Shaft DODGE DURANGO 2000 1.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: DURANGO, Model: DODGE DURANGO 2000 1.GPages: 193, PDF Size: 5.65 MB

Page 67 of 193

Downloaded from www.Manualslib.com manuals search engine (7) Rotate crankshaft until connecting rod journal

is on the center of cylinder bore. Insert rod and pis-

ton into cylinder bore and carefully position connect-

ing rod guides over crankshaft journal.

(8) Tap piston down in cylinder bore using a ham-

mer handle. While at the same time, guide connect-

ing rod into position on rod journal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

(9) Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 27 N´m (20 ft. lbs.) plus 90É.

(10) Install the following components: (Refer to

procedures in this section)

²Cylinder head(s).

²Timing chain and cover.

²Cylinder head covers.

²Oil pan and gasket/windage tray.

(11) Fill crankcase with proper engine oil to cor-

rect level.

(12) Connect negative cable to battery.

CRANKSHAFT

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine. Refer to Engine Assembly

in this section for procedure.

(2) Remove the engine oil pump. Refer to Oil

Pump in this section for procedure.

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove oil pan bolts and oil pan.

(4) Remove the oil pump pickup tube and oil pan

gasket /windage tray.

(5) Remove the bedplate mounting bolts. Note the

location of the three stud bolts for installation.

(6) Remove the connecting rods from the crank-

shaft.

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

sever damage to the crankshaft.

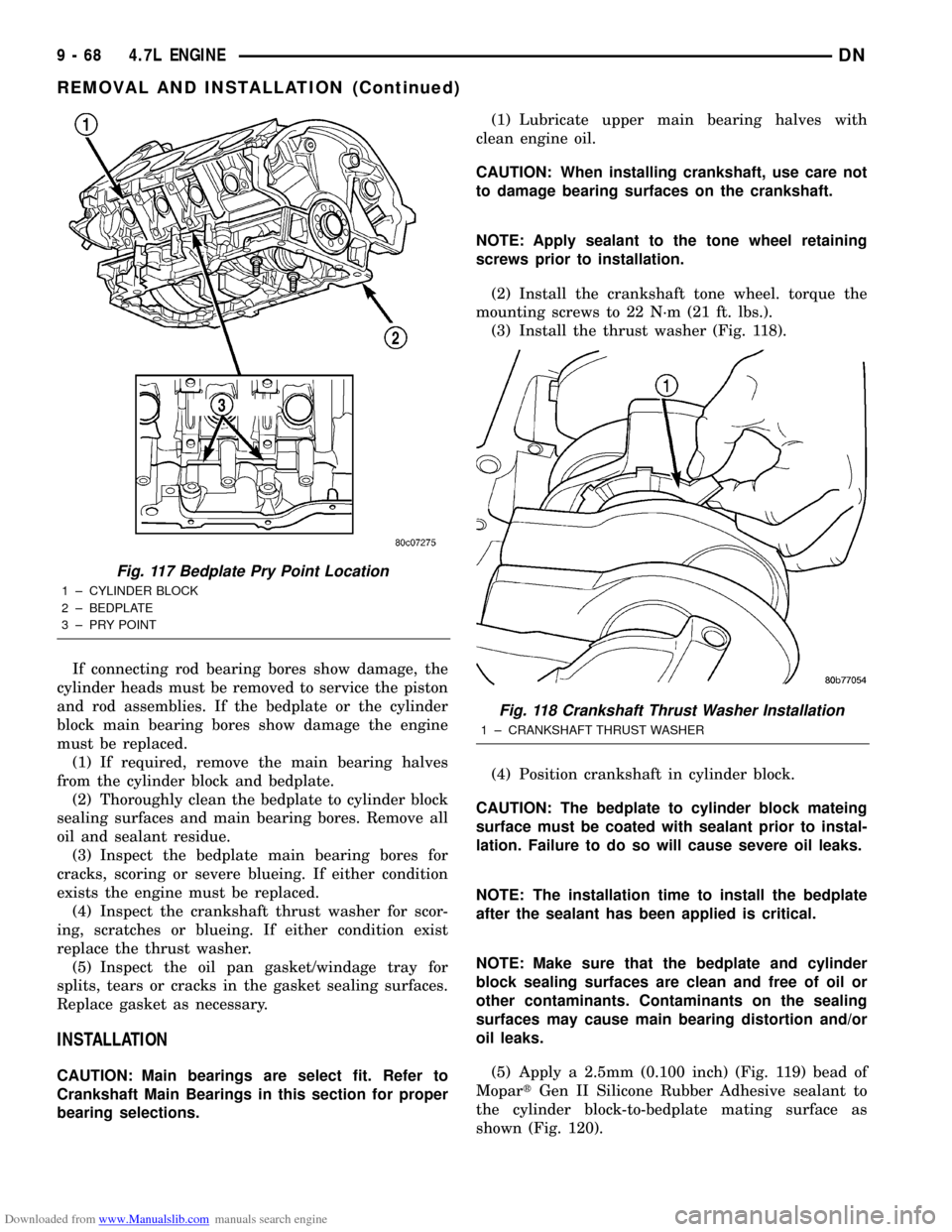

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are on both the

left and right sides, only the left side is shown.

(7) Carefully pry on the pry points (Fig. 117) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(8) Remove the crankshaft.

(9) Remove the crankshaft tone wheel.

INSPECTION

NOTE: Thoroughly inspect the connecting rod

bearing bores and main bearing bores for scoring,

blueing or severe scratches. Further disassembly

may be required.

