Group 8D DODGE DURANGO 1999 1.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: DURANGO, Model: DODGE DURANGO 1999 1.GPages: 193, PDF Size: 5.65 MB

Page 163 of 193

Downloaded from www.Manualslib.com manuals search engine (15) Discharge the air conditioning system, if

equipped. Refer to HEATING and AIR CONDITION-

ING.

(16) Disconnect the air conditioning hoses.

(17) Disconnect the power steering hoses, if

equipped.

(18) Remove starter motor. Refer to STARTING

SYSTEMS.

(19) Remove the generator.

(20) Raise and support the vehicle on a hoist.

(21) Disconnect exhaust pipe at manifold.

(22) Remove Transmission. Refer to TRANSMIS-

SIONS.

CAUTION: DO NOT lift the engine by the intake

manifold.

(23) Install an engine lifting fixture.

(24)2WD VEHICLESÐRemove engine front

mount bolts.

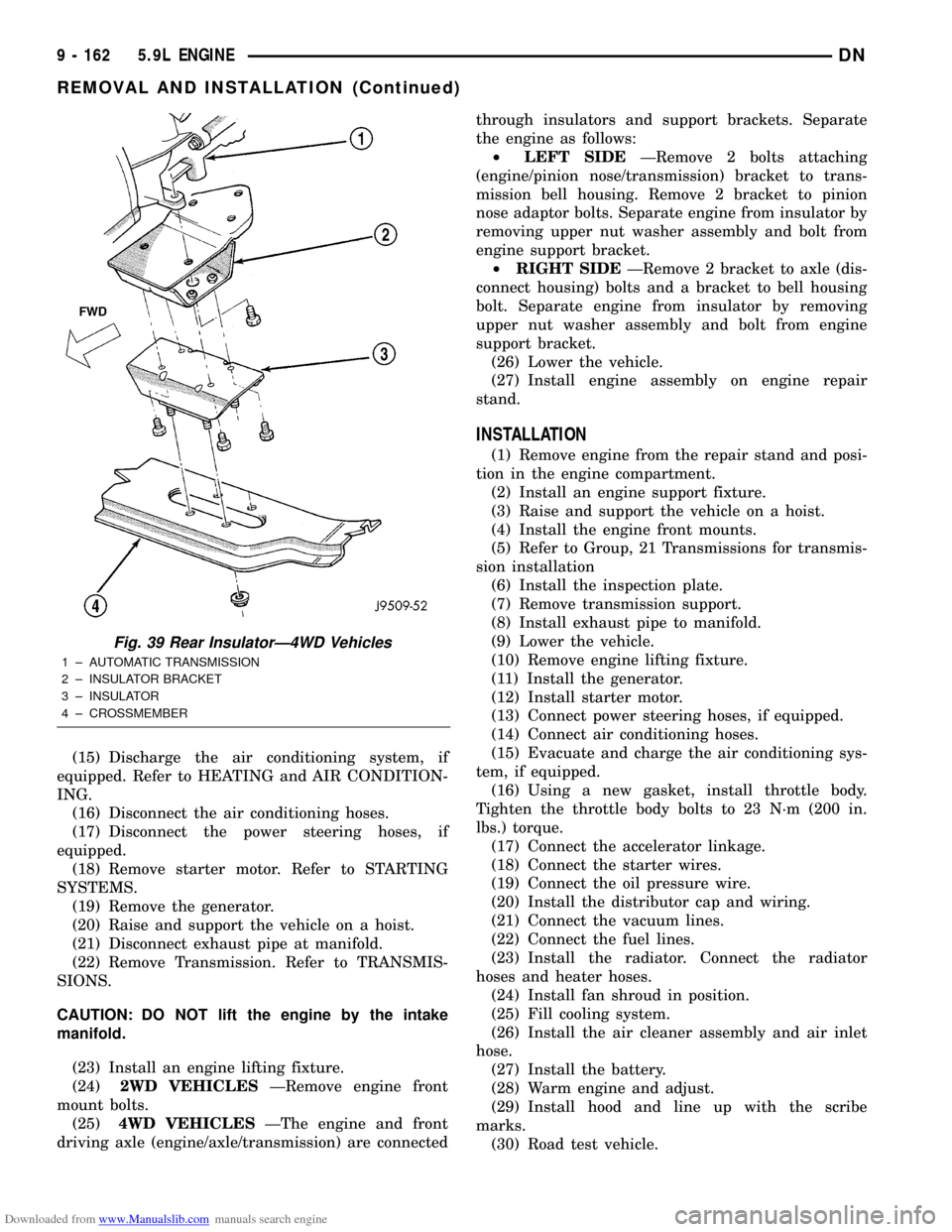

(25)4WD VEHICLESÐThe engine and front

driving axle (engine/axle/transmission) are connectedthrough insulators and support brackets. Separate

the engine as follows:

²LEFT SIDEÐRemove 2 bolts attaching

(engine/pinion nose/transmission) bracket to trans-

mission bell housing. Remove 2 bracket to pinion

nose adaptor bolts. Separate engine from insulator by

removing upper nut washer assembly and bolt from

engine support bracket.

²RIGHT SIDEÐRemove 2 bracket to axle (dis-

connect housing) bolts and a bracket to bell housing

bolt. Separate engine from insulator by removing

upper nut washer assembly and bolt from engine

support bracket.

(26) Lower the vehicle.

