torque DODGE DURANGO 1998 1.G Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 166 of 193

Downloaded from www.Manualslib.com manuals search engine EXHAUST MANIFOLD

REMOVAL

(1) Disconnect the battery negative cable.

(2) Raise the vehicle.

(3) Remove the exhaust pipe to manifold nuts.

(4) Lower the vehicle.

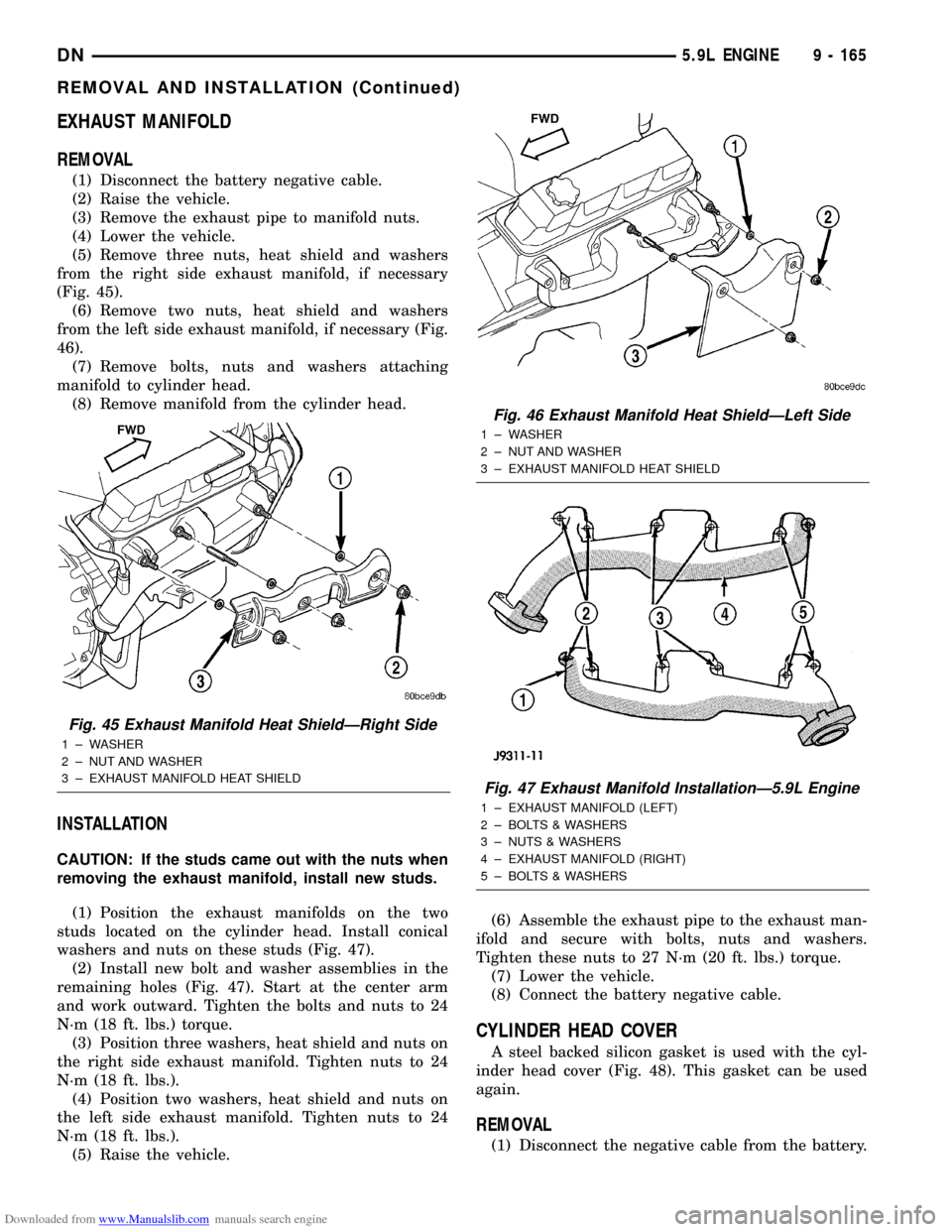

(5) Remove three nuts, heat shield and washers

from the right side exhaust manifold, if necessary

(Fig. 45).

(6) Remove two nuts, heat shield and washers

from the left side exhaust manifold, if necessary (Fig.

46).

(7) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(8) Remove manifold from the cylinder head.

INSTALLATION

CAUTION: If the studs came out with the nuts when

removing the exhaust manifold, install new studs.

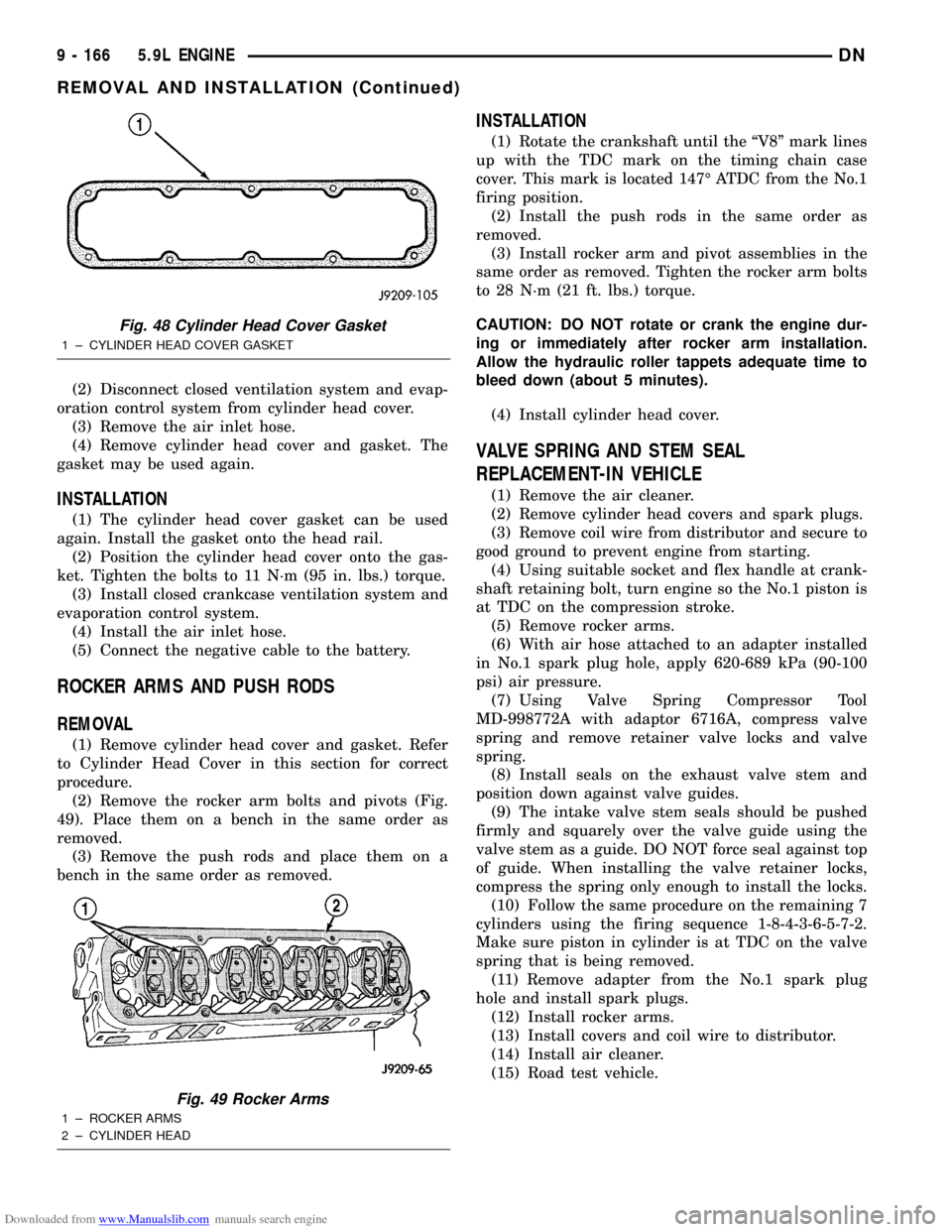

(1) Position the exhaust manifolds on the two

studs located on the cylinder head. Install conical

washers and nuts on these studs (Fig. 47).

