service DODGE DART 2015 PF / 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2015, Model line: DART, Model: DODGE DART 2015 PF / 1.GPages: 164, PDF Size: 25.19 MB

Page 105 of 164

The light also will turn on when the parking brake is applied with the ignition switch in the

ON/RUN position.

NOTE:

This light shows only that the parking brake is applied. It does not show the degree of

brake application.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system may

have failed. It will take longer to stop the vehicle. You could have a collision. Have the

vehicle checked immediately.

-MalfunctionIndicatorLight(MIL)

Certain conditions, such as a loose or missing gas cap, poor fuel quality, etc., may

illuminate the MIL after engine start. The vehicle should be serviced if the light stays on

through several typical driving cycles. In most situations, the vehicle will drive normally

and not require towing.

If the MIL flashes when the engine is running, serious conditions may exist that could lead

to immediate loss of power or severe catalytic converter damage. We recommend you do

not operate the vehicle. Have the vehicle serviced immediately.

-ElectronicStabilityControl(ESC)OFFIndicatorLight

This light indicates the Electronic Stability Control (ESC) is off.

-ChargingSystemLight

This light shows the status of the electrical charging system. If the charging system light

remains on, it means that the vehicle is experiencing a problem with the charging system.

We recommend you do not continue driving if the charging system light is on. Have the

vehicle serviced immediately.

-OilPressureWarningLight

This light indicates low engine oil pressure. If the light turns on while driving, stop the

vehicle and shut off the engine as soon as possible. A chime will sound when this light

turns on.

We recommend you do not operate the vehicle or engine damage will occur. Have the

vehicle serviced immediately.

-Anti-LockBrake(ABS)Light

This light monitors the Anti-Lock Brake System (ABS).

If the light is not on during starting, stays on, or turns on while driving, we recommend you

contact the nearest authorized dealer and have the vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

103

Page 106 of 164

-ElectronicThrottleControl(ETC)IndicatorLight

This light informs you of a problem with the system.

If a problem is detected, the light will come on while the engine is running. Cycle the

ignition when the vehicle has completely stopped and the shift lever is placed in the PARK

position; the light should turn off.

If the light remains lit with the engine running, your vehicle will usually be drivable;

however, see an authorized dealer immediately. If the light is flashing when the engine is

running, immediate service is required and you may experience reduced performance, an

elevated/rough idle or engine stall and your vehicle may require towing.

-AirBagWarningLight

If the light is not on during starting, stays on, or turns on while driving, have the vehicle

serviced by an authorized dealer immediately.

Fuel Cap/Loose Gas Cap Message

•Ifa“gascap”message(shownasCheckFuelCap)appears,tightenthegascapuntil

a“clicking”soundisheard.

•Presstheodometerresetbuttontoturnthemessageoff.

•Ifthemessagecontinuestoappearformorethanthreedaysaftertighteningthegas

cap, see your authorized service center.

Oil Change Indicator

•Yourvehicleisequippedwithanengineoilchangeindicatorsystem.The“OilChange

Due” message will flash in the EVIC display for approximately 10 seconds after a single

chime has sounded, to indicate the next scheduled oil change interval. The engine oil

change indicator system is duty cycle based, which means the engine oil change

interval may fluctuate, dependent upon your personal driving style.

•Unlessreset,thismessagewillcontinuetodisplayeachtimeyouturntheignition

switch to the ON/RUN position or cycle the ignition to the ON/RUN position if equipped

with Keyless Enter-N-Go™. To turn off the message temporarily, press and release the

MENU button. To reset the oil change indicator system (after performing the scheduled

maintenance) refer to the following procedure.

Vehicles Equipped With Keyless Enter-N-Go™

1. Without pressing the brake pedal, cycle the ignition to the ON/RUN position (do not

start the engine).

2. Fully depress the accelerator pedal, slowly, three times within 10 seconds.

3. Cycle the ignition to the OFF/LOCK position.

WHAT TO DO IN EMERGENCIES

104

Page 109 of 164

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the potential for overheating by taking

the appropriate action.

