adjuster DODGE DURANGO 1999 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: DURANGO, Model: DODGE DURANGO 1999 1.GPages: 193, PDF Size: 5.65 MB

Page 1 of 193

Downloaded from www.Manualslib.com manuals search engine ENGINE

TABLE OF CONTENTS

page page

4.7L ENGINE.............................. 1

5.2L ENGINE............................. 865.9L ENGINE............................ 135

4.7L ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE.................................2

ENGINE LUBRICATION SYSTEM..............3

CYLINDER BLOCK.........................5

CRANKSHAFT............................5

PISTON AND CONNECTING ROD.............5

CYLINDER HEAD..........................5

VALVE GUIDES...........................5

VALVES.................................5

VALVE STEM SEAL........................5

VALVE SPRING...........................6

HYDRAULIC LASH ADJUSTER...............6

TIMING DRIVE SYSTEM....................6

CAMSHAFT..............................6

ROCKER ARM............................6

CYLINDER HEAD COVER...................6

OILPAN.................................7

STRUCTURAL DUST COVER................7

INTAKE MANIFOLD........................7

EXHAUST MANIFOLD......................7

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐINTRODUCTION.........7

SERVICE DIAGNOSISÐPERFORMANCE.......8

SERVICE DIAGNOSISÐMECHANICAL.........10

SERVICE DIAGNOSISÐLUBRICATION.........11

INTAKE MANIFOLD LEAKAGE DIAGNOSIS.....11

CYLINDER COMPRESSION PRESSURE TEST . . 11

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS...........................12

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST........................12

ENGINE OIL LEAK INSPECTION.............13

REAR SEAL AREA LEAKSÐINSPECTION......14

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS...........................14

