torque DODGE DART 2015 PF / 1.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2015, Model line: DART, Model: DODGE DART 2015 PF / 1.GPages: 664, PDF Size: 16.96 MB

Page 443 of 664

If the transmission temperature exceeds normal operat-

ing limits, the transmission controller will modify the

transmission shift schedule and expand the range of

torque converter clutch engagement. This is done to

prevent transmission damage due to overheating. If the

transmission becomes extremely hot, the “Transmission

Temperature Warning Light” may illuminate and the

transmission may operate differently until the transmis-

sion cools down.

During very cold temperatures (-4°F [-20°C] or below),

transmission operation may be modified depending on

engine and transmission temperature as well as vehicle

speed. Normal operation will resume once the transmis-

sion temperature has risen to a suitable level.

Transmission Limp Home Mode

Transmission function is monitored electronically for

abnormal conditions. If a condition is detected that could

result in transmission damage, Transmission Limp Home

Mode is activated. In this mode, the transmission remains

in fourth gear regardless of which forward gear is

selected. PARK, REVERSE, and NEUTRAL will continue

to operate. The Malfunction Indicator Light (MIL) may be

illuminated. Limp Home Mode allows the vehicle to be

driven to an authorized dealer for service without dam-

aging the transmission.

In the event of a momentary problem, the transmission

can be reset to regain all forward gears by performing the

following steps:

1. Stop the vehicle.

2. Shift the transmission into PARK.

3. Turn the ignition switch to the OFF position.

4. Wait approximately 10 seconds.

5. Restart the engine.

5

STARTING AND OPERATING 441

Page 444 of 664

6. Shift into the desired gear range. If the problem is no

longer detected, the transmission will return to normal

operation.

NOTE:Even if the transmission can be reset, we recom-

mend that you visit your authorized dealer at your

earliest possible convenience. Your authorized dealer has

diagnostic equipment to determine if the problem could

recur.

If the transmission cannot be reset, authorized dealer

service is required.

Overdrive Operation

The automatic transmission includes an electronically

controlled Overdrive (sixth gear). The transmission will

automatically shift into Overdrive if the following con-

ditions are present:

•The shift lever is in the DRIVE position.

•The transmission fluid has reached an adequate tem-

perature.

•The engine coolant has reached an adequate tempera-

ture.

•Vehicle speed is sufficiently high.

•The driver is not heavily pressing the accelerator.

Torque Converter Clutch

A feature designed to improve fuel economy has been

included in the automatic transmission on your vehicle.

A clutch within the torque converter engages automati-

cally at calibrated speeds. This may result in a slightly

different feeling or response during normal operation in

the upper gears. When the vehicle speed drops or during

some accelerations, the clutch automatically disengages.

442 STARTING AND OPERATING

Page 445 of 664

NOTE:Engagement of the torque converter clutch is

inhibited at very cold temperatures. Because the engine

speed is higher when the torque converter clutch is not

engaged, it may seem as if the transmission is not shifting

into Overdrive when cold. This is normal. The torque

converter clutch will function normally once the trans-

mission is sufficiently warm.

AUTOSTICK®

AutoStick® is a driver-interactive transmission feature

providing manual shift control, giving you more control

of the vehicle. AutoStick® allows you to maximize en-

gine braking, eliminate undesirable upshifts and down-

shifts, and improve overall vehicle performance. This

system can also provide you with more control during

passing, city driving, cold slippery conditions, mountain

driving, and many other situations.

Operation

When the shift lever is in the AutoStick® position (beside

the DRIVE position), it can be moved forward and

rearward. This allows the driver to manually select the

transmission gear being used. Moving the shift lever

forward (-) triggers a downshift and rearward (+) an

upshift. The current gear is displayed in the instrument

cluster. In AutoStick® mode, the transmission will only

shift up or down when the driver moves the shift lever

rearward (+) or forward (-), unless an engine lugging or

overspeed condition would result. It will remain in the

selected gear until another upshift or downshift is cho-

sen, except as described below.

•For all models except GT, the transmission will auto-

matically upshift when necessary to prevent engine

over-speed.

5

STARTING AND OPERATING 443

Page 458 of 664

WARNING!

BAS cannot prevent the natural laws of physics from

acting on the vehicle, nor can it increase the traction

afforded by prevailing road conditions. BAS cannot

prevent accidents, including those resulting from

excessive speed in turns, driving on very slippery

surfaces, or hydroplaning. The capabilities of a BAS-

equipped vehicle must never be exploited in a reck-

less or dangerous manner, which could jeopardize

the user’s safety or the safety of others.

