DODGE DAKOTA 2004 3.G Owners Manual

Manufacturer: DODGE, Model Year: 2004, Model line: DAKOTA, Model: DODGE DAKOTA 2004 3.GPages: 300, PDF Size: 5.23 MB

Page 211 of 300

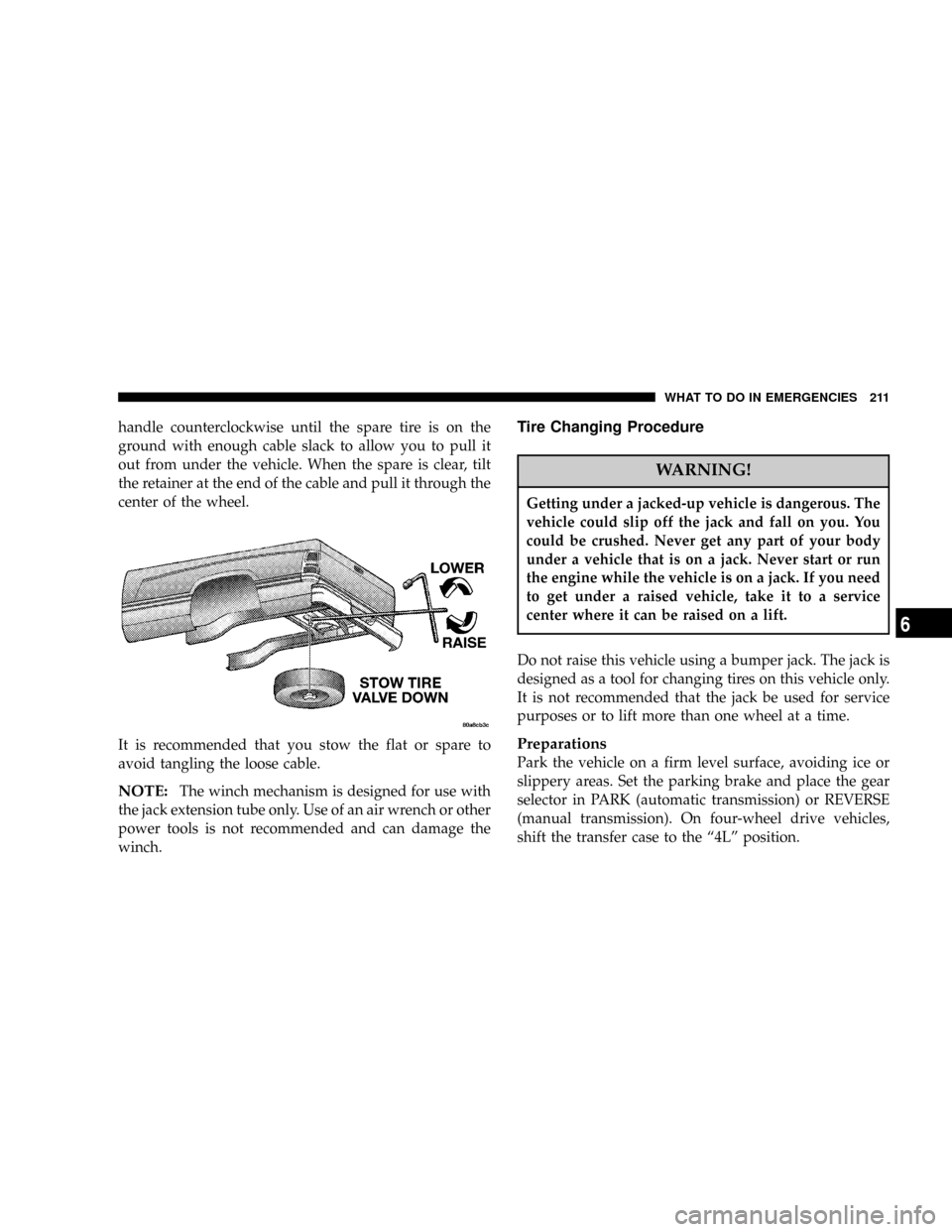

handle counterclockwise until the spare tire is on the

ground with enough cable slack to allow you to pull it

out from under the vehicle. When the spare is clear, tilt

the retainer at the end of the cable and pull it through the

center of the wheel.

