed capability can

result in sudden tire failure and loss of

vehicle control.

7

20_LD_OM_EN_USC_t.book Page 297

Page 304 of 412

302SERVICING AND MAINTENANCE

(Continued)

TIRE CHAINS AND TRACTION DEVICES —

SRT

Due to limited clearance, tire chains or traction

devices are not recommended.

TIRE ROTATION RECOMMENDATIONS —

N

ON-SRT

Tires on the front and rear axles of vehicles

operate at different loads and perform different

steering, driving, and braking functions. For

these reasons, they wear at unequal rates.

These effects can be reduced by timely rotation

of tires. The benefits of rotation are especially

worthwhile with aggressive tread designs such

as those on all season type tires. Rotation will increase tread life, help to maintain mud, snow

and wet traction levels, and contribute to a

smooth, quiet ride.

Refer to “Scheduled Servicing” in “Servicing

And Maintenance” for the proper maintenance

intervals. The reasons for any rapid or unusual

wear should be corrected prior to rotation being

performed.

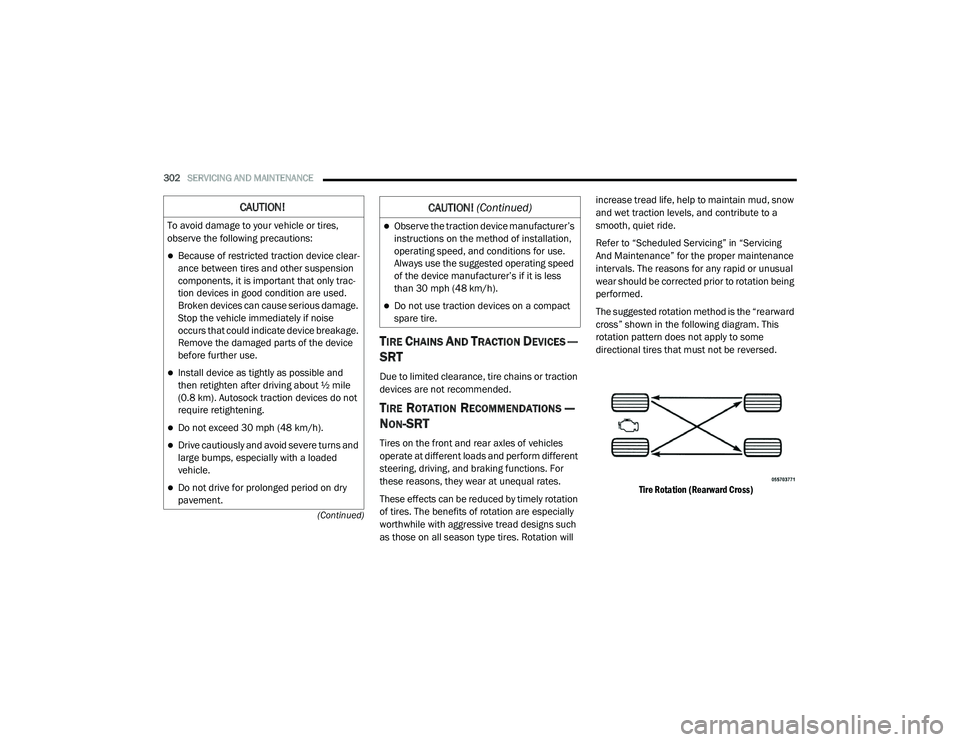

The suggested rotation method is the “rearward

cross” shown in the following diagram. This

rotation pattern does not apply to some

directional tires that must not be reversed.

Tire Rotation (Rearward Cross)

CAUTION!

To avoid damage to your vehicle or tires,

observe the following precautions:

Because of restricted traction device clear -

ance between tires and other suspension

components, it is important that only trac-

tion devices in good condition are used.

Broken devices can cause serious damage.

Stop the vehicle immediately if noise

occurs that could indicate device breakage.

Remove the damaged parts of the device

before further use.

Install device as tightly as possible and

then retighten after driving about ½ mile

(0.8 km). Autosock traction devices do not

require retightening.

Do not exceed 30 mph (48 km/h).

Drive cautiously and avoid severe turns and

large bumps, especially with a loaded

vehicle.

Do not drive for prolonged period on dry

pavement.

Observe the traction device manufacturer’s

instructions on the method of installation,

operating speed, and conditions for use.

Always use the suggested operating speed

of the device manufacturer’s if it is less

than 30 mph (48 km/h).

Do not use traction devices on a compact

spare tire.

CAUTION! (Continued)

20_LD_OM_EN_USC_t.book Page 302

Page 305 of 412

SERVICING AND MAINTENANCE303

TIRE ROTATION RECOMMENDATIONS —

SRT

Tires on the front and rear axles of vehicles

operate at different loads and perform different

steering, driving, and braking functions. For

these reasons, they wear at unequal rates.

These effects can be reduced by timely rotation

of tires. The benefits of rotation are especially

worthwhile with aggressive tread designs such

as those on all season type tires. Rotation will

increase tread life, help to maintain mud, snow

and wet traction levels, and contribute to a

smooth, quiet ride.

Refer to “Scheduled Servicing” in “Servicing

And Maintenance” for the proper maintenance

intervals. The reasons for any rapid or unusual

wear should be corrected prior to rotation being

performed.

Tire Rotation — Same Tire Size On Front And

Rear Axle

The suggested rotation method for vehicles

equipped with non directional three season and

all season tires is the “forward cross” as shown

in the following diagram.

Tire Rotation (Forward Cross)

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES

The following tire grading categories

were established by the National

Highway Traffic Safety Administration.

The specific grade rating assigned by the

tire's manufacturer in each category is

shown on the sidewall of the tires on

your vehicle.

All passenger vehicle tires must conform

to Federal safety requirements in

addition to these grades.

TREADWEAR

The Treadwear grade is a comparative

rating, based on the wear rate of the tire

when tested under controlled conditions

on a specified government test course.

For example, a tire graded 150 would

wear one and one-half times as well on

the government course as a tire graded

100. The relative performance of tires

depends upon the actual conditions of

their use, however, and may depart

significantly from the norm due to

variations in driving habits, service

practices, and differences in road

characteristics and climate.

TRACTION GRADES

The Traction grades, from highest to

lowest, are AA, A, B, and C. These grades

represent the tire's ability to stop on wet

pavement, as measured under controlled

conditions on specified government test

surfaces of asphalt and concrete. A tire

marked C may have poor traction

performance.

7

20_LD_OM_EN_USC_t.book Page 303