brake DODGE DART 2013 PF / 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2013, Model line: DART, Model: DODGE DART 2013 PF / 1.GPages: 132, PDF Size: 4.13 MB

Page 86 of 132

Vehicles Equipped With Keyless Enter-N-Go™

1. Without pressing the brake pedal, cycle the ignition to the ON/RUN position (do not startthe engine).

2. Fully depress the accelerator pedal, slowly, three times within 10 seconds.

3. Cycle the ignition to the OFF/LOCK position.

Vehicles Not Equipped With Keyless Enter-N-Go™

1. Turn the ignition switch to the ON/RUN position (do not start the engine).

2. Fully depress the accelerator pedal, slowly, three times within 10 seconds.

3. Turn the ignition switch to the OFF/LOCK position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change indicator

system did not reset. If necessary, repeat this procedure.

Resetting The Light After Servicing

• Vehicles Equipped With Keyless Enter-N-Go™

• Without pressing the brake pedal, push the ENGINE START/STOP button and cycle the ignition to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Without pressing the brake pedal, push the ENGINE START/STOP button once to return the ignition to the OFF/LOCK position.

• Vehicles Not Equipped With Keyless Enter-N-Go™

• Turn the ignition switch to the ON/RUN position (Do not start the engine.)

• Fully depress the accelerator pedal, slowly, three times within 10 seconds.

• Turn the ignition switch to the OFF/LOCK position.

WHAT TO DO IN EMERGENCIES

84

Page 89 of 132

Preparations For Jacking

1. Park the vehicle on a firm, level surface as far from the edge of the roadway as possible.Avoid icy or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn OFF the ignition.

6. Block the front and rear of the wheel diagonally opposite of the jacking position. For example, if changing the right front tire,

block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Jacking And Changing A Tire

1. Remove the spare tire, jack, and wheel bolt wrench.

2.

If equipped with aluminum wheels where

the center cap covers the wheel bolts, use

the wheel bolt wrench to pry the center cap

off carefully before raising the vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove,

the wheel bolts on the wheel with the flat

tire. Turn the wheel bolts counterclock-

wise one turn while the wheel is still on

the ground.

WHAT TO DO IN EMERGENCIES

87

Page 93 of 132

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pullfar enough off the road to avoid the danger of being hit when operating the jack or

changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the jack and

fall on you. You could be crushed. Never put any part of your body under a vehicle that

is on a jack. If you need to get under a raised vehicle, take it to an authorized service

center where it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack should not

be used to lift the vehicle for service purposes. The vehicle should be jacked on a firm

level surface only. Avoid ice or slippery areas.

• Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible

before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire

change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

• Raising the vehicle higher than necessary can make the vehicle less stable. It could

slip off the jack and hurt someone near it. Raise the vehicle only enough to remove

the tire.

• To avoid possible personal injury, handle the wheel covers with care to avoid contact

with any sharp edges.

• To avoid the risk of forcing the vehicle off the jack, do not tighten the wheel nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

personal injury.

• A loose tire or jack, thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired or replaced immediately.

WHAT TO DO IN EMERGENCIES

91

Page 95 of 132

TIREFIT Usage Precautions

• Replace the TIREFIT Sealant Bottle (1) and Sealant Hose (6) prior to the expiration date(printed on the bottle label) to assure optimum operation of the system. Refer to “Sealing

a Tire with TIREFIT” section (F) “Sealant Bottle and Hose Replacement”.

• The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use. After each use, always replace these components immediately at an authorized dealer.

• When the TIREFIT sealant is in a liquid form, clean water, and a damp cloth will remove the material from the vehicle or tire and wheel components. Once the sealant dries, it can

easily be peeled off and properly discarded.

• For optimum performance, make sure the valve stem on the wheel is free of debris before connecting the TIREFIT kit.

• You can use the TIREFIT air pump to inflate bicycle tires. The kit also comes with two needles, located in the Accessory Storage Compartment (on the bottom of the air pump)

for inflating sport balls, rafts, or similar inflatable items. However, use only the Air Pump

Hose (7) and make sure the Mode Select Knob (5) is in the Air Mode when inflating such

items to avoid injecting sealant into them. The TIREFIT Sealant is only intended to seal

punctures less than 1/4 in (6 mm) diameter in the tread of your vehicle.

