trailer DODGE CHARGER 2021 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2021, Model line: CHARGER, Model: DODGE CHARGER 2021Pages: 320, PDF Size: 20.61 MB

Page 118 of 320

116STARTING AND OPERATING

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Ú page 114.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link that

can be installed between the hitch receiver and the

trailer tongue that typically provides adjustable

friction associated with the telescoping motion to

dampen any unwanted trailer swaying motions

while traveling.

If equipped, the electronic TSC recognizes a

swaying trailer and automatically applies individual

wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and the

trailer axle(s). When used in accordance with the

manufacturer's directions, it provides for a more

level ride, offering more consistent steering and

brake control thereby enhancing towing safety.

The addition of a friction/hydraulic sway control

also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. Trailer sway control

and a weight distributing (load equalizing) hitch are

recommended for heavier Tongue Weights (TW) and

may be required depending on vehicle and trailer

configuration/loading to comply with Gross Axle

Weight Rating (GAWR) requirements.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the vehicle

and have a collision.

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability,

braking performance, and could result in a

collision.

Weight-distributing systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

21_LD_OM_EN_USC_t.book Page 116

Page 119 of 320

STARTING AND OPERATING117

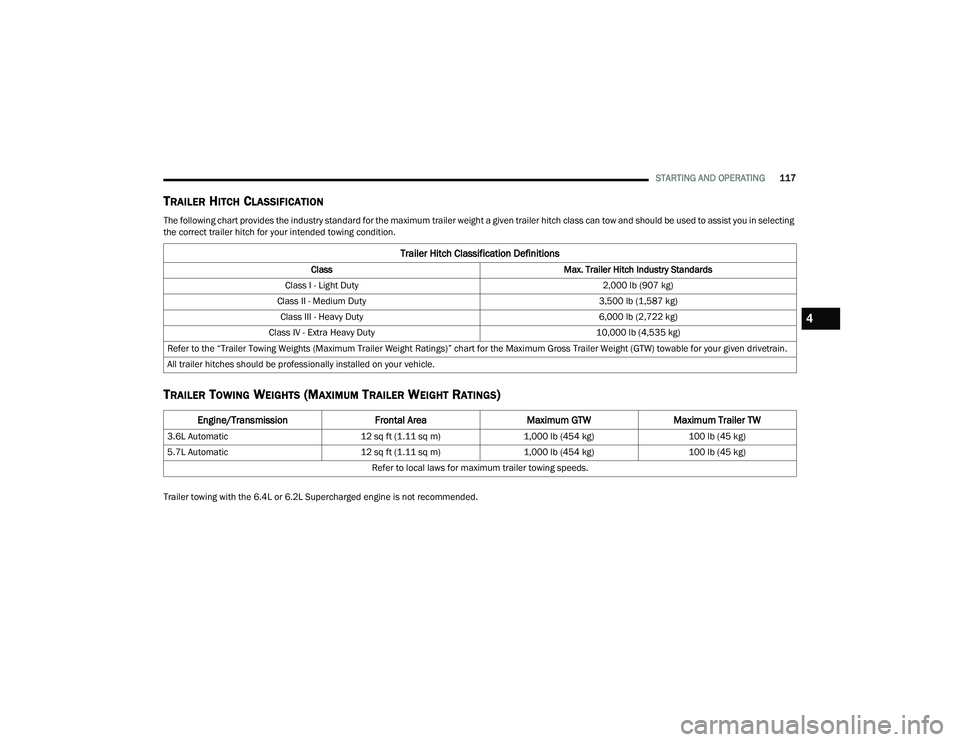

TRAILER HITCH CLASSIFICATION

The following chart provides the industry standard for the maximum trailer weight a given trailer hitch class can tow and should be used to assist you in selecting

the correct trailer hitch for your intended towing condition.

TRAILER TOWING WEIGHTS (MAXIMUM TRAILER WEIGHT RATINGS)

Trailer towing with the 6.4L or 6.2L Supercharged engine is not recommended.

