front end DODGE DURANGO 1999 1.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: DURANGO, Model: DODGE DURANGO 1999 1.GPages: 193, PDF Size: 5.65 MB

Page 177 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

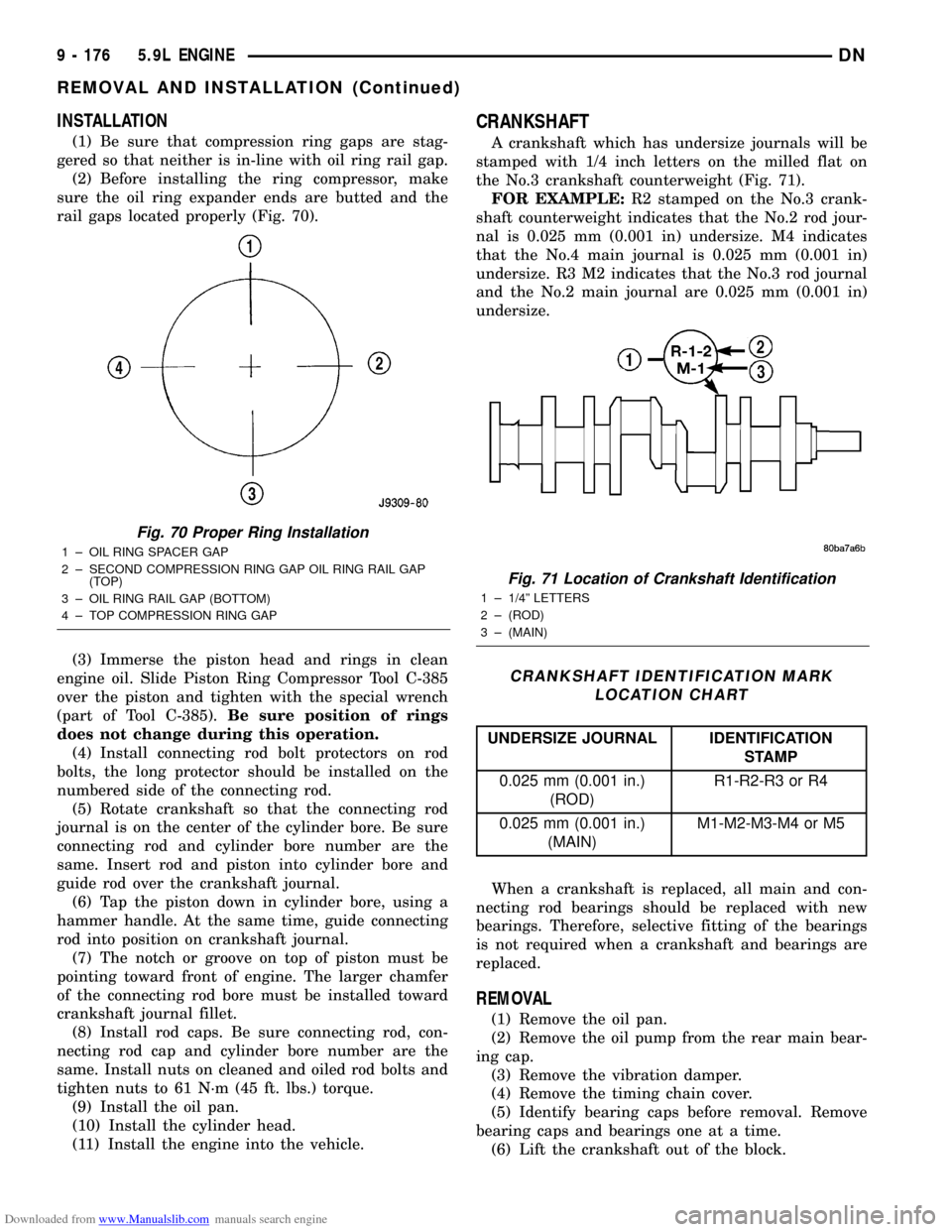

(1) Be sure that compression ring gaps are stag-

gered so that neither is in-line with oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located properly (Fig. 70).

