service DODGE DURANGO 1998 1.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 114 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service pro-

cedures are to be cleaned and oiled before installation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Start bearing in place, and insert Crankshaft

Main Bearing Remover/Installer Tool C-3059 into oil

hole of crankshaft (Fig. 58).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Tool C-3059.

(3)

Install the bearing caps. Clean and oil the bolts.

Tighten the capbolts to 115 N´m (85 ft. lbs.) torque.

(4) Install the oil pump.

(5) Install the oil pan.

(6) Start engine check for leaks.

DISTRIBUTOR DRIVE SHAFT BUSHING

REMOVAL

(1) Remove distributor, refer to Group 8D, Ignition

Systems for the proper procedure.

(2) Remove the intake manifold. Refer to Intake

Manifold in this section for correct procedure.

(3) Insert Distributor Drive Shaft Bushing Puller

Tool C-3052 into old bushing and thread down until a

tight fit is obtained (Fig. 59).

(4) Hold puller screw and tighten puller nut until

bushing is removed.

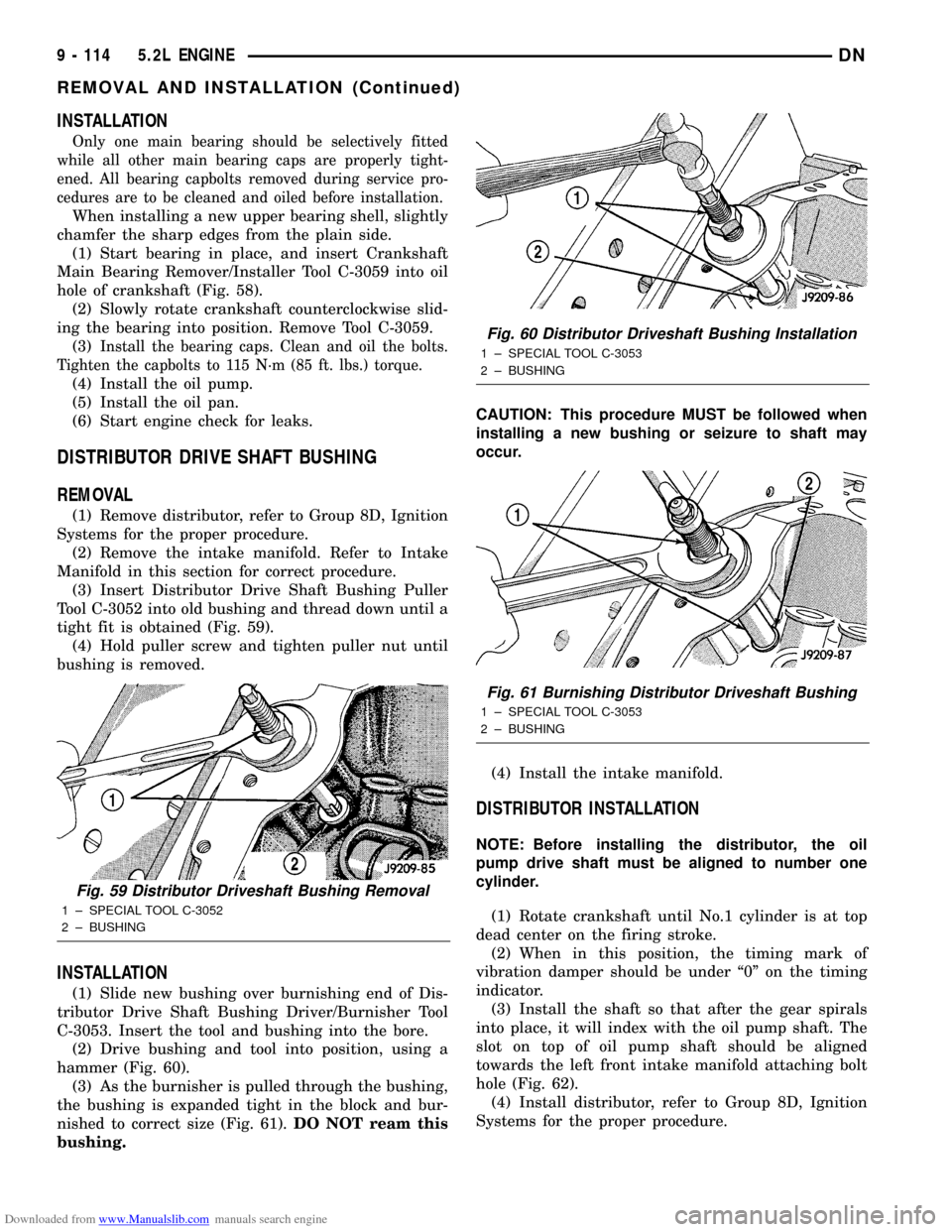

INSTALLATION

(1) Slide new bushing over burnishing end of Dis-

tributor Drive Shaft Bushing Driver/Burnisher Tool

C-3053. Insert the tool and bushing into the bore.

(2) Drive bushing and tool into position, using a

hammer (Fig. 60).

(3) As the burnisher is pulled through the bushing,

the bushing is expanded tight in the block and bur-

nished to correct size (Fig. 61).DO NOT ream this

bushing.CAUTION: This procedure MUST be followed when

installing a new bushing or seizure to shaft may

occur.

(4) Install the intake manifold.

DISTRIBUTOR INSTALLATION

NOTE: Before installing the distributor, the oil

pump drive shaft must be aligned to number one

cylinder.

(1) Rotate crankshaft until No.1 cylinder is at top

dead center on the firing stroke.

(2) When in this position, the timing mark of

vibration damper should be under ª0º on the timing

indicator.