(2) Install new bolt and washer assemblies in the

remaining holes (Fig. 47). Start at the center arm

and work outward. Tighten the bolts and nuts to 24

N´m (18 ft. lbs.) torque.

(3) Position three washers, heat shield and nuts on

the right side exhaust manifold. Tighten nuts to 24

N´m (18 ft. lbs.).

(4) Position two washers, heat shield and nuts on

the left side exhaust manifold. Tighten nuts to 24

N´m (18 ft. lbs.).

(5) Raise the vehicle.(6) Assemble the exhaust pipe to the exhaust man-

ifold and secure with bolts, nuts and washers.

Tighten these nuts to 27 N´m (20 ft. lbs.) torque.

(7) Lower the vehicle.

(8) Connect the battery negative cable.

CYLINDER HEAD COVER

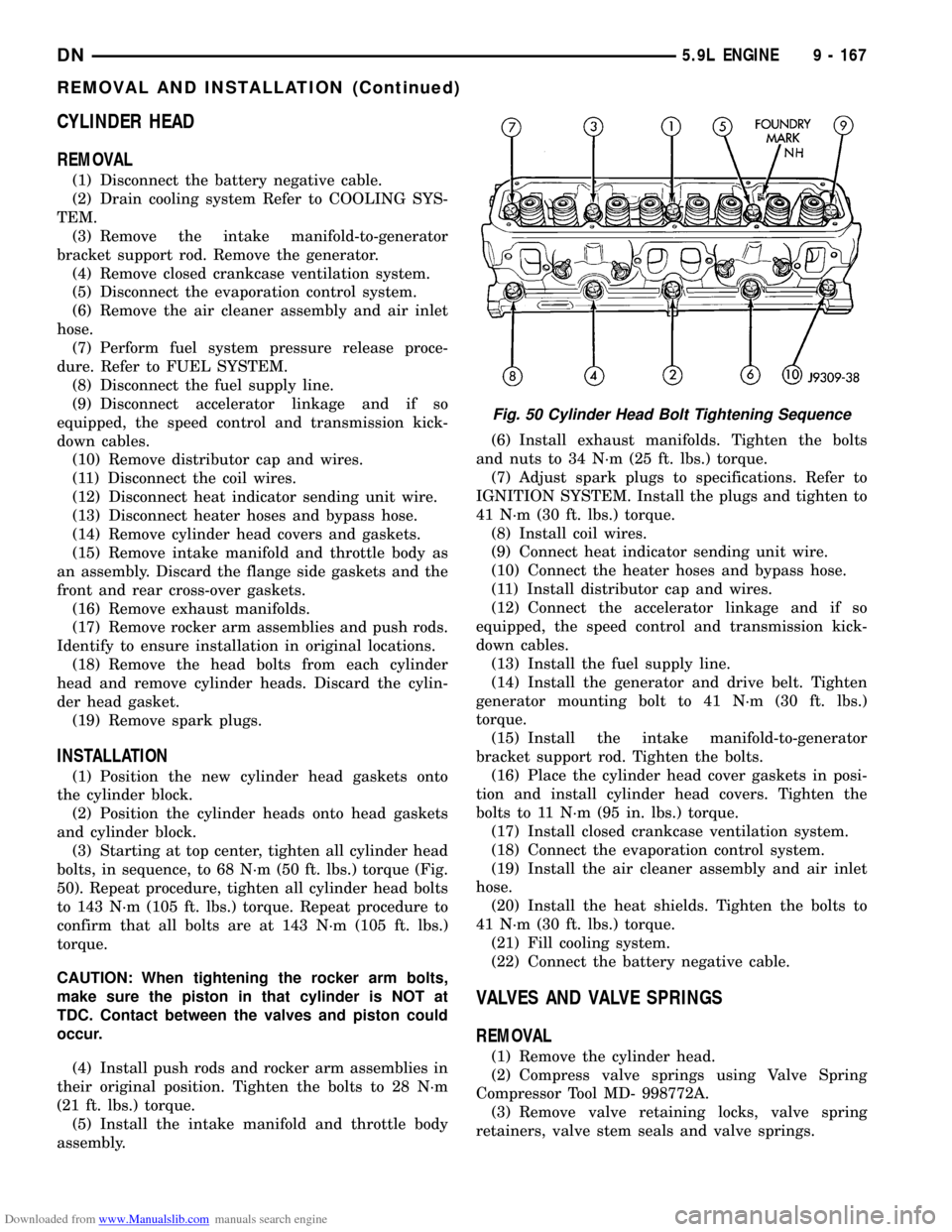

A steel backed silicon gasket is used with the cyl-

inder head cover (Fig. 48). This gasket can be used

again.

REMOVAL

(1) Disconnect the negative cable from the battery.

Fig. 45 Exhaust Manifold Heat ShieldÐRight Side

1 ± WASHER

2 ± NUT AND WASHER

3 ± EXHAUST MANIFOLD HEAT SHIELD

Fig. 46 Exhaust Manifold Heat ShieldÐLeft Side

1 ± WASHER

2 ± NUT AND WASHER

3 ± EXHAUST MANIFOLD HEAT SHIELD

Fig. 47 Exhaust Manifold InstallationÐ5.9L Engine

1 ± EXHAUST MANIFOLD (LEFT)

2 ± BOLTS & WASHERS

3 ± NUTS & WASHERS

4 ± EXHAUST MANIFOLD (RIGHT)

5 ± BOLTS & WASHERS

DN5.9L ENGINE 9 - 165

REMOVAL AND INSTALLATION (Continued)

Page 167 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Disconnect closed ventilation system and evap-

oration control system from cylinder head cover.

(3) Remove the air inlet hose.

(4) Remove cylinder head cover and gasket. The

gasket may be used again.

INSTALLATION

(1) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.

(2) Position the cylinder head cover onto the gas-

ket. Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(3) Install closed crankcase ventilation system and

evaporation control system.

(4) Install the air inlet hose.

(5) Connect the negative cable to the battery.

ROCKER ARMS AND PUSH RODS

REMOVAL

(1) Remove cylinder head cover and gasket. Refer

to Cylinder Head Cover in this section for correct

procedure.