•Onthehighways—slowdown.

•Incitytraffic—whilestopped,placethetransmissioninNEUTRAL,butdonot

increase engine idle speed.

NOTE:

There are steps that you can take to slow down an impending overheat condition:

•Ifyourairconditioner(A/C)ison,turnitoff.TheA/Csystemaddsheattotheengine

cooling system and turning the A/C off can help remove this heat.

•Youcanalsoturnthetemperaturecontroltomaximumheat,themodecontroltofloor

and the blower control to high. This allows the heater core to act as a supplement to the

radiator and aids in removing heat from the engine cooling system.

CAUTION!

Vehicles with base cluster

•Drivingwithahotcoolingsystemcoulddamageyourvehicle.Ifthetemperature

gauge reads H (hot), pull over and stop the vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops back into the normal range. If the

pointer remains on H (hot), turn the engine off immediately and call for service.

Vehicles with premium cluster

•Drivingwithahotcoolingsystemcoulddamageyourvehicle.Ifthetemperature

gauge reads 240°F (116 °C) or greater pull over and stop the vehicle. Idle the

vehicle with the air conditioner turned off until the pointer drops back into the

normal range 200–230°F (93–110°C). If the pointer remains at 240°F (116°C) or

greater and you hear a chime, turn the engine off immediately and call for service.

WARNING!

Yo u o r o t h e r s c a n b e b a d l y b u r n e d b y h o t e n g i n e c o o l a n t ( a n t i f r e e z e ) o r s t e a m f r o m y o u r

radiator. If you see or hear steam coming from under the hood, do not open the hood

until the radiator has had time to cool. Never try to open a cooling system pressure cap

when the radiator or coolant bottle is hot.