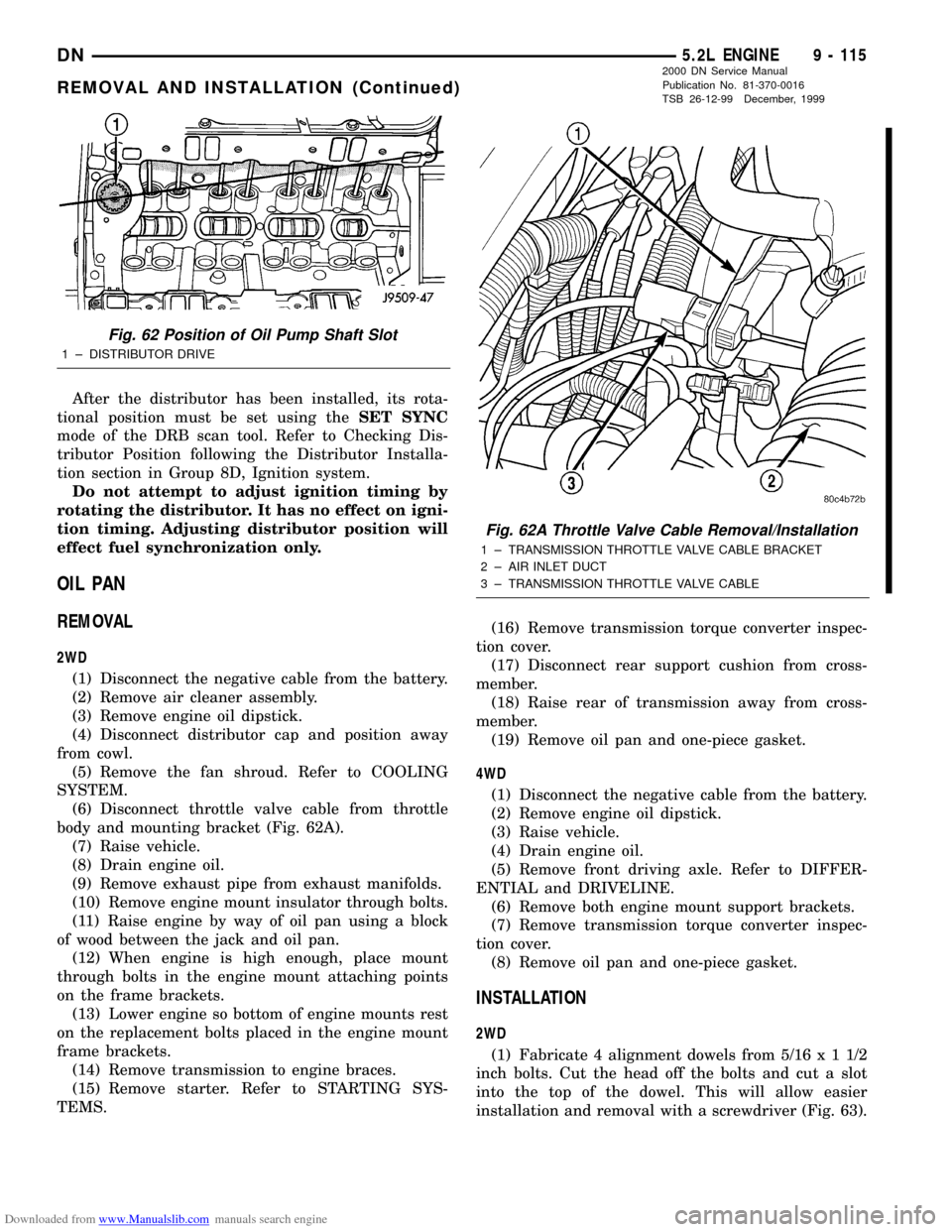

(3) Install the shaft so that after the gear spirals

into place, it will index with the oil pump shaft. The

slot on top of oil pump shaft should be aligned

towards the left front intake manifold attaching bolt

hole (Fig. 62).

(4) Install distributor, refer to Group 8D, Ignition

Systems for the proper procedure.

Fig. 59 Distributor Driveshaft Bushing Removal

1 ± SPECIAL TOOL C-3052

2 ± BUSHING

Fig. 60 Distributor Driveshaft Bushing Installation

1 ± SPECIAL TOOL C-3053

2 ± BUSHING

Fig. 61 Burnishing Distributor Driveshaft Bushing

1 ± SPECIAL TOOL C-3053

2 ± BUSHING

9 - 114 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 115 of 193

Downloaded from www.Manualslib.com manuals search engine After the distributor has been installed, its rota-

tional position must be set using theSET SYNC

mode of the DRB scan tool. Refer to Checking Dis-

tributor Position following the Distributor Installa-

tion section in Group 8D, Ignition system.

Do not attempt to adjust ignition timing by

rotating the distributor. It has no effect on igni-

tion timing. Adjusting distributor position will

effect fuel synchronization only.

OIL PAN

REMOVAL

2WD

(1) Disconnect the negative cable from the battery.

(2) Remove air cleaner assembly.

(3) Remove engine oil dipstick.

(4) Disconnect distributor cap and position away

from cowl.

(5) Remove the fan shroud. Refer to COOLING

SYSTEM.

(6) Disconnect throttle valve cable from throttle

body and mounting bracket (Fig. 62A).

(7) Raise vehicle.

(8) Drain engine oil.

(9) Remove exhaust pipe from exhaust manifolds.

(10) Remove engine mount insulator through bolts.

(11) Raise engine by way of oil pan using a block

of wood between the jack and oil pan.

(12) When engine is high enough, place mount

through bolts in the engine mount attaching points

on the frame brackets.

(13) Lower engine so bottom of engine mounts rest

on the replacement bolts placed in the engine mount

frame brackets.

(14) Remove transmission to engine braces.

(15) Remove starter. Refer to STARTING SYS-

TEMS.(16) Remove transmission torque converter inspec-

tion cover.

(17) Disconnect rear support cushion from cross-

member.

(18) Raise rear of transmission away from cross-

member.

(19) Remove oil pan and one-piece gasket.

4WD

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove front driving axle. Refer to DIFFER-

ENTIAL and DRIVELINE.

(6) Remove both engine mount support brackets.

(7) Remove transmission torque converter inspec-

tion cover.

(8) Remove oil pan and one-piece gasket.

INSTALLATION

2WD

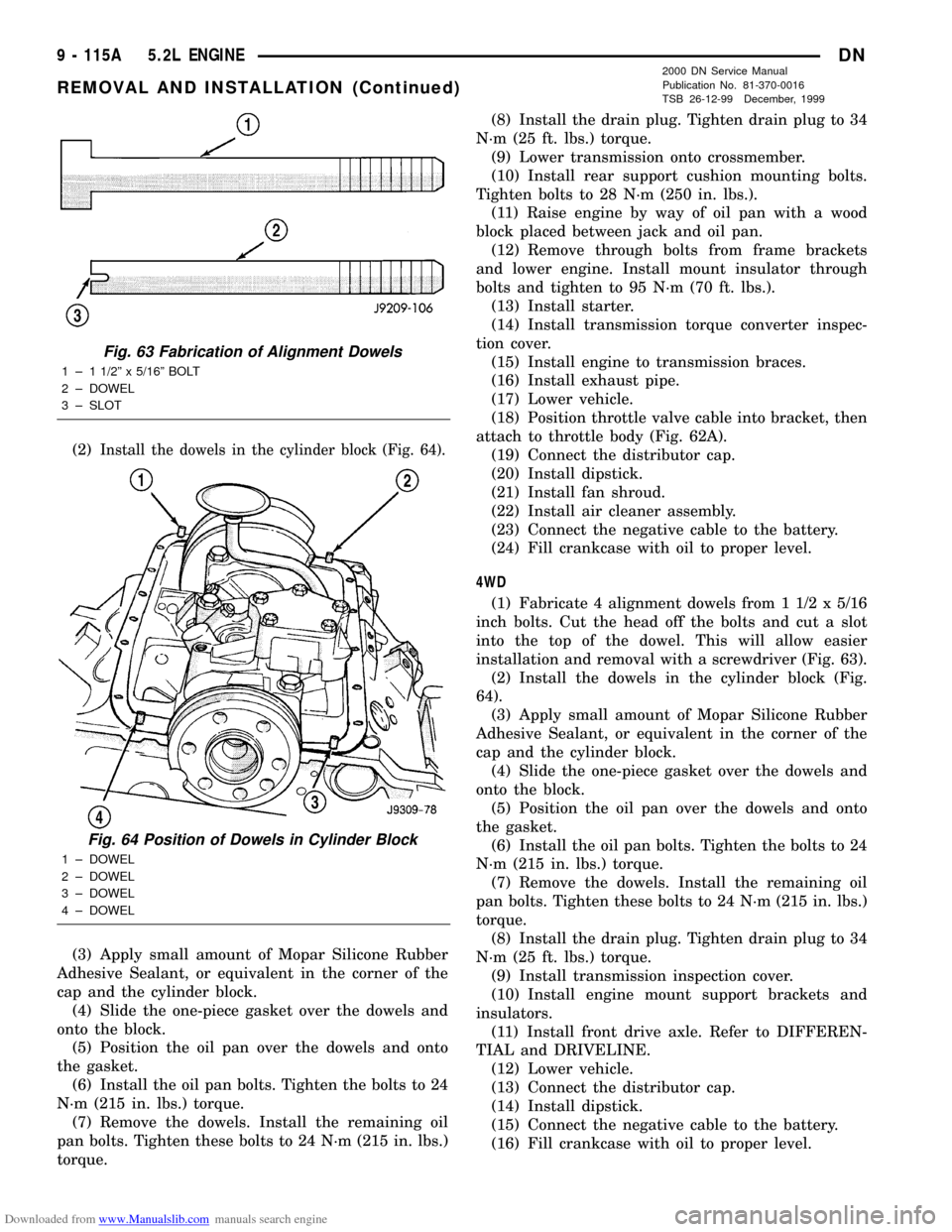

(1) Fabricate 4 alignment dowels from 5/16x11/2

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 63).