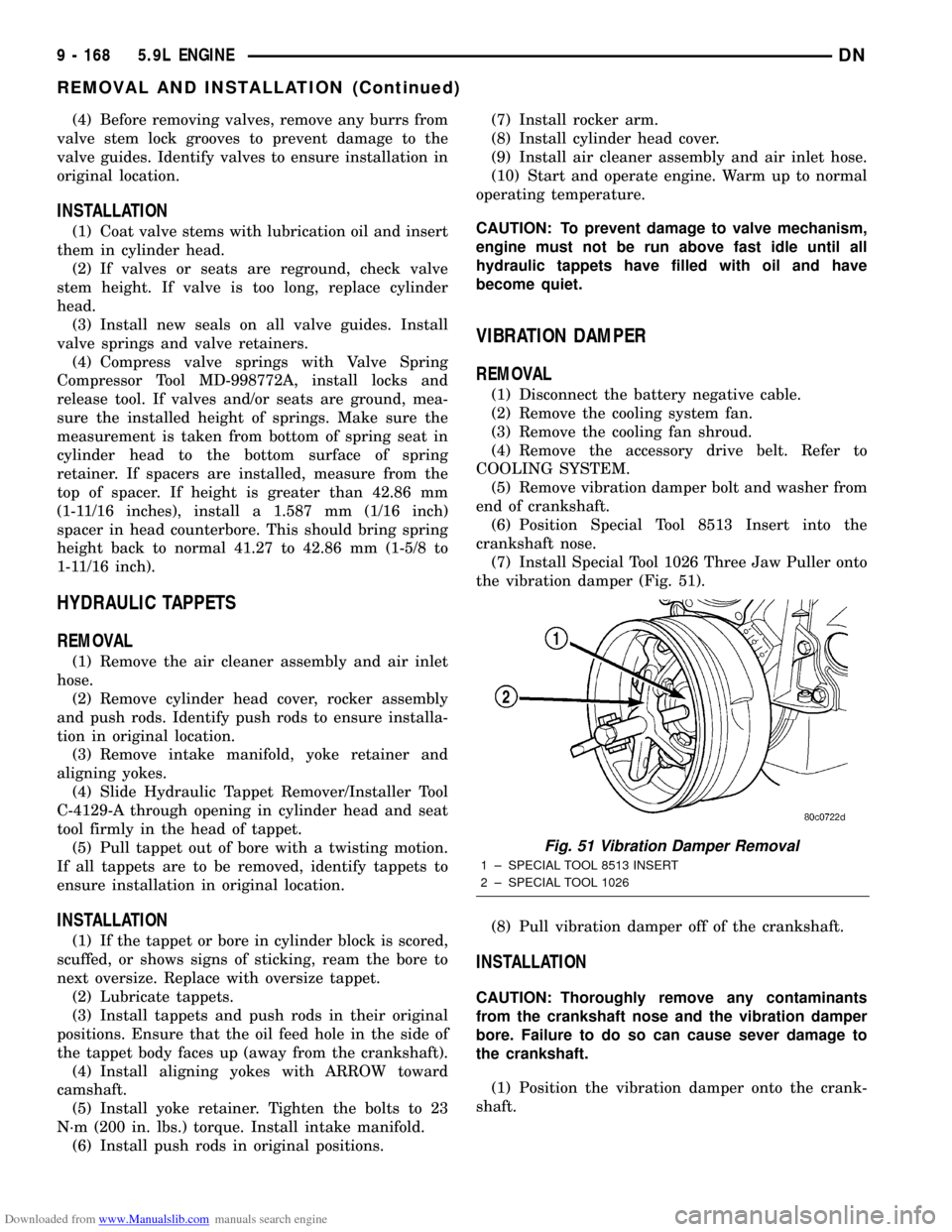

(2) Remove the rocker arm bolts and pivots (Fig.

49). Place them on a bench in the same order as

removed.

(3) Remove the push rods and place them on a

bench in the same order as removed.

INSTALLATION

(1) Rotate the crankshaft until the ªV8º mark lines

up with the TDC mark on the timing chain case

cover. This mark is located 147É ATDC from the No.1

firing position.

(2) Install the push rods in the same order as

removed.

(3) Install rocker arm and pivot assemblies in the

same order as removed. Tighten the rocker arm bolts

to 28 N´m (21 ft. lbs.) torque.

CAUTION: DO NOT rotate or crank the engine dur-

ing or immediately after rocker arm installation.

Allow the hydraulic roller tappets adequate time to

bleed down (about 5 minutes).

(4) Install cylinder head cover.

VALVE SPRING AND STEM SEAL

REPLACEMENT-IN VEHICLE

(1) Remove the air cleaner.

(2) Remove cylinder head covers and spark plugs.

(3) Remove coil wire from distributor and secure to

good ground to prevent engine from starting.

(4) Using suitable socket and flex handle at crank-

shaft retaining bolt, turn engine so the No.1 piston is

at TDC on the compression stroke.

(5) Remove rocker arms.

(6) With air hose attached to an adapter installed

in No.1 spark plug hole, apply 620-689 kPa (90-100

psi) air pressure.

(7) Using Valve Spring Compressor Tool

MD-998772A with adaptor 6716A, compress valve

spring and remove retainer valve locks and valve

spring.

(8) Install seals on the exhaust valve stem and

position down against valve guides.

(9) The intake valve stem seals should be pushed

firmly and squarely over the valve guide using the

valve stem as a guide. DO NOT force seal against top

of guide. When installing the valve retainer locks,

compress the spring only enough to install the locks.

(10) Follow the same procedure on the remaining 7

cylinders using the firing sequence 1-8-4-3-6-5-7-2.

Make sure piston in cylinder is at TDC on the valve

spring that is being removed.

(11) Remove adapter from the No.1 spark plug

hole and install spark plugs.

(12) Install rocker arms.

(13) Install covers and coil wire to distributor.

(14) Install air cleaner.

(15) Road test vehicle.

Fig. 48 Cylinder Head Cover Gasket

1 ± CYLINDER HEAD COVER GASKET

Fig. 49 Rocker Arms

1 ± ROCKER ARMS

2 ± CYLINDER HEAD

9 - 166 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 168 of 193

Downloaded from www.Manualslib.com manuals search engine CYLINDER HEAD

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system Refer to COOLING SYS-

TEM.

(3) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(4) Remove closed crankcase ventilation system.

(5) Disconnect the evaporation control system.

(6) Remove the air cleaner assembly and air inlet

hose.

(7) Perform fuel system pressure release proce-

dure. Refer to FUEL SYSTEM.

(8) Disconnect the fuel supply line.

(9) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect heat indicator sending unit wire.

(13) Disconnect heater hoses and bypass hose.

(14) Remove cylinder head covers and gaskets.

(15) Remove intake manifold and throttle body as

an assembly. Discard the flange side gaskets and the

front and rear cross-over gaskets.

(16) Remove exhaust manifolds.

(17) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(18) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(19) Remove spark plugs.

INSTALLATION

(1) Position the new cylinder head gaskets onto

the cylinder block.

(2) Position the cylinder heads onto head gaskets

and cylinder block.

(3) Starting at top center, tighten all cylinder head

bolts, in sequence, to 68 N´m (50 ft. lbs.) torque (Fig.

50). Repeat procedure, tighten all cylinder head bolts

to 143 N´m (105 ft. lbs.) torque. Repeat procedure to

confirm that all bolts are at 143 N´m (105 ft. lbs.)

torque.

CAUTION: When tightening the rocker arm bolts,

make sure the piston in that cylinder is NOT at

TDC. Contact between the valves and piston could

occur.

(4) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N´m

(21 ft. lbs.) torque.

(5) Install the intake manifold and throttle body

assembly.(6) Install exhaust manifolds. Tighten the bolts

and nuts to 34 N´m (25 ft. lbs.) torque.

(7) Adjust spark plugs to specifications. Refer to

IGNITION SYSTEM. Install the plugs and tighten to

41 N´m (30 ft. lbs.) torque.

(8) Install coil wires.

(9) Connect heat indicator sending unit wire.

(10) Connect the heater hoses and bypass hose.

(11) Install distributor cap and wires.

(12) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(13) Install the fuel supply line.

(14) Install the generator and drive belt. Tighten

generator mounting bolt to 41 N´m (30 ft. lbs.)

torque.

(15) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts.

(16) Place the cylinder head cover gaskets in posi-

tion and install cylinder head covers. Tighten the

bolts to 11 N´m (95 in. lbs.) torque.

(17) Install closed crankcase ventilation system.

(18) Connect the evaporation control system.

(19) Install the air cleaner assembly and air inlet

hose.

(20) Install the heat shields. Tighten the bolts to

41 N´m (30 ft. lbs.) torque.

(21) Fill cooling system.

(22) Connect the battery negative cable.

VALVES AND VALVE SPRINGS

REMOVAL

(1) Remove the cylinder head.

(2) Compress valve springs using Valve Spring

Compressor Tool MD- 998772A.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

Fig. 50 Cylinder Head Bolt Tightening Sequence

DN5.9L ENGINE 9 - 167

REMOVAL AND INSTALLATION (Continued)

Page 169 of 193

Downloaded from www.Manualslib.com manuals search engine (4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

INSTALLATION

(1) Coat valve stems with lubrication oil and insert

them in cylinder head.

(2) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(3) Install new seals on all valve guides. Install

valve springs and valve retainers.

(4) Compress valve springs with Valve Spring

Compressor Tool MD-998772A, install locks and

release tool. If valves and/or seats are ground, mea-

sure the installed height of springs. Make sure the

measurement is taken from bottom of spring seat in

cylinder head to the bottom surface of spring

retainer. If spacers are installed, measure from the

top of spacer. If height is greater than 42.86 mm

(1-11/16 inches), install a 1.587 mm (1/16 inch)

spacer in head counterbore. This should bring spring

height back to normal 41.27 to 42.86 mm (1-5/8 to

1-11/16 inch).

