lock DODGE CHARGER 2022 Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2022, Model line: CHARGER, Model: DODGE CHARGER 2022Pages: 312, PDF Size: 18.99 MB

Page 221 of 312

IN CASE OF EMERGENCY219

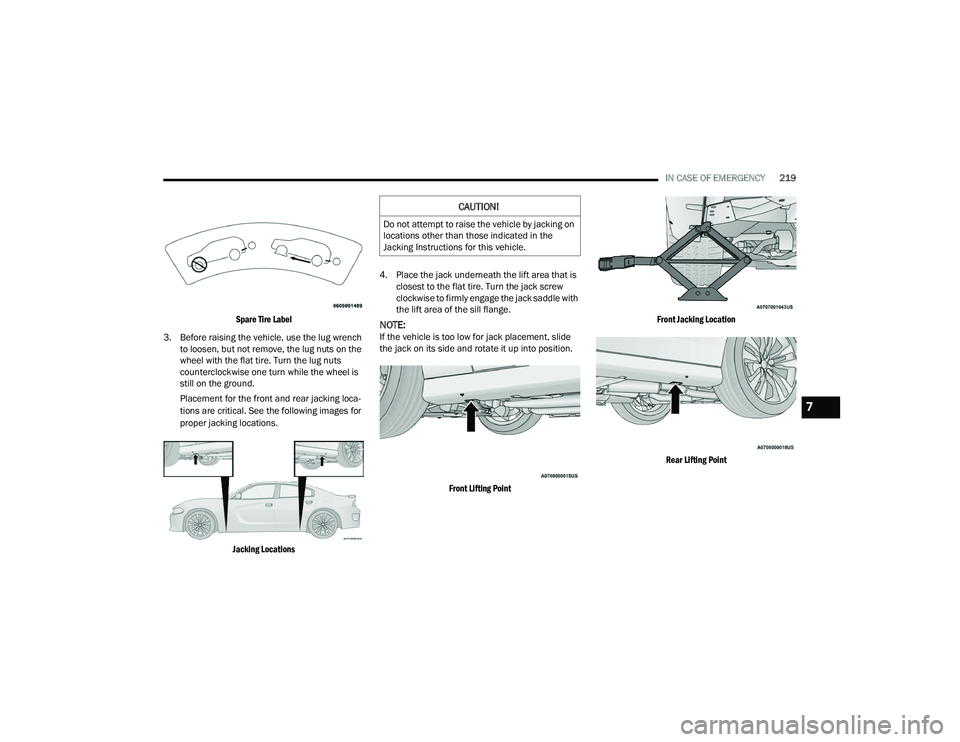

Spare Tire Label

3. Before raising the vehicle, use the lug wrench to loosen, but not remove, the lug nuts on the

wheel with the flat tire. Turn the lug nuts

counterclockwise one turn while the wheel is

still on the ground.

Placement for the front and rear jacking loca -

tions are critical. See the following images for

proper jacking locations.

Jacking Locations

4. Place the jack underneath the lift area that is

closest to the flat tire. Turn the jack screw

clockwise to firmly engage the jack saddle with

the lift area of the sill flange.

NOTE:If the vehicle is too low for jack placement, slide

the jack on its side and rotate it up into position.