• Do not lift or carry the TIREFIT kit by the hoses.

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the ground. This will allow the TIREFIT Hoses (6) and (7) to reach the valve stem and

keep the TIREFIT kit flat on the ground. This will provide the best positioning of the kit

when injecting the sealant into the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and cycle the ignition to the OFF position.

4. Set the parking brake.

(B) Setting Up To Use TIREFIT:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the TIREFIT kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

WHAT TO DO IN EMERGENCIES

93

Page 96 of 132

(C) Injecting TIREFIT Sealant Into The Deflated Tire:

• Always start the engine before turning ON the TIREFIT kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

• After pressing the Power Button (4), the sealant (white fluid) will flow from the SealantBottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

• If the sealant (white fluid) does not flow within 0 – 10 seconds through the Sealant

Hose (6):

1. Press the Power Button (4) to turn Off the TIREFIT kit. Disconnect the Sealant Hose (6) from the valve stem. Make sure the valve stem is free of debris. Reconnect the Sealant

Hose (6) to the valve stem. Check that the Mode Select Knob (5) is in the Sealant Mode

position and not Air Mode. Press the Power Button (4) to turn On the TIREFIT kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or another vehicle, if available. Make sure the engine is running before turning ON the TIREFIT kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense from

the Air Pump Hose (7) only, not the Sealant Hose (6).

• If the sealant (white fluid) does flow through the Sealant Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through the hose (typically takes 30 - 70 seconds). As the sealant flows through the Sealant Hose (6), the

Pressure Gauge (3) can read as high as 70 psi (5 kPa). The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (5 kPa) to the actual tire pressure when the

Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is empty. Continue to operate the pump and inflate the tire to the pressure indicated on the

tire pressure label on the driver-side latch pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (3).

• If the tire does not inflate to at least 26 psi (1.8 kPa) pressure within 15 minutes:

• The tire is too badly damaged. Do not attempt to drive the vehicle further. Call for assistance.

NOTE:

If the tire becomes over-inflated, press the Deflation Button to reduce the tire pressure to

the recommended inflation pressure before continuing.

WHAT TO DO IN EMERGENCIES

94

Page 100 of 132

JUMP-STARTING

• If your vehicle has a discharged battery itcan be jump-started using a set of jumper

cables and a battery in another vehicle or

by using a portable battery booster pack.

• Jump-starting can be dangerous if done improperly so please follow the proce-

dures in this section carefully.

NOTE:

When using a portable battery booster pack

follow the manufacturer’s operating instruc-

tions and precautions.

Preparations for Jump-Start

• The battery in your vehicle is located in the front of the engine compartment, be-

hind the left headlight assembly.

NOTE:

The positive battery post is covered with a protective cap. Lift up on the cap to gain access

to the positive battery post.

• Set the parking brake, shift the automatic transmission into PARK (manual transmission in NEUTRAL) and turn the ignition to LOCK.

• Turn off the heater, radio, and all unnecessary electrical accessories.

• If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

Jump-Starting Procedure

1. Connect the positive (+) end of the jumper cable to the remote positive (+) post of the discharged vehicle.

2. Connect the opposite end of the positive (+) jumper cable to the positive (+) post of the booster battery.

3. Connect the negative end (-) of the jumper cable to the negative (-) post of the booster battery.

4. Connect the opposite end of the negative (-) jumper cable to the remote negative (-) post of the vehicle with the discharged battery.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery.

Once the engine is started, remove the jumper cables in the reverse sequence:

1. Disconnect the negative (-) jumper cable from the remote negative (-) post of the vehicle with the discharged battery.

WHAT TO DO IN EMERGENCIES

98

Page 102 of 132

SHIFT LEVER OVERRIDE

• If a malfunction occurs and the shift levercannot be moved out of the PARK posi-

tion, you can use the following procedure

to temporarily move the shift lever:• Turn the ignition switch to the OFF posi-

tion.