(3) Immerse the piston head and rings in clean

engine oil. Slide Piston Ring Compressor Tool C-385

over the piston and tighten with the special wrench

(part of Tool C-385).Be sure position of rings

does not change during this operation.

(4) Install connecting rod bolt protectors on rod

bolts, the long protector should be installed on the

numbered side of the connecting rod.

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Be sure

connecting rod and cylinder bore number are the

same. Insert rod and piston into cylinder bore and

guide rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on crankshaft journal.

(7) The notch or groove on top of piston must be

pointing toward front of engine. The larger chamfer

of the connecting rod bore must be installed toward

crankshaft journal fillet.

(8) Install rod caps. Be sure connecting rod, con-

necting rod cap and cylinder bore number are the

same. Install nuts on cleaned and oiled rod bolts and

tighten nuts to 61 N´m (45 ft. lbs.) torque.

(9) Install the oil pan.

(10) Install the cylinder head.

(11) Install the engine into the vehicle.

CRANKSHAFT

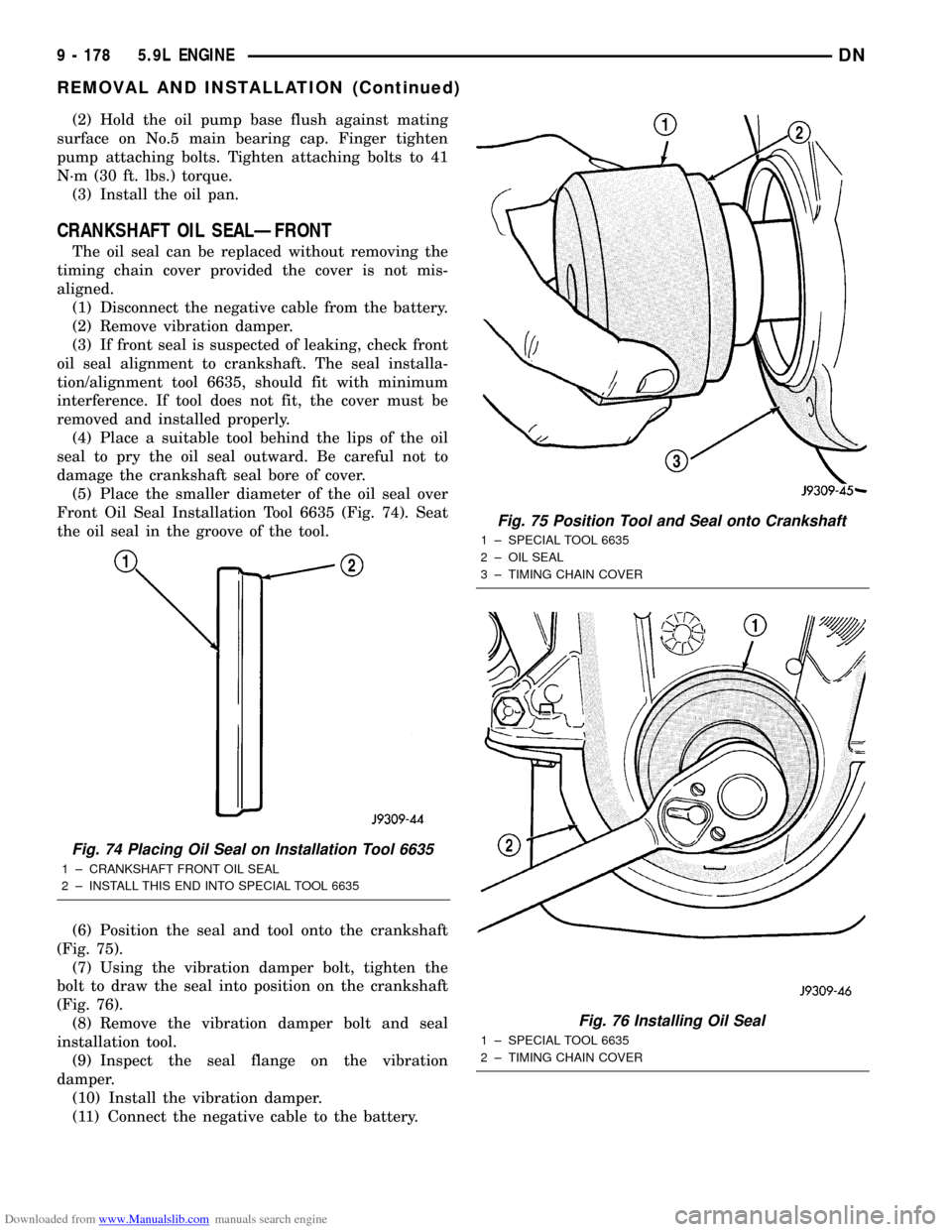

A crankshaft which has undersize journals will be

stamped with 1/4 inch letters on the milled flat on

the No.3 crankshaft counterweight (Fig. 71).

FOR EXAMPLE:R2 stamped on the No.3 crank-

shaft counterweight indicates that the No.2 rod jour-