HYDRAULIC TAPPETS

REMOVAL

(1) Remove the air cleaner assembly and air inlet

hose.

(2) Remove cylinder head cover, rocker assembly

and push rods. Identify push rods to ensure installa-

tion in original location.

(3) Remove intake manifold, yoke retainer and

aligning yokes.

(4) Slide Hydraulic Tappet Remover/Installer Tool

C-4129-A through opening in cylinder head and seat

tool firmly in the head of tappet.

(5) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed, identify tappets to

ensure installation in original location.

INSTALLATION

(1) If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore to

next oversize. Replace with oversize tappet.

(2) Lubricate tappets.

(3) Install tappets and push rods in their original

positions. Ensure that the oil feed hole in the side of

the tappet body faces up (away from the crankshaft).

(4) Install aligning yokes with ARROW toward

camshaft.

(5) Install yoke retainer. Tighten the bolts to 23

N´m (200 in. lbs.) torque. Install intake manifold.

(6) Install push rods in original positions.(7) Install rocker arm.

(8) Install cylinder head cover.

(9) Install air cleaner assembly and air inlet hose.

(10) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the cooling system fan.

(3) Remove the cooling fan shroud.

(4) Remove the accessory drive belt. Refer to

COOLING SYSTEM.

(5) Remove vibration damper bolt and washer from

end of crankshaft.

(6) Position Special Tool 8513 Insert into the

crankshaft nose.

(7) Install Special Tool 1026 Three Jaw Puller onto

the vibration damper (Fig. 51).

(8) Pull vibration damper off of the crankshaft.

INSTALLATION

CAUTION: Thoroughly remove any contaminants

from the crankshaft nose and the vibration damper

bore. Failure to do so can cause sever damage to

the crankshaft.

(1) Position the vibration damper onto the crank-

shaft.

Fig. 51 Vibration Damper Removal

1 ± SPECIAL TOOL 8513 INSERT

2 ± SPECIAL TOOL 1026

9 - 168 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 170 of 193

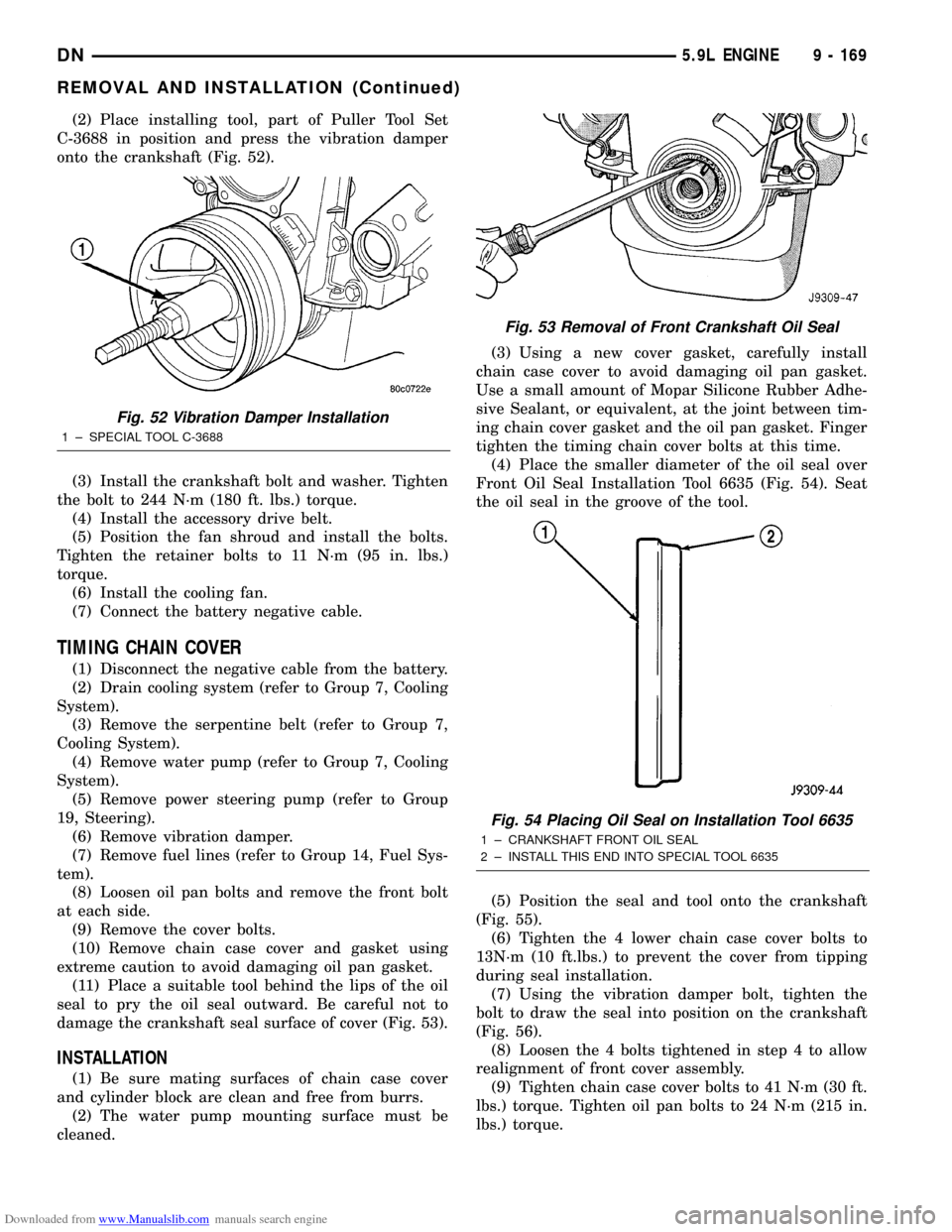

Downloaded from www.Manualslib.com manuals search engine (2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 52).

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 244 N´m (180 ft. lbs.) torque.

(4) Install the accessory drive belt.

(5) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N´m (95 in. lbs.)

torque.

(6) Install the cooling fan.

(7) Connect the battery negative cable.

TIMING CHAIN COVER

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (refer to Group 7, Cooling

System).

(3) Remove the serpentine belt (refer to Group 7,

Cooling System).

(4) Remove water pump (refer to Group 7, Cooling

System).

(5) Remove power steering pump (refer to Group

19, Steering).

(6) Remove vibration damper.

(7) Remove fuel lines (refer to Group 14, Fuel Sys-

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9) Remove the cover bolts.

(10) Remove chain case cover and gasket using

extreme caution to avoid damaging oil pan gasket.