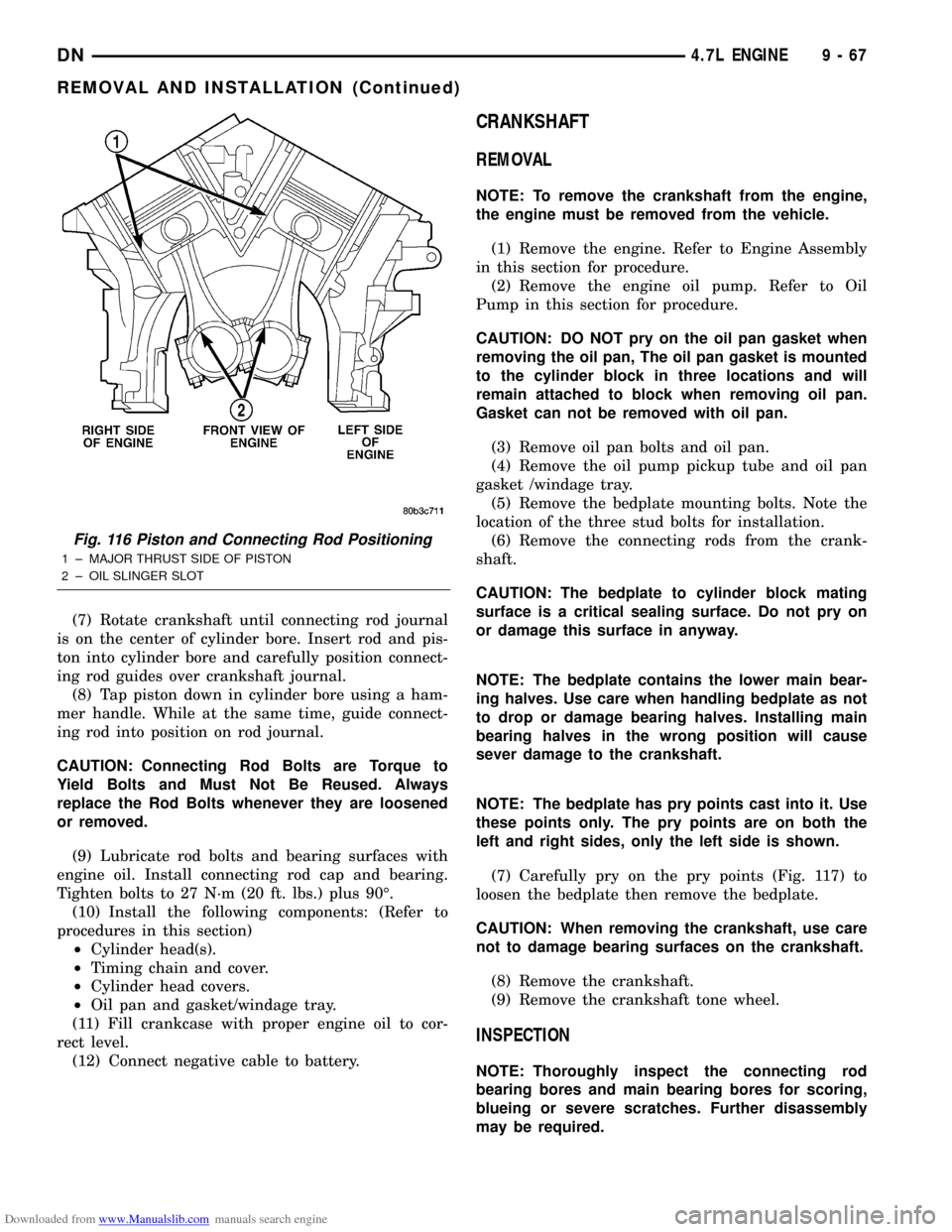

Fig. 116 Piston and Connecting Rod Positioning

1 ± MAJOR THRUST SIDE OF PISTON

2 ± OIL SLINGER SLOT

DN4.7L ENGINE 9 - 67

REMOVAL AND INSTALLATION (Continued)

Page 68 of 193

Downloaded from www.Manualslib.com manuals search engine If connecting rod bearing bores show damage, the

cylinder heads must be removed to service the piston

and rod assemblies. If the bedplate or the cylinder

block main bearing bores show damage the engine

must be replaced.

(1) If required, remove the main bearing halves

from the cylinder block and bedplate.

(2) Thoroughly clean the bedplate to cylinder block

sealing surfaces and main bearing bores. Remove all

oil and sealant residue.

(3) Inspect the bedplate main bearing bores for

cracks, scoring or severe blueing. If either condition

exists the engine must be replaced.

(4) Inspect the crankshaft thrust washer for scor-

ing, scratches or blueing. If either condition exist

replace the thrust washer.

(5) Inspect the oil pan gasket/windage tray for

splits, tears or cracks in the gasket sealing surfaces.

Replace gasket as necessary.

INSTALLATION

CAUTION: Main bearings are select fit. Refer to

Crankshaft Main Bearings in this section for proper

bearing selections.(1) Lubricate upper main bearing halves with

clean engine oil.

CAUTION: When installing crankshaft, use care not

to damage bearing surfaces on the crankshaft.

NOTE: Apply sealant to the tone wheel retaining

screws prior to installation.

(2) Install the crankshaft tone wheel. torque the

mounting screws to 22 N´m (21 ft. lbs.).

(3) Install the thrust washer (Fig. 118).

(4) Position crankshaft in cylinder block.

CAUTION: The bedplate to cylinder block mateing

surface must be coated with sealant prior to instal-

lation. Failure to do so will cause severe oil leaks.

NOTE: The installation time to install the bedplate

after the sealant has been applied is critical.

NOTE: Make sure that the bedplate and cylinder

block sealing surfaces are clean and free of oil or

other contaminants. Contaminants on the sealing

surfaces may cause main bearing distortion and/or

oil leaks.