CHECKING ENGINE OIL PRESSURE..........15SERVICE PROCEDURES

FORM-IN-PLACE GASKETS.................15

ENGINE OIL.............................16

REPAIR DAMAGED OR WORN THREADS......17

CYLINDER BOREÐHONING................18

HYDROSTATIC LOCK.....................18

VALVE SERVICE.........................19

ENGINE TIMINGÐVERIFICATION............19

TIMING CHAINÐMEASURING WEAR.........22

PISTONSÐFITTING.......................22

PISTON RINGSÐFITTING..................24

CONNECTING ROD BEARINGSÐFITTING.....25

CRANKSHAFT MAIN BEARINGS.............27

REMOVAL AND INSTALLATION

ENGINE MOUNTSÐLEFT AND RIGHT.........28

ENGINE MOUNTÐREAR...................29

STRUCTURAL COVER.....................30

ENGINE ASSEMBLY.......................31

INTAKE MANIFOLD.......................35

EXHAUST MANIFOLDS....................36

CYLINDER HEAD COVER..................38

ROCKER ARMS..........................40

CYLINDER HEADS........................41

VALVE SPRINGS AND SEALS...............46

HYDRAULIC LASH ADJUSTER..............46

CRANKSHAFT DAMPER...................47

TIMING CHAIN COVER....................48

TIMING CHAIN AND SPROCKETS............49

IDLER SHAFTÐTIMING DRIVE..............55

CAMSHAFTSÐIN VEHICLE.................56

CRANKSHAFT MAIN BEARINGS.............61

OIL PAN 4X2 VEHICLE.....................61

OIL PAN 4X4 VEHICLE.....................64

PISTON AND CONNECTING ROD............65

CRANKSHAFT...........................67

FLEXPLATE.............................69

DNENGINE 9 - 1

Page 3 of 193

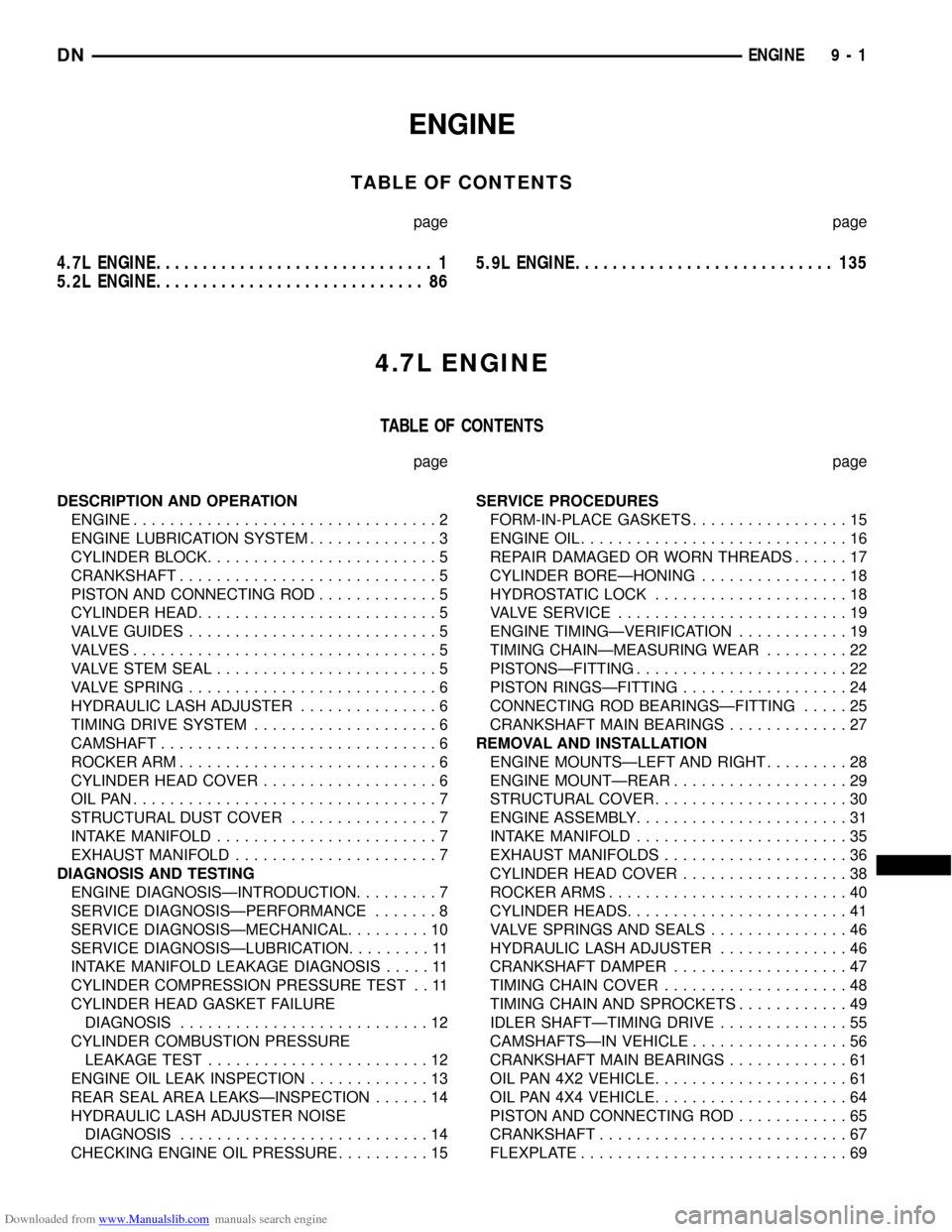

Downloaded from www.Manualslib.com manuals search engine firing order is 1±8±4±3±6±5±7±2. The engine serial

number is located at the right front side of the

engine block (Fig. 1)

ENGINE LUBRICATION SYSTEM

DESCRIPTION

The lubrication system (Fig. 2) is a full flow filtra-

tion pressure feed type.

OPERATION

Oil from the oil pan is pumped by a gerotor type oil

pump directly mounted to the crankshaft nose. Oil

pressure is controlled by a relief valve mounted

inside the oil pump housing. For lubrication flow

refer to (Fig. 2).

The camshaft exhaust valve lobes and rocker arms

are lubricated through a small hole in the rocker

arm; oil flows through the lash adjuster then through

the rocker arm and onto the camshaft lobe. Due to

the orentation of the rocker arm, the camshaft intake

lobes are not lubed in the same manner as the

exhaust lobes. The intake lobes are lubed through

internal passages in the camshaft. Oil flows through

a bore in the number 3 camshaft bearing bore, and

as the camshaft turns, a hole in the camshaft aligns

with the hole in the camshaft bore allowing engine

oil to enter the camshaft tube. The oil then exits

through 1.6mm (0.063 in.) holes drilled into theintake lobes, lubricating the lobes and the rocker

arms.

ENGINE LUBRICATION FLOW CHARTÐBLOCK: TABLE 1

FROM TO

Oil Pickup Tube Oil Pump

Oil Pump Oil Filter

Oil Filter Block Main Oil Gallery

Block Main Oil Gallery 1. Crankshaft Main Journal

2. Left Cylinder Head*

3. Right Cylinder Head*

Crankshaft Main Journals Crankshaft Rod Journals

Crankshaft Number One Main Journal 1.Front Timing Chain Idler Shaft

2. Both Secondary Chain Tensioners

Left Cylinder Head See Table 2

Right Cylinder Head See Table 2

* The cylinder head

gaskets have an oil restricter to control oil flow to the cylinder heads.

Fig. 1 Engine Identification Location.

1 ± VEHICLE VIN NUMBER LOCATION

2 ± CYLINDER BLOCK RIGHT HAND SIDE

3 ± CYLINDER BORE #2

DN4.7L ENGINE 9 - 3

DESCRIPTION AND OPERATION (Continued)

Page 5 of 193

Downloaded from www.Manualslib.com manuals search engine ENGINE LUBRICATION FLOW CHARTÐCYLINDER HEADS: TABLE 2

FROM TO

Cylinder Head Oil Port (in bolt hole) Diagonal Cross Drilling to Main Oil Gallery

Main Oil Gallery (drilled through head from rear to front)1. Base of Camshaft Towers

2. Lash Adjuster Towers

Base of Camshaft Towers Vertical Drilling Through Tower to Camshaft Bearings**

Lash Adjuster Towers Diagonal Drillings to Hydraulic Lash Adjuster Pockets

** The number three camshaft bearing journal feeds oil into the hollow camshaft tubes. Oil is routed to the intake

lobes, which have oil passages drilled into them to lubricate the rocker arms.

CYLINDER BLOCK

DESCRIPTION

The cylinder block is made of cast iron. The block

is a closed deck design with the left bank forward. To

provide high rigidity and improved NVH an

enhanced compacted graphite bedplate is bolted to

the block. The block design allows coolant flow

between the cylinders bores, and an internal coolant

bypass to a single poppet inlet thermostat is included

in the cast aluminum front cover.

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design

with eight counterweights for balancing purposes.

The crankshaft is supported by five select main bear-

ings with the number three serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The number eight counterweight has provisions for

crankshaft position sensor target wheel mounting.

The select fit main bearing markings are located on

the rear side of the target wheel. The crankshaft oil

seals are one piece design. The front oil seal is

retained in the timing chain cover, and the rear seal

is pressed in to a bore formed by the cylinder block

and the bedplate assembly.

PISTON AND CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark con-

necting rods as damage may result, instead use ink

or a scratch awl.