Fig. 62 Position of Oil Pump Shaft Slot

1 ± DISTRIBUTOR DRIVE

Fig. 62A Throttle Valve Cable Removal/Installation

1 ± TRANSMISSION THROTTLE VALVE CABLE BRACKET

2 ± AIR INLET DUCT

3 ± TRANSMISSION THROTTLE VALVE CABLE

DN5.2L ENGINE 9 - 115

REMOVAL AND INSTALLATION (Continued)

2000 DN Service Manual

Publication No. 81-370-0016

TSB 26-12-99 December, 1999

Page 116 of 193

Downloaded from www.Manualslib.com manuals search engine (2)Install the dowels in the cylinder block (Fig. 64).

(3) Apply small amount of Mopar Silicone Rubber

Adhesive Sealant, or equivalent in the corner of the

cap and the cylinder block.

(4) Slide the one-piece gasket over the dowels and

onto the block.

(5) Position the oil pan over the dowels and onto

the gasket.

(6) Install the oil pan bolts. Tighten the bolts to 24

N´m (215 in. lbs.) torque.

(7) Remove the dowels. Install the remaining oil

pan bolts. Tighten these bolts to 24 N´m (215 in. lbs.)

torque.(8) Install the drain plug. Tighten drain plug to 34

N´m (25 ft. lbs.) torque.

(9) Lower transmission onto crossmember.

(10) Install rear support cushion mounting bolts.

Tighten bolts to 28 N´m (250 in. lbs.).

(11) Raise engine by way of oil pan with a wood

block placed between jack and oil pan.

(12) Remove through bolts from frame brackets

and lower engine. Install mount insulator through

bolts and tighten to 95 N´m (70 ft. lbs.).

(13) Install starter.

(14) Install transmission torque converter inspec-

tion cover.

(15) Install engine to transmission braces.

(16) Install exhaust pipe.

(17) Lower vehicle.

(18) Position throttle valve cable into bracket, then

attach to throttle body (Fig. 62A).

(19) Connect the distributor cap.

(20) Install dipstick.

(21) Install fan shroud.

(22) Install air cleaner assembly.

(23) Connect the negative cable to the battery.

(24) Fill crankcase with oil to proper level.

4WD

(1) Fabricate 4 alignment dowels from 1 1/2 x 5/16

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 63).

(2) Install the dowels in the cylinder block (Fig.

64).

(3) Apply small amount of Mopar Silicone Rubber

Adhesive Sealant, or equivalent in the corner of the

cap and the cylinder block.

(4) Slide the one-piece gasket over the dowels and

onto the block.

(5) Position the oil pan over the dowels and onto

the gasket.

(6) Install the oil pan bolts. Tighten the bolts to 24

N´m (215 in. lbs.) torque.

(7) Remove the dowels. Install the remaining oil

pan bolts. Tighten these bolts to 24 N´m (215 in. lbs.)

torque.

(8) Install the drain plug. Tighten drain plug to 34

N´m (25 ft. lbs.) torque.

(9) Install transmission inspection cover.

(10) Install engine mount support brackets and

insulators.

(11) Install front drive axle. Refer to DIFFEREN-

TIAL and DRIVELINE.

(12) Lower vehicle.

(13) Connect the distributor cap.

(14) Install dipstick.

(15) Connect the negative cable to the battery.

(16) Fill crankcase with oil to proper level.

Fig. 63 Fabrication of Alignment Dowels

1 ± 1 1/2º x 5/16º BOLT

2 ± DOWEL

3 ± SLOT

Fig. 64 Position of Dowels in Cylinder Block

1 ± DOWEL

2 ± DOWEL

3 ± DOWEL

4 ± DOWEL

9 - 115A 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

2000 DN Service Manual

Publication No. 81-370-0016

TSB 26-12-99 December, 1999

Page 119 of 193

Downloaded from www.Manualslib.com manuals search engine interference. If tool does not fit, the cover must be

removed and installed properly.

(4) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal bore of cover.