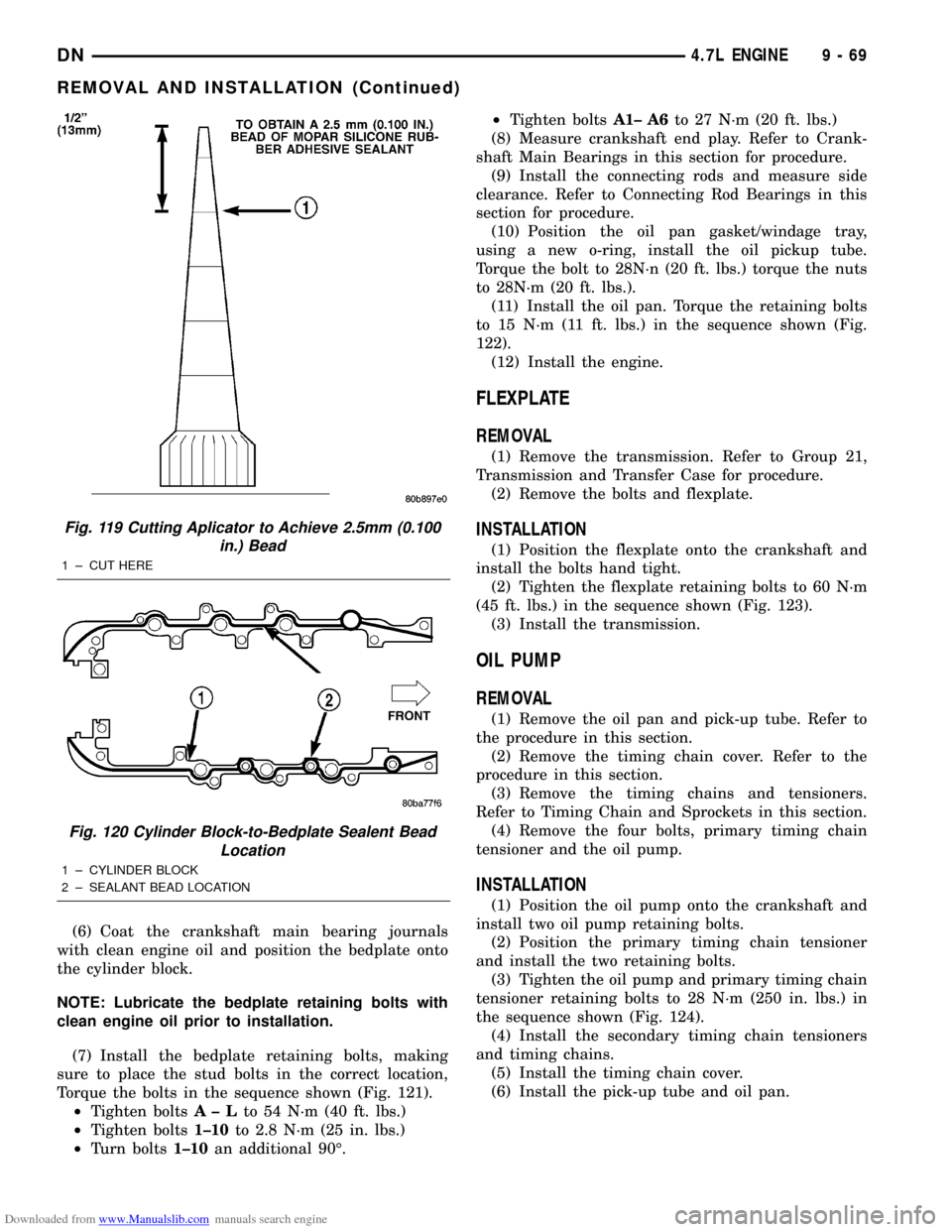

(5) Apply a 2.5mm (0.100 inch) (Fig. 119) bead of

MopartGen II Silicone Rubber Adhesive sealant to

the cylinder block-to-bedplate mating surface as

shown (Fig. 120).

Fig. 117 Bedplate Pry Point Location

1 ± CYLINDER BLOCK

2 ± BEDPLATE

3 ± PRY POINT

Fig. 118 Crankshaft Thrust Washer Installation

1 ± CRANKSHAFT THRUST WASHER

9 - 68 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 69 of 193

Downloaded from www.Manualslib.com manuals search engine (6) Coat the crankshaft main bearing journals

with clean engine oil and position the bedplate onto

the cylinder block.

NOTE: Lubricate the bedplate retaining bolts with

clean engine oil prior to installation.