WHAT TO DO IN EMERGENCIES

107

Page 112 of 164

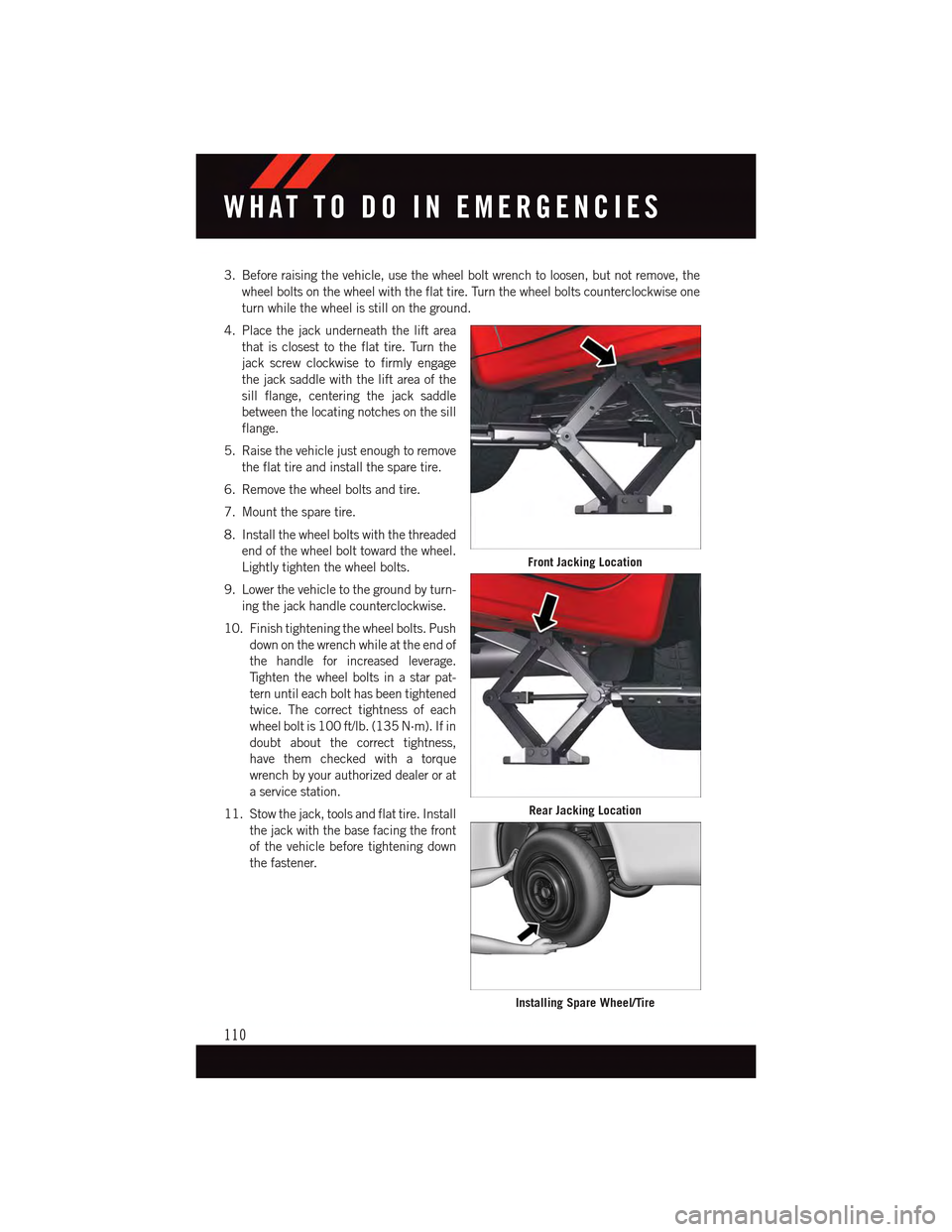

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove, the

wheel bolts on the wheel with the flat tire. Turn the wheel bolts counterclockwise one

turn while the wheel is still on the ground.

4. Place the jack underneath the lift area

that is closest to the flat tire. Turn the

jack screw clockwise to firmly engage

the jack saddle with the lift area of the

sill flange, centering the jack saddle

between the locating notches on the sill

flange.

5. Raise the vehicle just enough to remove

the flat tire and install the spare tire.

6. Remove the wheel bolts and tire.

7. Mount the spare tire.

8. Install the wheel bolts with the threaded

end of the wheel bolt toward the wheel.

Lightly tighten the wheel bolts.

9. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e w h e e l b o l t s i n a s t a r p a t -

tern until each bolt has been tightened

twice. The correct tightness of each

wheel bolt is 100 ft/lb. (135 N·m). If in

doubt about the correct tightness,

have them checked with a torque

wrench by your authorized dealer or at

aservicestation.

11. Stow the jack, tools and flat tire. Install

the jack with the base facing the front

of the vehicle before tightening down

the fastener.