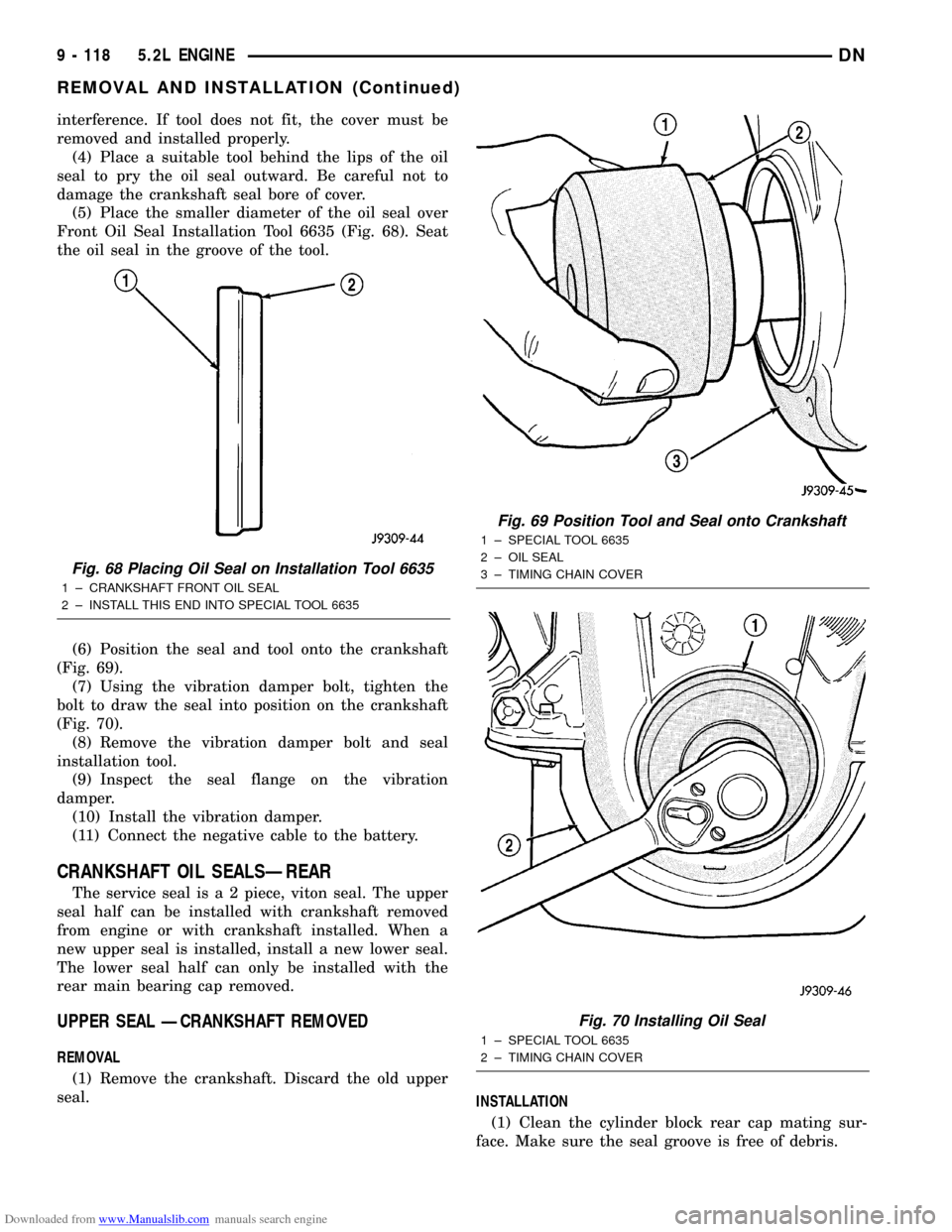

(5) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 68). Seat

the oil seal in the groove of the tool.

(6) Position the seal and tool onto the crankshaft

(Fig. 69).

(7) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft

(Fig. 70).

(8) Remove the vibration damper bolt and seal

installation tool.

(9) Inspect the seal flange on the vibration

damper.

(10) Install the vibration damper.

(11) Connect the negative cable to the battery.

CRANKSHAFT OIL SEALSÐREAR

The service seal is a 2 piece, viton seal. The upper

seal half can be installed with crankshaft removed

from engine or with crankshaft installed. When a

new upper seal is installed, install a new lower seal.

The lower seal half can only be installed with the

rear main bearing cap removed.

UPPER SEAL ÐCRANKSHAFT REMOVED

REMOVAL

(1) Remove the crankshaft. Discard the old upper

seal.

INSTALLATION

(1) Clean the cylinder block rear cap mating sur-

face. Make sure the seal groove is free of debris.

Fig. 68 Placing Oil Seal on Installation Tool 6635

1 ± CRANKSHAFT FRONT OIL SEAL

2 ± INSTALL THIS END INTO SPECIAL TOOL 6635

Fig. 69 Position Tool and Seal onto Crankshaft

1 ± SPECIAL TOOL 6635

2 ± OIL SEAL

3 ± TIMING CHAIN COVER

Fig. 70 Installing Oil Seal

1 ± SPECIAL TOOL 6635

2 ± TIMING CHAIN COVER

9 - 118 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 121 of 193

Downloaded from www.Manualslib.com manuals search engine (6) To align the bearing cap, use cap slot, align-

ment dowel and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than 2 times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten ALL cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump.

(9) Apply MopartSilicone Rubber Adhesive Seal-

ant, or equivalent, at bearing cap to block joint to

provide cap to block and oil pan sealing (Fig. 72).

Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan.

LOWER SEAL

REMOVAL

(1) Remove the oil pan.

(2) Remove the oil pump from the rear main bear-

ing cap.

(3) Remove the rear main bearing cap and discard

the old lower seal.

INSTALLATION

(1) Clean the rear main cap mating surfaces

including the oil pan gasket groove.

(2) Carefully install a new upper seal (refer to

Upper Seal Replacement - Crankshaft Installed pro-

cedure above).

(3) Lightly oil the new lower seal lips with engine

oil.

(4) Install a new lower seal in bearing cap with

the white paint facing the rear of engine.

(5) Apply 5 mm (0.20 in) drop of MopartGasket

Maker, or equivalent, on each side of the rear main

bearing cap (Fig. 71). DO NOT over apply sealant or

allow the sealant to contact the rubber seal. Assem-

ble bearing cap to cylinder block immediately after

sealant application.

(6) To align the bearing cap, use cap slot, align-

ment dowel and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than 2 times for proper engagement.

(7) Install the rear main bearing cap with cleaned

and oiled cap bolts. Alternately tighten the cap bolts

to 115 N´m (85 ft. lbs.) torque.

(8) Install oil pump.

(9) Apply MopartSilicone Rubber Adhesive Seal-

ant, or equivalent, at bearing cap to block joint to

provide cap to block and oil pan sealing (Fig. 72).

Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(10) Immediately install the oil pan.