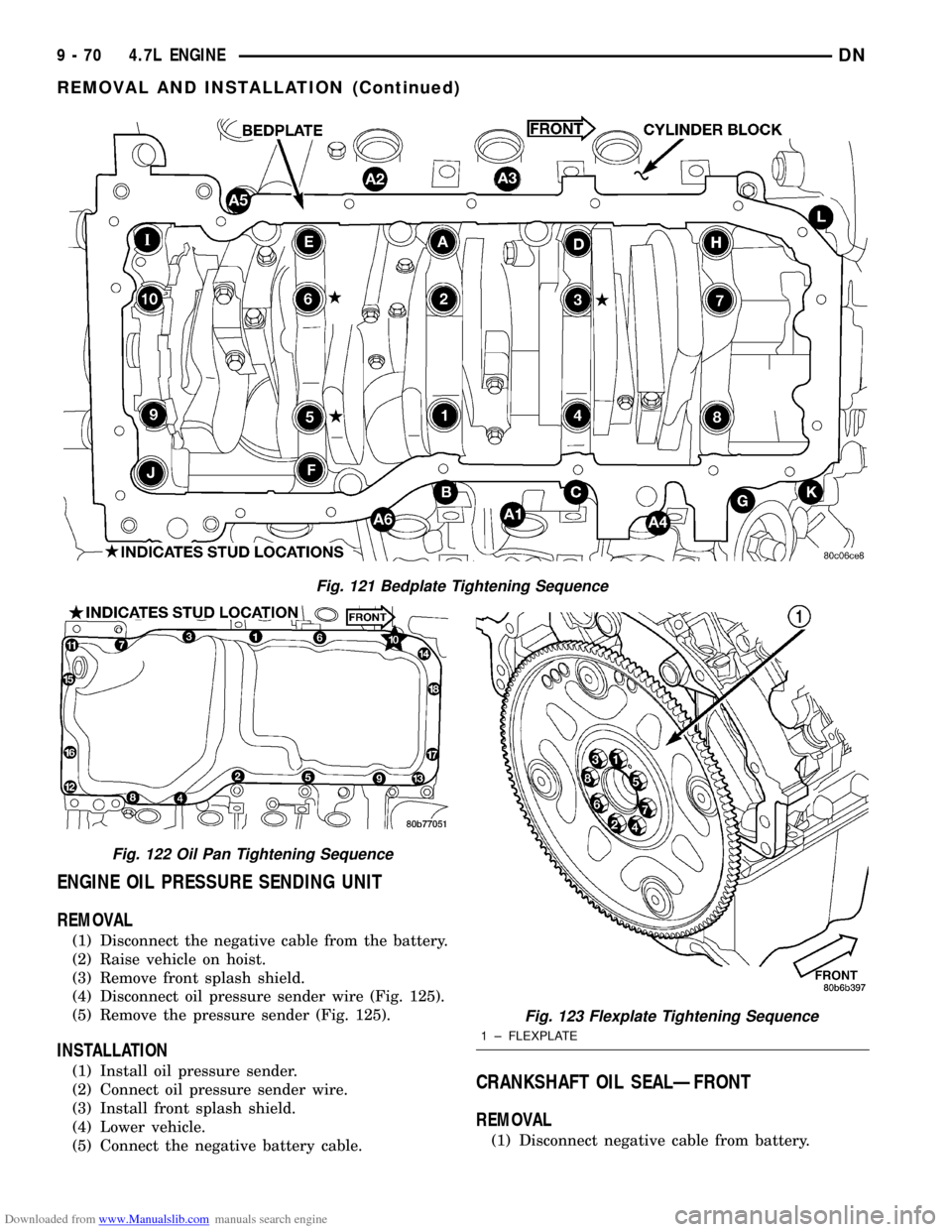

(7) Install the bedplate retaining bolts, making

sure to place the stud bolts in the correct location,

Torque the bolts in the sequence shown (Fig. 121).

²Tighten boltsA± Lto 54 N´m (40 ft. lbs.)

²Tighten bolts1±10to 2.8 N´m (25 in. lbs.)

²Turn bolts1±10an additional 90É.²Tighten boltsA1± A6to 27 N´m (20 ft. lbs.)

(8) Measure crankshaft end play. Refer to Crank-

shaft Main Bearings in this section for procedure.

(9) Install the connecting rods and measure side

clearance. Refer to Connecting Rod Bearings in this

section for procedure.

(10) Position the oil pan gasket/windage tray,

using a new o-ring, install the oil pickup tube.

Torque the bolt to 28N´n (20 ft. lbs.) torque the nuts

to 28N´m (20 ft. lbs.).

(11) Install the oil pan. Torque the retaining bolts

to 15 N´m (11 ft. lbs.) in the sequence shown (Fig.

122).

(12) Install the engine.

FLEXPLATE

REMOVAL

(1) Remove the transmission. Refer to Group 21,

Transmission and Transfer Case for procedure.

(2) Remove the bolts and flexplate.

INSTALLATION

(1) Position the flexplate onto the crankshaft and

install the bolts hand tight.

(2) Tighten the flexplate retaining bolts to 60 N´m

(45 ft. lbs.) in the sequence shown (Fig. 123).

(3) Install the transmission.

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube. Refer to

the procedure in this section.

(2) Remove the timing chain cover. Refer to the

procedure in this section.

(3) Remove the timing chains and tensioners.

Refer to Timing Chain and Sprockets in this section.