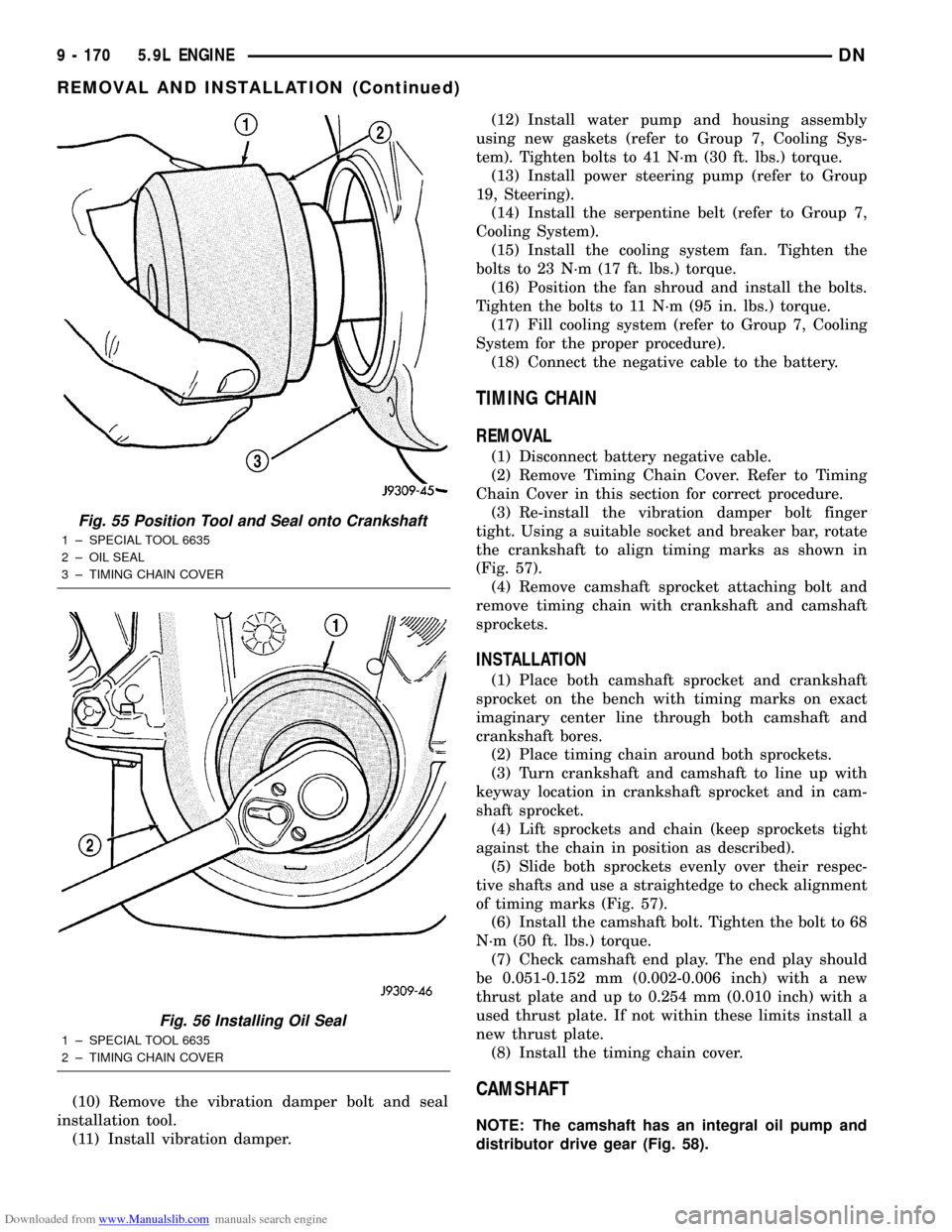

(11) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 53).

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

(2) The water pump mounting surface must be

cleaned.(3) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of Mopar Silicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

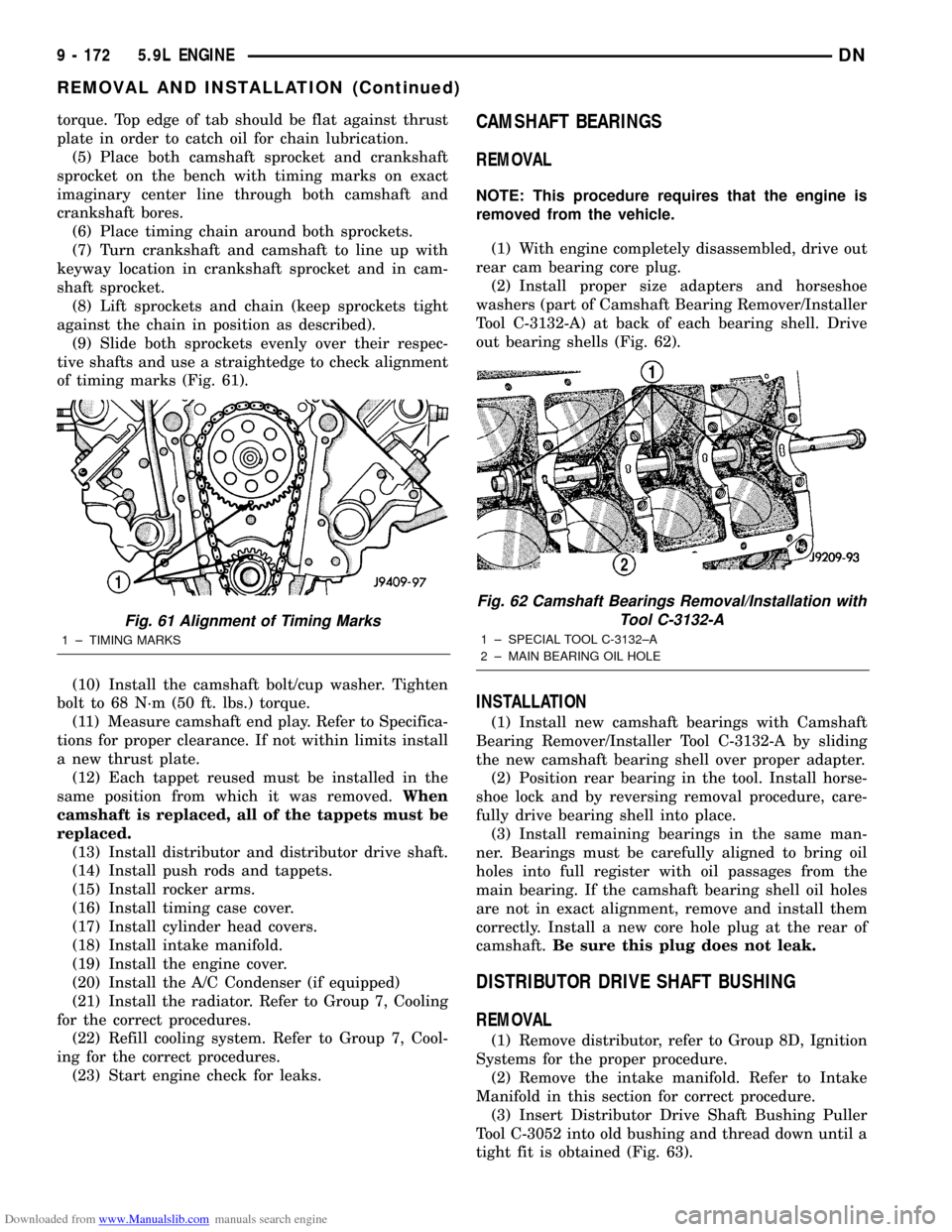

(4) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 54). Seat

the oil seal in the groove of the tool.

(5) Position the seal and tool onto the crankshaft

(Fig. 55).

(6) Tighten the 4 lower chain case cover bolts to

13N´m (10 ft.lbs.) to prevent the cover from tipping

during seal installation.

(7) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft

(Fig. 56).

(8) Loosen the 4 bolts tightened in step 4 to allow

realignment of front cover assembly.

(9) Tighten chain case cover bolts to 41 N´m (30 ft.

lbs.) torque. Tighten oil pan bolts to 24 N´m (215 in.

lbs.) torque.

Fig. 52 Vibration Damper Installation

1 ± SPECIAL TOOL C-3688

Fig. 53 Removal of Front Crankshaft Oil Seal

Fig. 54 Placing Oil Seal on Installation Tool 6635

1 ± CRANKSHAFT FRONT OIL SEAL

2 ± INSTALL THIS END INTO SPECIAL TOOL 6635

DN5.9L ENGINE 9 - 169

REMOVAL AND INSTALLATION (Continued)

Page 171 of 193

Downloaded from www.Manualslib.com manuals search engine (10) Remove the vibration damper bolt and seal

installation tool.

(11) Install vibration damper.(12) Install water pump and housing assembly

using new gaskets (refer to Group 7, Cooling Sys-

tem). Tighten bolts to 41 N´m (30 ft. lbs.) torque.

(13) Install power steering pump (refer to Group

19, Steering).

(14) Install the serpentine belt (refer to Group 7,

Cooling System).

(15) Install the cooling system fan. Tighten the

bolts to 23 N´m (17 ft. lbs.) torque.

(16) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(17) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure).

(18) Connect the negative cable to the battery.

TIMING CHAIN

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove Timing Chain Cover. Refer to Timing

Chain Cover in this section for correct procedure.