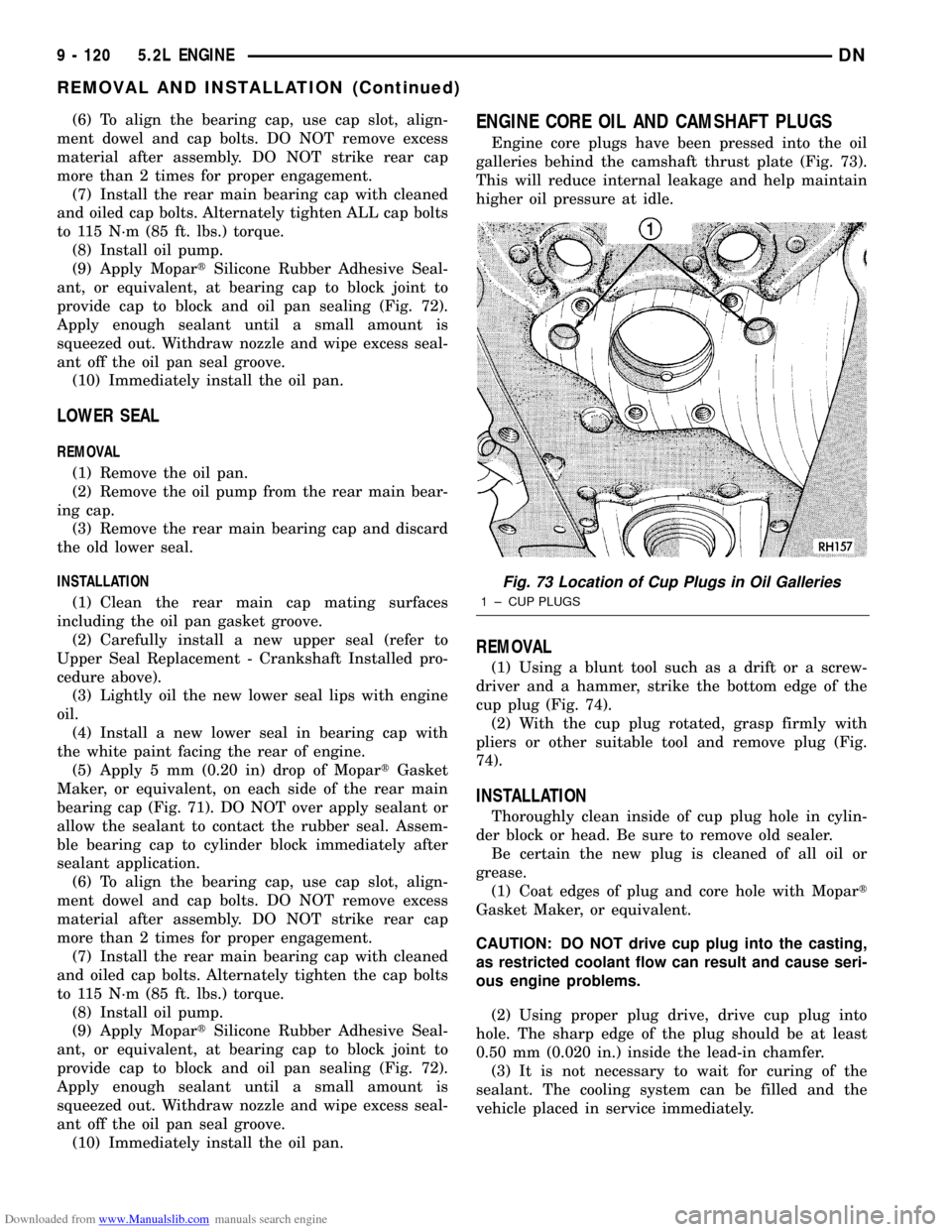

ENGINE CORE OIL AND CAMSHAFT PLUGS

Engine core plugs have been pressed into the oil

galleries behind the camshaft thrust plate (Fig. 73).

This will reduce internal leakage and help maintain

higher oil pressure at idle.

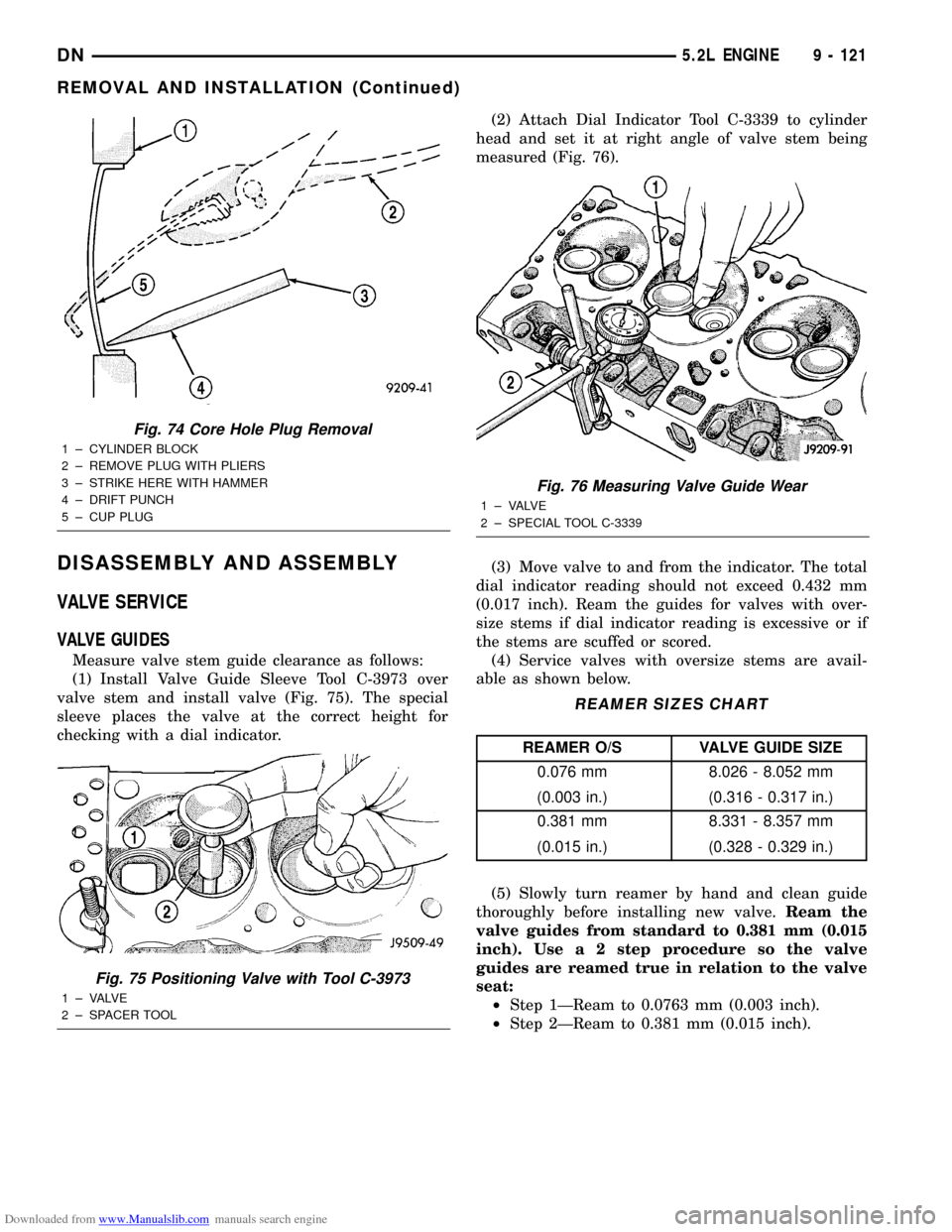

REMOVAL

(1) Using a blunt tool such as a drift or a screw-

driver and a hammer, strike the bottom edge of the

cup plug (Fig. 74).

(2) With the cup plug rotated, grasp firmly with

pliers or other suitable tool and remove plug (Fig.

74).

INSTALLATION

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Be certain the new plug is cleaned of all oil or

grease.

(1) Coat edges of plug and core hole with Mopart

Gasket Maker, or equivalent.

CAUTION: DO NOT drive cup plug into the casting,

as restricted coolant flow can result and cause seri-

ous engine problems.

(2) Using proper plug drive, drive cup plug into

hole. The sharp edge of the plug should be at least

0.50 mm (0.020 in.) inside the lead-in chamfer.

(3) It is not necessary to wait for curing of the

sealant. The cooling system can be filled and the

vehicle placed in service immediately.

Fig. 73 Location of Cup Plugs in Oil Galleries

1 ± CUP PLUGS

9 - 120 5.2L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 122 of 193

Downloaded from www.Manualslib.com manuals search engine DISASSEMBLY AND ASSEMBLY