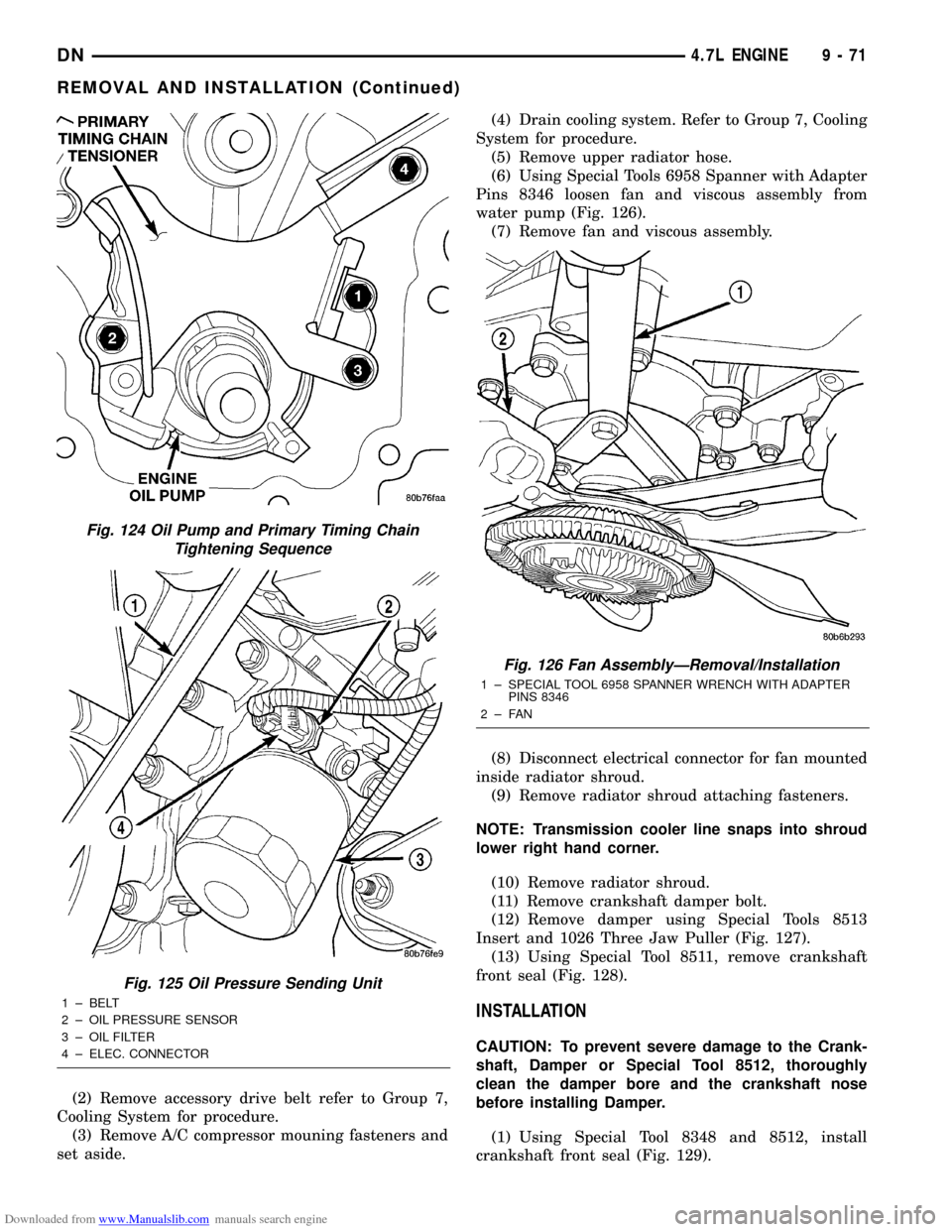

(4) Remove the four bolts, primary timing chain

tensioner and the oil pump.

INSTALLATION

(1) Position the oil pump onto the crankshaft and

install two oil pump retaining bolts.

(2) Position the primary timing chain tensioner

and install the two retaining bolts.

(3) Tighten the oil pump and primary timing chain

tensioner retaining bolts to 28 N´m (250 in. lbs.) in

the sequence shown (Fig. 124).

(4) Install the secondary timing chain tensioners

and timing chains.

(5) Install the timing chain cover.

(6) Install the pick-up tube and oil pan.

Fig. 119 Cutting Aplicator to Achieve 2.5mm (0.100

in.) Bead

1 ± CUT HERE

Fig. 120 Cylinder Block-to-Bedplate Sealent Bead

Location

1 ± CYLINDER BLOCK

2 ± SEALANT BEAD LOCATION

DN4.7L ENGINE 9 - 69

REMOVAL AND INSTALLATION (Continued)