Front Jacking Location

Rear Jacking Location

Installing Spare Wheel/Tire

WHAT TO DO IN EMERGENCIES

110

Page 113 of 164

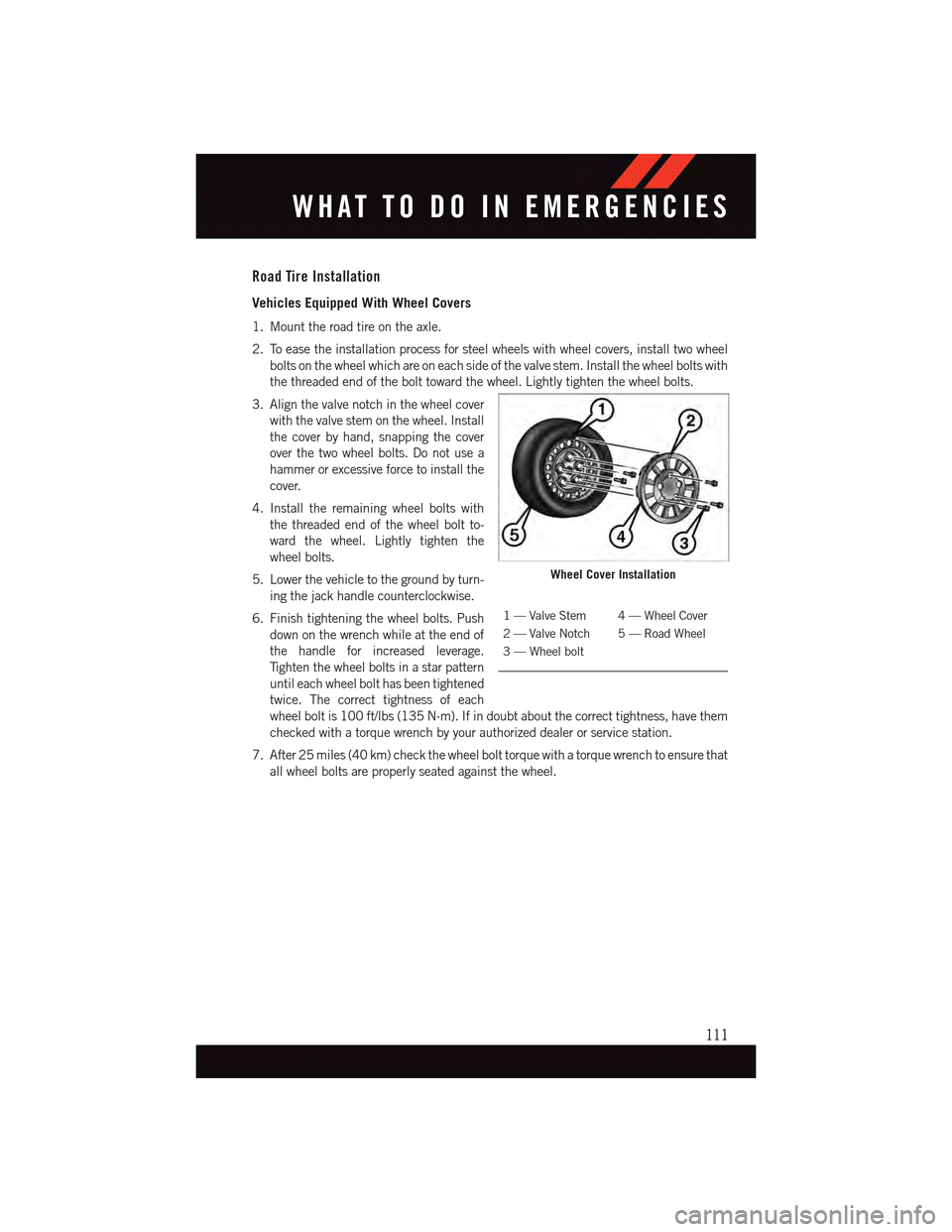

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two wheel

bolts on the wheel which are on each side of the valve stem. Install the wheel bolts with

the threaded end of the bolt toward the wheel. Lightly tighten the wheel bolts.

3. Align the valve notch in the wheel cover

with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two wheel bolts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining wheel bolts with

the threaded end of the wheel bolt to-

ward the wheel. Lightly tighten the

wheel bolts.

5. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

6. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e w h e e l b o l t s i n a s t a r p a t t e r n

until each wheel bolt has been tightened

twice. The correct tightness of each

wheel bolt is 100 ft/lbs (135 N·m). If in doubt about the correct tightness, have them

checked with a torque wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that

all wheel bolts are properly seated against the wheel.

Wheel Cover Installation

1—ValveStem 4—WheelCover

2—ValveNotch 5—RoadWheel

3—Wheelbolt

WHAT TO DO IN EMERGENCIES

111

Page 114 of 164

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten the wheel bolts in a star pattern until each bolt

has been tightened twice. The correct tightness of each wheel bolt is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a torque

wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that

all wheel bolts are properly seated against the wheel.