VALVE SERVICE

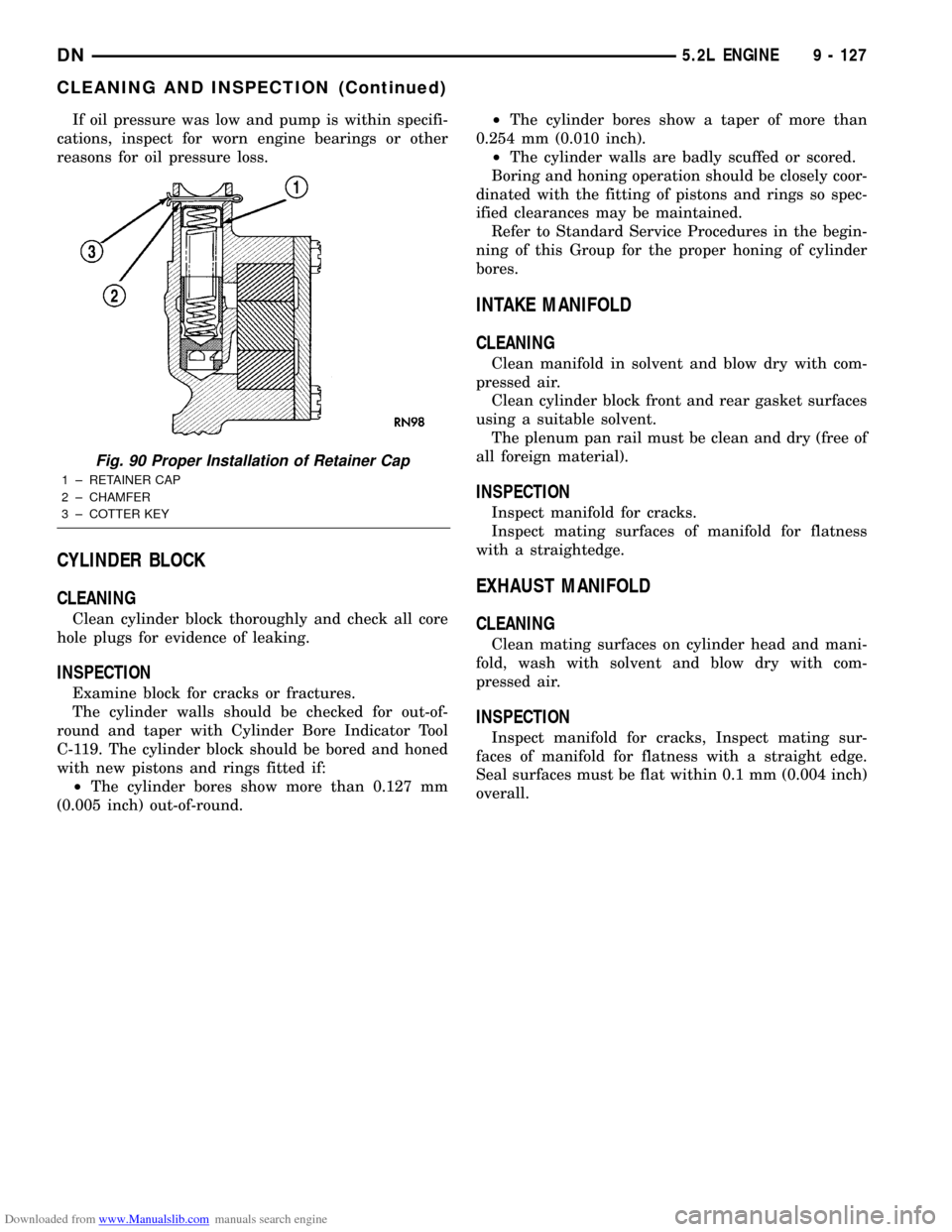

VALVE GUIDES

Measure valve stem guide clearance as follows:

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 75). The special

sleeve places the valve at the correct height for

checking with a dial indicator.(2) Attach Dial Indicator Tool C-3339 to cylinder

head and set it at right angle of valve stem being

measured (Fig. 76).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 inch). Ream the guides for valves with over-

size stems if dial indicator reading is excessive or if

the stems are scuffed or scored.

(4) Service valves with oversize stems are avail-

able as shown below.

(5) Slowly turn reamer by hand and clean guide

thoroughly before installing new valve.Ream the

valve guides from standard to 0.381 mm (0.015

inch). Use a 2 step procedure so the valve

guides are reamed true in relation to the valve

seat:

²Step 1ÐReam to 0.0763 mm (0.003 inch).

²Step 2ÐReam to 0.381 mm (0.015 inch).

Fig. 74 Core Hole Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

Fig. 75 Positioning Valve with Tool C-3973

1 ± VALVE

2 ± SPACER TOOL

Fig. 76 Measuring Valve Guide Wear

1 ± VALVE

2 ± SPECIAL TOOL C-3339

REAMER SIZES CHART

REAMER O/S VALVE GUIDE SIZE

0.076 mm 8.026 - 8.052 mm

(0.003 in.) (0.316 - 0.317 in.)

0.381 mm 8.331 - 8.357 mm

(0.015 in.) (0.328 - 0.329 in.)

DN5.2L ENGINE 9 - 121

REMOVAL AND INSTALLATION (Continued)

Page 128 of 193

Downloaded from www.Manualslib.com manuals search engine If oil pressure was low and pump is within specifi-

cations, inspect for worn engine bearings or other

reasons for oil pressure loss.

CYLINDER BLOCK

CLEANING

Clean cylinder block thoroughly and check all core

hole plugs for evidence of leaking.

INSPECTION

Examine block for cracks or fractures.

The cylinder walls should be checked for out-of-

round and taper with Cylinder Bore Indicator Tool

C-119. The cylinder block should be bored and honed

with new pistons and rings fitted if:

²The cylinder bores show more than 0.127 mm

(0.005 inch) out-of-round.²The cylinder bores show a taper of more than

0.254 mm (0.010 inch).

²The cylinder walls are badly scuffed or scored.

Boring and honing operation should be closely coor-

dinated with the fitting of pistons and rings so spec-

ified clearances may be maintained.

Refer to Standard Service Procedures in the begin-

ning of this Group for the proper honing of cylinder

bores.

INTAKE MANIFOLD

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

EXHAUST MANIFOLD

CLEANING

Clean mating surfaces on cylinder head and mani-

fold, wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks, Inspect mating sur-

faces of manifold for flatness with a straight edge.

Seal surfaces must be flat within 0.1 mm (0.004 inch)

overall.

Fig. 90 Proper Installation of Retainer Cap

1 ± RETAINER CAP

2 ± CHAMFER

3 ± COTTER KEY

DN5.2L ENGINE 9 - 127

CLEANING AND INSPECTION (Continued)