Page 70 of 193

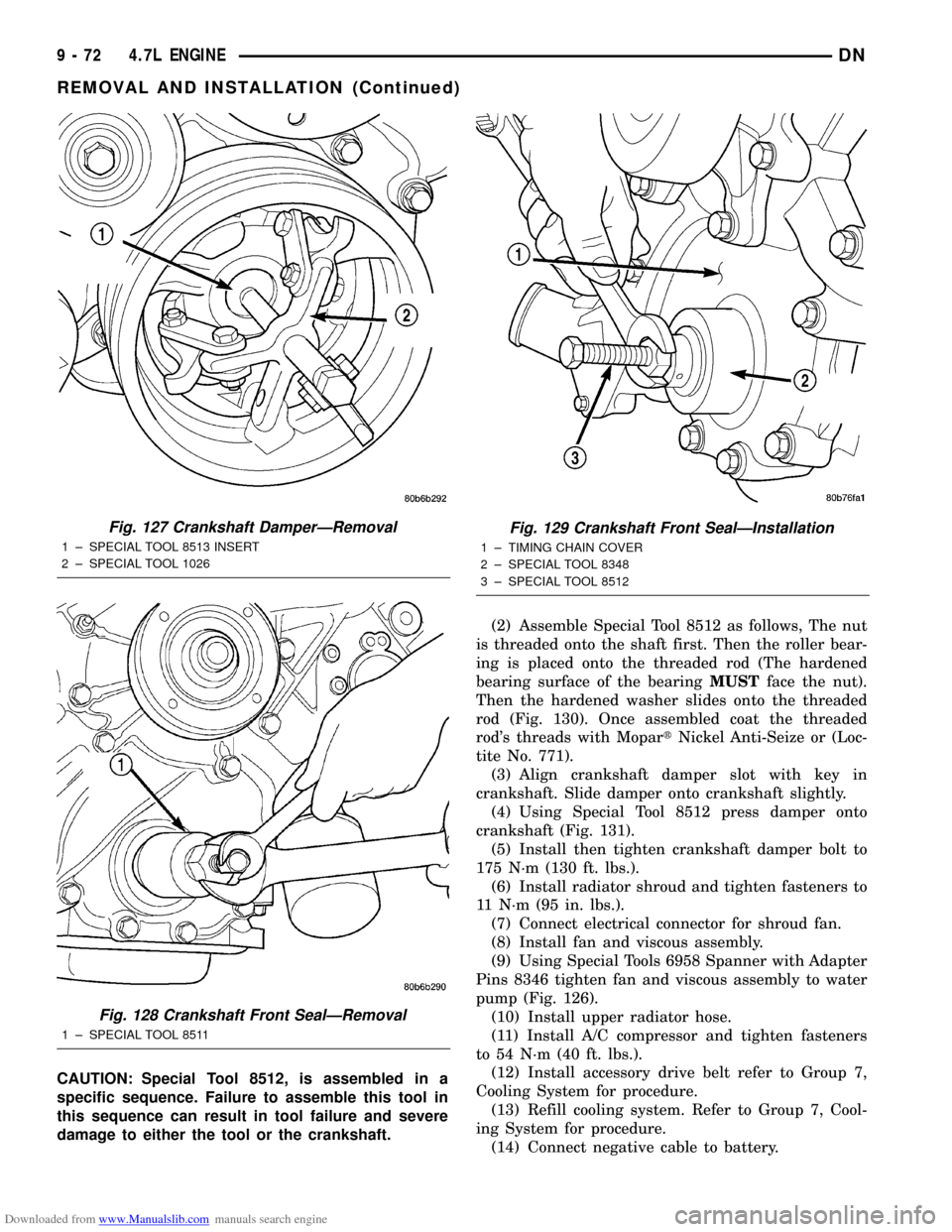

Downloaded from www.Manualslib.com manuals search engine ENGINE OIL PRESSURE SENDING UNIT

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Remove front splash shield.

(4) Disconnect oil pressure sender wire (Fig. 125).

(5) Remove the pressure sender (Fig. 125).

INSTALLATION

(1) Install oil pressure sender.

(2) Connect oil pressure sender wire.

(3) Install front splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Disconnect negative cable from battery.

Fig. 121 Bedplate Tightening Sequence

Fig. 122 Oil Pan Tightening Sequence

Fig. 123 Flexplate Tightening Sequence

1 ± FLEXPLATE

9 - 70 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 71 of 193

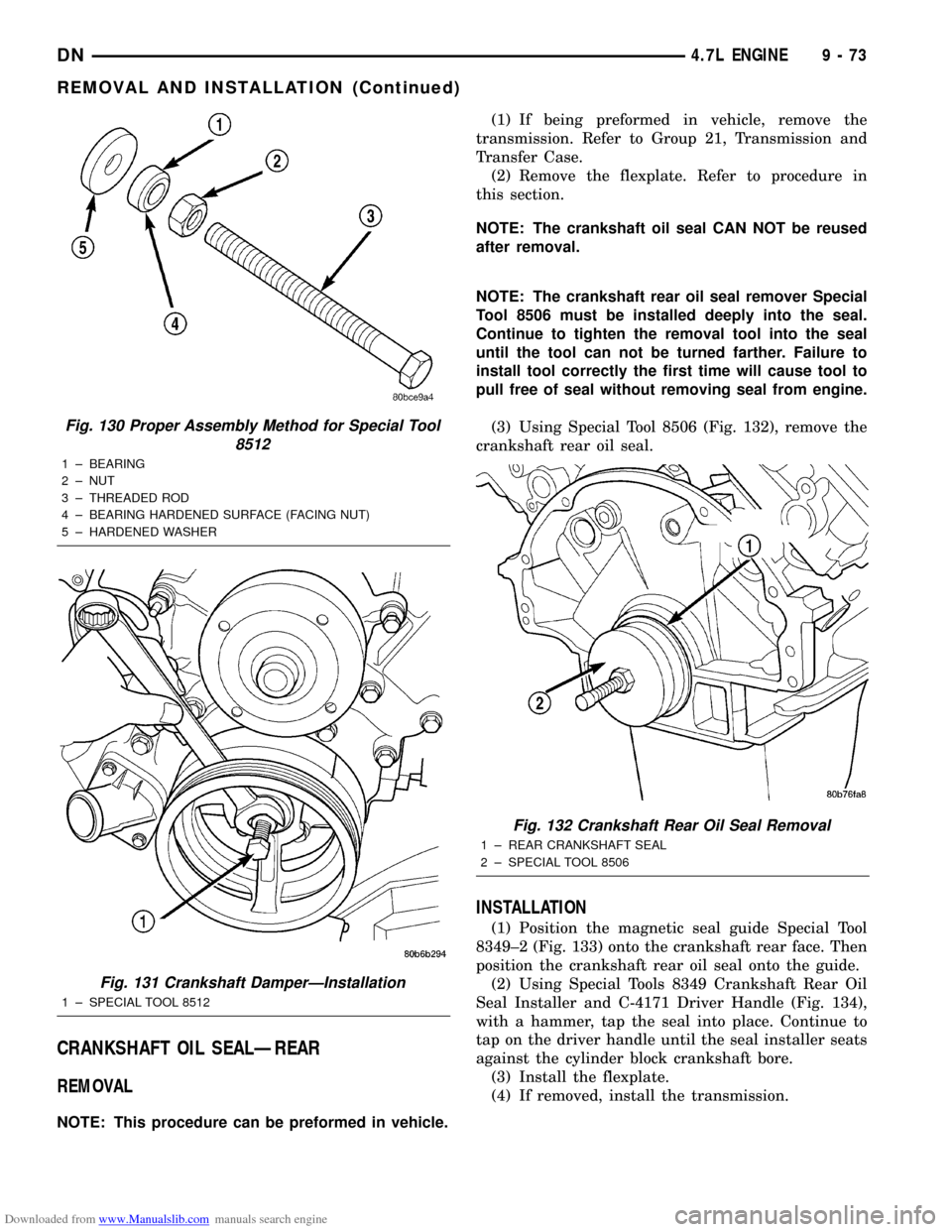

Downloaded from www.Manualslib.com manuals search engine (2) Remove accessory drive belt refer to Group 7,

Cooling System for procedure.