(3) Re-install the vibration damper bolt finger

tight. Using a suitable socket and breaker bar, rotate

the crankshaft to align timing marks as shown in

(Fig. 57).

(4) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

INSTALLATION

(1) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(2) Place timing chain around both sprockets.

(3) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(4) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(5) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 57).

(6) Install the camshaft bolt. Tighten the bolt to 68

N´m (50 ft. lbs.) torque.

(7) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

(8) Install the timing chain cover.

CAMSHAFT

NOTE: The camshaft has an integral oil pump and

distributor drive gear (Fig. 58).

Fig. 55 Position Tool and Seal onto Crankshaft

1 ± SPECIAL TOOL 6635

2 ± OIL SEAL

3 ± TIMING CHAIN COVER

Fig. 56 Installing Oil Seal

1 ± SPECIAL TOOL 6635

2 ± TIMING CHAIN COVER

9 - 170 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 173 of 193

Downloaded from www.Manualslib.com manuals search engine torque. Top edge of tab should be flat against thrust

plate in order to catch oil for chain lubrication.

(5) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(6) Place timing chain around both sprockets.

(7) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(8) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(9) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 61).

(10) Install the camshaft bolt/cup washer. Tighten

bolt to 68 N´m (50 ft. lbs.) torque.

(11) Measure camshaft end play. Refer to Specifica-

tions for proper clearance. If not within limits install

a new thrust plate.

(12) Each tappet reused must be installed in the

same position from which it was removed.When

camshaft is replaced, all of the tappets must be

replaced.

(13) Install distributor and distributor drive shaft.

(14) Install push rods and tappets.

(15) Install rocker arms.

(16) Install timing case cover.

(17) Install cylinder head covers.

(18) Install intake manifold.

(19) Install the engine cover.

(20) Install the A/C Condenser (if equipped)

(21) Install the radiator. Refer to Group 7, Cooling

for the correct procedures.

(22) Refill cooling system. Refer to Group 7, Cool-

ing for the correct procedures.

(23) Start engine check for leaks.CAMSHAFT BEARINGS

REMOVAL

NOTE: This procedure requires that the engine is

removed from the vehicle.

(1) With engine completely disassembled, drive out

rear cam bearing core plug.

(2) Install proper size adapters and horseshoe

washers (part of Camshaft Bearing Remover/Installer

Tool C-3132-A) at back of each bearing shell. Drive

out bearing shells (Fig. 62).

INSTALLATION

(1) Install new camshaft bearings with Camshaft

Bearing Remover/Installer Tool C-3132-A by sliding

the new camshaft bearing shell over proper adapter.

(2) Position rear bearing in the tool. Install horse-

shoe lock and by reversing removal procedure, care-

fully drive bearing shell into place.

(3) Install remaining bearings in the same man-

ner. Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the

main bearing. If the camshaft bearing shell oil holes

are not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft.Be sure this plug does not leak.

DISTRIBUTOR DRIVE SHAFT BUSHING

REMOVAL

(1) Remove distributor, refer to Group 8D, Ignition

Systems for the proper procedure.

(2) Remove the intake manifold. Refer to Intake

Manifold in this section for correct procedure.

(3) Insert Distributor Drive Shaft Bushing Puller

Tool C-3052 into old bushing and thread down until a

tight fit is obtained (Fig. 63).

Fig. 61 Alignment of Timing Marks

1 ± TIMING MARKS

Fig. 62 Camshaft Bearings Removal/Installation with

Tool C-3132-A

1 ± SPECIAL TOOL C-3132±A

2 ± MAIN BEARING OIL HOLE

9 - 172 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 175 of 193

Downloaded from www.Manualslib.com manuals search engine CRANKSHAFT MAIN BEARINGS

REMOVAL

(1) Remove the oil pan.

(2) Remove the oil pump from the rear main bear-

ing cap.

(3) Identify bearing caps before removal. Remove

bearing caps one at a time.

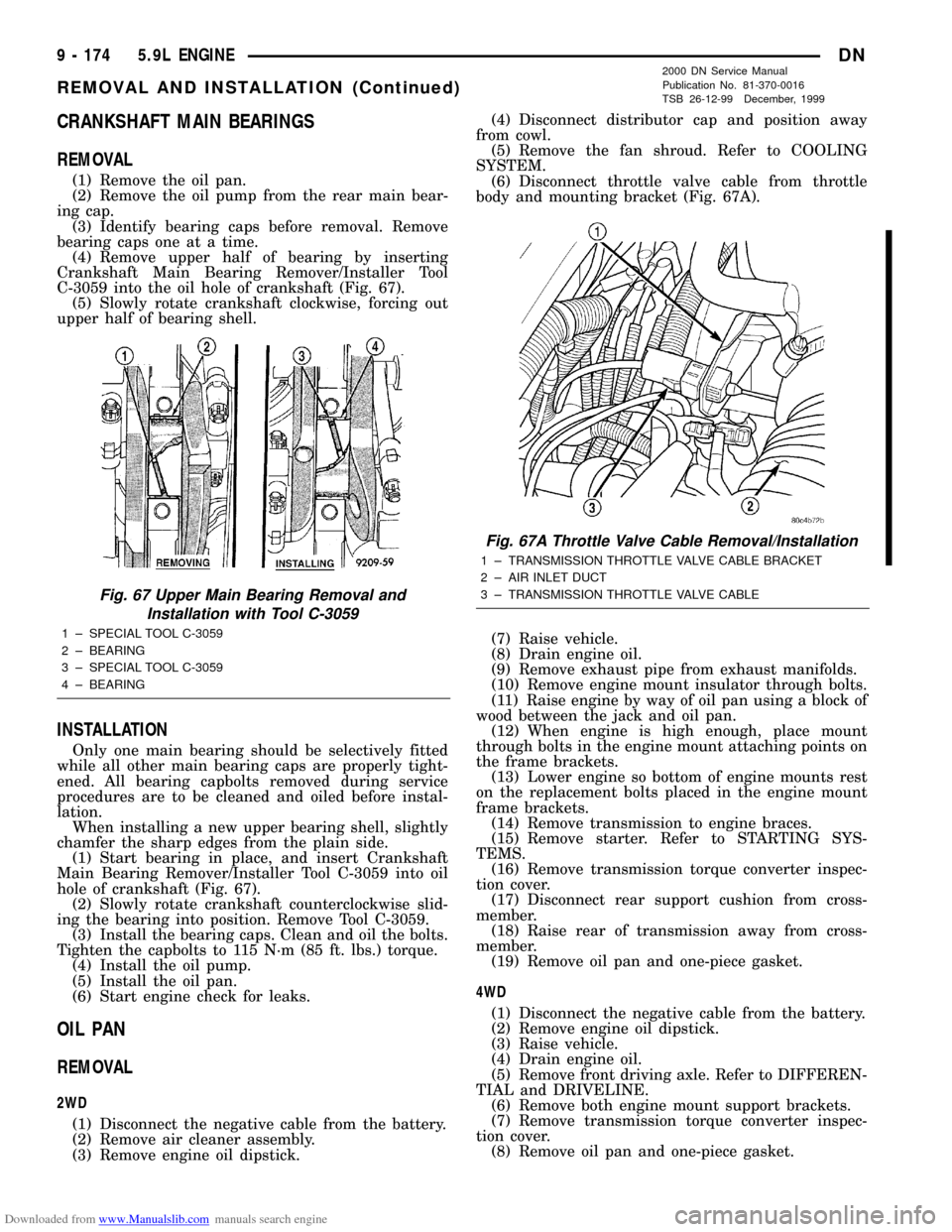

(4) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 67).

(5) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service

procedures are to be cleaned and oiled before instal-

lation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Start bearing in place, and insert Crankshaft

Main Bearing Remover/Installer Tool C-3059 into oil

hole of crankshaft (Fig. 67).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Tool C-3059.

(3) Install the bearing caps. Clean and oil the bolts.

Tighten the capbolts to 115 N´m (85 ft. lbs.) torque.

(4) Install the oil pump.

(5) Install the oil pan.