EARLY BUILD

The pistons are made of a high strength aluminum

alloy with an anodized top ring groove and crown. Piston

skirts are coated with a solid lubricant (Molykote) to

reduce friction and provide scuff resistance. The connect-

ing rods are made of forged powdered metal, with a

ªfractured capº design. A pressed fit piston pin is used to

attach the piston and connecting rod.

LATE BUILD

The pistons are made of high strength aluminum

alloy. The top ring groove and crown areNotanod-

ized, instead the top ring is coated with an anti-scuff

coating to reduce friction on the top ring. The piston

skirts are coated with a solid lubricant (Molykote) to

reduce friction and provide scuff resistance. The con-

necting rods are made of forged powdered metal,

with a ªfractured capº design. A pressed fit piston pin

is used to attach the piston and connecting rod.

CYLINDER HEAD

DESCRIPTION

The cylinder heads are made of an aluminum alloy.

The cylinder head features two valves per cylinder

with pressed in powdered metal valve guides. The

cylinder heads also provide enclosures for the timing

chain drain, necessitating unique left and right cylin-

der heads.

VALVE GUIDES

DESCRIPTION

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

VALVES

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

VALVE STEM SEAL

DESCRIPTION

The valve stem seals are made of rubber and incor-

porate an integral steel valve spring seat. The inte-

gral garter spring maintains consistent lubrication

control to the valve stems.

DN4.7L ENGINE 9 - 5

DESCRIPTION AND OPERATION (Continued)

2000 DN Service Manual

Publication No. 81-370-0016

TSB 26-12-99 December, 1999

Page 6 of 193

Downloaded from www.Manualslib.com manuals search engine VALVE SPRING

DESCRIPTION

The valve springs are made from high strength

chrome silicon steel. The springs are common for

intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which is a

positive type seal to control lubrication.

HYDRAULIC LASH ADJUSTER

DESCRIPTION

Valve lash is controlled by hydraulic lash adjusters

that are stationary mounted in the cylinder heads.

The lash adjusters have a hole in the ball plunger

that feeds oil through the rocker arm squirt holes for

rocker arm roller and camshaft lobe lubrication.

TIMING DRIVE SYSTEM

DESCRIPTION

The timing drive system has been designed to pro-

vide quiet performance and reliability to support a

non-free wheelingengine. Specifically the intake

valves are non-free wheeling and can be easily dam-

aged with forceful engine rotation if camshaft-to-

crankshaft timing is incorrect. The timing drive

system consists of a primary chain and two second-

ary timing chain drives.

OPERATION

The primary timing chain is a single inverted tooth

type. The primary chain drives the large fifty tooth

idler sprocket directly from a 25 tooth crankshaft

sprocket. Primary chain motion is controlled by a

pivoting leaf spring tensioner arm and a fixed guide.

The arm and the guide both use nylon plastic wear

faces for low friction and long wear. The primary

chain receives oil splash lubrication from the second-

ary chain drive and oil pump leakage. The idler

sprocket assembly connects the primary and second-

ary chain drives. The idler sprocket assembly con-

sists of two integral thirty tooth sprockets and a fifty

tooth sprocket that is splined to the assembly. The

spline joint is a non ± serviceable press fit anti rattle

type. A spiral ring is installed on the outboard side of

the fifty tooth sprocket to prevent spline disengage-

ment. The idler sprocket assembly spins on a station-

ary idler shaft. The idler shaft is press-fit into the

cylinder block. A large washer on the idler shaft bolt

and the rear flange of the idler shaft are used to con-

trol sprocket thrust movement. Pressurized oil is

routed through the center of the idler shaft to pro-

vide lubrication for the two bushings used in the

idler sprocket assembly.There are two secondary drive chains, both are

inverted tooth type, one to drive the camshaft in each

SOHC cylinder head. There are no shaft speed

changes in the secondary chain drive system. Each

secondary chain drives a thirty tooth cam sprocket

directly from the thirty tooth sprocket on the idler

sprocket assembly. A fixed chain guide and a hydrau-

lic oil damped tensioner are used to maintain tension

in each secondary chain system. The hydraulic ten-

sioners for the secondary chain systems are fed pres-

surized oil from oil reservoir pockets in the block.

Each tensioner also has a mechanical ratchet system

that limits chain slack if the tensioner piston bleeds

down after engine shut down. The tensioner arms

and guides also utilize nylon wear faces for low fric-

tion and long wear. The secondary timing chains

receive lubrication from a small orifice in the ten-

sioners. This orifice is protected from clogging by a

fine mesh screen which is located on the back of the

hydraulic tensioners.

CAMSHAFT

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. A steel

post or nose piece is friction-welded to the steel cam-

shaft tube. Five bearing journals are machined into

the camshaft, four on the steel tube and one on the

steel nose piece. Camshaft end play is controlled by

two thrust walls that border the nose piece journal.

Engine oil enters the hollow camshafts at the third

journal and lubricates every intake lobe rocker

through a drilled passage in the intake lobe.

ROCKER ARM

DESCRIPTION

The rocker arms are steel stampings with an inte-

gral roller bearing. The rocker arms incorporate a 2.8

mm (0.11 inch) oil hole in the lash adjuster socket for

roller and camshaft lubrication.

CYLINDER HEAD COVER

DESCRIPTION

The cylinder head covers are made of die cast mag-

nesium, and are not interchangeable from side-to-

side. It is imperative that nothing rest on the

cylinder head covers. Prolonged contact with other

items may wear a hole in the cylinder head cover.