Trailer Hitch Classification Definitions

Class Max. Trailer Hitch Industry Standards

Class I - Light Duty 2,000 lb (907 kg)

Class II - Medium Duty 3,500 lb (1,587 kg)

Class III - Heavy Duty 6,000 lb (2,722 kg)

Class IV - Extra Heavy Duty 10,000 lb (4,535 kg)

Refer to the “Trailer Towing Weights (Maximum Trailer Weight Ratings)” chart for the Maximum Gross Trailer Weight (GTW) towable for your given drivetrain.

All trailer hitches should be professionally installed on your vehicle.

Engine/Transmission Frontal AreaMaximum GTWMaximum Trailer TW

3.6L Automatic 12 sq ft (1.11 sq m)1,000 lb (454 kg) 100 lb (45 kg)

5.7L Automatic 12 sq ft (1.11 sq m)1,000 lb (454 kg) 100 lb (45 kg)

Refer to local laws for maximum trailer towing speeds.

4

21_LD_OM_EN_USC_t.book Page 117

Page 120 of 320

118STARTING AND OPERATING

(Continued)

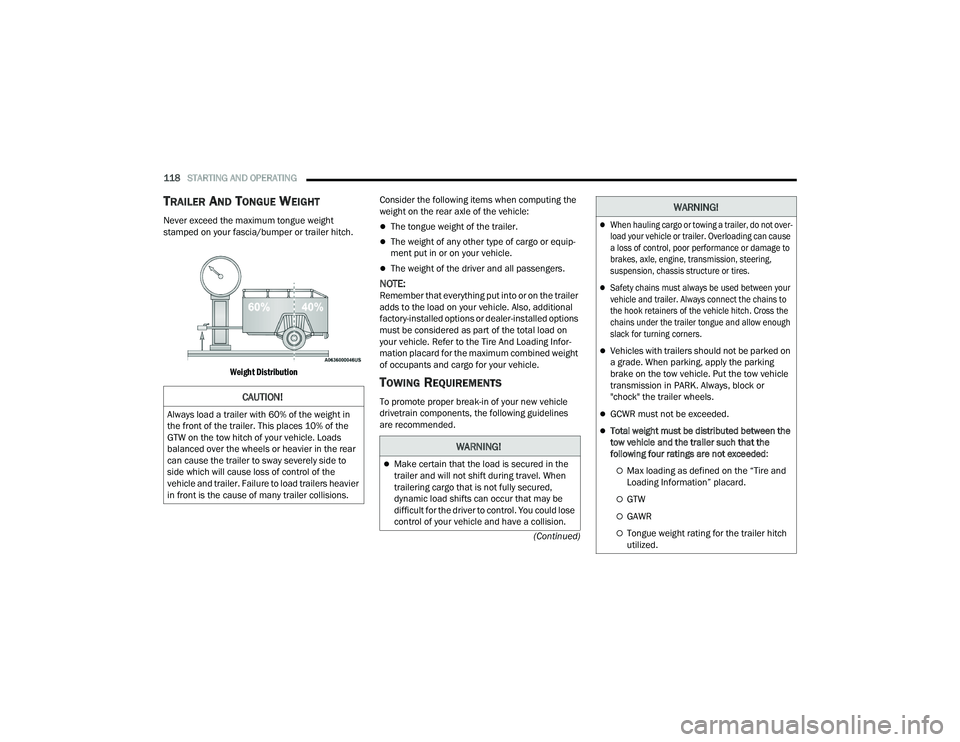

TRAILER AND TONGUE WEIGHT

Never exceed the maximum tongue weight

stamped on your fascia/bumper or trailer hitch.

Weight Distribution

Consider the following items when computing the

weight on the rear axle of the vehicle:The tongue weight of the trailer.

The weight of any other type of cargo or equip

-

ment put in or on your vehicle.

The weight of the driver and all passengers.

NOTE:Remember that everything put into or on the trailer

adds to the load on your vehicle. Also, additional

factory-installed options or dealer-installed options

must be considered as part of the total load on

your vehicle. Refer to the Tire And Loading Infor -

mation placard for the maximum combined weight

of occupants and cargo for your vehicle.