(27) Install engine assembly on engine repair

stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install the engine front mounts.

(5) Refer to Group, 21 Transmissions for transmis-

sion installation

(6) Install the inspection plate.

(7) Remove transmission support.

(8) Install exhaust pipe to manifold.

(9) Lower the vehicle.

(10) Remove engine lifting fixture.

(11) Install the generator.

(12) Install starter motor.

(13) Connect power steering hoses, if equipped.

(14) Connect air conditioning hoses.

(15) Evacuate and charge the air conditioning sys-

tem, if equipped.

(16) Using a new gasket, install throttle body.

Tighten the throttle body bolts to 23 N´m (200 in.

lbs.) torque.

(17) Connect the accelerator linkage.

(18) Connect the starter wires.

(19) Connect the oil pressure wire.

(20) Install the distributor cap and wiring.

(21) Connect the vacuum lines.

(22) Connect the fuel lines.

(23) Install the radiator. Connect the radiator

hoses and heater hoses.

(24) Install fan shroud in position.

(25) Fill cooling system.

(26) Install the air cleaner assembly and air inlet

hose.

(27) Install the battery.

(28) Warm engine and adjust.

(29) Install hood and line up with the scribe

marks.

(30) Road test vehicle.

Fig. 39 Rear InsulatorÐ4WD Vehicles

1 ± AUTOMATIC TRANSMISSION

2 ± INSULATOR BRACKET

3 ± INSULATOR

4 ± CROSSMEMBER

9 - 162 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 170 of 193

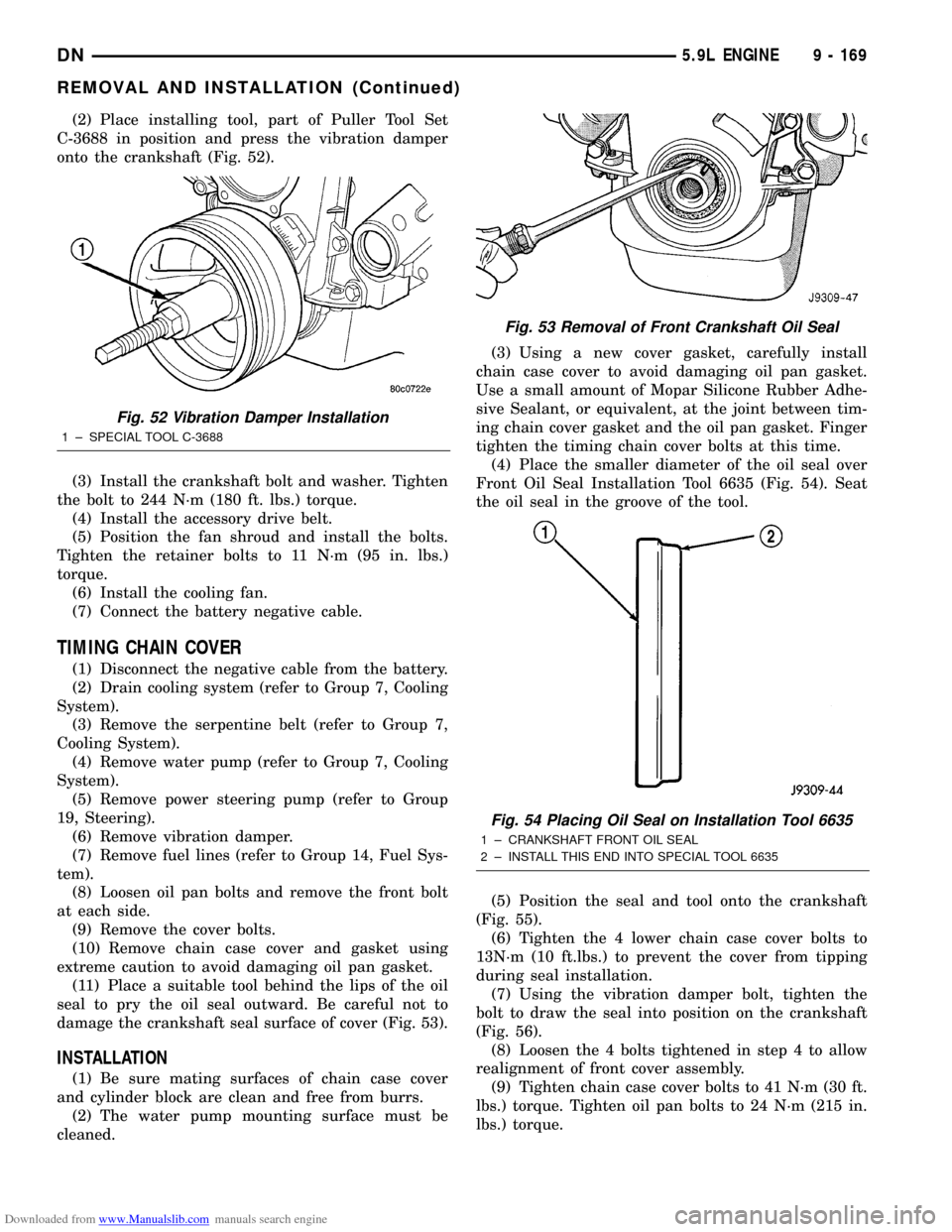

Downloaded from www.Manualslib.com manuals search engine (2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 52).

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 244 N´m (180 ft. lbs.) torque.