nal is 0.025 mm (0.001 in) undersize. M4 indicates

that the No.4 main journal is 0.025 mm (0.001 in)

undersize. R3 M2 indicates that the No.3 rod journal

and the No.2 main journal are 0.025 mm (0.001 in)

undersize.

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

is not required when a crankshaft and bearings are

replaced.

REMOVAL

(1) Remove the oil pan.

(2) Remove the oil pump from the rear main bear-

ing cap.

(3) Remove the vibration damper.

(4) Remove the timing chain cover.

(5) Identify bearing caps before removal. Remove

bearing caps and bearings one at a time.

(6) Lift the crankshaft out of the block.

Fig. 70 Proper Ring Installation

1 ± OIL RING SPACER GAP

2 ± SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 ± OIL RING RAIL GAP (BOTTOM)

4 ± TOP COMPRESSION RING GAP

Fig. 71 Location of Crankshaft Identification

1 ± 1/4º LETTERS

2 ± (ROD)

3 ± (MAIN)

CRANKSHAFT IDENTIFICATION MARK

LOCATION CHART

UNDERSIZE JOURNAL IDENTIFICATION

STAMP

0.025 mm (0.001 in.)

(ROD)R1-R2-R3 or R4

0.025 mm (0.001 in.)

(MAIN)M1-M2-M3-M4 or M5

9 - 176 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 179 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Hold the oil pump base flush against mating

surface on No.5 main bearing cap. Finger tighten

pump attaching bolts. Tighten attaching bolts to 41

N´m (30 ft. lbs.) torque.

(3) Install the oil pan.