TOWING REQUIREMENTS

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended.CAUTION!

Always load a trailer with 60% of the weight in

the front of the trailer. This places 10% of the

GTW on the tow hitch of your vehicle. Loads

balanced over the wheels or heavier in the rear

can cause the trailer to sway severely side to

side which will cause loss of control of the

vehicle and trailer. Failure to load trailers heavier

in front is the cause of many trailer collisions.

WARNING!

Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could lose

control of your vehicle and have a collision.

When hauling cargo or towing a trailer, do not over -

load your vehicle or trailer. Overloading can cause

a loss of control, poor performance or damage to

brakes, axle, engine, transmission, steering,

suspension, chassis structure or tires.

Safety chains must always be used between your

vehicle and trailer. Always connect the chains to

the hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

Vehicles with trailers should not be parked on

a grade. When parking, apply the parking

brake on the tow vehicle. Put the tow vehicle

transmission in PARK. Always, block or

"chock" the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between the

tow vehicle and the trailer such that the

following four ratings are not exceeded :

Max loading as defined on the “Tire and

Loading Information” placard.

GTW

GAWR

Tongue weight rating for the trailer hitch

utilized.

WARNING!

21_LD_OM_EN_USC_t.book Page 118

Page 121 of 320

STARTING AND OPERATING119

Perform the maintenance listed in the “Scheduled

Servicing” for the proper maintenance intervals

Ú page 245. When towing a trailer, never exceed

the GAWR or GCWR ratings.

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when

towing while using a full size spare tire.

Proper tire inflation pressures are essential to

the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer. For the proper

inspection procedure.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Ú page 275.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system

or vacuum system of your vehicle with that of

the trailer. This could cause inadequate braking

and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer with

electronically actuated brakes. When towing a

trailer equipped with a hydraulic surge actuated

brake system, an electronic brake controller is

not required.

Trailer brakes are recommended for trailers

over 1,000 lb (453 kg) and required for trailers

in excess of 2,000 lb (907 kg).

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is driven.

The engine, axle or other parts could be

damaged.

Then, during the first 500 miles (805 km) that

a trailer is towed, do not drive over 50 mph

(80 km/h) and do not make starts at full

throttle. This helps the engine and other parts

of the vehicle wear in at the heavier loads.

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your

brake system and cause it to fail. You might

not have brakes when you need them and

could have an accident.

Towing any trailer will increase your stopping

distance. When towing, you should allow for

additional space between your vehicle and the

vehicle in front of you. Failure to do so could

result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do

this could lead to accelerated brake lining wear,

higher brake pedal effort, and longer stopping

distances.