CAUTION!

•Thewinchmechanismisdesignedforusewiththejack-handleonly.Useofanair

wrench or other power tools is not recommended and they can damage the winch.•Donotattempttoraisethevehiclebyjackingonlocationsotherthanthose

indicated in the Jacking Instructions for this vehicle.

•Besuretomountthesparetirewiththevalvestemfacingoutward.Thevehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

112

Page 115 of 164

WARNING!

•Donotattempttochangeatireonthesideofthevehicleclosetomovingtraffic.

Pull far enough off the road to avoid the danger of being hit when operating the jack

or changing the wheel.

•Beingunderajacked-upvehicleisdangerous.Thevehiclecouldslipoffthejack

and fall on you. You could be crushed. Never put any part of your body under a

vehicle that is on a jack. If you need to get under a raised vehicle, take it to an

authorized service center where it can be raised on a lift.

•Neverstartorruntheenginewhilethevehicleisonajack.

•Thejackisdesignedtobeusedasatoolforchangingtiresonly.Thejackshouldnot

be used to lift the vehicle for service purposes. The vehicle should be jacked on a

firm level surface only. Avoid ice or slippery areas.

•Carefullyfollowthesetirechangingwarningstohelppreventpersonalinjuryor

damage to your vehicle:

•Alwaysparkonafirm,levelsurfaceasfarfromtheedgeoftheroadwayaspossible

before raising the vehicle.

•TurnontheHazardWarningflasher.

•Blockthewheeldiagonallyoppositethewheeltoberaised.

•SettheparkingbrakefirmlyandsetanautomatictransmissioninPARK.

•Donotletanyonesitinthevehiclewhenitisonajack.

•Donotgetunderthevehiclewhenitisonajack.

•Onlyusethejackinthepositionsindicatedandforliftingthisvehicleduringatire

change.

•Ifworkingonorneararoadway,beextremelycarefulofmotortraffic.

•Toassurethatsparetires,flatorinflated,aresecurelystowed,sparesmustbe

stowed with the valve stem facing the ground.

•Raisingthevehiclehigherthannecessarycanmakethevehiclelessstable.Itcould

slip off the jack and hurt someone near it. Raise the vehicle only enough to remove

the tire.

•Toavoidpossiblepersonalinjury,handlethewheelcoverswithcaretoavoidcontact

with any sharp edges.

•Toavoidtheriskofforcingthevehicleoffthejack,donottightenthewheelnuts

fully until the vehicle has been lowered. Failure to follow this warning may result in

personal injury.

•Aloosetireorjack,thrownforwardinacollisionorhardstopcouldendangerthe

occupants of the vehicle. Always stow the jack parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired or replaced immediately.