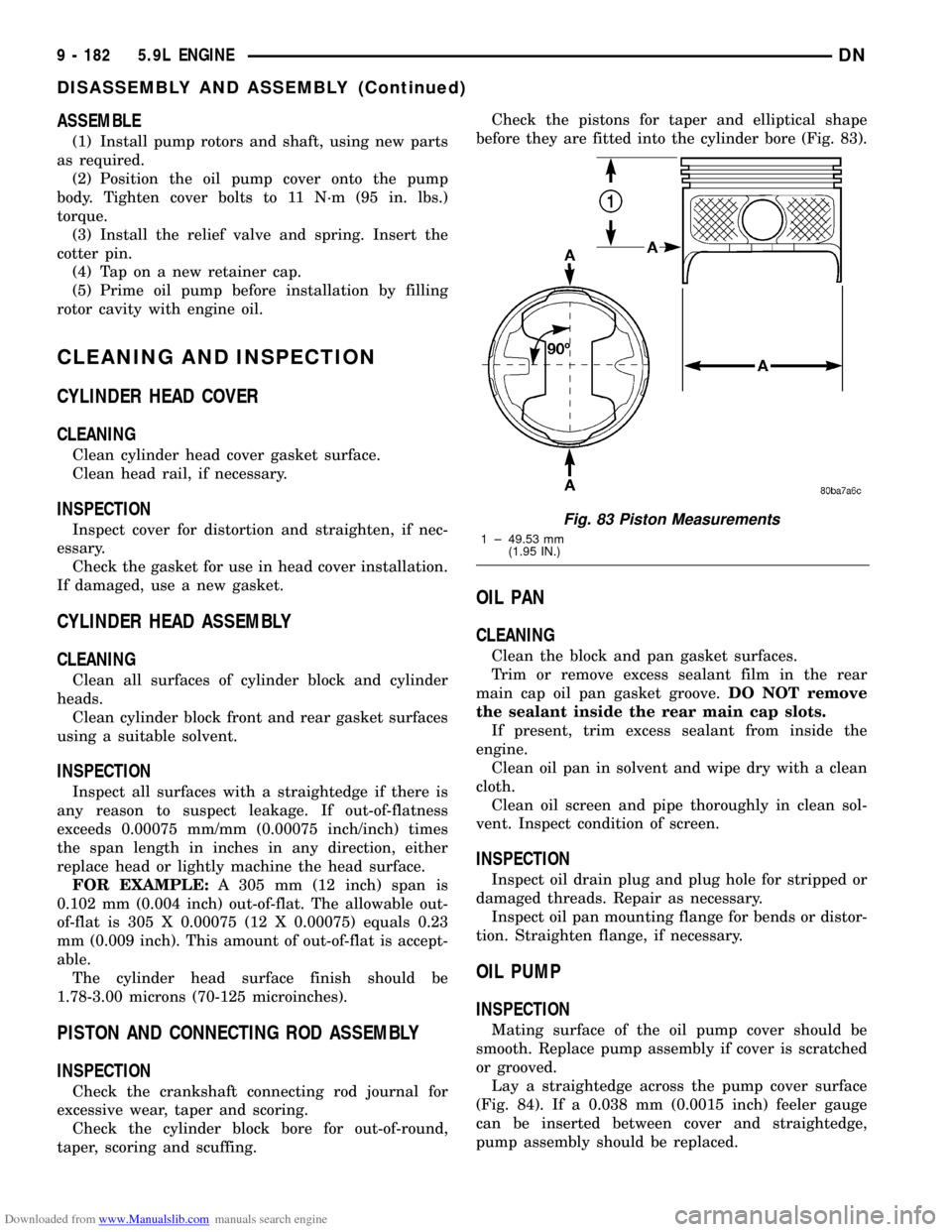

CRANKSHAFT OIL SEALÐFRONT

The oil seal can be replaced without removing the

timing chain cover provided the cover is not mis-

aligned.

(1) Disconnect the negative cable from the battery.

(2) Remove vibration damper.

(3) If front seal is suspected of leaking, check front

oil seal alignment to crankshaft. The seal installa-

tion/alignment tool 6635, should fit with minimum

interference. If tool does not fit, the cover must be

removed and installed properly.

(4) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal bore of cover.

(5) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 74). Seat

the oil seal in the groove of the tool.

(6) Position the seal and tool onto the crankshaft

(Fig. 75).

(7) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft

(Fig. 76).

(8) Remove the vibration damper bolt and seal

installation tool.

(9) Inspect the seal flange on the vibration

damper.

(10) Install the vibration damper.

(11) Connect the negative cable to the battery.

Fig. 74 Placing Oil Seal on Installation Tool 6635

1 ± CRANKSHAFT FRONT OIL SEAL

2 ± INSTALL THIS END INTO SPECIAL TOOL 6635

Fig. 75 Position Tool and Seal onto Crankshaft

1 ± SPECIAL TOOL 6635

2 ± OIL SEAL

3 ± TIMING CHAIN COVER

Fig. 76 Installing Oil Seal

1 ± SPECIAL TOOL 6635

2 ± TIMING CHAIN COVER

9 - 178 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 183 of 193

Downloaded from www.Manualslib.com manuals search engine ASSEMBLE

(1) Install pump rotors and shaft, using new parts

as required.

(2) Position the oil pump cover onto the pump

body. Tighten cover bolts to 11 N´m (95 in. lbs.)

torque.

(3) Install the relief valve and spring. Insert the

cotter pin.

(4) Tap on a new retainer cap.

(5) Prime oil pump before installation by filling

rotor cavity with engine oil.

