ECO mode DODGE CHARGER 2021 Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2021, Model line: CHARGER, Model: DODGE CHARGER 2021Pages: 320, PDF Size: 20.61 MB

Page 222 of 320

220SAFETY

SAFETY TIPS

TRANSPORTING PASSENGERS

NEVER TRANSPORT PASSENGERS IN THE CARGO

AREA.

TRANSPORTING PETS

Air Bags deploying in the front seat could harm

your pet. An unrestrained pet will be thrown about

and possibly injured, or injure a passenger during

panic braking or in a collision.

Pets should be restrained in the rear seat

(if equipped) in pet harnesses or pet carriers

that are secured by seat belts.

SAFETY CHECKS YOU SHOULD MAKE

I

NSIDE THE VEHICLE

Seat Belts

Inspect the seat belt system periodically, checking

for cuts, frays, and loose parts. Damaged parts

must be replaced immediately. Do not

disassemble or modify the system.

If your vehicle is involved in a collision, or if you

have questions regarding the seat belt or retractor

conditions, take your vehicle to an authorized FCA

dealer or authorized FCA Certified Collision Care

Program facility for inspection.

Air Bag Warning Light

The Air Bag Warning Light will turn on for four to

eight seconds as a bulb check when the ignition

switch is first placed in the ON/RUN position. If the

light is either not on during starting, stays on, or

turns on while driving, have the system inspected

at an authorized dealer as soon as possible. After

the bulb check, this light will illuminate with a

single chime when a fault with the Air Bag System

has been detected. It will stay on until the fault is

removed. If the light comes on intermittently or

remains on while driving, have an authorized

dealer service the vehicle immediately

Ú page 193.

Defroster

Check operation by selecting the defrost mode and

place the blower control on high speed. You should be

able to feel the air directed against the windshield. See

an authorized dealer for service if your defroster is

inoperable.

WARNING!

Do not leave children or animals inside parked

vehicles in hot weather. Interior heat build-up

may cause serious injury or death.

It is extremely dangerous to ride in a cargo

area, inside or outside of a vehicle. In a colli -

sion, people riding in these areas are more

likely to be seriously injured or killed.

Do not allow people to ride in any area of your

vehicle that is not equipped with seats and

seat belts.

Be sure everyone in your vehicle is in a seat

and using a seat belt properly.

21_LD_OM_EN_USC_t.book Page 220

Page 223 of 320

SAFETY221

(Continued)

(Continued)

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle.

Only use a floor mat that does not interfere with the

operation of the accelerator, brake or clutch pedals.

Only use a floor mat that is securely attached using the

floor mat fasteners so it cannot slip out of position and

interfere with the accelerator, brake or clutch pedals or

impair safe operation of your vehicle in other ways.

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nuts/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

WARNING!

An improperly attached, damaged, folded, or

stacked floor mat, or damaged floor mat

fasteners may cause your floor mat to interfere

with the accelerator, brake, or clutch pedals and

cause a loss of vehicle control. To prevent

SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor mat

using the floor mat fasteners. DO NOT install

your floor mat upside down or turn your floor

mat over. Lightly pull to confirm mat is

secured using the floor mat fasteners on a

regular basis.

ALWAYS REMOVE THE EXISTING FLOOR MAT

FROM THE VEHICLE before installing any

other floor mat. NEVER install or stack an addi -

tional floor mat on top of an existing floor mat.

ONLY install floor mats designed to fit your

vehicle. NEVER install a floor mat that cannot

be properly attached and secured to your

vehicle. If a floor mat needs to be replaced, only

use a FCA approved floor mat for the specific

make, model, and year of your vehicle.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for interfer -

ence, with the vehicle properly parked with the

engine off, fully depress the accelerator, the

brake, and the clutch pedal (if present) to check

for interference. If your floor mat interferes with

the operation of any pedal, or is not secure to

the floor, remove the floor mat from the vehicle

and place the floor mat in your trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide

into the driver’s side floor area when the vehicle

is moving. Objects can become trapped under

accelerator, brake, or clutch pedals and could

cause a loss of vehicle control.

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

WARNING!