4

21_LD_OM_EN_USC_t.book Page 119

Page 122 of 320

120STARTING AND OPERATING

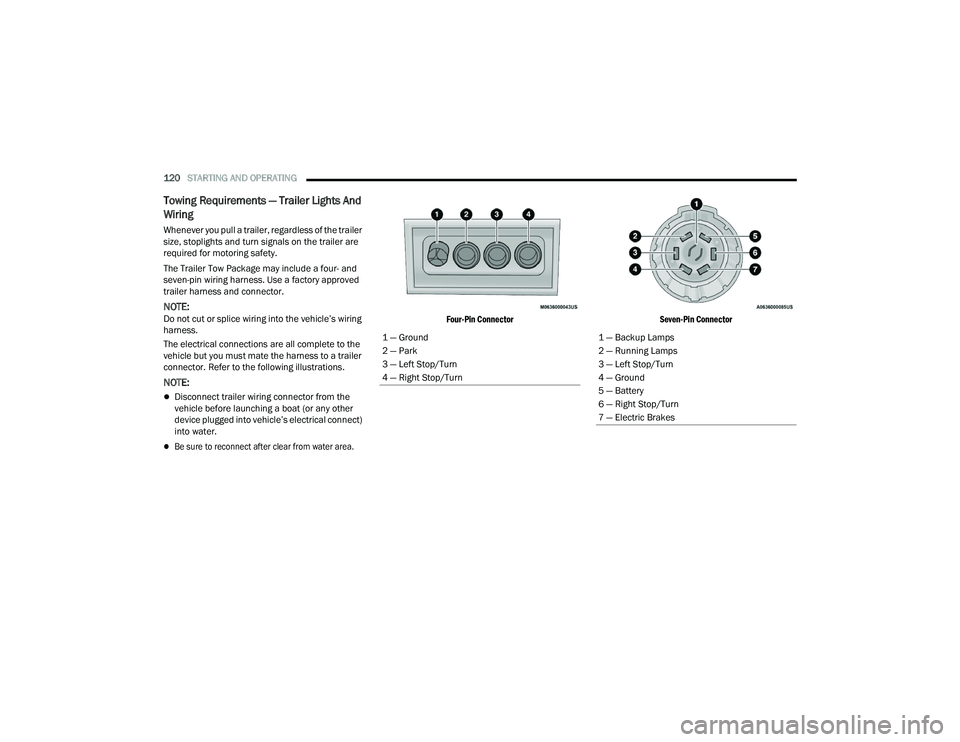

Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the trailer

size, stoplights and turn signals on the trailer are

required for motoring safety.

The Trailer Tow Package may include a four- and

seven-pin wiring harness. Use a factory approved

trailer harness and connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the

vehicle but you must mate the harness to a trailer

connector. Refer to the following illustrations.

NOTE:

Disconnect trailer wiring connector from the

vehicle before launching a boat (or any other

device plugged into vehicle’s electrical connect)

into water.

Be sure to reconnect after clear from water area.

Four-Pin Connector

Seven-Pin Connector

1 — Ground

2 — Park

3 — Left Stop/Turn

4 — Right Stop/Turn

1 — Backup Lamps

2 — Running Lamps

3 — Left Stop/Turn

4 — Ground

5 — Battery

6 — Right Stop/Turn

7 — Electric Brakes

21_LD_OM_EN_USC_t.book Page 120

Page 123 of 320

STARTING AND OPERATING121

TOWING TIPS

Before towing, practice turning, stopping, and

backing up the trailer in an area located away from

heavy traffic.

Automatic Transmission

Select the DRIVE range when towing.

The transmission controls include a drive

strategy to avoid frequent shifting when towing.

However, if frequent shifting does occur while in

DRIVE, you can use the AutoStick shift control to

manually select a lower gear.

NOTE:Using a lower gear while operating the vehicle

under heavy loading conditions will improve perfor -

mance and extend transmission life by reducing

excessive shifting and heat buildup. This action will

also provide better engine braking.

Cruise Control — If Equipped

Do not use on hilly terrain or with heavy loads.

When using the Cruise Control, if you experience

speed drops greater than 10 mph (16 km/h),

disengage until you can get back to cruising

speed.

Use Cruise Control in flat terrain and with light

loads to maximize fuel efficiency.

AutoStick

When using the AutoStick shift control, select

the highest gear that allows for adequate

performance and avoid frequent downshifts.

For example, choose “5” if the desired speed can

be maintained. Choose “4” or “3” if needed to

maintain the desired speed.

To prevent excess heat generation, avoid

continuous driving at high RPM. Reduce vehicle

speed as necessary to avoid extended driving at

high RPM. Return to a higher gear or vehicle

speed when grade and road conditions allow.

RECREATIONAL TOWING (BEHIND

MOTORHOME)

Recreational towing (with all four wheels on the

ground, or using a tow dolly) is NOT ALLOWED.

The only acceptable method for towing this vehicle

(behind another vehicle) is on a vehicle trailer with

all four wheels OFF the ground.

CAUTION!

Towing this vehicle in violation of the above

requirements can cause severe transmission

and/or transfer case damage. Damage from

improper towing is not covered under the New

Vehicle Limited Warranty.4

21_LD_OM_EN_USC_t.book Page 121

Page 185 of 320

SAFETY183

"Partial Off"

This mode may be useful if the vehicle becomes

stuck. This mode may modify TCS and ESC

thresholds for activation, which allows for more

wheel spin than normally allowed.