(3) Remove A/C compressor mouning fasteners and

set aside.(4) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(5) Remove upper radiator hose.

(6) Using Special Tools 6958 Spanner with Adapter

Pins 8346 loosen fan and viscous assembly from

water pump (Fig. 126).

(7) Remove fan and viscous assembly.

(8) Disconnect electrical connector for fan mounted

inside radiator shroud.

(9) Remove radiator shroud attaching fasteners.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

(10) Remove radiator shroud.

(11) Remove crankshaft damper bolt.

(12) Remove damper using Special Tools 8513

Insert and 1026 Three Jaw Puller (Fig. 127).

(13) Using Special Tool 8511, remove crankshaft

front seal (Fig. 128).

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

(1) Using Special Tool 8348 and 8512, install

crankshaft front seal (Fig. 129).

Fig. 124 Oil Pump and Primary Timing Chain

Tightening Sequence

Fig. 125 Oil Pressure Sending Unit

1 ± BELT

2 ± OIL PRESSURE SENSOR

3 ± OIL FILTER

4 ± ELEC. CONNECTOR

Fig. 126 Fan AssemblyÐRemoval/Installation

1 ± SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2±FAN

DN4.7L ENGINE 9 - 71

REMOVAL AND INSTALLATION (Continued)

Page 72 of 193

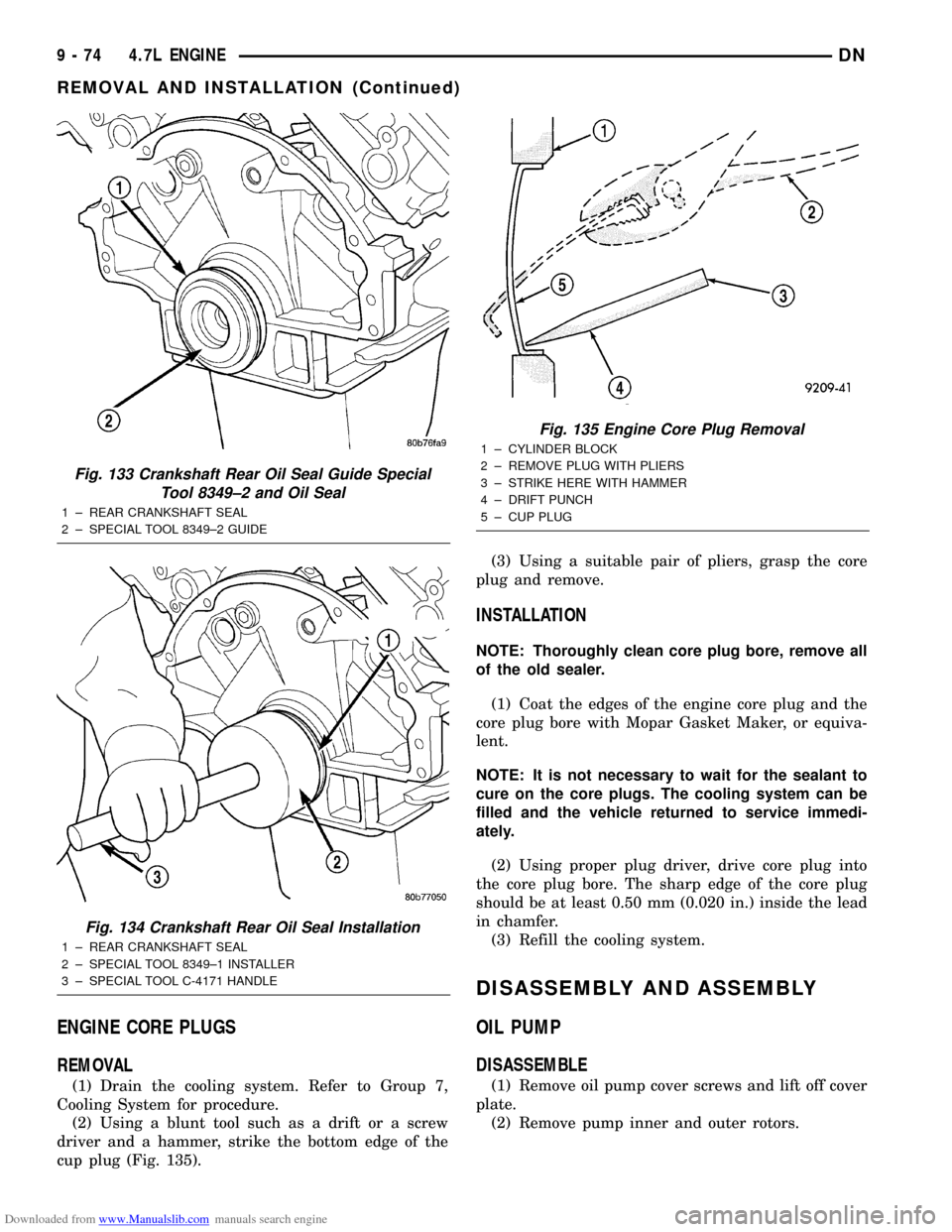

Downloaded from www.Manualslib.com manuals search engine CAUTION: Special Tool 8512, is assembled in a

specific sequence. Failure to assemble this tool in

this sequence can result in tool failure and severe

damage to either the tool or the crankshaft.(2) Assemble Special Tool 8512 as follows, The nut

is threaded onto the shaft first. Then the roller bear-

ing is placed onto the threaded rod (The hardened

bearing surface of the bearingMUSTface the nut).