(4) Install the accessory drive belt.

(5) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N´m (95 in. lbs.)

torque.

(6) Install the cooling fan.

(7) Connect the battery negative cable.

TIMING CHAIN COVER

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (refer to Group 7, Cooling

System).

(3) Remove the serpentine belt (refer to Group 7,

Cooling System).

(4) Remove water pump (refer to Group 7, Cooling

System).

(5) Remove power steering pump (refer to Group

19, Steering).

(6) Remove vibration damper.

(7) Remove fuel lines (refer to Group 14, Fuel Sys-

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9) Remove the cover bolts.

(10) Remove chain case cover and gasket using

extreme caution to avoid damaging oil pan gasket.

(11) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 53).

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

(2) The water pump mounting surface must be

cleaned.(3) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of Mopar Silicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

(4) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 54). Seat

the oil seal in the groove of the tool.

(5) Position the seal and tool onto the crankshaft

(Fig. 55).

(6) Tighten the 4 lower chain case cover bolts to

13N´m (10 ft.lbs.) to prevent the cover from tipping

during seal installation.

(7) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft

(Fig. 56).

(8) Loosen the 4 bolts tightened in step 4 to allow

realignment of front cover assembly.

(9) Tighten chain case cover bolts to 41 N´m (30 ft.

lbs.) torque. Tighten oil pan bolts to 24 N´m (215 in.

lbs.) torque.

Fig. 52 Vibration Damper Installation

1 ± SPECIAL TOOL C-3688

Fig. 53 Removal of Front Crankshaft Oil Seal

Fig. 54 Placing Oil Seal on Installation Tool 6635

1 ± CRANKSHAFT FRONT OIL SEAL

2 ± INSTALL THIS END INTO SPECIAL TOOL 6635

DN5.9L ENGINE 9 - 169

REMOVAL AND INSTALLATION (Continued)

Page 171 of 193

Downloaded from www.Manualslib.com manuals search engine (10) Remove the vibration damper bolt and seal

installation tool.

(11) Install vibration damper.(12) Install water pump and housing assembly

using new gaskets (refer to Group 7, Cooling Sys-

tem). Tighten bolts to 41 N´m (30 ft. lbs.) torque.

(13) Install power steering pump (refer to Group

19, Steering).

(14) Install the serpentine belt (refer to Group 7,

Cooling System).

(15) Install the cooling system fan. Tighten the

bolts to 23 N´m (17 ft. lbs.) torque.

(16) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(17) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure).

(18) Connect the negative cable to the battery.