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

6

21_LD_OM_EN_USC_t.book Page 221

Page 236 of 320

234IN CASE OF EMERGENCY

If the sealant (white fluid) does not flow within 0 –

10 seconds through the Sealant Hose :

1. Push the Power Button (3) to turn Off the Tire Service Kit. Disconnect the Sealant Hose (4)

from the valve stem. Make sure the valve

stem is free of debris. Reconnect the Sealant

Hose (4) to the valve stem. Check that the

Mode Select Knob (6) is in the Sealant Mode

position and not Air Mode. Push the Power

Button (3) to turn On the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another

vehicle, if available. Make sure the engine is

running before turning ON the Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob (6) is on Air Mode and the

pump is operating, air will dispense from the Air

Pump Hose (8) only, not the Sealant Hose (4). If the sealant (white fluid) does flow through the

Sealant Hose :

1. Continue to operate the pump until sealant is no

longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through

the Sealant Hose (4), the Pressure Gauge (5)

can read as high as 70 psi (4.8 Bar). The

Pressure Gauge (5) will decrease quickly from

approximately 70 psi (4.8 Bar) to the actual tire

pressure when the Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is

empty. Continue to operate the pump and

inflate the tire to the pressure indicated on the

tire pressure label on the driver-side latch

pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (5).

If the tire does not inflate to at least 26 psi

(1.8 Bar) pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

NOTE:If the tire becomes overinflated, push the Deflation

Button (2) to reduce the tire pressure to the recom -

mended inflation pressure before continuing. If the tire inflates to the recommended pressure or

is at least 26 psi (1.8 Bar) pressure within

15 minutes:

1. Push the Power Button (3) to turn off the Tire

Service Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the sticker on

the instrument panel.

3. Immediately disconnect the Sealant Hose (4) from the valve stem, reinstall the cap on the

fitting at the end of the hose, and place the Tire

Service Kit in the vehicle storage location.

CAUTION!

The metal end fitting from Power Plug (3) may get

hot after use, so it should be handled carefully.

Failure to reinstall the cap on the fitting at the end

of the Sealant Hose (4) can result in sealant

contacting your skin, clothing, and the vehicle’s

interior. It can also result in sealant contacting

internal Tire Service Kit components which may

cause permanent damage to the kit.

21_LD_OM_EN_USC_t.book Page 234

Page 237 of 320

IN CASE OF EMERGENCY235

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the

tire, drive the vehicle 5 miles (8 km) or 10 minutes

to ensure distribution of the Tire Service Kit Sealant

within the tire. Do not exceed 50 mph (80 km/h).

(E) After Driving:

Pull over to a safe location before continuing

Úpage 233.

1. Push in the Mode Select Knob (6) and turn to the Air Mode position.

2. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet.

3. Uncoil the Air Pump Hose (8) (black in color) and screw the fitting at the end of hose (8)

onto the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge (5). If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (3) to turn on Tire

Service Kit and inflate the tire to the pressure

indicated on the tire and loading information

label on the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation

Button (2) to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and

unplug from 12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been

repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (4) assembly at an authorized dealer as

soon as possible.

NOTE:When having the tire serviced, advise the autho -

rized dealer or service center that the tire has been

sealed using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (4) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the

bottle and dispose of it accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (4) aligns

with the hose slot in the front of the housing.

Push the bottle into the housing. An audible

click will be heard indicating the bottle is

locked into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (4) and return the

hose to its storage area (located on the bottom

of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.WARNING!

Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced

after using Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced.

Failure to follow this warning can result in injuries

that are serious or fatal to you, your passengers, and

others around you.

7

21_LD_OM_EN_USC_t.book Page 235

Page 244 of 320

242IN CASE OF EMERGENCY

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow,

it can often be moved using a rocking motion.

Turn the steering wheel right and left to clear the

area around the front wheels. For vehicles with

automatic transmission, push and hold the lock

button on the gear selector. Then shift back and

forth between DRIVE and REVERSE (with automatic

transmission) or FIRST gear and REVERSE (with

manual transmission), while gently pressing the

accelerator. Use the least amount of accelerator

pedal pressure that will maintain the rocking motion,

without spinning the wheels or racing the engine.

NOTE:

For vehicles with automatic transmission: Shifts

between DRIVE and REVERSE can only be achieved

at wheel speeds of 5 mph (8 km/h) or less.

Whenever the transmission remains in NEUTRAL for

more than two seconds, you must press the brake

pedal to engage DRIVE or REVERSE.

Push the ESC OFF button to place the Electronic

Stability Control (ESC) system in “Partial OFF”

mode, before rocking the vehicle Ú page 182.

Once the vehicle has been freed, push the ESC OFF

button again to restore “ESC On” mode.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after every

five rocking-motion cycles. This will minimize

overheating and reduce the risk of clutch or

transmission failure during prolonged efforts to

free a stuck vehicle.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may cause

damage, or even failure, of the axle and tires.