Traction Control System (TCS)

This system monitors the amount of wheel spin of each of

the driven wheels. If wheel spin is detected, brake

pressure is applied to the slipping wheel(s) and engine

power is reduced to provide enhanced acceleration and

stability. A feature of the TCS system, Brake Limited

Differential (BLD), functions similar to a limited slip

differential and controls the wheel spin across a driven

axle. If one wheel on a driven axle is spinning faster than

the other, the system will apply the brake of the spinning

wheel. This will allow more engine torque to be applied

to the wheel that is not spinning. This feature remains

active even if TCS and ESC are in the “Partial Off” mode.

Refer to “Electronic Stability Control (ESC)” in this

section for more information.

Electronic Roll Mitigation (ERM)

This system anticipates the potential for wheel lift by

monitoring the driver ’s steering wheel input and the

speed of the vehicle. When ERM determines that the rate

of change of the steering wheel angle and vehicle’s speed

are sufficient to potentially cause wheel lift, it then

applies the appropriate brake and may also reduce

engine power to lessen the chance that wheel lift will

occur. ERM will only intervene during very severe or

evasive driving maneuvers.

456 STARTING AND OPERATING

Page 463 of 664

WARNING!(Continued)

•Failure to follow these warnings may cause the

vehicle to roll down the incline and could collide

with another vehicle, object or person, and cause

serious or fatal injury. Always remember to use the

parking brake while parking on a hill and that the

driver is responsible for braking the vehicle.

NOTE:The HSA system may also be turned on and off

if the vehicle is equipped with the Electronic Vehicle

Information Center (EVIC) or Driver Information Display

(DID). Refer to “Electronic Vehicle Information Center

(EVIC) or Driver Information Display (DID)” in “Under-

standing Your Instrument Panel” for further information.

Electronic Stability Control (ESC)

This system enhances directional control and stability of

the vehicle under various driving conditions. ESC cor-

rects for over-steering and under-steering the vehicle by

applying the brake of the appropriate wheel. Engine

power may also be reduced to help the vehicle maintain

the desired path.

ESC reduces engine torque and applies brake pressure to

select individual wheels to mitigate vehicle under-steer

and vehicle over-steer. The system uses engine torque

reduction along with individual wheel brake pressure to

correct under-steer and over-steer conditions.

•Over-steer - when the vehicle is turning more than

appropriate for the steering wheel position.

•Under-steer - when the vehicle is turning less than

appropriate for the steering wheel position.

5

STARTING AND OPERATING 461

Page 527 of 664

WHAT TO DO IN EMERGENCIES

CONTENTS

!HAZARD WARNING FLASHERS...........527

!IF YOUR ENGINE OVERHEATS............527

!WHEEL AND TIRE TORQUE

SPECIFICATIONS......................528

▫Torque Specifications..................528

!TIRE SERVICE KIT — IF EQUIPPED.........530

▫Tire Service Kit Storage.................530

▫Tire Service Kit Components And Operation . .530

▫Tire Service Kit Usage Precautions..........531

▫Sealing A Tire With Tire Service Kit.........534

!JACKING AND TIRE CHANGING..........539

▫Jack Location/Spare Tire Stowage —

If Equipped.........................540

▫Preparations For Jacking................542

▫Jacking And Changing A Tire.............543

▫Road Tire Installation...................548

!JUMP-STARTING PROCEDURES...........551

▫Preparations For Jump-Start..............551

▫Jump-Starting Procedure................553

!FREEING A STUCK VEHICLE.............555

6

Page 530 of 664

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If the temperature gauge reads “H,”

pull over and stop the vehicle. Idle the vehicle with

the air conditioner turned off until the pointer drops

back into the normal range. If the pointer remains on

the “H,” turn the engine off immediately and call for

service.

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If

you see or hear steam coming from under the hood,

do not open the hood until the radiator has had time

to cool. Never try to open a cooling system pressure

cap when the radiator or coolant bottle is hot.