• Firmly set the parking brake.

•

Remove the rubber storage tray liner

from the center console, then lift up the

front of the shift lever bezel, carefully

disengage the bezel from the shift lever

housing, and slide it up to the top of the

shift lever.

• Press and maintain firm pressure on the brake pedal.

• Insert a small screwdriver or similar tool down into the access slot at the front of the shift lever assembly, and push and hold the

white override release lever down.

• Move the shift lever into the NEUTRAL position.

• The vehicle may then be started in NEUTRAL.

• Reinstall the shift lever bezel (use care to avoid pinching the wiring), and the rubber storage tray liner.

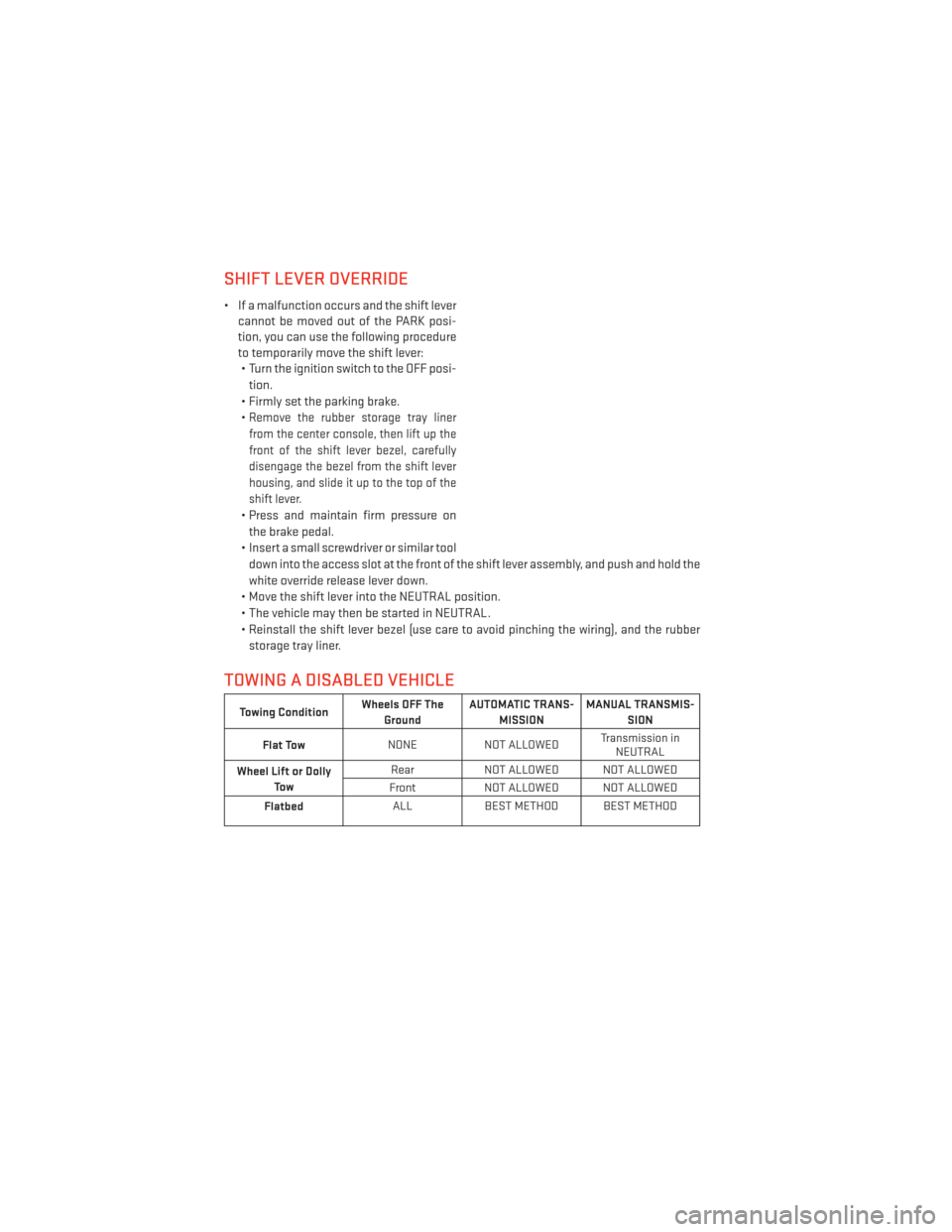

TOWING A DISABLED VEHICLE

Towing Condition Wheels OFF The

Ground AUTOMATIC TRANS-

MISSION MANUAL TRANSMIS-

SION

Flat Tow NONE

NOT ALLOWED Transmission in

NEUTRAL

Wheel Lift or Dolly To w Rear

NOT ALLOWED NOT ALLOWED

Front NOT ALLOWED NOT ALLOWED

Flatbed ALL

BEST METHOD BEST METHOD

WHAT TO DO IN EMERGENCIES

100

Page 104 of 132

EVENT DATA RECORDER (EDR)

• This vehicle is equipped with an Event Data Recorder (EDR). The main purpose of an EDRis to record, in certain crash or near crash-like situations, such as an air bag deployment

or hitting a road obstacle, data that will assist in understanding how a vehicle’s systems

performed. The EDR is designed to record data related to vehicle dynamics and safety

systems for a short period of time, typically 30 seconds or less. The EDR in this vehicle is

designed to record such data as:• How various systems in your vehicle were operating.

• Whether or not the driver and passenger safety belts were buckled/fastened.

• How far (if at all) the driver was depressing the accelerator and/or brake pedal.

• How fast the vehicle was traveling.

• These data can help provide a better understanding of the circumstances in which crashes and injuries occur.

NOTE:

EDR data are recorded by your vehicle only if a non-trivial crash situation occurs; no data are

recorded by the EDR under normal driving conditions and no personal data (e.g. name,

gender, age, and crash location) are recorded. However, other parties, such as law enforce-

ment, could combine the EDR data with the type of personally identifying data routinely

acquired during a crash investigation.

• To read data recorded by an EDR, special equipment is required, and access to the vehicle or the EDR is needed. In addition to the vehicle manufacturer, other parties such

as law enforcement, that have the special equipment, can read the information if they

have access to the vehicle or the EDR.