Front Lifting Point Front Jacking Location

Rear Lifting Point

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

7

22_LD_OM_EN_USC_t.book Page 219

Page 222 of 312

220IN CASE OF EMERGENCY

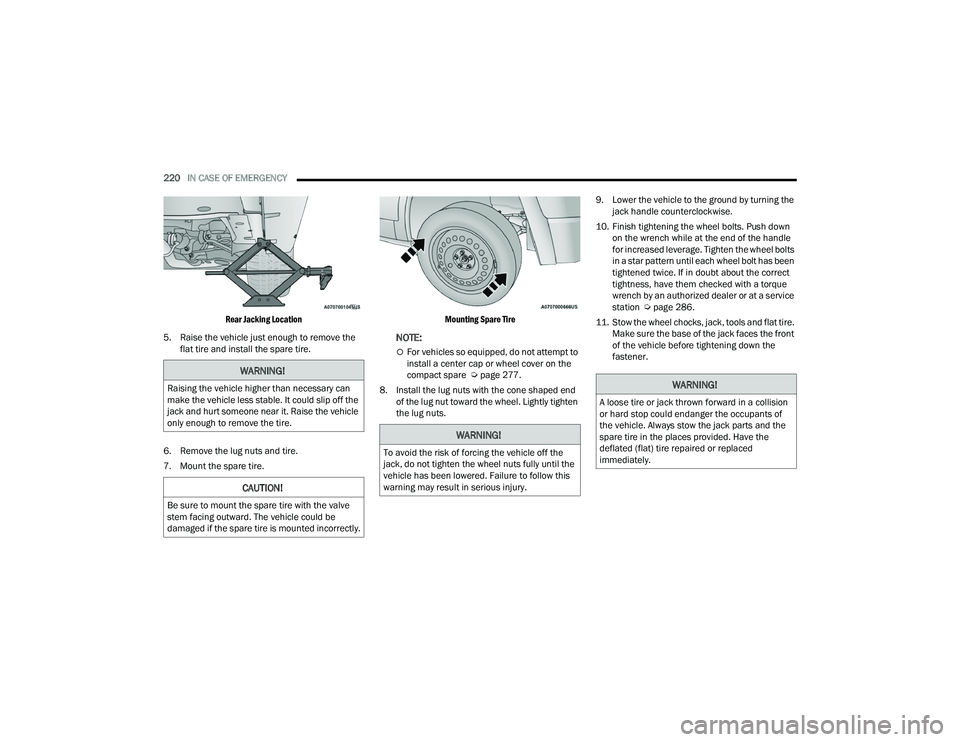

Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire and install the spare tire.

6. Remove the lug nuts and tire.

7. Mount the spare tire.

Mounting Spare Tire

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare Ú

page 277.

8. Install the lug nuts with the cone shaped end of the lug nut toward the wheel. Lightly tighten

the lug nuts. 9. Lower the vehicle to the ground by turning the

jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a service

station Ú page 286.

11. Stow the wheel chocks, jack, tools and flat tire. Make sure the base of the jack faces the front

of the vehicle before tightening down the

fastener.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

22_LD_OM_EN_USC_t.book Page 220

Page 227 of 312

IN CASE OF EMERGENCY225

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (3) to turn on Tire Service Kit and inflate the tire to the pressure

indicated on the tire and loading information

label on the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation

Button (2) to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and

unplug from 12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been

repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (4) assembly at an authorized dealer as

soon as possible.

NOTE:When having the tire serviced, advise the autho -

rized dealer or service center that the tire has been

sealed using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (4) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the

bottle and dispose of it accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (4) aligns

with the hose slot in the front of the housing.

Push the bottle into the housing. An audible

click will be heard indicating the bottle is

locked into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (4) and return the

hose to its storage area (located on the bottom

of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.

JUMP STARTING

If your vehicle has a discharged battery, it can be

jump started using a set of jumper cables and a

battery in another vehicle, or by using a portable

battery booster pack. Jump starting can be

dangerous if done improperly, so please follow the

procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow

the manufacturer's operating instructions and

precautions.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system voltage

greater than 12 Volts or damage to the battery,

starter motor, alternator or electrical system may

occur.