A tire could explode and injure someone. Do not

spin your vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you are stuck

and do not let anyone near a spinning wheel, no

matter what the speed.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after every

five rocking-motion cycles. This will minimize

overheating and reduce the risk of transmis -

sion failure during prolonged efforts to free a

stuck vehicle.

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or

drivetrain damage may result.

Revving the engine or spinning the wheels too

fast may lead to transmission overheating and

failure. It can also damage the tires. Do not spin

the wheels above 30 mph (48 km/h) while in

gear (no transmission shifting occurring).

21_LD_OM_EN_USC_t.book Page 242

Page 245 of 320

IN CASE OF EMERGENCY243

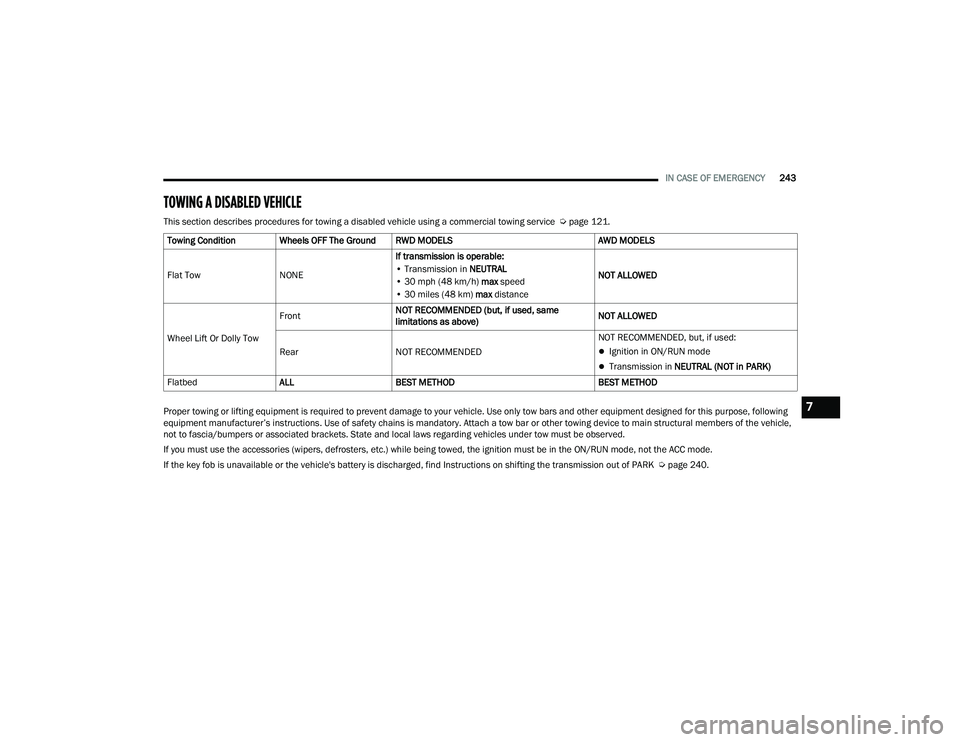

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service Ú page 121.

Proper towing or lifting equipment is required to prevent damage to your vehicle. Use only tow bars and other equipment designed for this purpose, following

equipment manufacturer’s instructions. Use of safety chains is mandatory. Attach a tow bar or other towing device to main structural members of the vehicle,

not to fascia/bumpers or associated brackets. State and local laws regarding vehicles under tow must be observed.

If you must use the accessories (wipers, defrosters, etc.) while being towed, the ignition must be in the ON/RUN mode, not the ACC mode.

If the key fob is unavailable or the vehicle's battery is discharged, find Instructions on shifting the transmission out of PARK Ú page 240.

Towing Condition Wheels OFF The Ground RWD MODELS

AWD MODELS

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max speed

• 30 miles (48 km) max distance NOT ALLOWED

Wheel Lift Or Dolly Tow Front

NOT RECOMMENDED (but, if used, same

limitations as above) NOT ALLOWED

Rear NOT RECOMMENDED NOT RECOMMENDED, but, if used:

Ignition in ON/RUN mode

Transmission in

NEUTRAL (NOT in PARK)

Flatbed ALL BEST METHOD BEST METHOD

7

21_LD_OM_EN_USC_t.book Page 243

Page 246 of 320

244IN CASE OF EMERGENCY

ALL WHEEL DRIVE (AWD) MODELS

FCA US LLC recommends towing your vehicle with

all four wheels OFF the ground using a flatbed.