(6) Start engine check for leaks.

OIL PAN

REMOVAL

2WD

(1) Disconnect the negative cable from the battery.

(2) Remove air cleaner assembly.

(3) Remove engine oil dipstick.(4) Disconnect distributor cap and position away

from cowl.

(5) Remove the fan shroud. Refer to COOLING

SYSTEM.

(6) Disconnect throttle valve cable from throttle

body and mounting bracket (Fig. 67A).

(7) Raise vehicle.

(8) Drain engine oil.

(9) Remove exhaust pipe from exhaust manifolds.

(10) Remove engine mount insulator through bolts.

(11) Raise engine by way of oil pan using a block of

wood between the jack and oil pan.

(12) When engine is high enough, place mount

through bolts in the engine mount attaching points on

the frame brackets.

(13) Lower engine so bottom of engine mounts rest

on the replacement bolts placed in the engine mount

frame brackets.

(14) Remove transmission to engine braces.

(15) Remove starter. Refer to STARTING SYS-

TEMS.

(16) Remove transmission torque converter inspec-

tion cover.

(17) Disconnect rear support cushion from cross-

member.

(18) Raise rear of transmission away from cross-

member.

(19) Remove oil pan and one-piece gasket.

4WD

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove front driving axle. Refer to DIFFEREN-

TIAL and DRIVELINE.

(6) Remove both engine mount support brackets.

(7) Remove transmission torque converter inspec-

tion cover.

(8) Remove oil pan and one-piece gasket.

Fig. 67 Upper Main Bearing Removal and

Installation with Tool C-3059

1 ± SPECIAL TOOL C-3059

2 ± BEARING

3 ± SPECIAL TOOL C-3059

4 ± BEARING

Fig. 67A Throttle Valve Cable Removal/Installation

1 ± TRANSMISSION THROTTLE VALVE CABLE BRACKET

2 ± AIR INLET DUCT

3 ± TRANSMISSION THROTTLE VALVE CABLE

9 - 174 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

2000 DN Service Manual

Publication No. 81-370-0016

TSB 26-12-99 December, 1999

Page 176 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

2WD

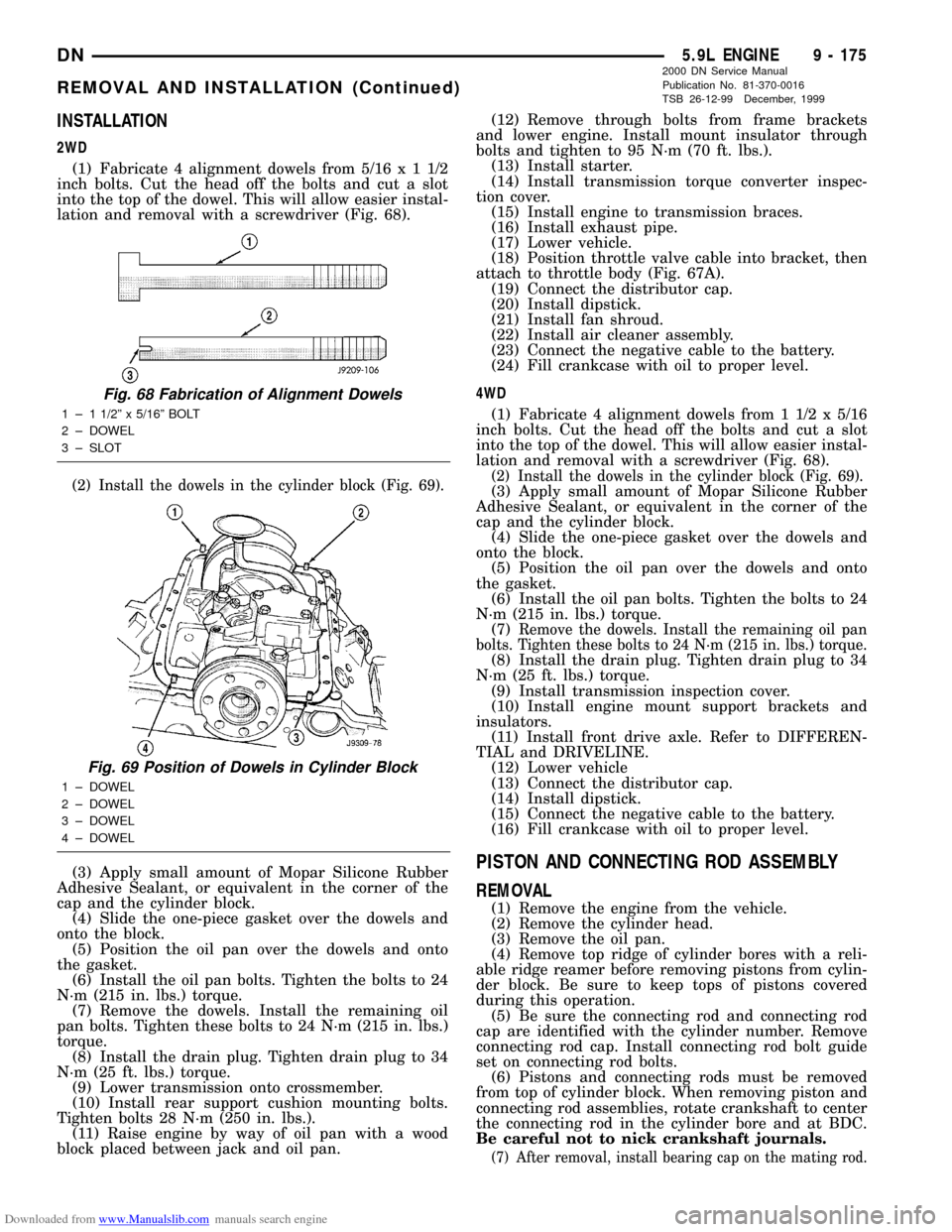

(1) Fabricate 4 alignment dowels from 5/16x11/2

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier instal-

lation and removal with a screwdriver (Fig. 68).

(2) Install the dowels in the cylinder block (Fig. 69).

(3) Apply small amount of Mopar Silicone Rubber

Adhesive Sealant, or equivalent in the corner of the

cap and the cylinder block.

(4) Slide the one-piece gasket over the dowels and

onto the block.

(5) Position the oil pan over the dowels and onto

the gasket.

(6) Install the oil pan bolts. Tighten the bolts to 24

N´m (215 in. lbs.) torque.

(7) Remove the dowels. Install the remaining oil

pan bolts. Tighten these bolts to 24 N´m (215 in. lbs.)

torque.

(8) Install the drain plug. Tighten drain plug to 34

N´m (25 ft. lbs.) torque.

(9) Lower transmission onto crossmember.

(10) Install rear support cushion mounting bolts.

Tighten bolts 28 N´m (250 in. lbs.).

(11) Raise engine by way of oil pan with a wood

block placed between jack and oil pan.(12) Remove through bolts from frame brackets

and lower engine. Install mount insulator through

bolts and tighten to 95 N´m (70 ft. lbs.).

(13) Install starter.

(14) Install transmission torque converter inspec-

tion cover.

(15) Install engine to transmission braces.

(16) Install exhaust pipe.

(17) Lower vehicle.

(18) Position throttle valve cable into bracket, then

attach to throttle body (Fig. 67A).

(19) Connect the distributor cap.

(20) Install dipstick.

(21) Install fan shroud.

(22) Install air cleaner assembly.

(23) Connect the negative cable to the battery.

(24) Fill crankcase with oil to proper level.

4WD

(1) Fabricate 4 alignment dowels from 1 1/2 x 5/16

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier instal-

lation and removal with a screwdriver (Fig. 68).

(2) Install the dowels in the cylinder block (Fig. 69).(3) Apply small amount of Mopar Silicone Rubber

Adhesive Sealant, or equivalent in the corner of the

cap and the cylinder block.

(4) Slide the one-piece gasket over the dowels and

onto the block.

(5) Position the oil pan over the dowels and onto

the gasket.

(6) Install the oil pan bolts. Tighten the bolts to 24

N´m (215 in. lbs.) torque.