Page 129 of 193

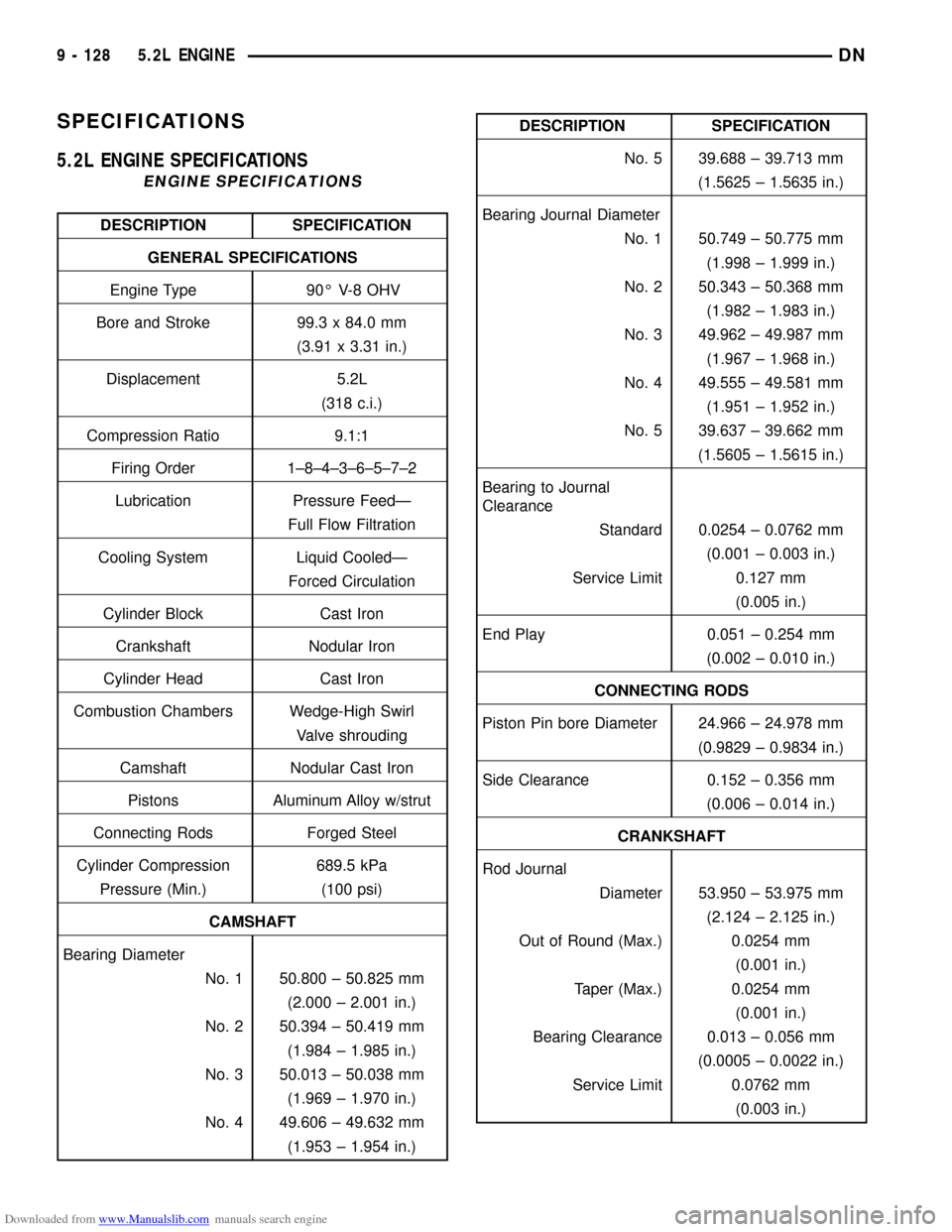

Downloaded from www.Manualslib.com manuals search engine SPECIFICATIONS

5.2L ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É V-8 OHV

Bore and Stroke 99.3 x 84.0 mm

(3.91 x 3.31 in.)

Displacement 5.2L

(318 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure FeedÐ

Full Flow Filtration

Cooling System Liquid CooledÐ

Forced Circulation

Cylinder Block Cast Iron

Crankshaft Nodular Iron

Cylinder Head Cast Iron

Combustion Chambers Wedge-High Swirl

Valve shrouding

Camshaft Nodular Cast Iron

Pistons Aluminum Alloy w/strut

Connecting Rods Forged Steel

Cylinder Compression 689.5 kPa

Pressure (Min.) (100 psi)

CAMSHAFT

Bearing Diameter

No. 1 50.800 ± 50.825 mm

(2.000 ± 2.001 in.)

No. 2 50.394 ± 50.419 mm

(1.984 ± 1.985 in.)

No. 3 50.013 ± 50.038 mm

(1.969 ± 1.970 in.)

No. 4 49.606 ± 49.632 mm

(1.953 ± 1.954 in.)

DESCRIPTION SPECIFICATION

No. 5 39.688 ± 39.713 mm

(1.5625 ± 1.5635 in.)

Bearing Journal Diameter

No. 1 50.749 ± 50.775 mm

(1.998 ± 1.999 in.)

No. 2 50.343 ± 50.368 mm

(1.982 ± 1.983 in.)

No. 3 49.962 ± 49.987 mm

(1.967 ± 1.968 in.)

No. 4 49.555 ± 49.581 mm

(1.951 ± 1.952 in.)

No. 5 39.637 ± 39.662 mm

(1.5605 ± 1.5615 in.)

Bearing to Journal

Clearance

Standard 0.0254 ± 0.0762 mm

(0.001 ± 0.003 in.)

Service Limit 0.127 mm

(0.005 in.)

End Play 0.051 ± 0.254 mm

(0.002 ± 0.010 in.)

CONNECTING RODS

Piston Pin bore Diameter 24.966 ± 24.978 mm

(0.9829 ± 0.9834 in.)

Side Clearance 0.152 ± 0.356 mm

(0.006 ± 0.014 in.)

CRANKSHAFT

Rod Journal

Diameter 53.950 ± 53.975 mm

(2.124 ± 2.125 in.)

Out of Round (Max.) 0.0254 mm

(0.001 in.)

Taper (Max.) 0.0254 mm

(0.001 in.)

Bearing Clearance 0.013 ± 0.056 mm

(0.0005 ± 0.0022 in.)

Service Limit 0.0762 mm

(0.003 in.)

9 - 128 5.2L ENGINEDN

Page 130 of 193

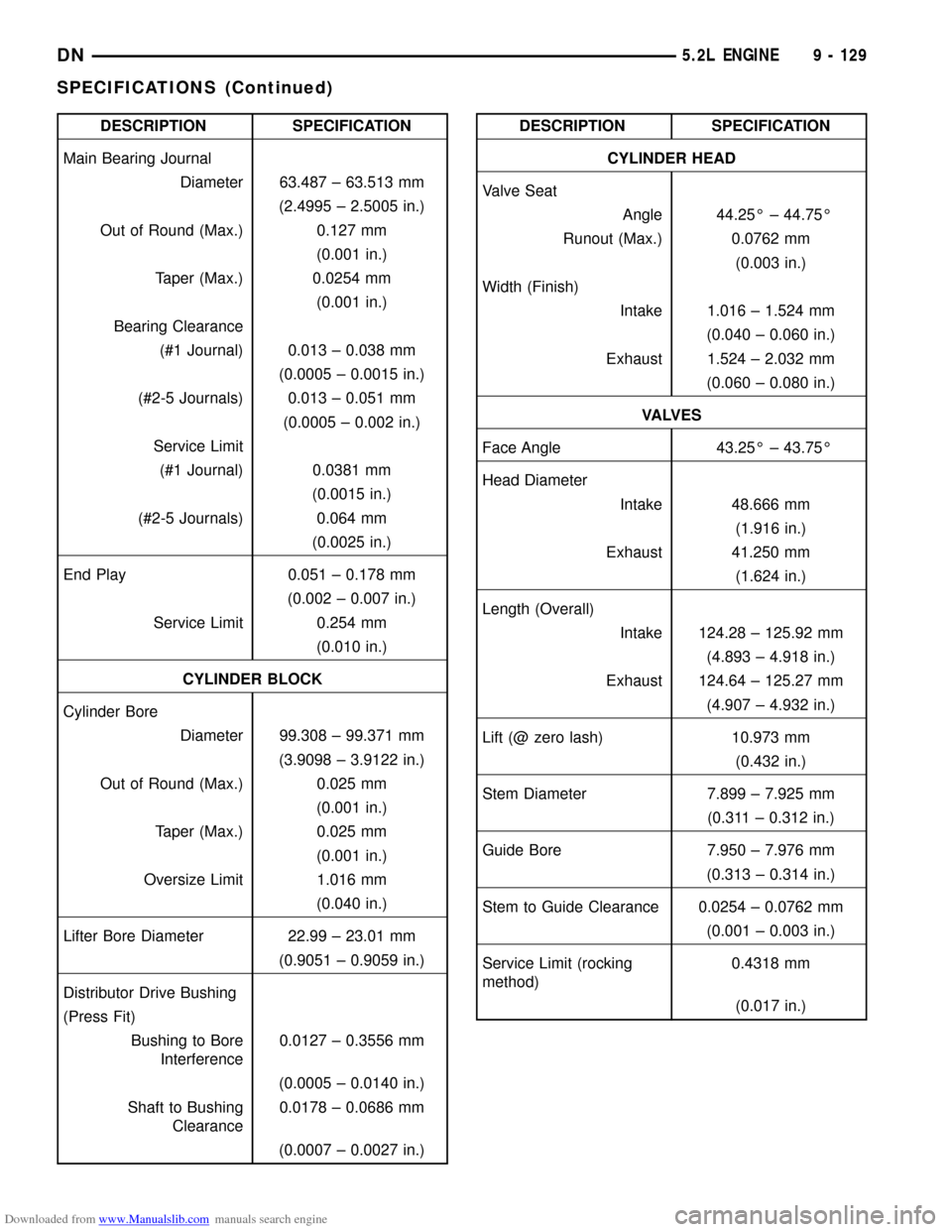

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

Main Bearing Journal

Diameter 63.487 ± 63.513 mm

(2.4995 ± 2.5005 in.)