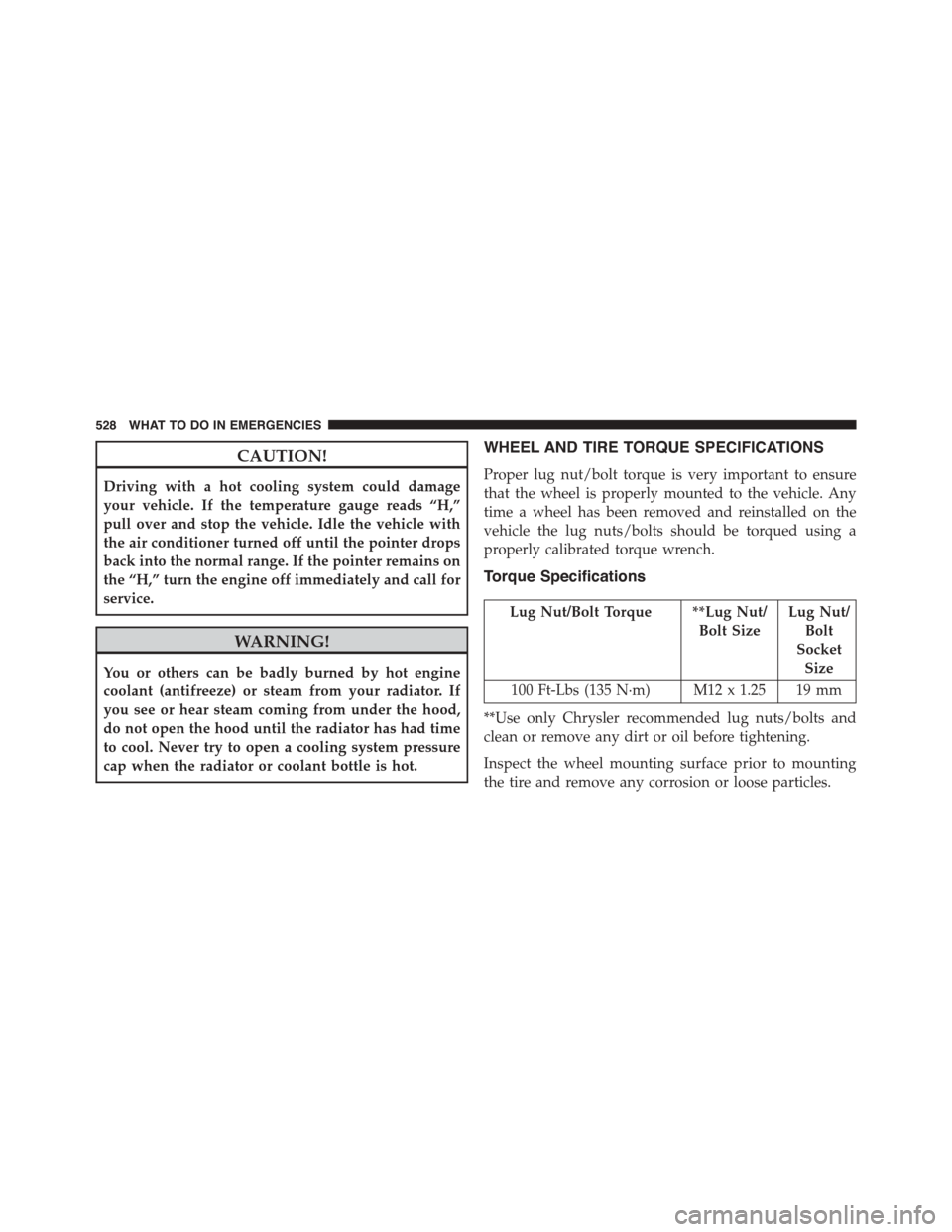

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure

that the wheel is properly mounted to the vehicle. Any

time a wheel has been removed and reinstalled on the

vehicle the lug nuts/bolts should be torqued using a

properly calibrated torque wrench.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/

Bolt Size

Lug Nut/

Bolt

Socket

Size

100 Ft-Lbs (135 N·m) M12 x 1.25 19 mm

**Use only Chrysler recommended lug nuts/bolts and

clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting

the tire and remove any corrosion or loose particles.