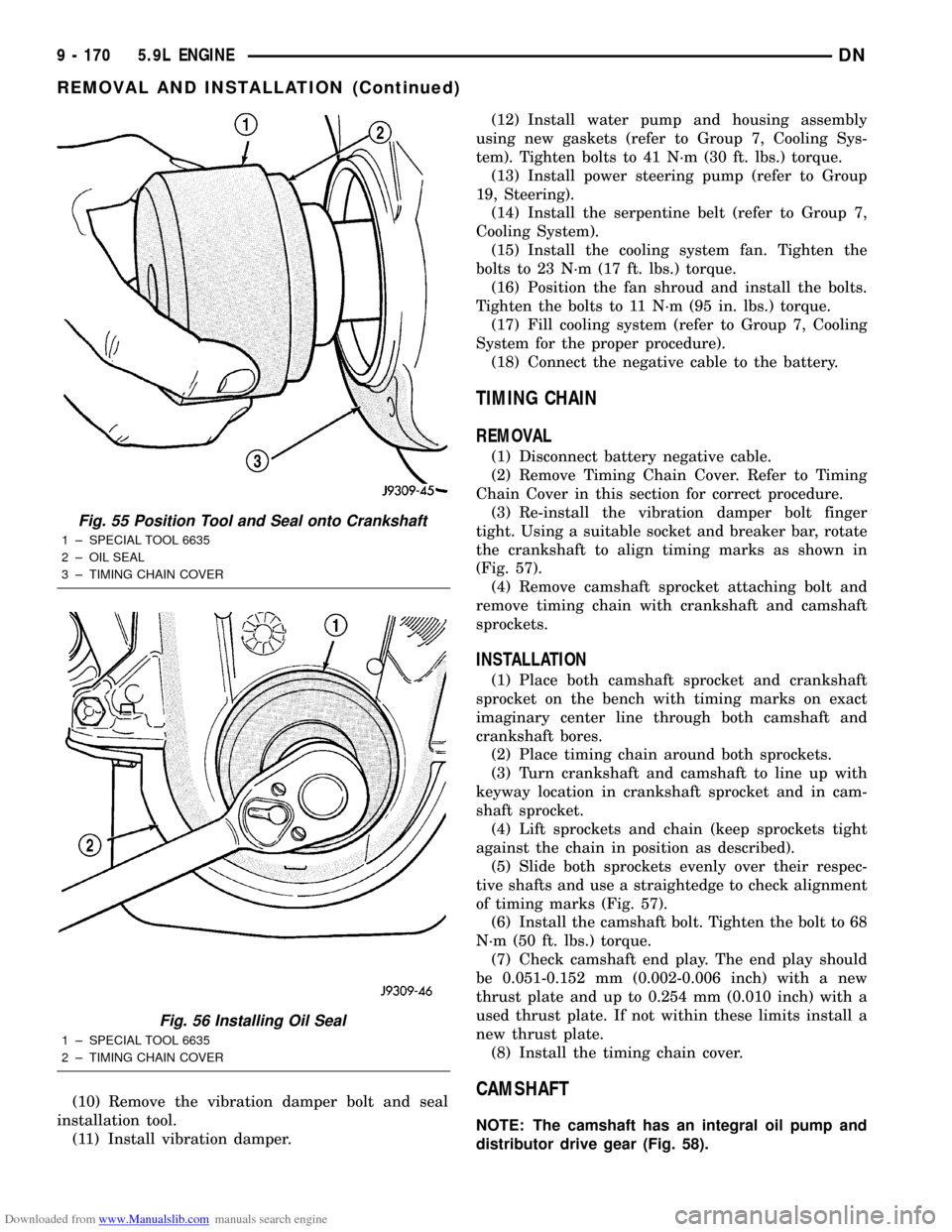

TIMING CHAIN

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove Timing Chain Cover. Refer to Timing

Chain Cover in this section for correct procedure.

(3) Re-install the vibration damper bolt finger

tight. Using a suitable socket and breaker bar, rotate

the crankshaft to align timing marks as shown in

(Fig. 57).

(4) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

INSTALLATION

(1) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(2) Place timing chain around both sprockets.

(3) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(4) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(5) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 57).

(6) Install the camshaft bolt. Tighten the bolt to 68

N´m (50 ft. lbs.) torque.

(7) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

(8) Install the timing chain cover.

CAMSHAFT

NOTE: The camshaft has an integral oil pump and

distributor drive gear (Fig. 58).

Fig. 55 Position Tool and Seal onto Crankshaft

1 ± SPECIAL TOOL 6635

2 ± OIL SEAL

3 ± TIMING CHAIN COVER

Fig. 56 Installing Oil Seal

1 ± SPECIAL TOOL 6635

2 ± TIMING CHAIN COVER

9 - 170 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 172 of 193

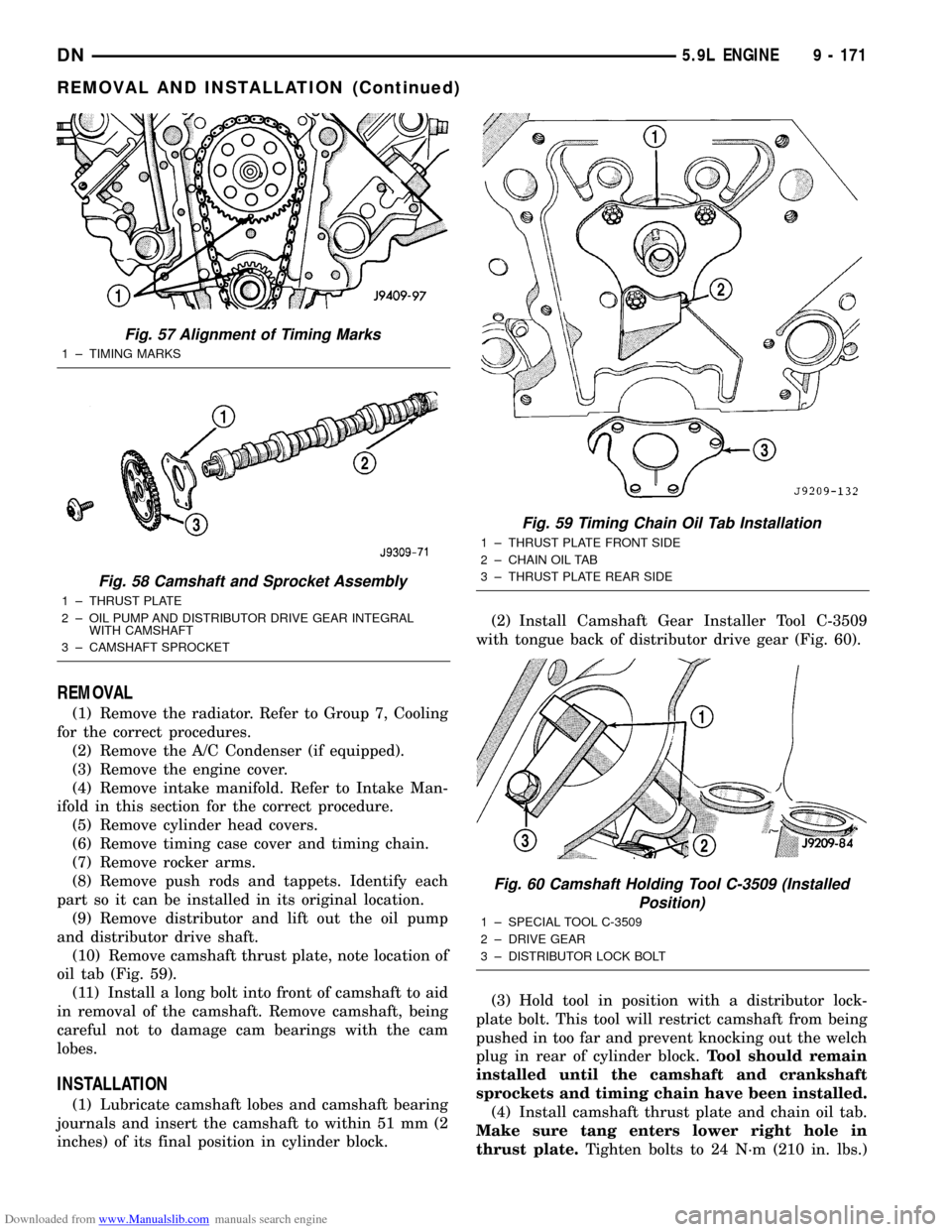

Downloaded from www.Manualslib.com manuals search engine REMOVAL

(1) Remove the radiator. Refer to Group 7, Cooling

for the correct procedures.