WHAT TO DO IN EMERGENCIES

113

Page 116 of 164

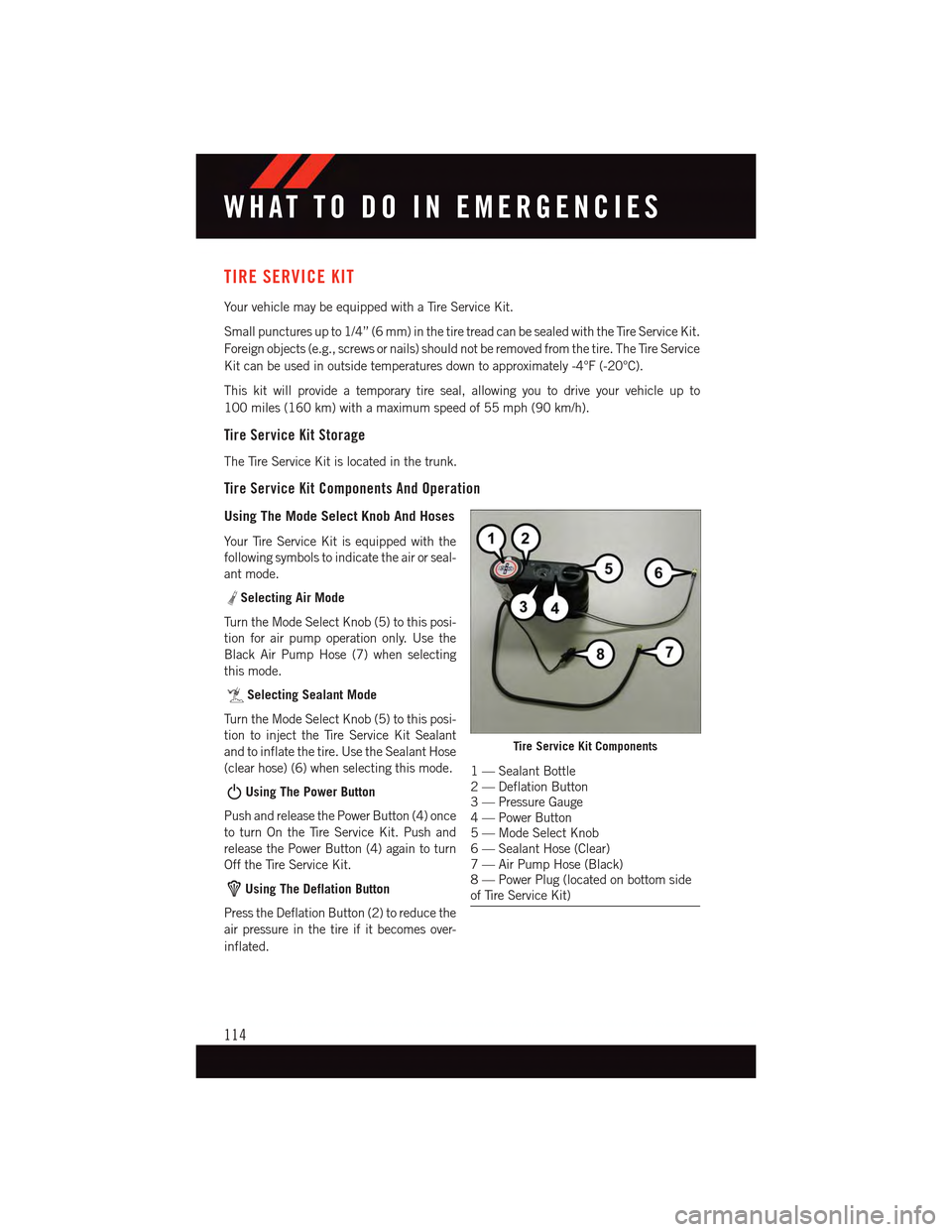

TIRE SERVICE KIT

Yo u r v e h i c l e m a y b e e q u i p p e d w i t h a Ti r e S e r v i c e K i t .

Small punctures up to 1/4” (6 mm) in the tire tread can be sealed with the Tire Service Kit.

Foreign objects (e.g., screws or nails) should not be removed from the tire. The Tire Service

Kit can be used in outside temperatures down to approximately -4°F (-20°C).

This kit will provide a temporary tire seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of 55 mph (90 km/h).

Tire Service Kit Storage

The Tire Service Kit is located in the trunk.

Tire Service Kit Components And Operation

Using The Mode Select Knob And Hoses

Yo u r Ti r e S e r v i c e K i t i s e q u i p p e d w i t h t h e

following symbols to indicate the air or seal-

ant mode.

Selecting Air Mode

Tu r n t h e M o d e S e l e c t K n o b ( 5 ) t o t h i s p o s i -

tion for air pump operation only. Use the

Black Air Pump Hose (7) when selecting

this mode.

Selecting Sealant Mode

Tu r n t h e M o d e S e l e c t K n o b ( 5 ) t o t h i s p o s i -

tion to inject the Tire Service Kit Sealant

and to inflate the tire. Use the Sealant Hose

(clear hose) (6) when selecting this mode.