9 - 6 4.7L ENGINEDN

DESCRIPTION AND OPERATION (Continued)

Page 10 of 193

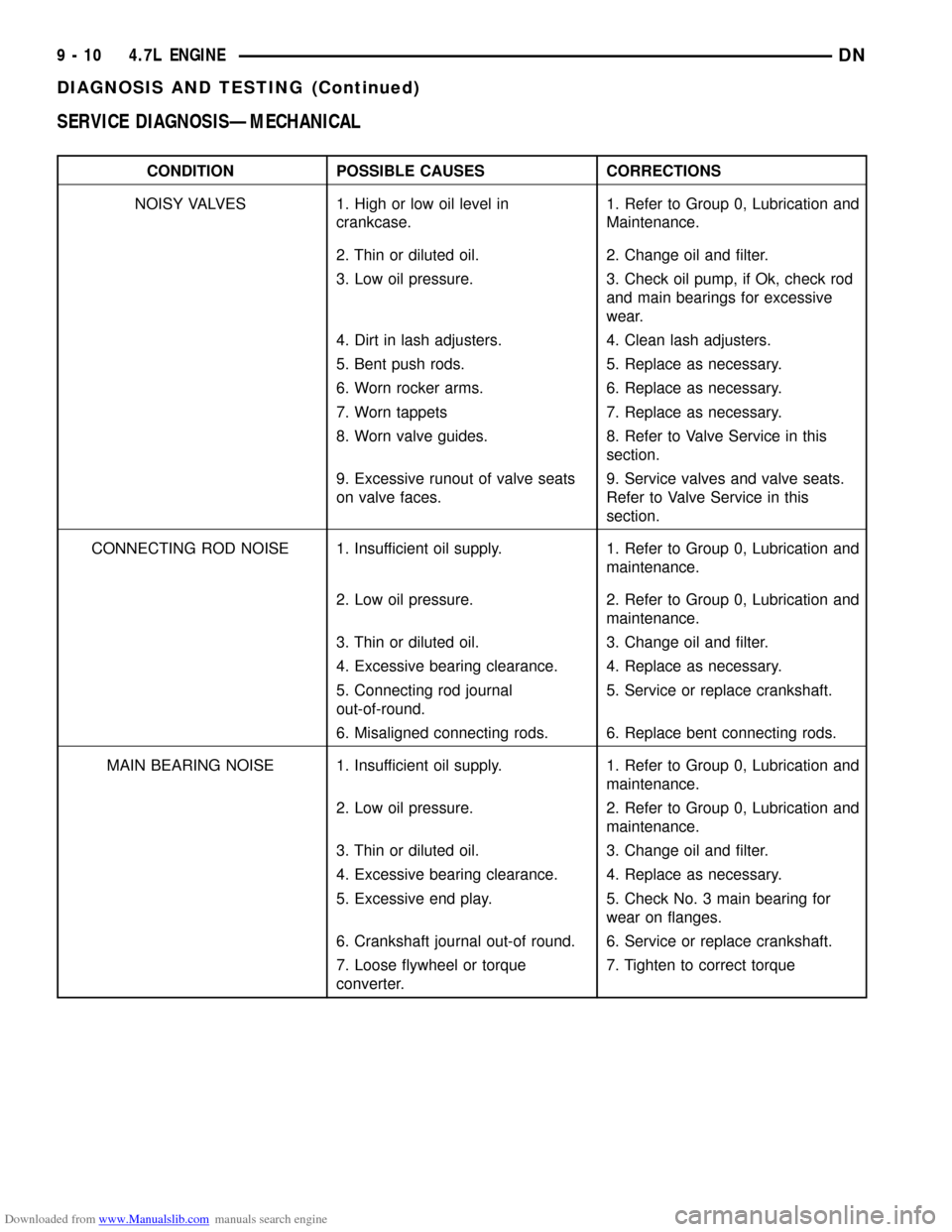

Downloaded from www.Manualslib.com manuals search engine SERVICE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.1. Refer to Group 0, Lubrication and

Maintenance.

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

4. Dirt in lash adjusters. 4. Clean lash adjusters.

5. Bent push rods. 5. Replace as necessary.

6. Worn rocker arms. 6. Replace as necessary.

7. Worn tappets 7. Replace as necessary.

8. Worn valve guides. 8. Refer to Valve Service in this

section.

9. Excessive runout of valve seats

on valve faces.9. Service valves and valve seats.

Refer to Valve Service in this

section.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Refer to Group 0, Lubrication and

maintenance.

2. Low oil pressure. 2. Refer to Group 0, Lubrication and

maintenance.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal

out-of-round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Refer to Group 0, Lubrication and

maintenance.

2. Low oil pressure. 2. Refer to Group 0, Lubrication and

maintenance.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check No. 3 main bearing for

wear on flanges.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.7. Tighten to correct torque

9 - 10 4.7L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 14 of 193

Downloaded from www.Manualslib.com manuals search engine filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

REAR SEAL AREA LEAKSÐINSPECTION

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces. See Group 9, Engines, for

proper repair procedures of these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible thecrankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. Refer to the service DiagnosisÐMechani-

cal, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, Refer to Group

9, EnginesÐCrankshaft Rear Oil Seals, for proper

replacement procedures.

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.