WHAT TO DO IN EMERGENCIES

102

Page 111 of 132

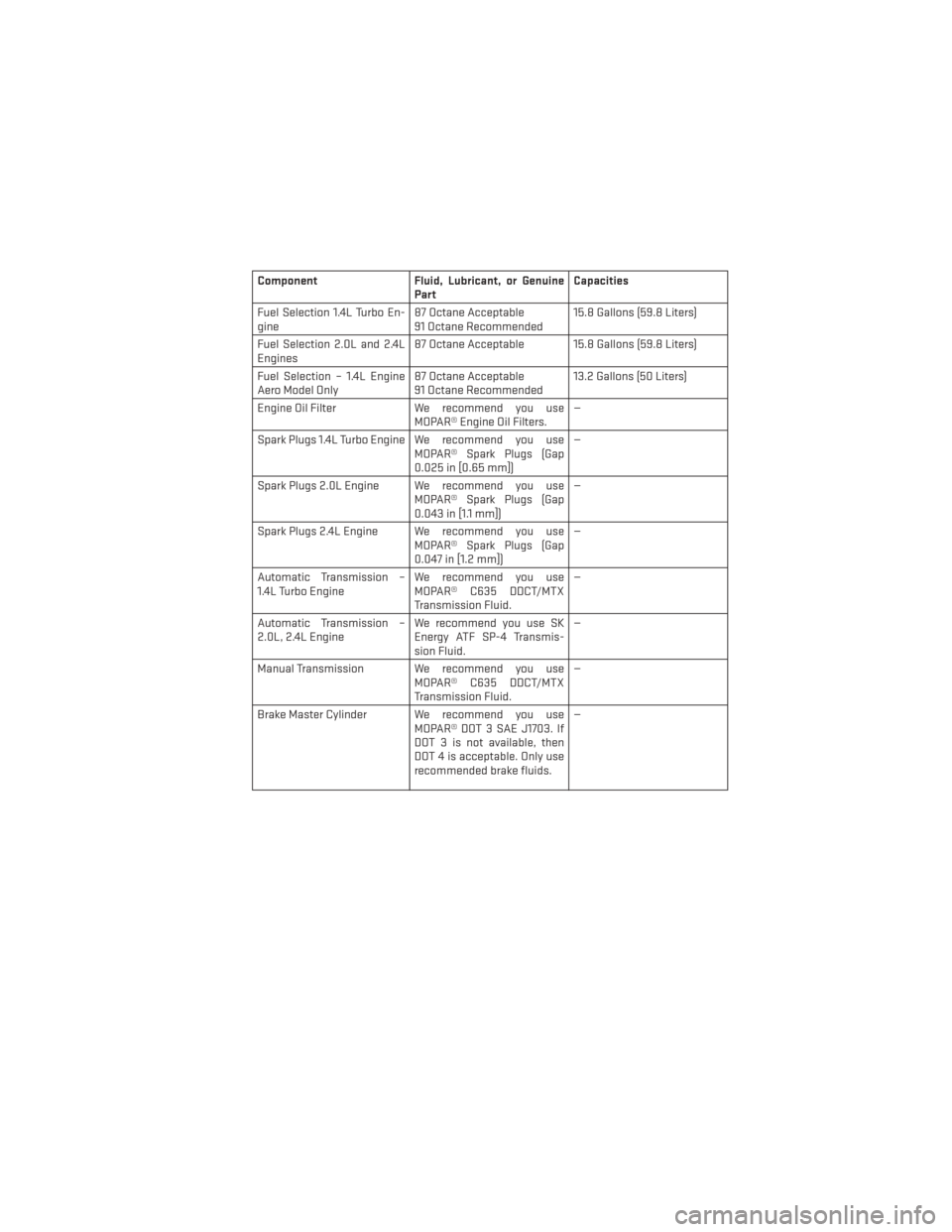

ComponentFluid, Lubricant, or Genuine

Part Capacities

Fuel Selection 1.4L Turbo En-

gine 87 Octane Acceptable

91 Octane Recommended 15.8 Gallons (59.8 Liters)

Fuel Selection 2.0L and 2.4L

Engines 87 Octane Acceptable 15.8 Gallons (59.8 Liters)