It is recommended that you stow the flat or spare to

avoid tangling the loose cable.

NOTE:The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

Tire Changing Procedure

WARNING!

Getting under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to a service

center where it can be raised on a lift.

Do not raise this vehicle using a bumper jack. The jack is

designed as a tool for changing tires on this vehicle only.

It is not recommended that the jack be used for service

purposes or to lift more than one wheel at a time.

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the gear

selector in PARK (automatic transmission) or REVERSE

(manual transmission). On four-wheel drive vehicles,

shift the transfer case to the ª4Lº position.

WHAT TO DO IN EMERGENCIES 211

6

Page 212 of 300

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Turn on the Hazard Warning Flasher.

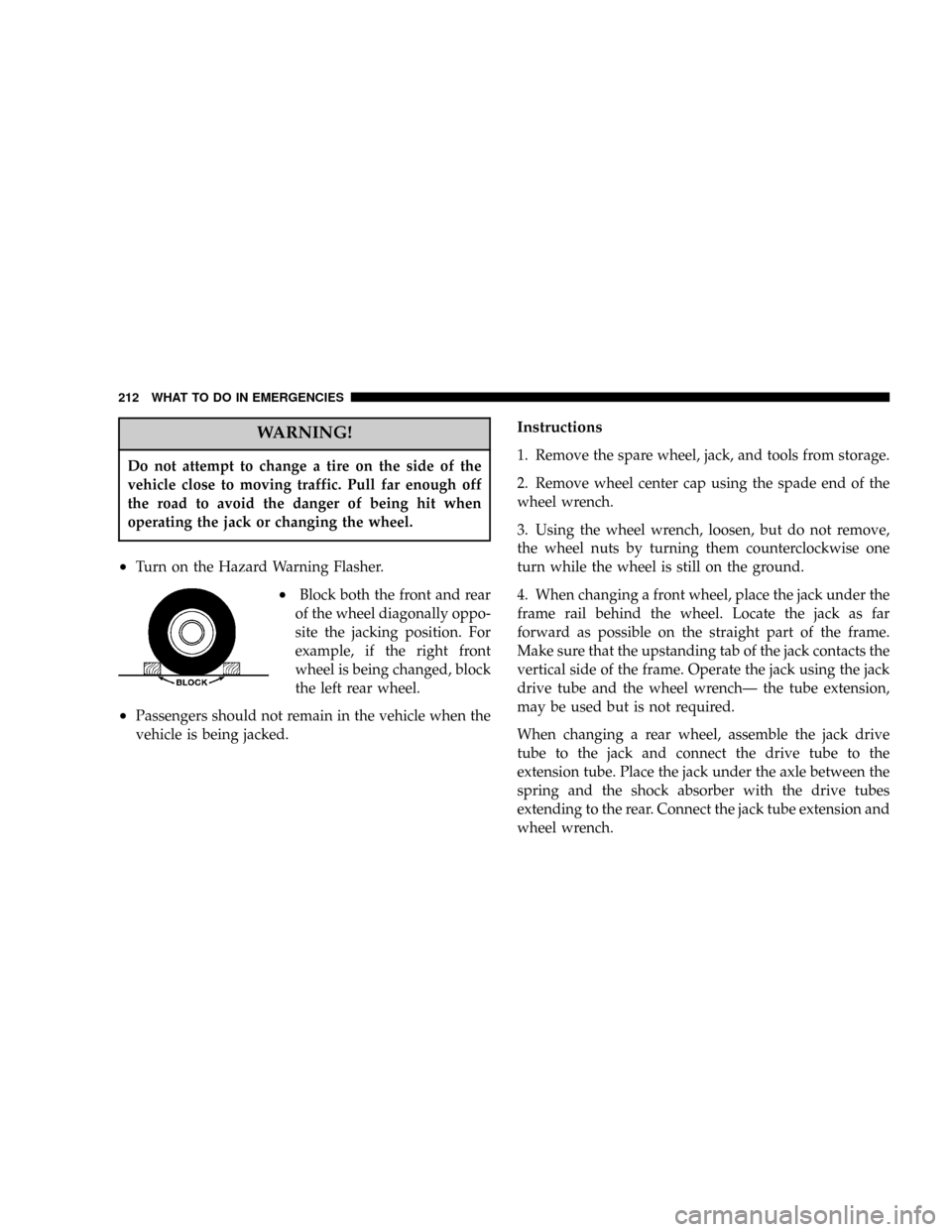

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if the right front

wheel is being changed, block

the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

1. Remove the spare wheel, jack, and tools from storage.

2. Remove wheel center cap using the spade end of the

wheel wrench.

3. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

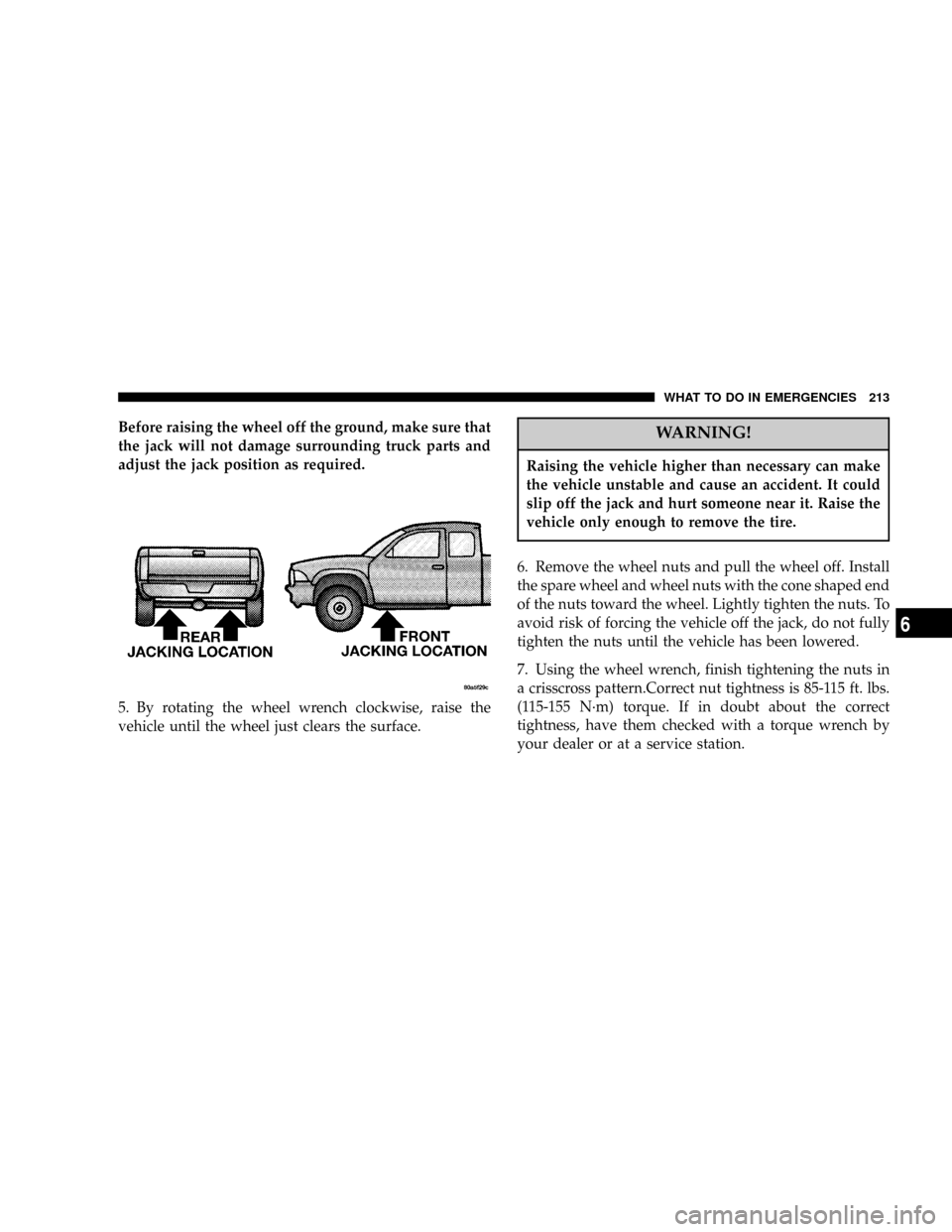

4. When changing a front wheel, place the jack under the

frame rail behind the wheel. Locate the jack as far

forward as possible on the straight part of the frame.