CLEANING AND INSPECTION

CYLINDER HEAD COVER

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec-

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

CYLINDER HEAD ASSEMBLY

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075 mm/mm (0.00075 inch/inch) times

the span length in inches in any direction, either

replace head or lightly machine the head surface.

FOR EXAMPLE:A 305 mm (12 inch) span is

0.102 mm (0.004 inch) out-of-flat. The allowable out-

of-flat is 305 X 0.00075 (12 X 0.00075) equals 0.23

mm (0.009 inch). This amount of out-of-flat is accept-

able.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

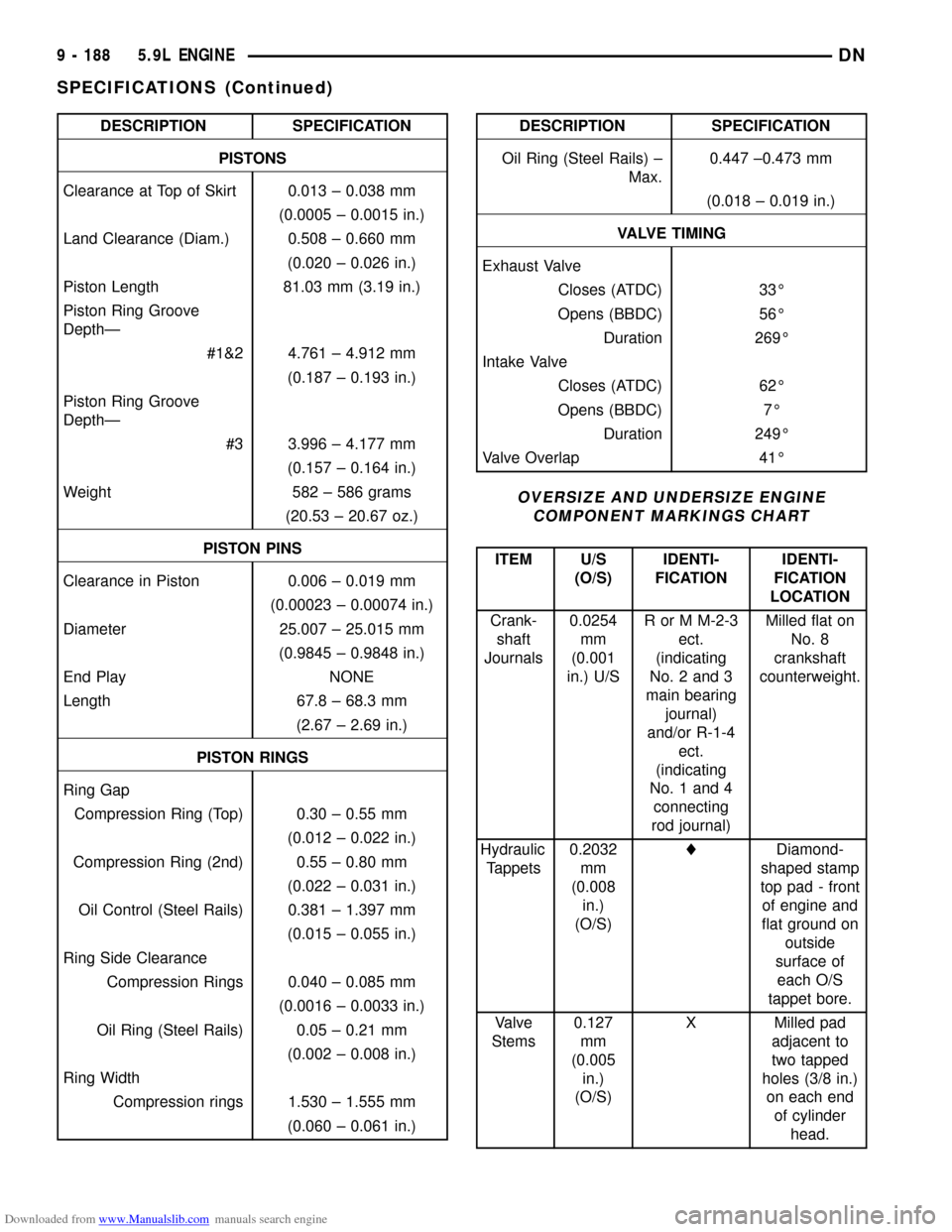

PISTON AND CONNECTING ROD ASSEMBLY

INSPECTION

Check the crankshaft connecting rod journal for

excessive wear, taper and scoring.