(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

9 - 14 4.7L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 40 of 193

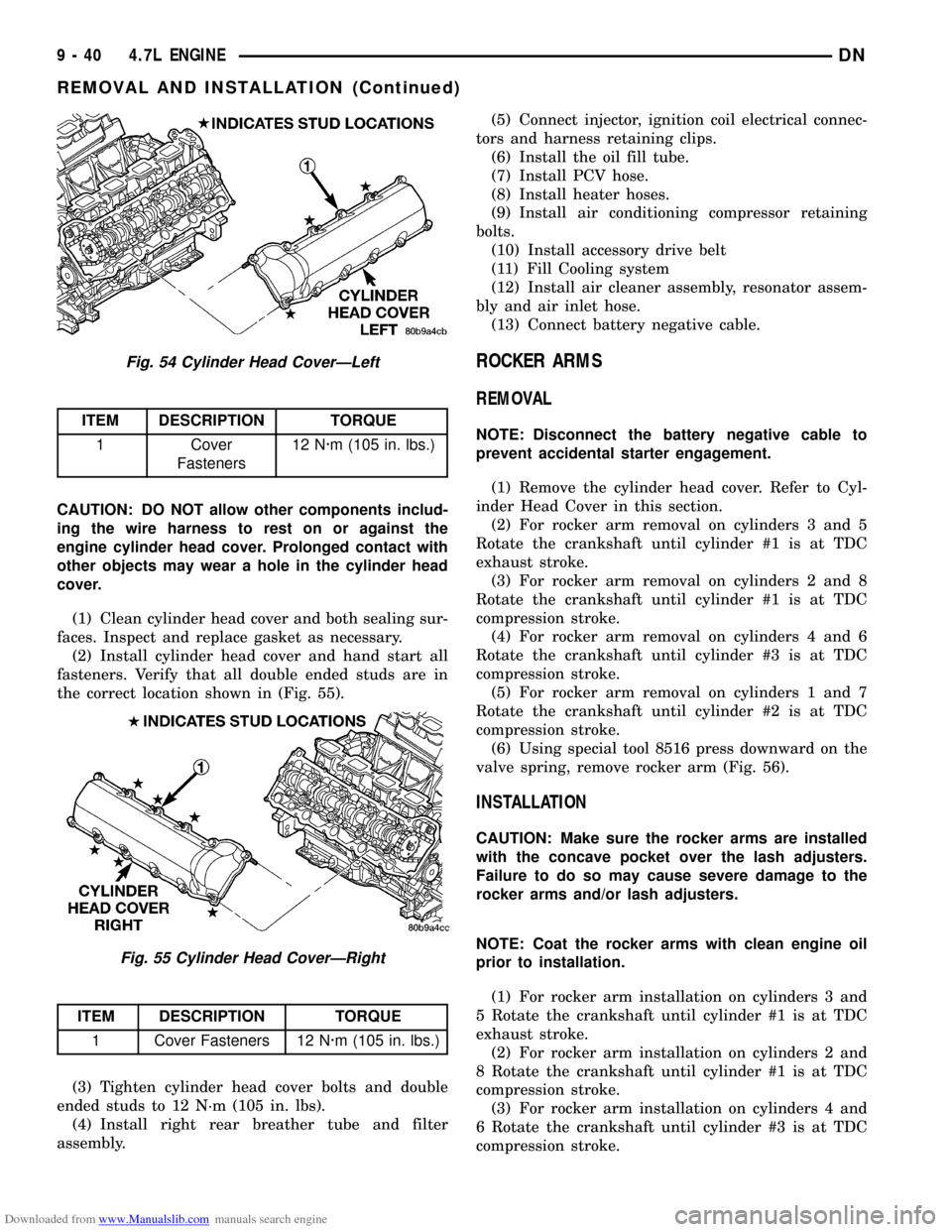

Downloaded from www.Manualslib.com manuals search engine CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Install cylinder head cover and hand start all

fasteners. Verify that all double ended studs are in

the correct location shown in (Fig. 55).

(3) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(4) Install right rear breather tube and filter

assembly.(5) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(6) Install the oil fill tube.

(7) Install PCV hose.

(8) Install heater hoses.

(9) Install air conditioning compressor retaining

bolts.

(10) Install accessory drive belt

(11) Fill Cooling system

(12) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(13) Connect battery negative cable.

ROCKER ARMS

REMOVAL

NOTE: Disconnect the battery negative cable to

prevent accidental starter engagement.

(1) Remove the cylinder head cover. Refer to Cyl-

inder Head Cover in this section.

(2) For rocker arm removal on cylinders 3 and 5

Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(3) For rocker arm removal on cylinders 2 and 8

Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(4) For rocker arm removal on cylinders 4 and 6

Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

(5) For rocker arm removal on cylinders 1 and 7

Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

(6) Using special tool 8516 press downward on the

valve spring, remove rocker arm (Fig. 56).

INSTALLATION

CAUTION: Make sure the rocker arms are installed

with the concave pocket over the lash adjusters.

Failure to do so may cause severe damage to the

rocker arms and/or lash adjusters.

NOTE: Coat the rocker arms with clean engine oil

prior to installation.

(1) For rocker arm installation on cylinders 3 and

5 Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(2) For rocker arm installation on cylinders 2 and

8 Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(3) For rocker arm installation on cylinders 4 and

6 Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

Fig. 54 Cylinder Head CoverÐLeft

ITEM DESCRIPTION TORQUE

1 Cover

Fasteners12 N´m (105 in. lbs.)

Fig. 55 Cylinder Head CoverÐRight

ITEM DESCRIPTION TORQUE

1 Cover Fasteners 12 N´m (105 in. lbs.)

9 - 40 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 46 of 193

Downloaded from www.Manualslib.com manuals search engine (14) Install the crankshaft damper. Tighten

damper bolt 175 N´m (130 Ft. Lbs.).

(15) Install accessory drive belt.

(16) Install the fan shroud.

(17) Install the cylinder head cover.

(18) Install the intake manifold.

(19) Install oil fill housing onto cylinder head.

(20) Refill the cooling system.

(21) Raise the vehicle.