Make sure that the upstanding tab of the jack contacts the

vertical side of the frame. Operate the jack using the jack

drive tube and the wheel wrenchÐ the tube extension,

may be used but is not required.

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle between the

spring and the shock absorber with the drive tubes

extending to the rear. Connect the jack tube extension and

wheel wrench.

212 WHAT TO DO IN EMERGENCIES

Page 213 of 300

Before raising the wheel off the ground, make sure that

the jack will not damage surrounding truck parts and

adjust the jack position as required.

5. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

6. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel. Lightly tighten the nuts. To

avoid risk of forcing the vehicle off the jack, do not fully

tighten the nuts until the vehicle has been lowered.

7. Using the wheel wrench, finish tightening the nuts in

a crisscross pattern.Correct nut tightness is 85-115 ft. lbs.

(115-155 N´m) torque. If in doubt about the correct

tightness, have them checked with a torque wrench by

your dealer or at a service station.

WHAT TO DO IN EMERGENCIES 213

6

Page 214 of 300

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle.

Always stow the jack parts and the extra tire and

wheel in the places provided.

8. Install wheel center cap and remove wheel blocks. Do

not install chrome or aluminum wheel center caps on the

spare wheel. This may result in cap damage.

9. Lower the jack to its fully closed position. Stow the

replaced tire, jack, and tools as previously described.

10. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

²Always park on a firm, level surface as far from

the edge of the roadway as possible before raising

the vehicle.

²Block the wheel diagonally opposite the wheel to

be raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on

a jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely

careful of motor traffic.

214 WHAT TO DO IN EMERGENCIES

Page 215 of 300

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Attach the wheel wrench to the extension tube. Rotate the

winch mechanism until the wheel is drawn into place

against the underside of the vehicle. Continue to rotate

until you feel the winch mechanism slip or click 3 or 4

times. It cannot be overtightened. Push against the tire

several times to be sure it is firmly in place.

JUMP STARTING

WARNING!

²Battery fluid is a corrosive acid solution; do not

allow battery fluid to contact eyes, skin or cloth-

ing. Don't lean over battery when attaching

clamps or allow the clamps to touch each other. If

acid splashes in eyes or on skin, flush the con-

taminated area immediately with large quantities

of water.

²A battery generates hydrogen gas which is flam-

mable and explosive. Keep flame or spark away

from the vent holes. Do not use a booster battery

or any other booster source with an output that

exceeds 12 volts.

Check the Battery Test Indicator (if equipped). If a yellow

or bright colored dot is visible in the indicator (if

equipped), DO NOT jump-start the battery.

WHAT TO DO IN EMERGENCIES 215

6

Page 216 of 300

If the indicator (if equipped) is dark or shows a green dot,

proceed as follows:

1. Wear eye protection and remove all metal jewelry such

as watch bands or bracelets which might make an

unintended electrical contact.

2. Park the booster vehicle within cable reach but with-

out letting the vehicles touch. Set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition OFF on

both vehicles.

3. Turn OFF heater, radio and all unnecessary electrical

loads.

4. Connect one end of a jumper cable to the positive

terminal of the booster battery. Connect the other end of

the same cable to the positive terminal of the discharged

battery.WARNING!

Do not permit vehicles to touch each other as this

could establish a ground connection and personal

injury could result.

5. Connect the other cable, first to the negative terminal

of the booster battery and then to the engine of the

vehicle with the discharged battery. Make sure you have

a good contact on the engine.