Check the cylinder block bore for out-of-round,

taper, scoring and scuffing.Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore (Fig. 83).

OIL PAN

CLEANING

Clean the block and pan gasket surfaces.

Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

OIL PUMP

INSPECTION

Mating surface of the oil pump cover should be

smooth. Replace pump assembly if cover is scratched

or grooved.

Lay a straightedge across the pump cover surface

(Fig. 84). If a 0.038 mm (0.0015 inch) feeler gauge

can be inserted between cover and straightedge,

pump assembly should be replaced.

Fig. 83 Piston Measurements

1 ± 49.53 mm

(1.95 IN.)

9 - 182 5.9L ENGINEDN

DISASSEMBLY AND ASSEMBLY (Continued)

Page 189 of 193

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

PISTONS

Clearance at Top of Skirt 0.013 ± 0.038 mm

(0.0005 ± 0.0015 in.)

Land Clearance (Diam.) 0.508 ± 0.660 mm

(0.020 ± 0.026 in.)

Piston Length 81.03 mm (3.19 in.)

Piston Ring Groove

DepthÐ

#1&2 4.761 ± 4.912 mm

(0.187 ± 0.193 in.)

Piston Ring Groove

DepthÐ

#3 3.996 ± 4.177 mm

(0.157 ± 0.164 in.)

Weight 582 ± 586 grams

(20.53 ± 20.67 oz.)

PISTON PINS

Clearance in Piston 0.006 ± 0.019 mm

(0.00023 ± 0.00074 in.)

Diameter 25.007 ± 25.015 mm

(0.9845 ± 0.9848 in.)

End Play NONE

Length 67.8 ± 68.3 mm

(2.67 ± 2.69 in.)

PISTON RINGS

Ring Gap

Compression Ring (Top) 0.30 ± 0.55 mm

(0.012 ± 0.022 in.)

Compression Ring (2nd) 0.55 ± 0.80 mm

(0.022 ± 0.031 in.)

Oil Control (Steel Rails) 0.381 ± 1.397 mm

(0.015 ± 0.055 in.)

Ring Side Clearance

Compression Rings 0.040 ± 0.085 mm

(0.0016 ± 0.0033 in.)

Oil Ring (Steel Rails) 0.05 ± 0.21 mm

(0.002 ± 0.008 in.)

Ring Width

Compression rings 1.530 ± 1.555 mm

(0.060 ± 0.061 in.)DESCRIPTION SPECIFICATION

Oil Ring (Steel Rails) ±

Max.0.447 ±0.473 mm

(0.018 ± 0.019 in.)

VALVE TIMING

Exhaust Valve

Closes (ATDC) 33É

Opens (BBDC) 56É

Duration 269É

Intake Valve

Closes (ATDC) 62É

Opens (BBDC) 7É

Duration 249É

Valve Overlap 41É

OVERSIZE AND UNDERSIZE ENGINE

COMPONENT MARKINGS CHART

ITEM U/S

(O/S)IDENTI-

FICATIONIDENTI-

FICATION

LOCATION

Crank-

shaft

Journals0.0254

mm

(0.001

in.) U/SR or M M-2-3

ect.

(indicating

No. 2 and 3

main bearing

journal)

and/or R-1-4

ect.

(indicating

No. 1 and 4

connecting

rod journal)Milled flat on

No. 8

crankshaft

counterweight.

Hydraulic

Tappets0.2032

mm

(0.008

in.)

(O/S)lDiamond-

shaped stamp

top pad - front

of engine and

flat ground on

outside

surface of

each O/S

tappet bore.

Valve

Stems0.127

mm

(0.005

in.)

(O/S)X Milled pad

adjacent to

two tapped

holes (3/8 in.)

on each end

of cylinder

head.

9 - 188 5.9L ENGINEDN

SPECIFICATIONS (Continued)