(2) Remove the A/C Condenser (if equipped).

(3) Remove the engine cover.

(4) Remove intake manifold. Refer to Intake Man-

ifold in this section for the correct procedure.

(5) Remove cylinder head covers.

(6) Remove timing case cover and timing chain.

(7) Remove rocker arms.

(8) Remove push rods and tappets. Identify each

part so it can be installed in its original location.

(9) Remove distributor and lift out the oil pump

and distributor drive shaft.

(10) Remove camshaft thrust plate, note location of

oil tab (Fig. 59).

(11) Install a long bolt into front of camshaft to aid

in removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSTALLATION

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft to within 51 mm (2

inches) of its final position in cylinder block.(2) Install Camshaft Gear Installer Tool C-3509

with tongue back of distributor drive gear (Fig. 60).

(3) Hold tool in position with a distributor lock-

plate bolt. This tool will restrict camshaft from being

pushed in too far and prevent knocking out the welch

plug in rear of cylinder block.Tool should remain

installed until the camshaft and crankshaft

sprockets and timing chain have been installed.

(4) Install camshaft thrust plate and chain oil tab.

Make sure tang enters lower right hole in

thrust plate.Tighten bolts to 24 N´m (210 in. lbs.)

Fig. 57 Alignment of Timing Marks

1 ± TIMING MARKS

Fig. 58 Camshaft and Sprocket Assembly

1 ± THRUST PLATE

2 ± OIL PUMP AND DISTRIBUTOR DRIVE GEAR INTEGRAL

WITH CAMSHAFT

3 ± CAMSHAFT SPROCKET

Fig. 59 Timing Chain Oil Tab Installation

1 ± THRUST PLATE FRONT SIDE

2 ± CHAIN OIL TAB

3 ± THRUST PLATE REAR SIDE

Fig. 60 Camshaft Holding Tool C-3509 (Installed

Position)

1 ± SPECIAL TOOL C-3509

2 ± DRIVE GEAR

3 ± DISTRIBUTOR LOCK BOLT

DN5.9L ENGINE 9 - 171

REMOVAL AND INSTALLATION (Continued)

Page 173 of 193

Downloaded from www.Manualslib.com manuals search engine torque. Top edge of tab should be flat against thrust

plate in order to catch oil for chain lubrication.

(5) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(6) Place timing chain around both sprockets.

(7) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(8) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