216 WHAT TO DO IN EMERGENCIES

Page 217 of 300

WARNING!

Do not connect the cable to the negative post of the

discharge battery. The resulting electrical spark

could cause the battery to explode.

During cold weather when temperatures are below

freezing point, electrolyte in a discharged battery

may freeze. Do not attempt jump starting because

the battery could rupture or explode. The battery

temperature must be brought up above freezing

point before attempting jump start.

6. Start the engine in the vehicle which has the booster

battery, let the engine idle a few minutes, then start the

engine in the vehicle with the discharged battery.

7. When removing the jumper cables, reverse the above

sequence exactly. Be careful of the moving belts and fan.

WARNING!

Any procedure other than above could result in:

1. Personal injury caused by electrolyte squirting

out the battery vent;

2. Personal injury or property damage due to battery

explosion;

3. Damage to charging system of booster vehicle or

of immobilized vehicle.

TOWING A DISABLED VEHICLE

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use of safety chains is recom-

mended.Attach towing device to main structural mem-

bers of the vehicle Ð not to bumpers or associated

brackets. State and local laws applying to vehicles

under tow must be observed.

WHAT TO DO IN EMERGENCIES 217

6

Page 218 of 300

Four-Wheel Drive Vehicles

The manufacturer recommends towing with all wheels

off the ground. Acceptable methods are to tow the vehicle

on a flatbed or with one end of the vehicle raised and the

opposite end on a towing dolly.

Two-Wheel Drive Vehicles

Provided that the transmission is operable, tow with the

transmission in Neutral and the ignition key in the OFF

position along with the front wheels raised and the rear

wheels on the ground. The speed must not exceed 30

mph (50 km/h) and the distance must not exceed 15

miles (25 km).If the vehicle is to be towed more than 15 miles (25 km),

it must be towed on a flatbed, or with the rear wheels

raised and the front wheels on the ground, or with the

front end raised and the rear wheels on a towing dolly.

218 WHAT TO DO IN EMERGENCIES

Page 219 of 300

MAINTAINING YOUR VEHICLE

CONTENTS

mEngine Compartment 3.7L V6.............221

mEngine Compartment 4.7L V-8............222

mOnboard Diagnostic System Ð OBD II......223

mEmissions Inspection And Maintenance

Programs

............................224

mReplacement Parts.....................225

mDealer Service........................225

mMaintenance Procedures.................226

NEngine Oil..........................226

NEngine Oil Filter......................229

NDrive Belts Ð Check Condition And Tension . . 230

NSpark Plugs.........................230NIgnition Cables.......................230

NEngine Air Cleaner Filter................230

NEngine Fuel Filter.....................231

NCatalytic Converter....................231

NMaintenance-Free Battery................232

NAir Conditioner Maintenance.............233

NPower Steering Ð Fluid Check............234

NFront Suspension Ball Joints..............235

NSteering Linkage......................235

NDrive Shaft Constant Velocity

Joints Ð 4X4 Models...................235

NBody Lubrication.....................235

7

Page 220 of 300

NWindshield Wiper Blades................235

NWindshield Washers...................236

NExhaust System......................236

NCooling System.......................237

NEmission Related Components............241

NBrake System........................243

NClutch Hydraulic System................245

NManual Transmission..................245

NAutomatic Transmission................245

NTransfer Case........................248

NAxles..............................248

NSelection Of Lubricating Grease...........248

NAppearance Care And Protection From

Corrosion...........................249

mPower Distribution Center...............252

mFuse Block...........................253

mVehicle Storage........................254

mReplacement Light Bulbs................254

mBulb Replacement......................255

NHeadlights..........................255

NParking/Turn Signal Lights..............256

NRear Side Marker, Tail Lights, Turn Signals

And Backup Lights Ð Replacement........256

NLicense Lights........................257

NCenter High-Mounted Stoplight...........257

NFog Lights..........................257

mFluids And Capacities...................258

mRecommended Fluids, Lubricants And

Genuine Parts

.........................259

NEngine.............................259

NChassis............................260

220 MAINTAINING YOUR VEHICLE