528 WHAT TO DO IN EMERGENCIES

Page 531 of 664

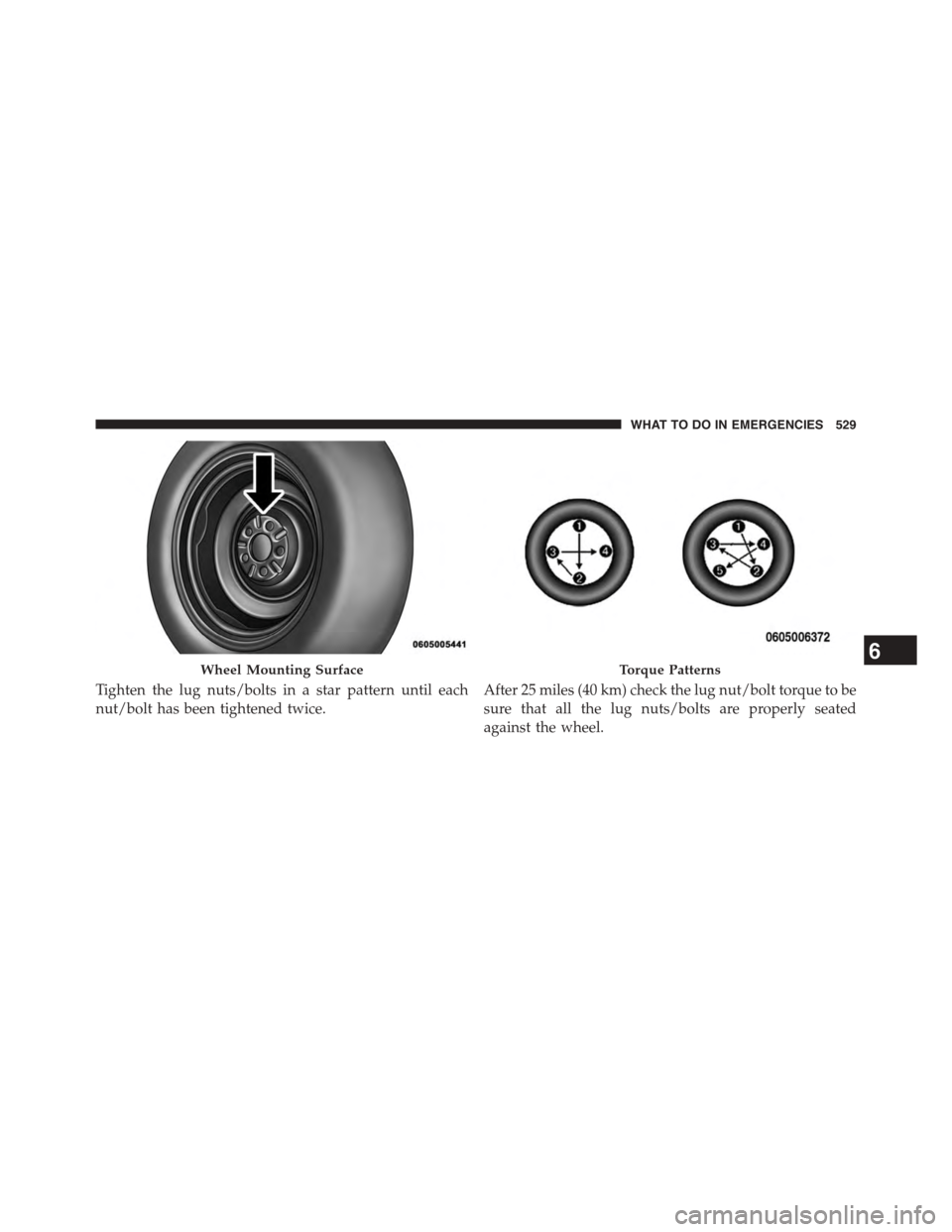

Tighten the lug nuts/bolts in a star pattern until each

nut/bolt has been tightened twice.

After 25 miles (40 km) check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated

against the wheel.

Wheel Mounting SurfaceTorque Patterns6

WHAT TO DO IN EMERGENCIES 529

Page 550 of 664

9. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. Refer

to “Torque Specifications” in this section for proper

lug bolt torque. If in doubt about the correct tight-

ness, have them checked with a torque wrench by

your authorized dealer or at a service station.

11. Lower the jack until it is free. Remove the wheel

blocks. Reassemble the lug wrench to the jack assem-

bly and stow it in the spare tire area. Secure the

assembly using the means provided. Release the

parking brake before driving the vehicle.

12. Stow the jack, tools and flat tire.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with

wheel covers, install two wheel bolts on the wheel

which are on each side of the valve stem. Install the

wheel bolts with the threaded end of the bolt toward

the wheel. Lightly tighten the wheel bolts.

548 WHAT TO DO IN EMERGENCIES

Page 552 of 664

“Torque Specifications” in this section for proper lug

bolt torque. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

7. Lower the jack until it is free. Remove the wheel

blocks. Reassemble the lug wrench to the jack assem-

bly and stow it in the spare tire area. Secure the

assembly using the means provided. Release the park-

ing brake before driving the vehicle.

8. After 25 miles (40 km) check the wheel bolt torque

with a torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded

end of the wheel bolt toward the wheel. Lightly

tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

3. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in this section for the proper

lug bolt torque. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

550 WHAT TO DO IN EMERGENCIES