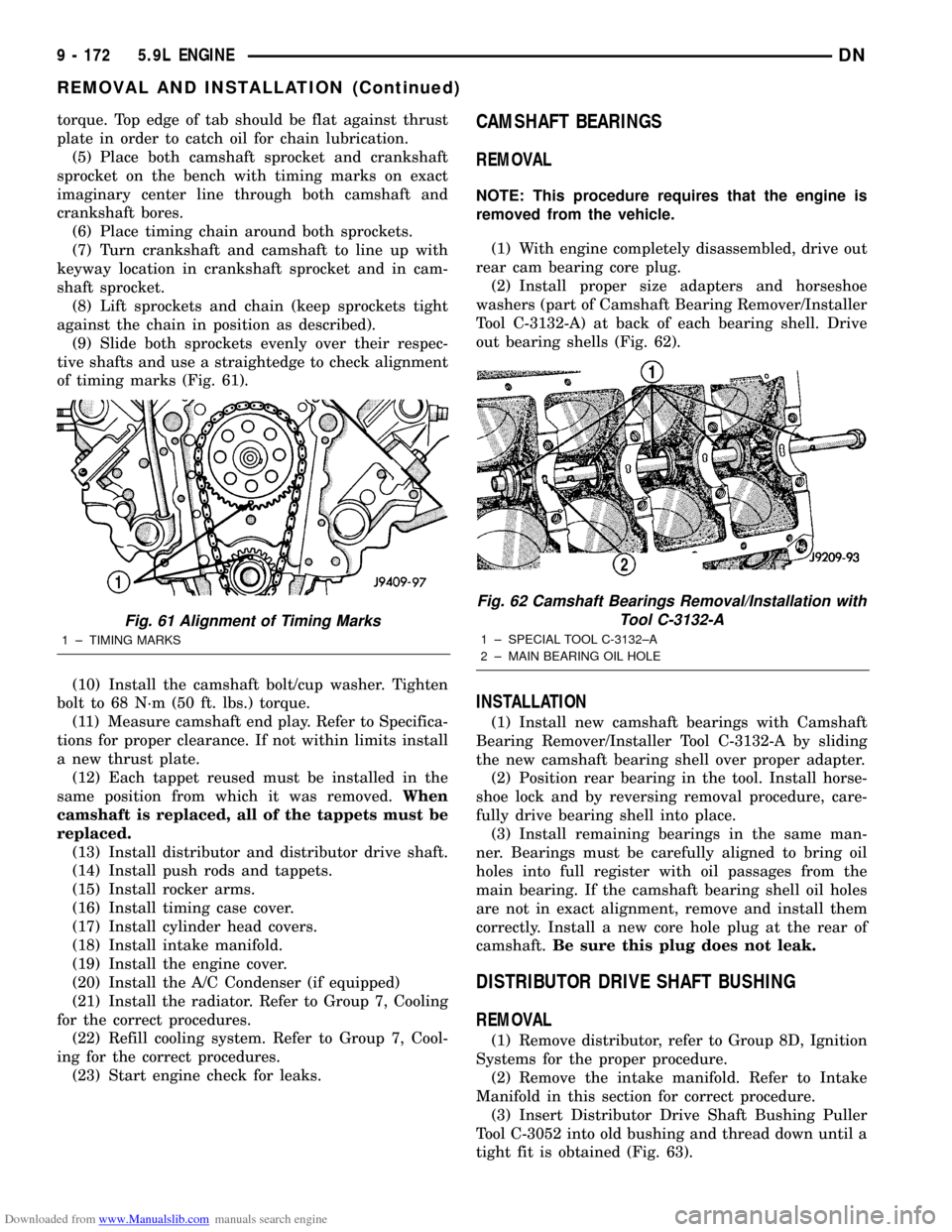

(9) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 61).

(10) Install the camshaft bolt/cup washer. Tighten

bolt to 68 N´m (50 ft. lbs.) torque.

(11) Measure camshaft end play. Refer to Specifica-

tions for proper clearance. If not within limits install

a new thrust plate.

(12) Each tappet reused must be installed in the

same position from which it was removed.When

camshaft is replaced, all of the tappets must be

replaced.

(13) Install distributor and distributor drive shaft.

(14) Install push rods and tappets.

(15) Install rocker arms.

(16) Install timing case cover.

(17) Install cylinder head covers.

(18) Install intake manifold.

(19) Install the engine cover.

(20) Install the A/C Condenser (if equipped)

(21) Install the radiator. Refer to Group 7, Cooling

for the correct procedures.

(22) Refill cooling system. Refer to Group 7, Cool-

ing for the correct procedures.

(23) Start engine check for leaks.CAMSHAFT BEARINGS

REMOVAL

NOTE: This procedure requires that the engine is

removed from the vehicle.

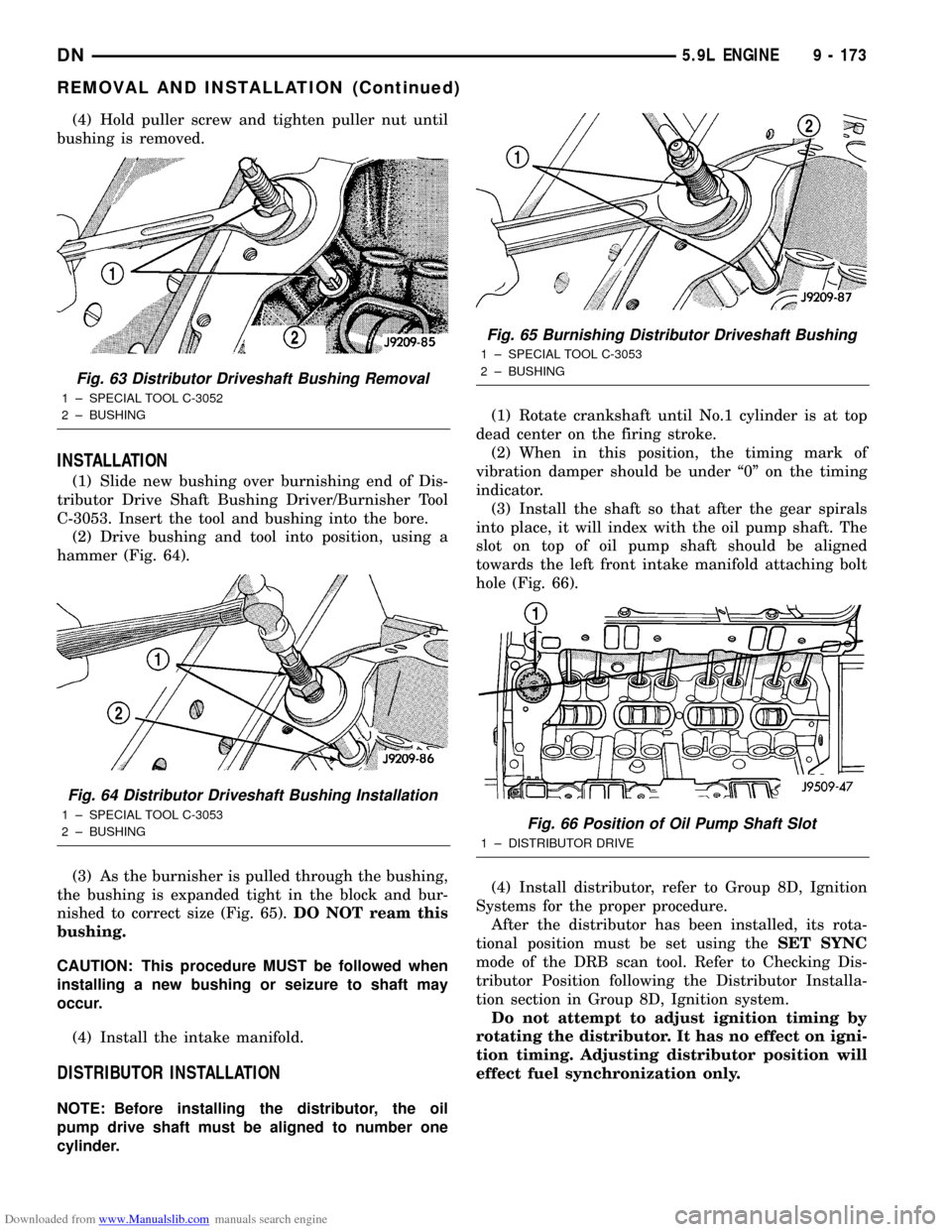

(1) With engine completely disassembled, drive out

rear cam bearing core plug.