7

22_LD_OM_EN_USC_t.book Page 225

Page 232 of 312

230IN CASE OF EMERGENCY

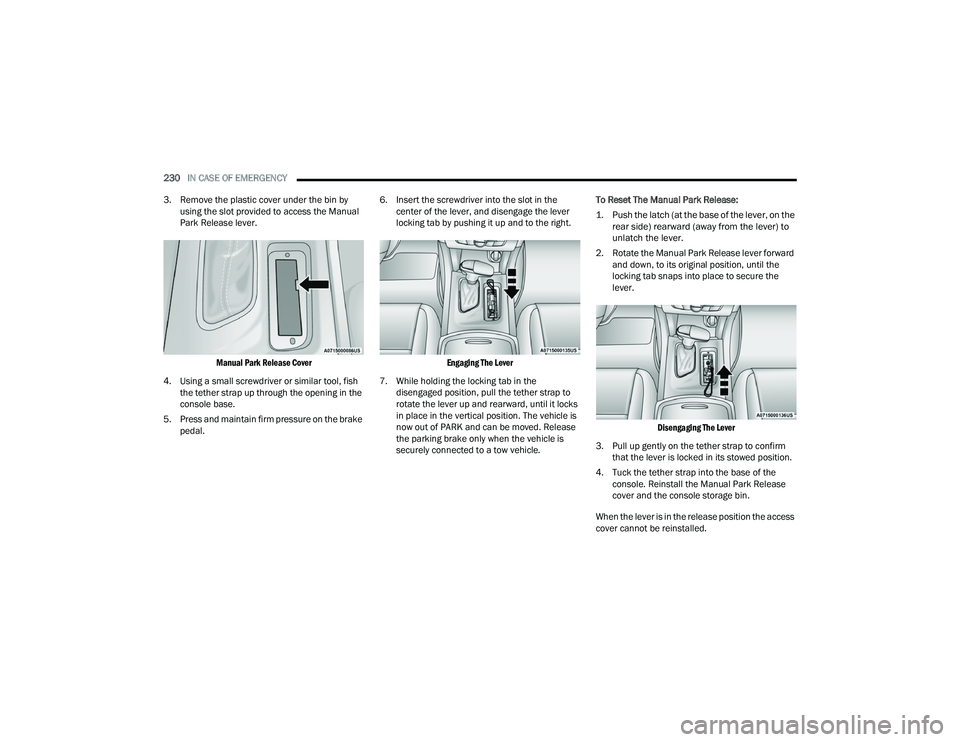

3. Remove the plastic cover under the bin by using the slot provided to access the Manual

Park Release lever.

Manual Park Release Cover

4. Using a small screwdriver or similar tool, fish the tether strap up through the opening in the

console base.

5. Press and maintain firm pressure on the brake pedal. 6. Insert the screwdriver into the slot in the

center of the lever, and disengage the lever

locking tab by pushing it up and to the right.

Engaging The Lever

7. While holding the locking tab in the disengaged position, pull the tether strap to

rotate the lever up and rearward, until it locks

in place in the vertical position. The vehicle is

now out of PARK and can be moved. Release

the parking brake only when the vehicle is

securely connected to a tow vehicle. To Reset The Manual Park Release:

1. Push the latch (at the base of the lever, on the

rear side) rearward (away from the lever) to

unlatch the lever.

2. Rotate the Manual Park Release lever forward and down, to its original position, until the

locking tab snaps into place to secure the

lever.

Disengaging The Lever

3. Pull up gently on the tether strap to confirm that the lever is locked in its stowed position.

4. Tuck the tether strap into the base of the console. Reinstall the Manual Park Release

cover and the console storage bin.

When the lever is in the release position the access

cover cannot be reinstalled.

22_LD_OM_EN_USC_t.book Page 230

Page 233 of 312

IN CASE OF EMERGENCY231

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. For

vehicles with automatic transmission, push and

hold the lock button on the gear selector. Then

shift back and forth between DRIVE and REVERSE

(with automatic transmission) or FIRST gear and

REVERSE (with manual transmission), while gently

pressing the accelerator. Use the least amount of

accelerator pedal pressure that will maintain the

rocking motion, without spinning the wheels or

racing the engine.