(22) Install the exhaust pipe onto the right

exhaust manifold.

(23) Lower the vehicle.

(24) Reconnect battery negitive cable.

(25) Start the engine and check for leaks.

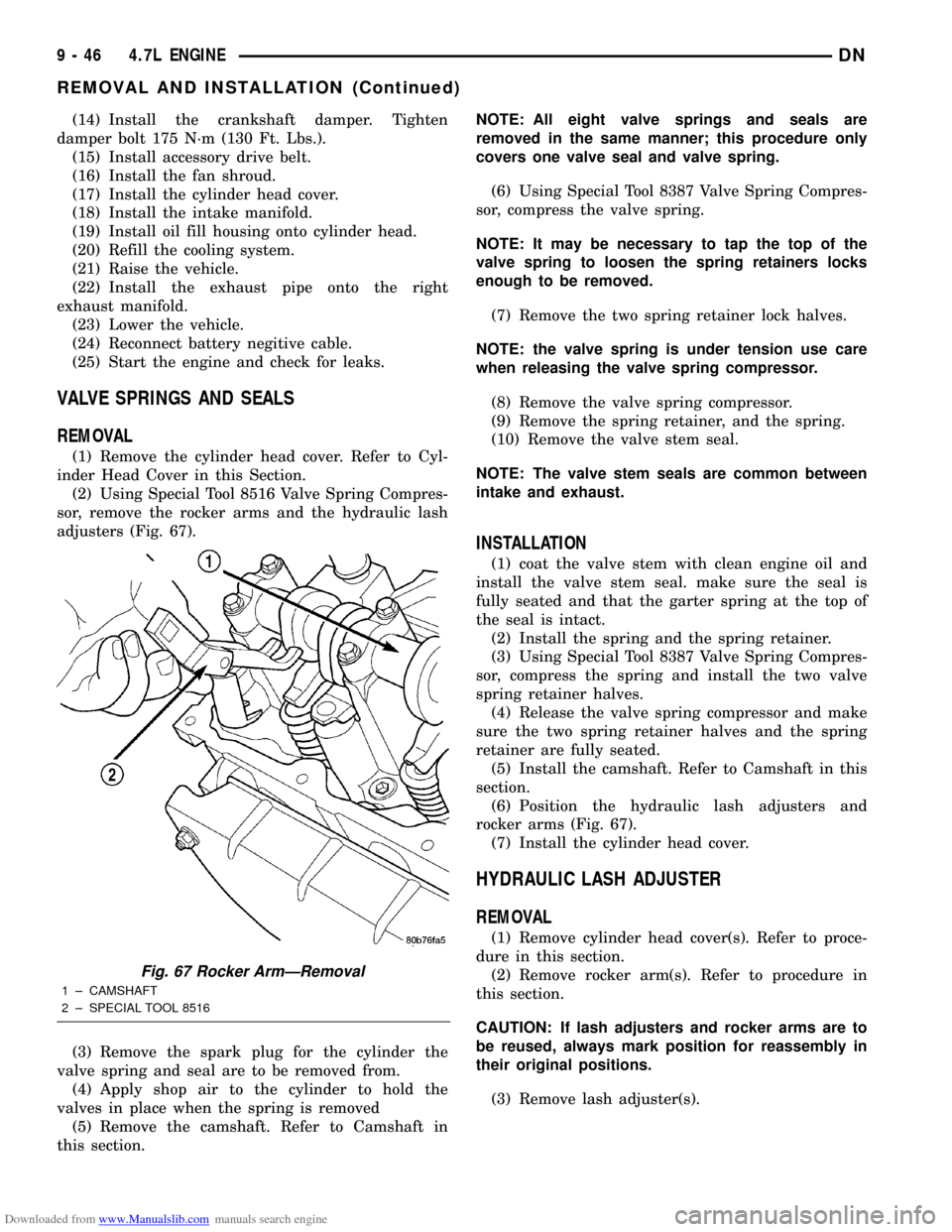

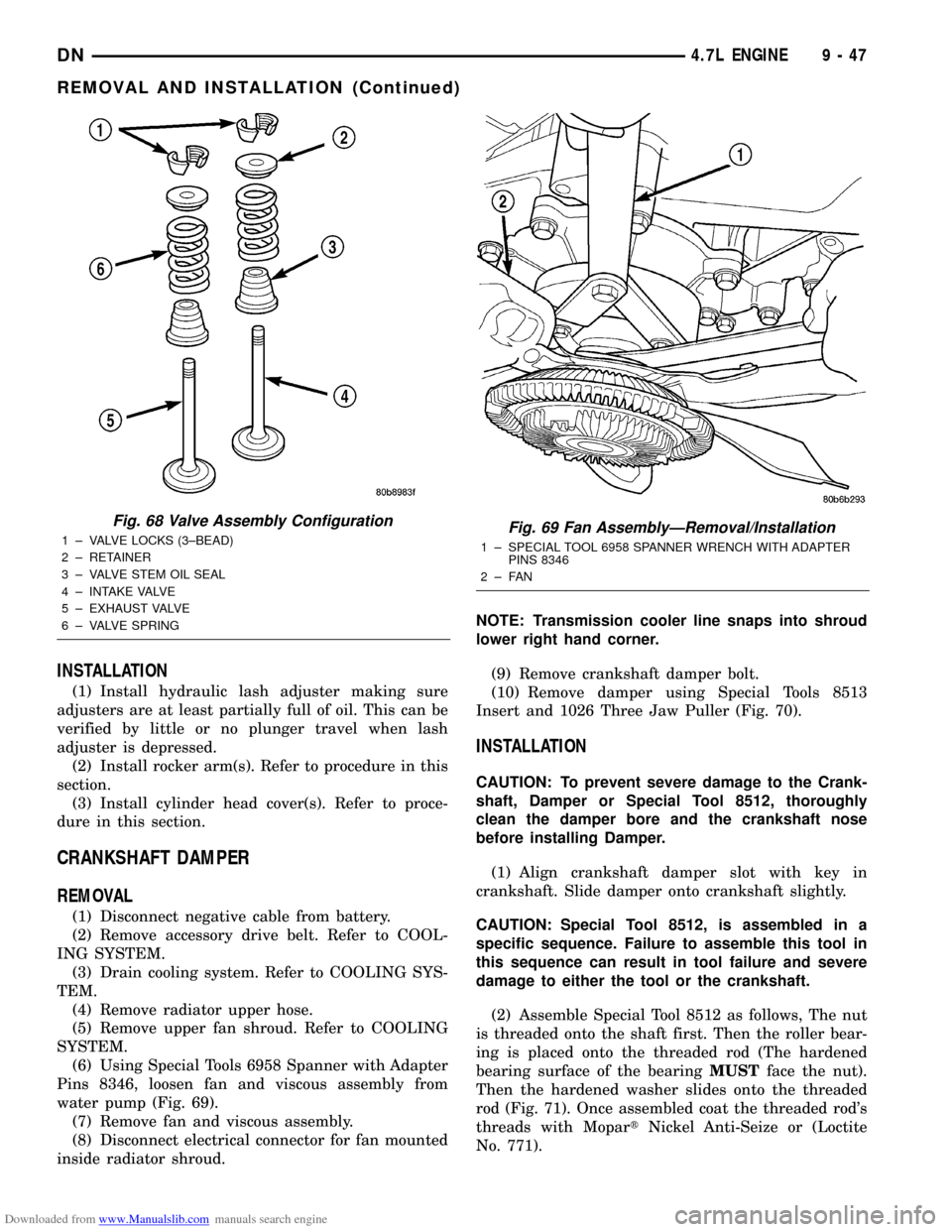

VALVE SPRINGS AND SEALS

REMOVAL

(1) Remove the cylinder head cover. Refer to Cyl-

inder Head Cover in this Section.

(2) Using Special Tool 8516 Valve Spring Compres-

sor, remove the rocker arms and the hydraulic lash

adjusters (Fig. 67).

(3) Remove the spark plug for the cylinder the

valve spring and seal are to be removed from.

(4) Apply shop air to the cylinder to hold the

valves in place when the spring is removed

(5) Remove the camshaft. Refer to Camshaft in

this section.NOTE: All eight valve springs and seals are

removed in the same manner; this procedure only

covers one valve seal and valve spring.

(6) Using Special Tool 8387 Valve Spring Compres-

sor, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(7) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(8) Remove the valve spring compressor.

(9) Remove the spring retainer, and the spring.

(10) Remove the valve stem seal.

NOTE: The valve stem seals are common between

intake and exhaust.

INSTALLATION

(1) coat the valve stem with clean engine oil and

install the valve stem seal. make sure the seal is

fully seated and that the garter spring at the top of

the seal is intact.

(2) Install the spring and the spring retainer.

(3) Using Special Tool 8387 Valve Spring Compres-

sor, compress the spring and install the two valve

spring retainer halves.

(4) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(5) Install the camshaft. Refer to Camshaft in this

section.

(6) Position the hydraulic lash adjusters and

rocker arms (Fig. 67).

(7) Install the cylinder head cover.

HYDRAULIC LASH ADJUSTER

REMOVAL

(1) Remove cylinder head cover(s). Refer to proce-

dure in this section.

(2) Remove rocker arm(s). Refer to procedure in

this section.

CAUTION: If lash adjusters and rocker arms are to

be reused, always mark position for reassembly in

their original positions.

(3) Remove lash adjuster(s).

Fig. 67 Rocker ArmÐRemoval

1 ± CAMSHAFT

2 ± SPECIAL TOOL 8516

9 - 46 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 47 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

(1) Install hydraulic lash adjuster making sure

adjusters are at least partially full of oil. This can be

verified by little or no plunger travel when lash

adjuster is depressed.

(2) Install rocker arm(s). Refer to procedure in this

section.

(3) Install cylinder head cover(s). Refer to proce-

dure in this section.