(2) Install proper size adapters and horseshoe

washers (part of Camshaft Bearing Remover/Installer

Tool C-3132-A) at back of each bearing shell. Drive

out bearing shells (Fig. 62).

INSTALLATION

(1) Install new camshaft bearings with Camshaft

Bearing Remover/Installer Tool C-3132-A by sliding

the new camshaft bearing shell over proper adapter.

(2) Position rear bearing in the tool. Install horse-

shoe lock and by reversing removal procedure, care-

fully drive bearing shell into place.

(3) Install remaining bearings in the same man-

ner. Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the

main bearing. If the camshaft bearing shell oil holes

are not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft.Be sure this plug does not leak.

DISTRIBUTOR DRIVE SHAFT BUSHING

REMOVAL

(1) Remove distributor, refer to Group 8D, Ignition

Systems for the proper procedure.

(2) Remove the intake manifold. Refer to Intake

Manifold in this section for correct procedure.

(3) Insert Distributor Drive Shaft Bushing Puller

Tool C-3052 into old bushing and thread down until a

tight fit is obtained (Fig. 63).

Fig. 61 Alignment of Timing Marks

1 ± TIMING MARKS

Fig. 62 Camshaft Bearings Removal/Installation with

Tool C-3132-A

1 ± SPECIAL TOOL C-3132±A

2 ± MAIN BEARING OIL HOLE

9 - 172 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 174 of 193

Downloaded from www.Manualslib.com manuals search engine (4) Hold puller screw and tighten puller nut until

bushing is removed.

INSTALLATION

(1) Slide new bushing over burnishing end of Dis-

tributor Drive Shaft Bushing Driver/Burnisher Tool

C-3053. Insert the tool and bushing into the bore.

(2) Drive bushing and tool into position, using a

hammer (Fig. 64).