NOTE:For vehicles with automatic transmission: Shifts

between DRIVE and REVERSE can only be

achieved at wheel speeds of 5 mph (8 km/h) or

less. Whenever the transmission remains in

NEUTRAL for more than two seconds, you must

press the brake pedal to engage DRIVE or

REVERSE.

Push the ESC OFF button to place the Electronic

Stability Control (ESC) system in “Partial OFF”

mode, before rocking the vehicle Ú page 170.

Once the vehicle has been freed, push the ESC OFF

button again to restore “ESC On” mode.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission in

NEUTRAL for at least one minute after every five

rocking-motion cycles. This will minimize

overheating and reduce the risk of clutch or

transmission failure during prolonged efforts to

free a stuck vehicle.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle and

tires. A tire could explode and injure someone.

Do not spin your vehicle's wheels faster than

30 mph (48 km/h) or for longer than 30

seconds continuously without stopping when

you are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after every

five rocking-motion cycles. This will minimize

overheating and reduce the risk of transmis -

sion failure during prolonged efforts to free a

stuck vehicle.

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin the

wheels faster than 15 mph (24 km/h), or

drivetrain damage may result.

Revving the engine or spinning the wheels too

fast may lead to transmission overheating and

failure. It can also damage the tires. Do not

spin the wheels above 30 mph (48 km/h)

while in gear (no transmission shifting occur -

ring).

7

22_LD_OM_EN_USC_t.book Page 231

Page 247 of 312

SERVICING AND MAINTENANCE245

When inspecting accessory drive belts, small

cracks that run across ribbed surface of belt from

rib to rib, are considered normal. These are not a

reason to replace belt. However, cracks running

along a rib (not across) are not normal. Any belt

with cracks running along a rib must be replaced.

Also have the belt replaced if it has excessive wear,

frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two

ribs)

Belt slips

Groove jumping (belt does not maintain correct

position on pulley)

Belt broken (identify and correct problem before

new belt is installed)

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation)

Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically with

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and to

protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating, excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated. The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove

accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield.