If the transmission and driveline are operable,

AWD models can also be towed with the ignition in

the ON/RUN mode, the transmission in NEUTRAL

(not in PARK!), and the rear wheels OFF the ground

with no limitation on speed or distance. Since the

ignition MUST be in the ON/RUN mode to tow in

this manner, AWD vehicles must be towed with ALL

FOUR wheels OFF the ground (e.g. on a flatbed

truck) if the key fob is unavailable.

REAR WHEEL DRIVE (RWD) MODELS

FCA US LLC recommends towing your vehicle with

all four wheels OFF the ground using a flatbed. If flatbed equipment is not available, and the

transmission is operable, this vehicle may be flat

towed (with all four wheels on the ground) under

the following conditions:

The transmission must be in NEUTRAL (N). Instruc

-

tions on shifting the transmission to NEUTRAL (N)

when the engine is off

Ú

page 240.

The towing speed must not exceed 30 mph

(48 km/h).

The towing distance must not exceed 30 miles

(48 km).

If the transmission is not operable, or the vehicle

must be towed faster than 30 mph (48 km/h)

or farther than 30 miles (48 km), then the only

acceptable method of towing is with a flatbed

truck.

ENHANCED ACCIDENT RESPONSE

SYSTEM (EARS)

This vehicle is equipped with an Enhanced

Accident Response System.

This feature is a communication network that

takes effect in the event of an impact Úpage 207.

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an event data

recorder (EDR). The main purpose of an EDR is to

record data that will assist in understanding how a

vehicle’s systems performed under certain crash

or near crash-like situations, such as an air bag

deployment or hitting a road obstacle Úpage 208.

CAUTION!

Towing this vehicle using any other method

can cause severe transmission and/or

transfer case damage.

Damage from improper towing is not covered

under the New Vehicle Limited Warranty.CAUTION!

Towing this vehicle in violation of the above

requirements can cause severe transmission

damage. Damage from improper towing is not

covered under the New Vehicle Limited Warranty.

21_LD_OM_EN_USC_t.book Page 244

Page 258 of 320

256SERVICING AND MAINTENANCE

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts, small

cracks that run across ribbed surface of belt from

rib to rib, are considered normal. These are not a

reason to replace belt. However, cracks running

along a rib (not across) are not normal. Any belt

with cracks running along a rib must be replaced.

Also have the belt replaced if it has excessive wear,

frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between

two ribs)

Belt slips

“Groove jumping" (belt does not maintain

correct position on pulley)

Belt broken (note: identify and correct problem

before new belt is installed)

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation) Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically with

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and

to protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating, excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WARNING!

Do not attempt to inspect an accessory drive

belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could be

injured by the moving fan blades.