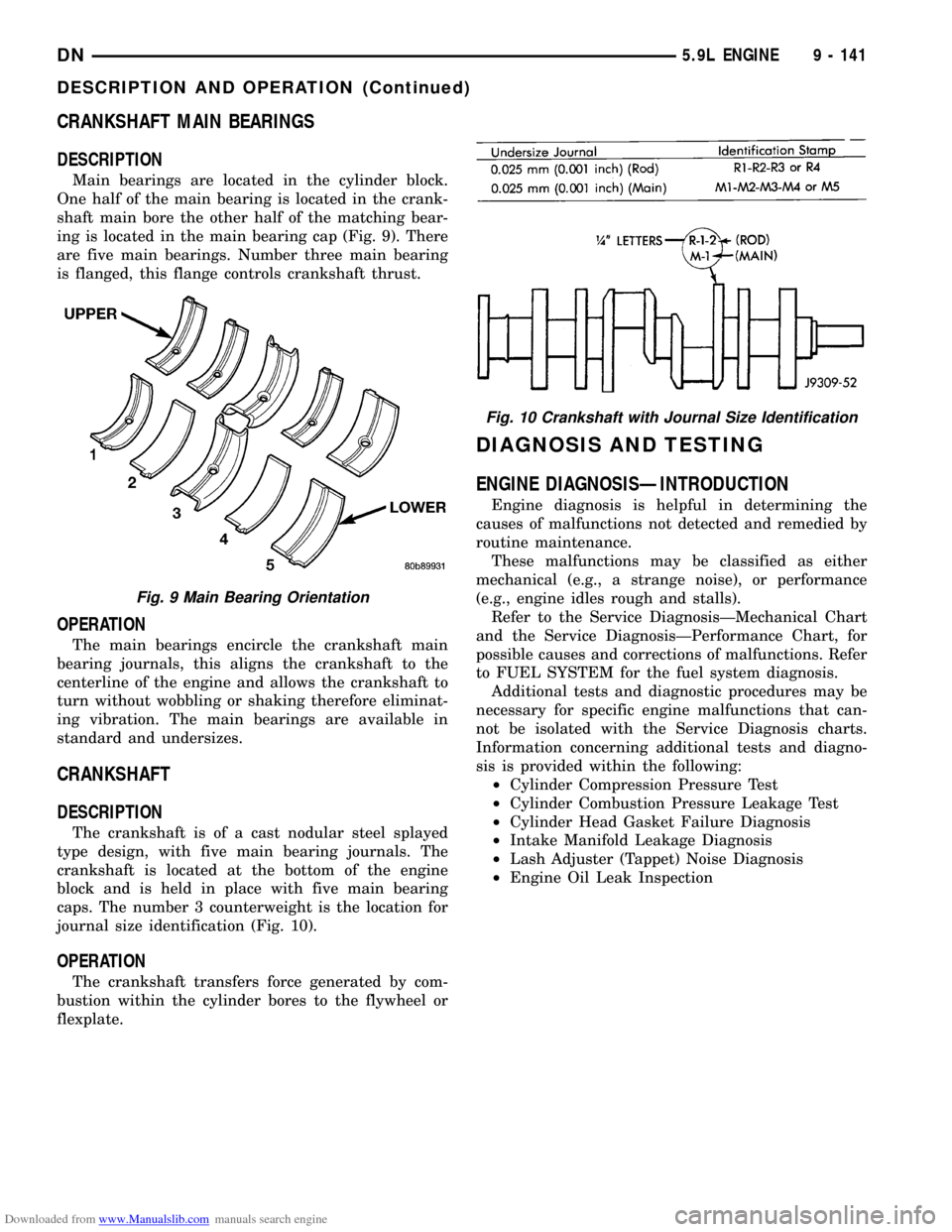

CRANKSHAFT DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(3) Drain cooling system. Refer to COOLING SYS-

TEM.

(4) Remove radiator upper hose.

(5) Remove upper fan shroud. Refer to COOLING

SYSTEM.

(6) Using Special Tools 6958 Spanner with Adapter

Pins 8346, loosen fan and viscous assembly from

water pump (Fig. 69).

(7) Remove fan and viscous assembly.

(8) Disconnect electrical connector for fan mounted

inside radiator shroud.NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

(9) Remove crankshaft damper bolt.

(10) Remove damper using Special Tools 8513

Insert and 1026 Three Jaw Puller (Fig. 70).

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

(1) Align crankshaft damper slot with key in

crankshaft. Slide damper onto crankshaft slightly.

CAUTION: Special Tool 8512, is assembled in a

specific sequence. Failure to assemble this tool in

this sequence can result in tool failure and severe

damage to either the tool or the crankshaft.

(2) Assemble Special Tool 8512 as follows, The nut

is threaded onto the shaft first. Then the roller bear-

ing is placed onto the threaded rod (The hardened

bearing surface of the bearingMUSTface the nut).

Then the hardened washer slides onto the threaded

rod (Fig. 71). Once assembled coat the threaded rod's

threads with MopartNickel Anti-Seize or (Loctite

No. 771).

Fig. 68 Valve Assembly Configuration

1 ± VALVE LOCKS (3±BEAD)

2 ± RETAINER

3 ± VALVE STEM OIL SEAL

4 ± INTAKE VALVE

5 ± EXHAUST VALVE

6 ± VALVE SPRINGFig. 69 Fan AssemblyÐRemoval/Installation

1 ± SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2±FAN

DN4.7L ENGINE 9 - 47

REMOVAL AND INSTALLATION (Continued)

Page 142 of 193

Downloaded from www.Manualslib.com manuals search engine CRANKSHAFT MAIN BEARINGS

DESCRIPTION

Main bearings are located in the cylinder block.

One half of the main bearing is located in the crank-

shaft main bore the other half of the matching bear-

ing is located in the main bearing cap (Fig. 9). There

are five main bearings. Number three main bearing

is flanged, this flange controls crankshaft thrust.

OPERATION

The main bearings encircle the crankshaft main

bearing journals, this aligns the crankshaft to the

centerline of the engine and allows the crankshaft to

turn without wobbling or shaking therefore eliminat-

ing vibration. The main bearings are available in

standard and undersizes.

CRANKSHAFT

DESCRIPTION

The crankshaft is of a cast nodular steel splayed

type design, with five main bearing journals. The

crankshaft is located at the bottom of the engine

block and is held in place with five main bearing

caps. The number 3 counterweight is the location for

journal size identification (Fig. 10).

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder bores to the flywheel or

flexplate.

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐINTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to FUEL SYSTEM for the fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Lash Adjuster (Tappet) Noise Diagnosis

²Engine Oil Leak Inspection

Fig. 9 Main Bearing Orientation

Fig. 10 Crankshaft with Journal Size Identification

DN5.9L ENGINE 9 - 141

DESCRIPTION AND OPERATION (Continued)