Using The Power Button

Push and release the Power Button (4) once

to turn On the Tire Service Kit. Push and

release the Power Button (4) again to turn

Off the Tire Service Kit.

Using The Deflation Button

Press the Deflation Button (2) to reduce the

air pressure in the tire if it becomes over-

inflated.

Tire Service Kit Components

1—SealantBottle2—DeflationButton3—PressureGauge4—PowerButton5—ModeSelectKnob6—SealantHose(Clear)7—AirPumpHose(Black)8—PowerPlug(locatedonbottomsideof Tire Service Kit)

WHAT TO DO IN EMERGENCIES

114

Page 117 of 164

Tire Service Kit Usage Precautions

•ReplacetheTireServiceKitSealantBottle(1)andSealantHose(6)priortothe

expiration date (printed on the bottle label) to assure optimum operation of the system.

Refer to “Sealing A Tire With Tire Service Kit” section (F) “Sealant Bottle and Hose

Replacement.”

•TheSealantBottle(1)andSealantHose(6)areaonetireapplicationuse.Aftereach

use, always replace these components immediately at an authorized dealer.

•WhentheTireServiceKitsealantisinaliquidform,cleanwater,andadampclothwill

remove the material from the vehicle or tire and wheel components. Once the sealant

dries, it can easily be peeled off and properly discarded.

•Foroptimumperformance,makesurethevalvestemonthewheelisfreeofdebris

before connecting the Tire Service Kit.

•Yo u c a n u s e t h e Ti r e S e r v i c e K i t a i r p u m p t o i n f l a t e b i c y c l e t i r e s . T h e k i t a l s o c o m e s w i t h t w oneedles, located in the Accessory Storage Compartment (on the bottom of the air pump) forinflating sport balls, rafts, or similar inflatable items. However, use only the Air Pump Hose(7) and make sure the Mode Select Knob (5) is in the Air Mode when inflating such itemsto avoid injecting sealant into them. The Tire Service Kit Sealant is only intended to sealpunctures less than 1/4 inch (6 mm) diameter in the tread of your vehicle.

•DonotliftorcarrytheTireServiceKitbythehoses.

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2.Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near

to the ground. This will allow the Tire Service Kit Hoses (6) and (7) to reach the valve stem

and keep the Tire Service Kit flat on the ground. This will provide the best positioning of the

kit when injecting the sealant into the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission)

and cycle the ignition to the OFF position.

4. Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the

hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

WHAT TO DO IN EMERGENCIES

115

Page 118 of 164

(C) Injecting Tire Service Kit Sealant Into The Deflated Tire:

Always start the engine before turning ON the Tire Service Kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the shift lever in

NEUTRAL.

After pressing the Power Button (4), the sealant (white fluid) will flow from the Sealant

Bottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within0–10seconds through the Sealant

Hose (6):

1. Press the Power Button (4) to turn Off the Tire Service Kit. Disconnect the Sealant

Hose (6) from the valve stem. Make sure the valve stem is free of debris. Reconnect the

Sealant Hose (6) to the valve stem. Check that the Mode Select Knob (5) is in the

Sealant Mode position and not Air Mode. Press the Power Button (4) to turn On the Tire

Service Kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or

another vehicle, if available. Make sure the engine is running before turning ON the

Ti r e S e r v i c e K i t .

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense

from the Air Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant Hose (6):

1. Continue to operate the pump until sealant is no longer flowing through the hose

(typically takes 30 - 70 seconds). As the sealant flows through the Sealant Hose (6),

the Pressure Gauge (3) can read as high as 70 psi (4.8 Bar). The Pressure Gauge (3)

will decrease quickly from approximately 70 psi (4.8 Bar) to the actual tire pressure

when the Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1)

is empty. Continue to operate the pump and inflate the tire to the pressure indicated

on the tire pressure label on the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure Gauge (3).

WHAT TO DO IN EMERGENCIES

116