Avoid using the wiper blades to remove frost or ice

from the windshield. Keep the blade rubber out of

contact with petroleum products such as engine

oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending

on geographical area and frequency of use. Poor

performance of blades may be present with chat

-

tering, marks, water lines or wet spots. If any of

these conditions are present, clean the wiper

blades or replace as necessary.8

22_LD_OM_EN_USC_t.book Page 245

Page 248 of 312

246SERVICING AND MAINTENANCE

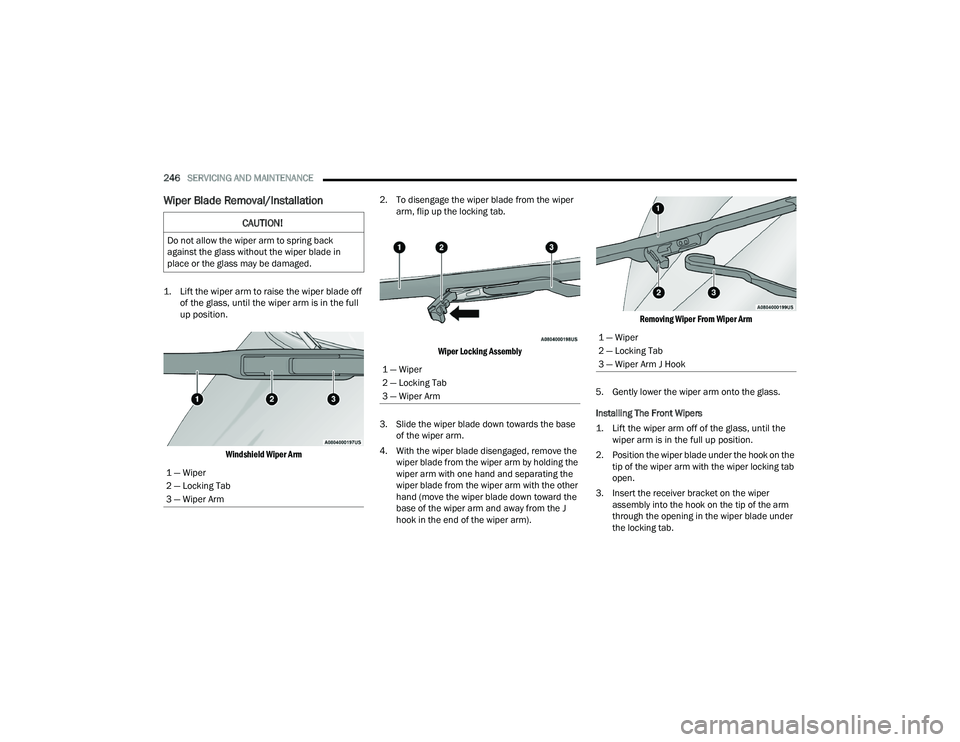

Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off

of the glass, until the wiper arm is in the full

up position.

Windshield Wiper Arm

2. To disengage the wiper blade from the wiper

arm, flip up the locking tab.

Wiper Locking Assembly

3. Slide the wiper blade down towards the base of the wiper arm.

4. With the wiper blade disengaged, remove the wiper blade from the wiper arm by holding the

wiper arm with one hand and separating the

wiper blade from the wiper arm with the other

hand (move the wiper blade down toward the

base of the wiper arm and away from the J

hook in the end of the wiper arm).

Removing Wiper From Wiper Arm

5. Gently lower the wiper arm onto the glass.

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the wiper arm is in the full up position.

2. Position the wiper blade under the hook on the tip of the wiper arm with the wiper locking tab

open.

3. Insert the receiver bracket on the wiper assembly into the hook on the tip of the arm

through the opening in the wiper blade under

the locking tab.

CAUTION!

Do not allow the wiper arm to spring back

against the glass without the wiper blade in

place or the glass may be damaged.

1 — Wiper

2 — Locking Tab

3 — Wiper Arm

1 — Wiper

2 — Locking Tab

3 — Wiper Arm

1 — Wiper

2 — Locking Tab

3 — Wiper Arm J Hook

22_LD_OM_EN_USC_t.book Page 246

Page 249 of 312

SERVICING AND MAINTENANCE247

(Continued)

4. Slide the wiper blade onto the arm until motion

stops, then fold down the locking tab to

secure.

NOTE:The locking tab will not snap into place until the

blade is properly positioned on the wiper arm hook.

5. Gently lower the wiper blade onto the glass.

EXHAUST SYSTEM

The best protection against carbon monoxide entry

into the vehicle body is a properly maintained

engine exhaust system.

If you notice a change in the sound of the exhaust

system; or if the exhaust fumes can be detected

inside the vehicle; or when the underside or rear of

the vehicle is damaged; have an authorized

technician inspect the complete exhaust system

and adjacent body areas for broken, damaged,

deteriorated, or mispositioned parts. Open seams

or loose connections could permit exhaust fumes

to seep into the passenger compartment. In

addition, have the exhaust system inspected each

time the vehicle is raised for lubrication or oil

change. Replace as required. Under normal operating conditions, the catalytic

converter will not require maintenance. However, it

is important to keep the engine properly tuned to

ensure proper catalyst operation and prevent

possible catalyst damage.

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you.

In unusual situations involving grossly

malfunctioning engine operation, a scorching odor

may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn off

the engine and allow it to cool. Service, including a

tune-up to manufacturer's specifications, should

be obtained immediately.

WARNING!

Exhaust gases can injure or kill. They contain

Carbon Monoxide (CO), which is colorless and

odorless. Breathing it can make you uncon

-

scious and can eventually poison you

Ú

page 211.

A hot exhaust system can start a fire if you

park over materials that can burn. Such

materials might be grass or leaves coming

into contact with your exhaust system. Do not

park or operate your vehicle in areas where

your exhaust system can contact anything

that can burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as an

emissions control device and may seriously

reduce engine performance and cause

serious damage to the engine.