(7)

Remove the dowels. Install the remaining oil pan

bolts. Tighten these bolts to 24 N´m (215 in. lbs.) torque.

(8) Install the drain plug. Tighten drain plug to 34

N´m (25 ft. lbs.) torque.

(9) Install transmission inspection cover.

(10) Install engine mount support brackets and

insulators.

(11) Install front drive axle. Refer to DIFFEREN-

TIAL and DRIVELINE.

(12) Lower vehicle

(13) Connect the distributor cap.

(14) Install dipstick.

(15) Connect the negative cable to the battery.

(16) Fill crankcase with oil to proper level.

PISTON AND CONNECTING ROD ASSEMBLY

REMOVAL

(1) Remove the engine from the vehicle.

(2) Remove the cylinder head.

(3) Remove the oil pan.

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cylin-

der block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure the connecting rod and connecting rod

cap are identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing piston and

connecting rod assemblies, rotate crankshaft to center

the connecting rod in the cylinder bore and at BDC.

Be careful not to nick crankshaft journals.

(7) After removal, install bearing cap on the mating rod.

Fig. 68 Fabrication of Alignment Dowels

1 ± 1 1/2º x 5/16º BOLT

2 ± DOWEL

3 ± SLOT

Fig. 69 Position of Dowels in Cylinder Block

1 ± DOWEL

2 ± DOWEL

3 ± DOWEL

4 ± DOWEL

DN5.9L ENGINE 9 - 175

REMOVAL AND INSTALLATION (Continued)

2000 DN Service Manual

Publication No. 81-370-0016

TSB 26-12-99 December, 1999

Page 177 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

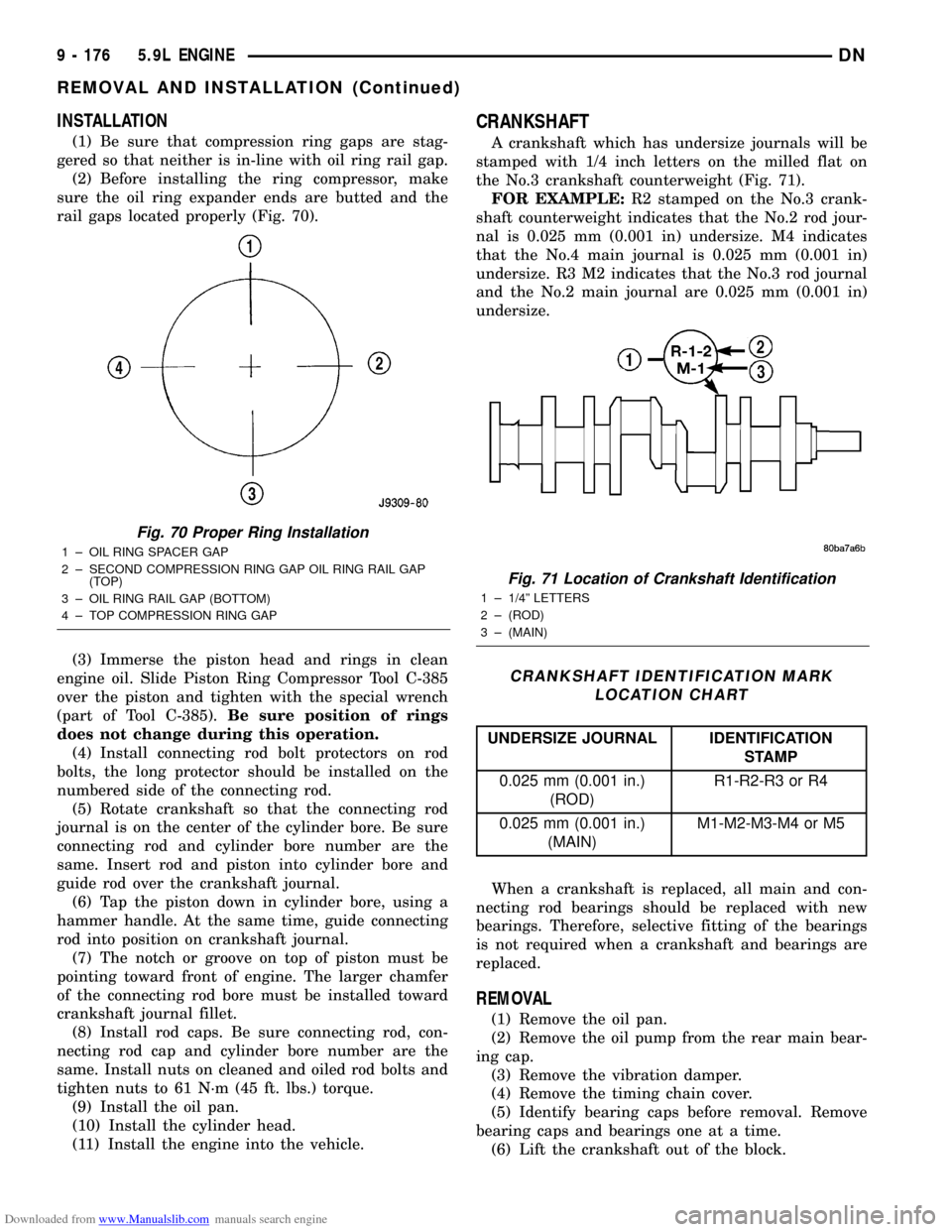

(1) Be sure that compression ring gaps are stag-

gered so that neither is in-line with oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located properly (Fig. 70).

(3) Immerse the piston head and rings in clean

engine oil. Slide Piston Ring Compressor Tool C-385

over the piston and tighten with the special wrench

(part of Tool C-385).Be sure position of rings

does not change during this operation.

(4) Install connecting rod bolt protectors on rod

bolts, the long protector should be installed on the

numbered side of the connecting rod.

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Be sure

connecting rod and cylinder bore number are the

same. Insert rod and piston into cylinder bore and

guide rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on crankshaft journal.

(7) The notch or groove on top of piston must be

pointing toward front of engine. The larger chamfer

of the connecting rod bore must be installed toward

crankshaft journal fillet.

(8) Install rod caps. Be sure connecting rod, con-

necting rod cap and cylinder bore number are the

same. Install nuts on cleaned and oiled rod bolts and

tighten nuts to 61 N´m (45 ft. lbs.) torque.

(9) Install the oil pan.

(10) Install the cylinder head.

(11) Install the engine into the vehicle.

CRANKSHAFT

A crankshaft which has undersize journals will be

stamped with 1/4 inch letters on the milled flat on

the No.3 crankshaft counterweight (Fig. 71).

FOR EXAMPLE:R2 stamped on the No.3 crank-

shaft counterweight indicates that the No.2 rod jour-

nal is 0.025 mm (0.001 in) undersize. M4 indicates

that the No.4 main journal is 0.025 mm (0.001 in)

undersize. R3 M2 indicates that the No.3 rod journal

and the No.2 main journal are 0.025 mm (0.001 in)

undersize.

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

is not required when a crankshaft and bearings are

replaced.

REMOVAL

(1) Remove the oil pan.

(2) Remove the oil pump from the rear main bear-

ing cap.

(3) Remove the vibration damper.

(4) Remove the timing chain cover.

(5) Identify bearing caps before removal. Remove

bearing caps and bearings one at a time.

(6) Lift the crankshaft out of the block.

Fig. 70 Proper Ring Installation

1 ± OIL RING SPACER GAP

2 ± SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 ± OIL RING RAIL GAP (BOTTOM)

4 ± TOP COMPRESSION RING GAP

Fig. 71 Location of Crankshaft Identification

1 ± 1/4º LETTERS

2 ± (ROD)

3 ± (MAIN)

CRANKSHAFT IDENTIFICATION MARK

LOCATION CHART

UNDERSIZE JOURNAL IDENTIFICATION

STAMP

0.025 mm (0.001 in.)

(ROD)R1-R2-R3 or R4

0.025 mm (0.001 in.)

(MAIN)M1-M2-M3-M4 or M5

9 - 176 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)