To enter the “Partial Off” mode, momentarily push

the ESC OFF button and the ESC OFF Indicator

Light will illuminate. To turn the ESC on again,

momentarily push the ESC OFF button and the ESC

OFF Indicator Light will turn off.

NOTE:

For vehicles with multiple partial ESC modes,

the push and release of the button will toggle

the ESC modes. Multiple attempts may be

required to return to "ESC On" mode.

Trailer Sway Control (TSC) is disabled when the

ESC system is in the “Partial Off” mode.

If Equipped — "ESC Sport" and "ESC Track" are

ESC “Partial Off” mode(s). “Full Off” – If Equipped

This mode is intended for off-highway or off-road use

only and should not be used on any public roadways.

In this mode, TCS and ESC features are turned off.

To enter the “Full Off” mode, push and hold the ESC

OFF button for five seconds while the vehicle is stopped

with the engine running. After five seconds, a chime will

sound, the ESC OFF Indicator Light will illuminate, and

the ESC OFF message will display in the instrument

cluster. To turn ESC on again, momentarily push the

ESC OFF button.

ESC Activation/Malfunction Indicator Light

And ESC OFF Indicator Light

The ESC Activation/Malfunction Indicator

Light in the instrument cluster will come

on when the ignition is placed in the

ON/RUN mode. It should go out with the

engine running. If the ESC Activation/Malfunction

Indicator Light comes on continuously with the

engine running, a malfunction has been detected

in the ESC system. If this light remains on after

several ignition cycles, and the vehicle has been

driven several miles (kilometers) at speeds greater

than 30 mph (48 km/h), see an authorized dealer

as soon as possible to have the problem

diagnosed and corrected.

The ESC Activation/Malfunction Indicator Light

(located in the instrument cluster) starts to flash as

soon as the tires lose traction and the ESC system

becomes active. The ESC Activation/Malfunction

Indicator Light also flashes when TCS is active.

If the ESC Activation/Malfunction Indicator Light

begins to flash during acceleration, ease up on the

accelerator and apply as little throttle as possible.

Be sure to adapt your speed and driving to the

prevailing road conditions.

The ESC OFF Indicator Light indicates

the customer has elected to have the

Electronic Stability Control (ESC) in a

reduced mode.

WARNING!

When in “Partial Off” mode, the TCS functionality of

ESC, except for the limited slip feature described in

the TCS section, has been disabled and the ESC OFF

Indicator Light will be illuminated. When in “Partial

Off” mode, the engine power reduction feature of

Traction Control System (TCS) is disabled, and the

enhanced vehicle stability offered by the ESC system

is reduced.

WARNING!

In the ESC “Full Off” mode, the engine torque

reduction and stability features are disabled.

Therefore, enhanced vehicle stability offered

by the ESC system is unavailable. In an emer -

gency evasive maneuver, the ESC system will

not engage to assist in maintaining stability.

ESC “Full Off” mode is intended for

off-highway or off-road use only.

The Electronic Stability Control (ESC) cannot

prevent the natural laws of physics from

acting on the vehicle, nor can it increase the

traction afforded by prevailing road condi -

tions. ESC cannot prevent all accidents,

including those resulting from excessive

speed in turns, driving on very slippery

surfaces, or hydroplaning. ESC also cannot

prevent collisions.

6

21_LD_OM_EN_USC_t.book Page 183

Page 186 of 320

184SAFETY

NOTE:

The ESC Activation/Malfunction Indicator

Light and the ESC OFF Indicator Light come on

momentarily each time the ignition is placed in

the ON mode.

Each time the ignition is placed in the ON mode,

the ESC system will be on even if it was turned

off previously.

The ESC system will make buzzing or clicking

sounds when it is active. This is normal; the

sounds will stop when ESC becomes inactive

following the maneuver that caused the ESC

activation.