Damage to the catalytic converter can result if

your vehicle is not kept in proper operating

condition. In the event of engine malfunction,

particularly involving engine misfire or other

apparent loss of performance, have your

vehicle serviced promptly. Continued opera -

tion of your vehicle with a severe malfunction

could cause the converter to overheat,

resulting in possible damage to the converter

and vehicle.

CAUTION!

8

22_LD_OM_EN_USC_t.book Page 247

Page 257 of 312

SERVICING AND MAINTENANCE255

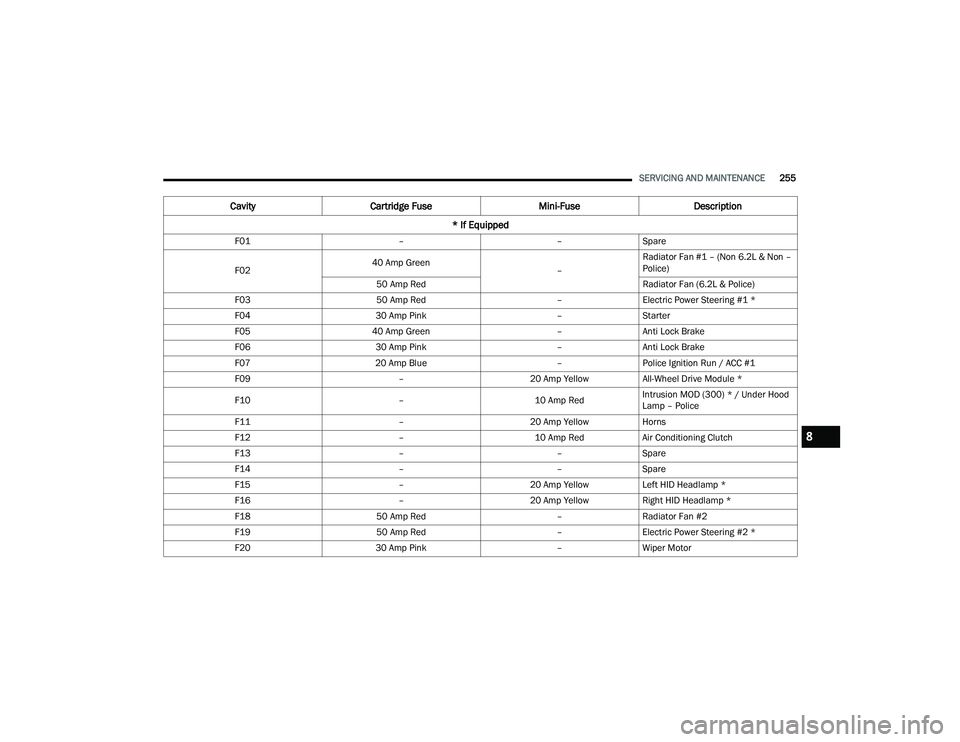

CavityCartridge Fuse Mini-FuseDescription

* If Equipped

F01 ––Spare

F02 40 Amp Green

–Radiator Fan #1 – (Non 6.2L & Non –

Police)