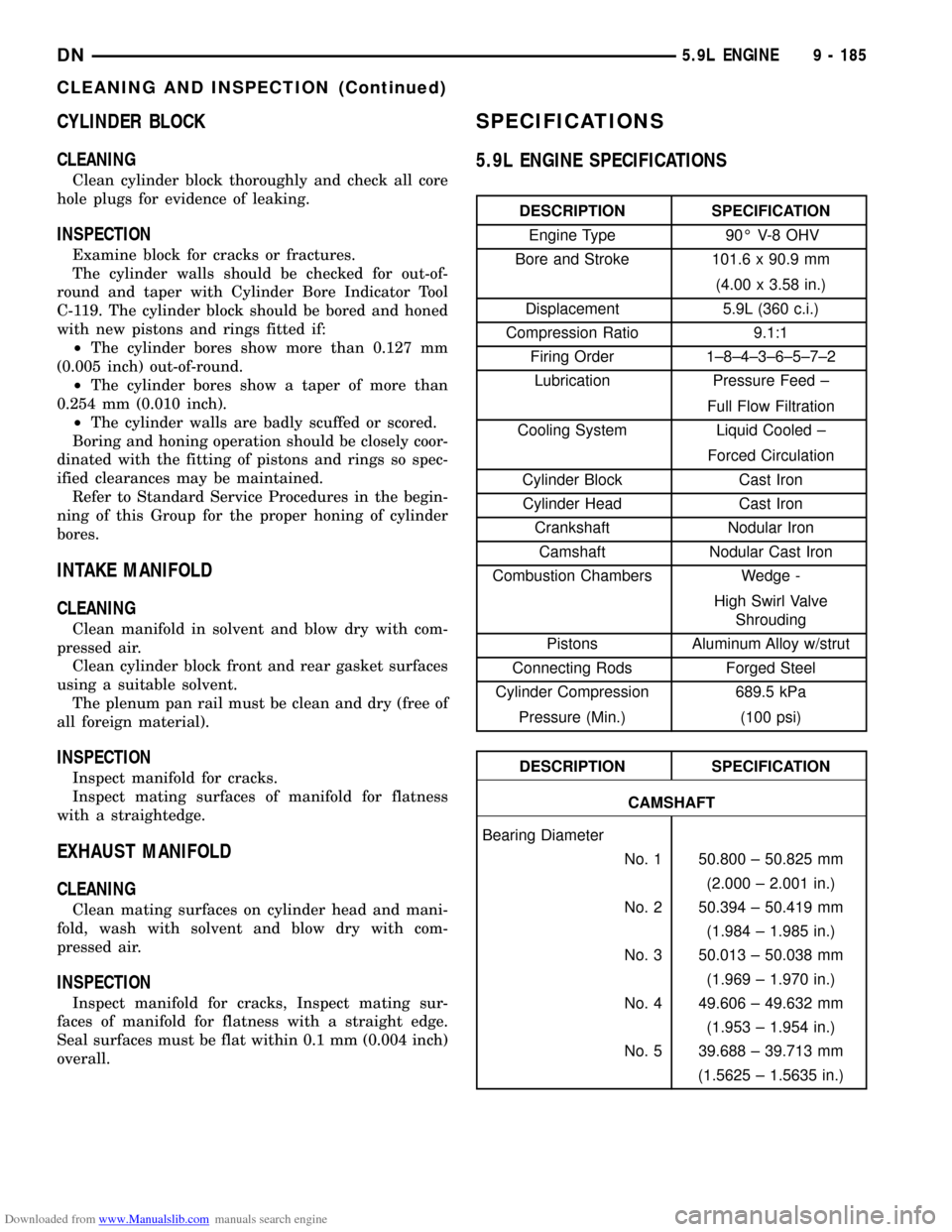

(3) As the burnisher is pulled through the bushing,

the bushing is expanded tight in the block and bur-

nished to correct size (Fig. 65).DO NOT ream this

bushing.

CAUTION: This procedure MUST be followed when

installing a new bushing or seizure to shaft may

occur.

(4) Install the intake manifold.

DISTRIBUTOR INSTALLATION

NOTE: Before installing the distributor, the oil

pump drive shaft must be aligned to number one

cylinder.(1) Rotate crankshaft until No.1 cylinder is at top

dead center on the firing stroke.

(2) When in this position, the timing mark of

vibration damper should be under ª0º on the timing

indicator.

(3) Install the shaft so that after the gear spirals

into place, it will index with the oil pump shaft. The

slot on top of oil pump shaft should be aligned

towards the left front intake manifold attaching bolt

hole (Fig. 66).

(4) Install distributor, refer to Group 8D, Ignition

Systems for the proper procedure.

After the distributor has been installed, its rota-

tional position must be set using theSET SYNC

mode of the DRB scan tool. Refer to Checking Dis-

tributor Position following the Distributor Installa-

tion section in Group 8D, Ignition system.

Do not attempt to adjust ignition timing by

rotating the distributor. It has no effect on igni-

tion timing. Adjusting distributor position will

effect fuel synchronization only.

Fig. 63 Distributor Driveshaft Bushing Removal

1 ± SPECIAL TOOL C-3052

2 ± BUSHING

Fig. 64 Distributor Driveshaft Bushing Installation

1 ± SPECIAL TOOL C-3053

2 ± BUSHING

Fig. 65 Burnishing Distributor Driveshaft Bushing

1 ± SPECIAL TOOL C-3053

2 ± BUSHING

Fig. 66 Position of Oil Pump Shaft Slot

1 ± DISTRIBUTOR DRIVE

DN5.9L ENGINE 9 - 173

REMOVAL AND INSTALLATION (Continued)

Page 186 of 193

Downloaded from www.Manualslib.com manuals search engine CYLINDER BLOCK

CLEANING

Clean cylinder block thoroughly and check all core

hole plugs for evidence of leaking.

INSPECTION

Examine block for cracks or fractures.

The cylinder walls should be checked for out-of-

round and taper with Cylinder Bore Indicator Tool

C-119. The cylinder block should be bored and honed

with new pistons and rings fitted if:

²The cylinder bores show more than 0.127 mm

(0.005 inch) out-of-round.

²The cylinder bores show a taper of more than

0.254 mm (0.010 inch).

²The cylinder walls are badly scuffed or scored.

Boring and honing operation should be closely coor-

dinated with the fitting of pistons and rings so spec-

ified clearances may be maintained.

Refer to Standard Service Procedures in the begin-

ning of this Group for the proper honing of cylinder

bores.

INTAKE MANIFOLD

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

EXHAUST MANIFOLD

CLEANING

Clean mating surfaces on cylinder head and mani-

fold, wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks, Inspect mating sur-

faces of manifold for flatness with a straight edge.

Seal surfaces must be flat within 0.1 mm (0.004 inch)

overall.

SPECIFICATIONS

5.9L ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Engine Type 90É V-8 OHV

Bore and Stroke 101.6 x 90.9 mm

(4.00 x 3.58 in.)

Displacement 5.9L (360 c.i.)

Compression Ratio 9.1:1

Firing Order 1±8±4±3±6±5±7±2

Lubrication Pressure Feed ±

Full Flow Filtration

Cooling System Liquid Cooled ±

Forced Circulation

Cylinder Block Cast Iron

Cylinder Head Cast Iron

Crankshaft Nodular Iron

Camshaft Nodular Cast Iron

Combustion Chambers Wedge -

High Swirl Valve

Shrouding

Pistons Aluminum Alloy w/strut

Connecting Rods Forged Steel

Cylinder Compression 689.5 kPa

Pressure (Min.) (100 psi)

DESCRIPTION SPECIFICATION

CAMSHAFT

Bearing Diameter

No. 1 50.800 ± 50.825 mm

(2.000 ± 2.001 in.)

No. 2 50.394 ± 50.419 mm

(1.984 ± 1.985 in.)

No. 3 50.013 ± 50.038 mm

(1.969 ± 1.970 in.)

No. 4 49.606 ± 49.632 mm

(1.953 ± 1.954 in.)

No. 5 39.688 ± 39.713 mm

(1.5625 ± 1.5635 in.)

DN5.9L ENGINE 9 - 185

CLEANING AND INSPECTION (Continued)