Hill Start Assist (HSA)

HSA is designed to mitigate roll back from a

complete stop while on an incline. If the driver

releases the brake while stopped on an incline,

HSA will continue to hold the brake pressure for a

short period. If the driver does not apply the

throttle before this time expires, the system will

release brake pressure and the vehicle will roll

down the hill as normal.

The following conditions must be met in order for

HSA to activate:

The feature must be enabled.

The vehicle must be stopped.

The parking brake must be off.

The driver door must be closed.

The vehicle must be on a sufficient grade.

The gear selection must match vehicle uphill

direction (i.e., vehicle facing uphill is in forward

gear; vehicle backing uphill is in REVERSE gear).

HSA will work in REVERSE gear and all forward

gears. The system will not activate if the trans -

mission is in PARK or NEUTRAL. For vehicles

equipped with a manual transmission, if the

clutch is pressed, HSA will remain active.

Disabling And Enabling HSA

This feature can be turned on or turned off. To

change the current setting, proceed as follows:

To disable HSA, see Ú page 125 for further

information.

Towing With HSA

HSA will also provide assistance to mitigate roll

back while towing a trailer.

WARNING!

There may be situations where the Hill Start Assist

(HSA) will not activate and slight rolling may occur,

such as on minor hills or with a loaded vehicle, or

while pulling a trailer. HSA is not a substitute for

active driving involvement. It is always the driver’s

responsibility to be attentive to distance to other

vehicles, people, and objects, and most

importantly brake operation to ensure safe

operation of the vehicle under all road conditions.

Your complete attention is always required while

driving to maintain safe control of your vehicle.

Failure to follow these warnings can result in a

collision or serious personal injury.

WARNING!

If you use a trailer brake controller with your

trailer, the trailer brakes may be activated and

deactivated with the brake switch. If so, there

may not be enough brake pressure to hold

both the vehicle and the trailer on a hill when

the brake pedal is released. In order to avoid

rolling down an incline while resuming accel -

eration, manually activate the trailer brake or

apply more vehicle brake pressure prior to

releasing the brake pedal.

HSA is not a parking brake. Always apply the

parking brake fully when exiting your vehicle. Also,

be certain to place the transmission in PARK.

Failure to follow these warnings can result in a

collision or serious personal injury.

21_LD_OM_EN_USC_t.book Page 184

Page 187 of 320

SAFETY185

Rain Brake Support (RBS)

RBS may improve braking performance in wet

conditions. It will periodically apply a small amount

of brake pressure to remove any water buildup

on the front brake rotors. It functions when the

windshield wipers are in LO or HI speed. When RBS

is active, there is no notification to the driver and

no driver interaction is required.

Ready Alert Braking (RAB)

RAB may reduce the time required to reach full braking

during emergency braking situations. It anticipates

when an emergency braking situation may occur by

monitoring how fast the throttle is released by the

driver. The Electronic Brake Controller (EBC) will

prepare the brake system for a panic stop.

Traction Control System (TCS)

The TCS monitors the amount of wheel spin of each of

the driven wheels. If wheel spin is detected, the TCS

may apply brake pressure to the spinning wheel(s)

and/or reduce engine power to provide enhanced

acceleration and stability. A feature of the TCS, Brake

Limited Differential (BLD) functions similarly to a

limited slip differential and controls the wheel spin

across a driven axle. If one wheel on a driven axle is

spinning faster than the other, the system will apply the

brake of the spinning wheel. This will allow more engine

power to be applied to the wheel that is not spinning.

BLD may remain enabled even if TCS and ESC are in

reduced modes.