50 Amp Red Radiator Fan (6.2L & Police)

F03 50 Amp Red –Electric Power Steering #1 *

F04 30 Amp Pink –Starter

F05 40 Amp Green –Anti Lock Brake

F06 30 Amp Pink –Anti Lock Brake

F07 20 Amp Blue –Police Ignition Run / ACC #1

F09 –20 Amp YellowAll-Wheel Drive Module *

F10 –10 Amp RedIntrusion MOD (300) * / Under Hood

Lamp – Police

F11 –20 Amp YellowHorns

F12 –10 Amp RedAir Conditioning Clutch

F13 ––Spare

F14 ––Spare

F15 –20 Amp YellowLeft HID Headlamp *

F16 –20 Amp YellowRight HID Headlamp *

F18 50 Amp Red –Radiator Fan #2

F19 50 Amp Red –Electric Power Steering #2 *

F20 30 Amp Pink –Wiper Motor

8

22_LD_OM_EN_USC_t.book Page 255

Page 258 of 312

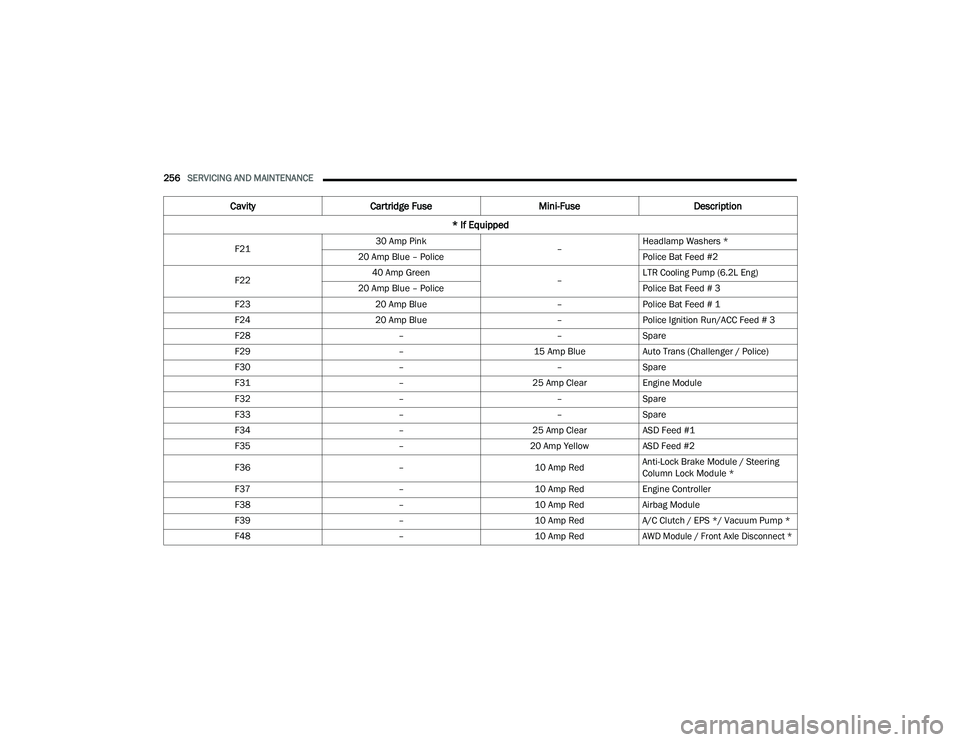

256SERVICING AND MAINTENANCE

F21 30 Amp Pink

–Headlamp Washers *

20 Amp Blue – Police Police Bat Feed #2

F22 40 Amp Green

–LTR Cooling Pump (6.2L Eng)

20 Amp Blue – Police Police Bat Feed # 3

F23 20 Amp Blue –Police Bat Feed # 1

F24 20 Amp Blue –Police Ignition Run/ACC Feed # 3

F28 ––Spare

F29 –15 Amp BlueAuto Trans (Challenger / Police)

F30 ––Spare

F31 –25 Amp ClearEngine Module

F32 ––Spare

F33 ––Spare

F34 –25 Amp ClearASD Feed #1

F35 –20 Amp YellowASD Feed #2

F36 –10 Amp RedAnti-Lock Brake Module / Steering

Column Lock Module *

F37 –10 Amp RedEngine Controller

F38 –10 Amp RedAirbag Module

F39 –10 Amp RedA/C Clutch / EPS */ Vacuum Pump *

F48 –10 Amp Red

AWD Module / Front Axle Disconnect *

Cavity Cartridge Fuse Mini-FuseDescription

* If Equipped

22_LD_OM_EN_USC_t.book Page 256