Fuel Selection – 1.4L Engine

Aero Model Only 87 Octane Acceptable

91 Octane Recommended 13.2 Gallons (50 Liters)

Engine Oil Filter We recommend you use

MOPAR® Engine Oil Filters. —

Spark Plugs 1.4L Turbo Engine We recommend you use MOPAR® Spark Plugs (Gap

0.025 in [0.65 mm]) —

Spark Plugs 2.0L Engine We recommend you use MOPAR® Spark Plugs (Gap

0.043 in [1.1 mm]) —

Spark Plugs 2.4L Engine We recommend you use MOPAR® Spark Plugs (Gap

0.047 in [1.2 mm]) —

Automatic Transmission –

1.4L Turbo Engine We recommend you use

MOPAR® C635 DDCT/MTX

Transmission Fluid. —

Automatic Transmission –

2.0L, 2.4L Engine We recommend you use SK

Energy ATF SP-4 Transmis-

sion Fluid. —

Manual Transmission We recommend you use MOPAR® C635 DDCT/MTX

Transmission Fluid. —

Brake Master Cylinder We recommend you use MOPAR® DOT 3 SAE J1703. If

DOT 3 is not available, then

DOT 4 is acceptable. Only use

recommended brake fluids. —

MAINTAINING YOUR VEHICLE

109

Page 113 of 132

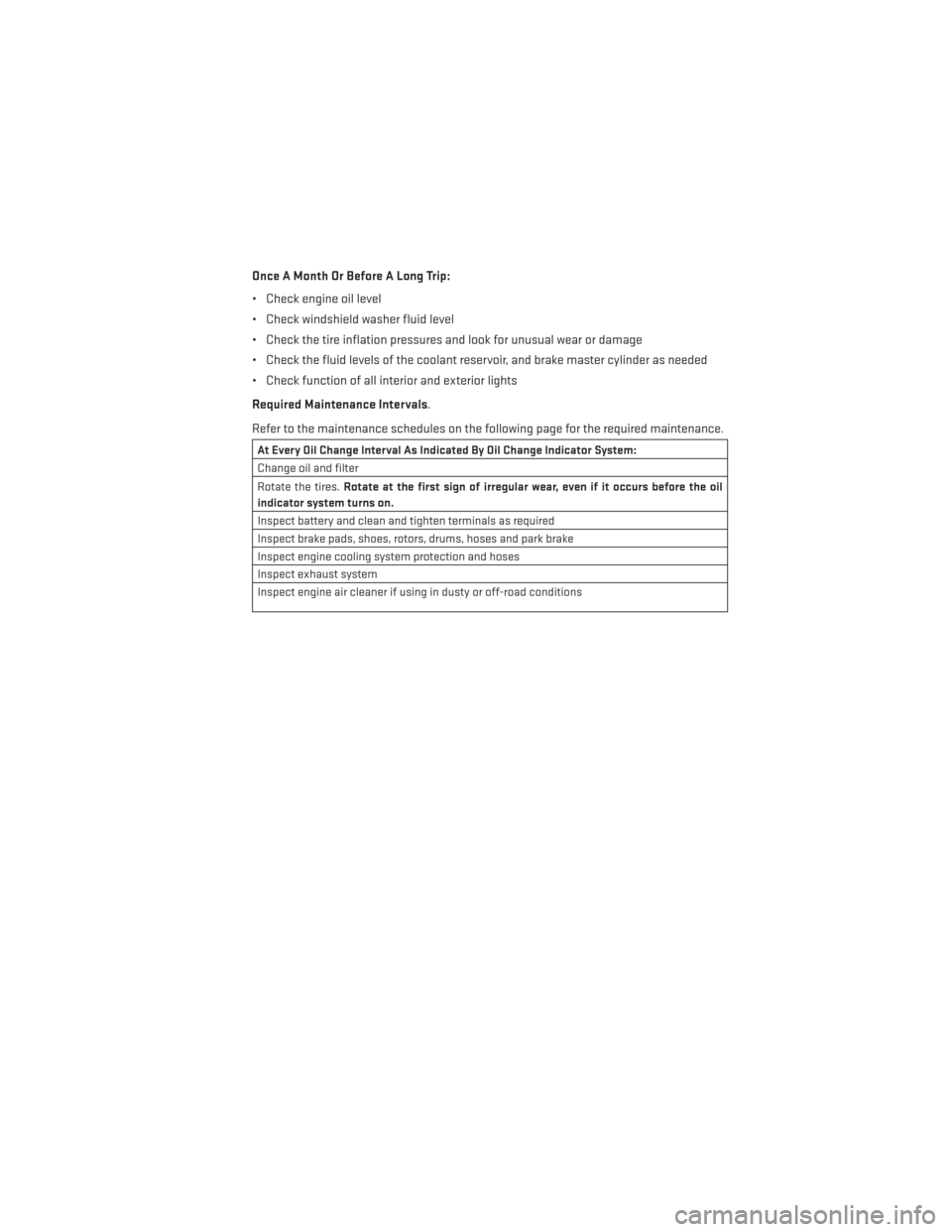

Once A Month Or Before A Long Trip:

• Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual wear or damage

• Check the fluid levels of the coolant reservoir, and brake master cylinder as needed

• Check function of all interior and exterior lights

Required Maintenance Intervals.

Refer to the maintenance schedules on the following page for the required maintenance.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

Change oil and filter

Rotate the tires.Rotate at the first sign of irregular wear, even if it occurs before the oil

indicator system turns on.

Inspect battery and clean and tighten terminals as required

Inspect brake pads, shoes, rotors, drums, hoses and park brake

Inspect engine cooling system protection and hoses

Inspect exhaust system

Inspect engine air cleaner if using in dusty or off-road conditions

MAINTAINING YOUR VEHICLE

111