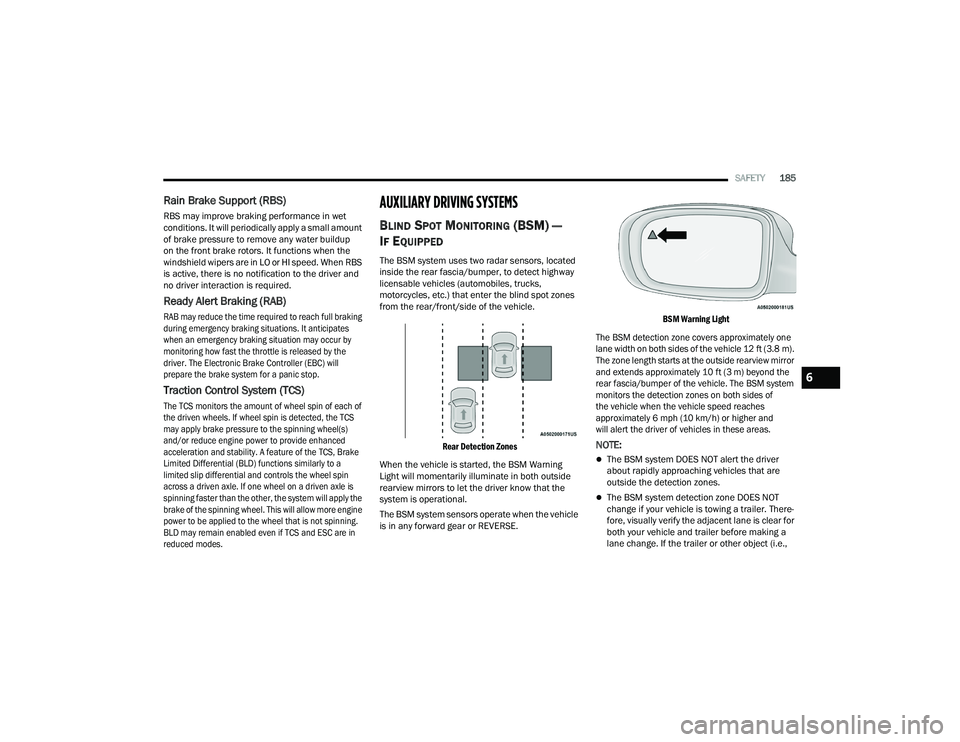

AUXILIARY DRIVING SYSTEMS

BLIND SPOT MONITORING (BS M) —

I

F EQUIPPED

The BSM system uses two radar sensors, located

inside the rear fascia/bumper, to detect highway

licensable vehicles (automobiles, trucks,

motorcycles, etc.) that enter the blind spot zones

from the rear/front/side of the vehicle.

Rear Detection Zones

When the vehicle is started, the BSM Warning

Light will momentarily illuminate in both outside

rearview mirrors to let the driver know that the

system is operational.

The BSM system sensors operate when the vehicle

is in any forward gear or REVERSE.

BSM Warning Light

The BSM detection zone covers approximately one

lane width on both sides of the vehicle 12 ft (3.8 m).

The zone length starts at the outside rearview mirror

and extends approximately 10 ft (3 m) beyond the

rear fascia/bumper of the vehicle. The BSM system

monitors the detection zones on both sides of

the vehicle when the vehicle speed reaches

approximately 6 mph (10 km/h) or higher and

will alert the driver of vehicles in these areas.

NOTE:

The BSM system DOES NOT alert the driver

about rapidly approaching vehicles that are

outside the detection zones.

The BSM system detection zone DOES NOT

change if your vehicle is towing a trailer. There -

fore, visually verify the adjacent lane is clear for

both your vehicle and trailer before making a

lane change. If the trailer or other object (i.e.,

6

21_LD_OM_EN_USC_t.book Page 185

Page 247 of 320

245

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

3.6L AND 5.7L ENGINES

These vehicles are equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the

oil change indicator message will illuminate.

This means that service is required for your

vehicle. Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the

“Change Oil” or “Oil Change Required” message is

displayed. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).The “Oil Change Required” message will be

displayed in the instrument cluster and a single

chime will sound, indicating that an oil change is

necessary.

An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, the

message can be reset by referring to “Instrument

Cluster Display” Ú

page 67.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear

or damage. Rotate tires at the first sign of irreg

-

ular wear, even if it occurs before your next

scheduled service.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering

(if equipped) and fill as needed.

Check function of all interior and exterior lights.

8

21_LD_OM_EN_USC_t.book Page 245