Out of Round (Max.) 0.127 mm

(0.001 in.)

Taper (Max.) 0.0254 mm

(0.001 in.)

Bearing Clearance

(#1 Journal) 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

(#2-5 Journals) 0.013 ± 0.051 mm

(0.0005 ± 0.002 in.)

Service Limit

(#1 Journal) 0.0381 mm

(0.0015 in.)

(#2-5 Journals) 0.064 mm

(0.0025 in.)

End Play 0.051 ± 0.178 mm

(0.002 ± 0.007 in.)

Service Limit 0.254 mm

(0.010 in.)

CYLINDER BLOCK

Cylinder Bore

Diameter 99.308 ± 99.371 mm

(3.9098 ± 3.9122 in.)

Out of Round (Max.) 0.025 mm

(0.001 in.)

Taper (Max.) 0.025 mm

(0.001 in.)

Oversize Limit 1.016 mm

(0.040 in.)

Lifter Bore Diameter 22.99 ± 23.01 mm

(0.9051 ± 0.9059 in.)

Distributor Drive Bushing

(Press Fit)

Bushing to Bore

Interference0.0127 ± 0.3556 mm

(0.0005 ± 0.0140 in.)

Shaft to Bushing

Clearance0.0178 ± 0.0686 mm

(0.0007 ± 0.0027 in.)DESCRIPTION SPECIFICATION

CYLINDER HEAD

Valve Seat

Angle 44.25É ± 44.75É

Runout (Max.) 0.0762 mm

(0.003 in.)

Width (Finish)

Intake 1.016 ± 1.524 mm

(0.040 ± 0.060 in.)

Exhaust 1.524 ± 2.032 mm

(0.060 ± 0.080 in.)

VA LV E S

Face Angle 43.25É ± 43.75É

Head Diameter

Intake 48.666 mm

(1.916 in.)

Exhaust 41.250 mm

(1.624 in.)

Length (Overall)

Intake 124.28 ± 125.92 mm

(4.893 ± 4.918 in.)

Exhaust 124.64 ± 125.27 mm

(4.907 ± 4.932 in.)

Lift (@ zero lash) 10.973 mm

(0.432 in.)

Stem Diameter 7.899 ± 7.925 mm

(0.311 ± 0.312 in.)

Guide Bore 7.950 ± 7.976 mm

(0.313 ± 0.314 in.)

Stem to Guide Clearance 0.0254 ± 0.0762 mm

(0.001 ± 0.003 in.)

Service Limit (rocking

method)0.4318 mm

(0.017 in.)

DN5.2L ENGINE 9 - 129

SPECIFICATIONS (Continued)

Page 136 of 193

Downloaded from www.Manualslib.com manuals search engine 5.9L ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE...............................136

ENGINE LUBRICATION SYSTEM............136

EXHAUST MANIFOLD....................139

INTAKE MANIFOLD......................139

CYLINDER HEAD COVER GASKET..........140

CYLINDER HEAD........................140

VALVES AND VALVE SPRINGS.............140

ENGINE OIL PAN........................140

CRANKSHAFT OIL SEALS.................140

PISTON AND CONNECTING ROD...........140

CRANKSHAFT MAIN BEARINGS............141

CRANKSHAFT..........................141

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐINTRODUCTION.......141

SERVICE DIAGNOSISÐGASOLINE ENGINES . . 142

INTAKE MANIFOLD LEAKAGE DIAGNOSIS....145

CYLINDER COMPRESSION PRESSURE TEST . 145

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS...........................146

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.......................146

INSPECTION (ENGINE OIL LEAKS IN

GENERAL)...........................147

REAR SEAL AREA LEAKSÐINSPECTION.....147

HYDRAULIC TAPPETS....................148

ENGINE OIL PRESSURE..................148

SERVICE PROCEDURES

FORM-IN-PLACE GASKETS................149

ENGINE PERFORMANCE.................149

ENGINE OIL............................150

REPAIR DAMAGED OR WORN THREADS.....151

CYLINDER BOREÐHONING...............152

HYDROSTATIC LOCK.....................152

VALVE TIMING..........................153

VALVE SERVICE........................153

MEASURING TIMING CHAIN STRETCH.......155

PISTONSÐFITTING......................156

PISTON RINGSÐFITTING.................156

CONNECTING ROD BEARINGSÐFITTING.....157

CRANKSHAFT MAIN BEARINGSÐFITTING....157

REMOVAL AND INSTALLATION

ENGINE FRONT MOUNTS.................158ENGINE REAR SUPPORT.................160

ENGINE ASSEMBLY......................161

INTAKE MANIFOLD......................163

EXHAUST MANIFOLD....................165

CYLINDER HEAD COVER.................165

ROCKER ARMS AND PUSH RODS..........166

VALVE SPRING AND STEM SEAL

REPLACEMENT-IN VEHICLE.............166

CYLINDER HEAD........................167

VALVES AND VALVE SPRINGS.............167

HYDRAULIC TAPPETS....................168

VIBRATION DAMPER.....................168

TIMING CHAIN COVER...................169

TIMING CHAIN..........................170

CAMSHAFT............................170

CAMSHAFT BEARINGS...................172

DISTRIBUTOR DRIVE SHAFT BUSHING......172

CRANKSHAFT MAIN BEARINGS............174

OILPAN...............................174

PISTON AND CONNECTING ROD ASSEMBLY . . 175

CRANKSHAFT..........................176

OIL PUMP.............................177

CRANKSHAFT OIL SEALÐFRONT...........178

CRANKSHAFT OIL SEALSÐREAR...........179

ENGINE CORE OIL AND CAMSHAFT PLUGS . . 180

DISASSEMBLY AND ASSEMBLY

OIL PUMP.............................181

CLEANING AND INSPECTION

CYLINDER HEAD COVER.................182

CYLINDER HEAD ASSEMBLY..............182

PISTON AND CONNECTING ROD ASSEMBLY . . 182

OILPAN...............................182

OIL PUMP.............................182

CYLINDER BLOCK.......................185

INTAKE MANIFOLD......................185

EXHAUST MANIFOLD....................185

SPECIFICATIONS

5.9L ENGINE SPECIFICATIONS.............185

SPECIFICATIONS........................189

SPECIAL TOOLS

5.9L ENGINE...........................189

DN5.9L ENGINE 9 - 135