You can be badly injured working on or around

a motor vehicle. Only do service work for which

you have the knowledge and the proper equip

-

ment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

21_LD_OM_EN_USC_t.book Page 256

Page 275 of 320

SERVICING AND MAINTENANCE273

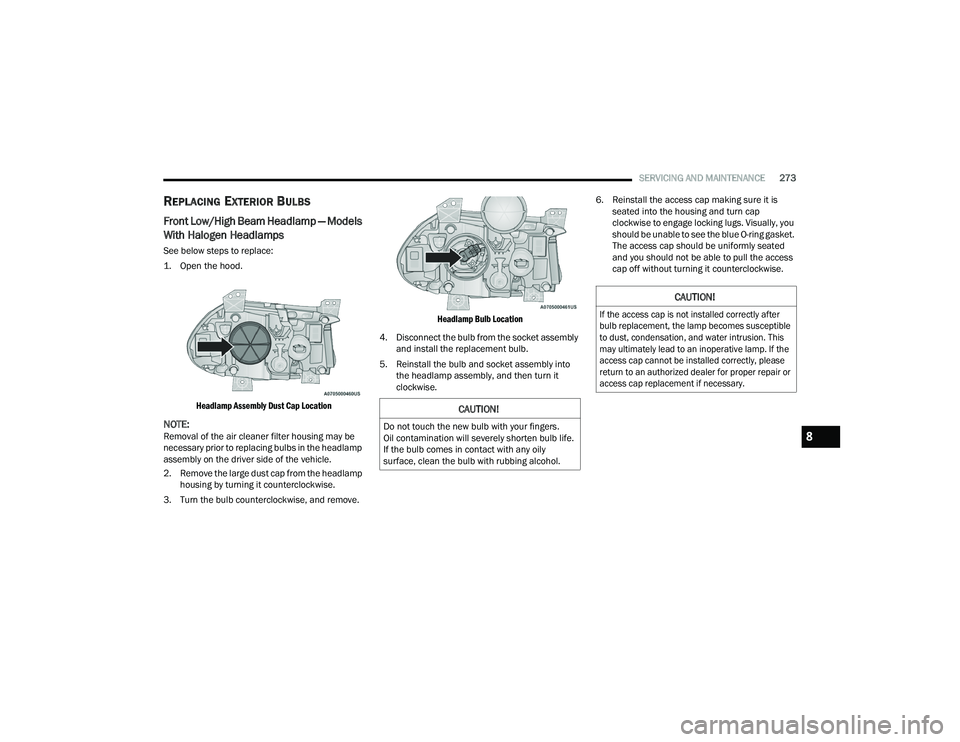

REPLACING EXTERIOR BULBS

Front Low/High Beam Headlamp — Models

With Halogen Headlamps

See below steps to replace:

1. Open the hood.

Headlamp Assembly Dust Cap Location

NOTE:Removal of the air cleaner filter housing may be

necessary prior to replacing bulbs in the headlamp

assembly on the driver side of the vehicle.

2. Remove the large dust cap from the headlamp housing by turning it counterclockwise.

3. Turn the bulb counterclockwise, and remove.

Headlamp Bulb Location

4. Disconnect the bulb from the socket assembly and install the replacement bulb.

5. Reinstall the bulb and socket assembly into the headlamp assembly, and then turn it

clockwise. 6. Reinstall the access cap making sure it is

seated into the housing and turn cap

clockwise to engage locking lugs. Visually, you

should be unable to see the blue O-ring gasket.

The access cap should be uniformly seated

and you should not be able to pull the access

cap off without turning it counterclockwise.

CAUTION!

Do not touch the new bulb with your fingers.

Oil contamination will severely shorten bulb life.

If the bulb comes in contact with any oily

surface, clean the bulb with rubbing alcohol.

CAUTION!

If the access cap is not installed correctly after

bulb replacement, the lamp becomes susceptible

to dust, condensation, and water intrusion. This

may ultimately lead to an inoperative lamp. If the

access cap cannot be installed correctly, please

return to an authorized dealer for proper repair or

access cap replacement if necessary.

8

21_LD_OM_EN_USC_t.book Page 273

Page 276 of 320

274SERVICING AND MAINTENANCE

Front Low/High Beam Headlamp — Models

With High Intensity Discharge (HID)

Headlamps

The headlamps are a type of high voltage

discharge tube. High voltage can remain in the

circuit even with the headlamp switch off and the

key removed. Because of this, you should not

attempt to service a headlamp bulb yourself. If a

headlamp bulb fails, take your vehicle to an

authorized dealer for service.

NOTE:On vehicles equipped with HID headlamps, when

the headlamps are turned on, there is a blue hue

to the lights. This diminishes and becomes more

white after approximately 10 seconds, as the

system charges.

Front/Rear Side Marker Lamp

The Side Markers use LED lamps that are not

serviceable separately. The Side Markers must be

replaced as an assembly, see an authorized dealer.

Front Fog Lamp

The Front Fog Lamps use LED sources that are not

serviceable separately. The Front Fog Lamp must

be replaced as an assembly; see an authorized

dealer.

Front Turn Signal Lamps

The Front Park/Turn function is part of the

headlamp assembly and use LED lamps that are

not serviceable separately. The headlamps must

be replaced as an assembly, see an authorized

dealer.

Backup Lamps

The Backup Lamps use LED sources that are not

serviceable separately. The Applique must be

replaced as an assembly; see an authorized

dealer.

License Lamp

The License Lamp uses an LED source that is not

serviceable separately. The License Lamp must be

replaced as an assembly; see an authorized

dealer.

Center High Mounted Stop Lamp (CHMSL)

The CHMSL Lamp uses LED sources that are not

serviceable separately. The CHMSL Lamp must be

replaced as an assembly; see an authorized

dealer.

WARNING!

A transient high voltage occurs at the bulb

sockets of HID headlamps when the headlamp

switch is turned ON. It may cause serious

electrical shock or electrocution if not serviced

properly. See an authorized dealer for service.

21_LD_OM_EN_USC_t.book Page 274