Then the hardened washer slides onto the threaded

rod (Fig. 130). Once assembled coat the threaded

rod's threads with MopartNickel Anti-Seize or (Loc-

tite No. 771).

(3) Align crankshaft damper slot with key in

crankshaft. Slide damper onto crankshaft slightly.

(4) Using Special Tool 8512 press damper onto

crankshaft (Fig. 131).

(5) Install then tighten crankshaft damper bolt to

175 N´m (130 ft. lbs.).

(6) Install radiator shroud and tighten fasteners to

11 N´m (95 in. lbs.).

(7) Connect electrical connector for shroud fan.

(8) Install fan and viscous assembly.

(9) Using Special Tools 6958 Spanner with Adapter

Pins 8346 tighten fan and viscous assembly to water

pump (Fig. 126).

(10) Install upper radiator hose.

(11) Install A/C compressor and tighten fasteners

to 54 N´m (40 ft. lbs.).

(12) Install accessory drive belt refer to Group 7,

Cooling System for procedure.

(13) Refill cooling system. Refer to Group 7, Cool-

ing System for procedure.

(14) Connect negative cable to battery.

Fig. 127 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 8513 INSERT

2 ± SPECIAL TOOL 1026

Fig. 128 Crankshaft Front SealÐRemoval

1 ± SPECIAL TOOL 8511

Fig. 129 Crankshaft Front SealÐInstallation

1 ± TIMING CHAIN COVER

2 ± SPECIAL TOOL 8348

3 ± SPECIAL TOOL 8512

9 - 72 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 73 of 193

Downloaded from www.Manualslib.com manuals search engine CRANKSHAFT OIL SEALÐREAR

REMOVAL

NOTE: This procedure can be preformed in vehicle.(1) If being preformed in vehicle, remove the

transmission. Refer to Group 21, Transmission and

Transfer Case.

(2) Remove the flexplate. Refer to procedure in

this section.

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506 (Fig. 132), remove the

crankshaft rear oil seal.

INSTALLATION

(1) Position the magnetic seal guide Special Tool

8349±2 (Fig. 133) onto the crankshaft rear face. Then

position the crankshaft rear oil seal onto the guide.

(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 134),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) If removed, install the transmission.

Fig. 130 Proper Assembly Method for Special Tool

8512

1 ± BEARING

2 ± NUT

3 ± THREADED ROD

4 ± BEARING HARDENED SURFACE (FACING NUT)

5 ± HARDENED WASHER

Fig. 131 Crankshaft DamperÐInstallation

1 ± SPECIAL TOOL 8512

Fig. 132 Crankshaft Rear Oil Seal Removal

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8506

DN4.7L ENGINE 9 - 73

REMOVAL AND INSTALLATION (Continued)

Page 74 of 193

Downloaded from www.Manualslib.com manuals search engine ENGINE CORE PLUGS

REMOVAL

(1) Drain the cooling system. Refer to Group 7,

Cooling System for procedure.

(2) Using a blunt tool such as a drift or a screw

driver and a hammer, strike the bottom edge of the

cup plug (Fig. 135).(3) Using a suitable pair of pliers, grasp the core

plug and remove.

INSTALLATION

NOTE: Thoroughly clean core plug bore, remove all

of the old sealer.

(1) Coat the edges of the engine core plug and the

core plug bore with Mopar Gasket Maker, or equiva-

lent.

NOTE: It is not necessary to wait for the sealant to

cure on the core plugs. The cooling system can be

filled and the vehicle returned to service immedi-

ately.

(2) Using proper plug driver, drive core plug into

the core plug bore. The sharp edge of the core plug

should be at least 0.50 mm (0.020 in.) inside the lead

in chamfer.

(3) Refill the cooling system.

DISASSEMBLY AND ASSEMBLY

OIL PUMP

DISASSEMBLE

(1) Remove oil pump cover screws and lift off cover

plate.

(2) Remove pump inner and outer rotors.

Fig. 133 Crankshaft Rear Oil Seal Guide Special

Tool 8349±2 and Oil Seal

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8349±2 GUIDE

Fig. 134 Crankshaft Rear Oil Seal Installation

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8349±1 INSTALLER

3 ± SPECIAL TOOL C-4171 HANDLE

Fig. 135 Engine Core Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

9 - 74 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 76 of 193

Downloaded from www.Manualslib.com manuals search engine PISTON AND CONNECTING ROD

CLEANING

CAUTION: DO NOT use a wire wheel or other abra-

sive cleaning devise to clean the pistons or con-

necting rods. The pistons have a Moly coating, this

coating must not be damaged.

(1) Using a suitable cleaning solvent clean the pis-

tons in warm water and towel dry.

(2) Use a wood or plastic scraper to clean the ring

land grooves.

CAUTION: DO NOT remove the piston pin from the

piston and connecting rod assembly.

INSPECTION

Check the crankshaft connecting rod journal for

excessive wear, taper and scoring.

Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore.

Replace any piston and connecting rod not meeting

the specifications.

OIL PAN

CLEANING

(1) Clean oil pan in solvent and wipe dry with a

clean cloth.

(2) Clean the oil pan gasket surface.DO NOTuse

a grinder wheel or other abrasive tool to clean seal-

ing surface.

(3) Clean oil screen and tube thoroughly in clean

solvent.

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads. Repair as necessary.

(2) Inspect the oil pan mounting flange for bends

or distortion. Straighten flange, if necessary.

OIL PUMP

CLEANING

(1) Wash all parts in a suitable solvent.

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

the these components are disassembled andùr

removed from the pump the entire oil pump assem-

bly must be replaced.(1) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

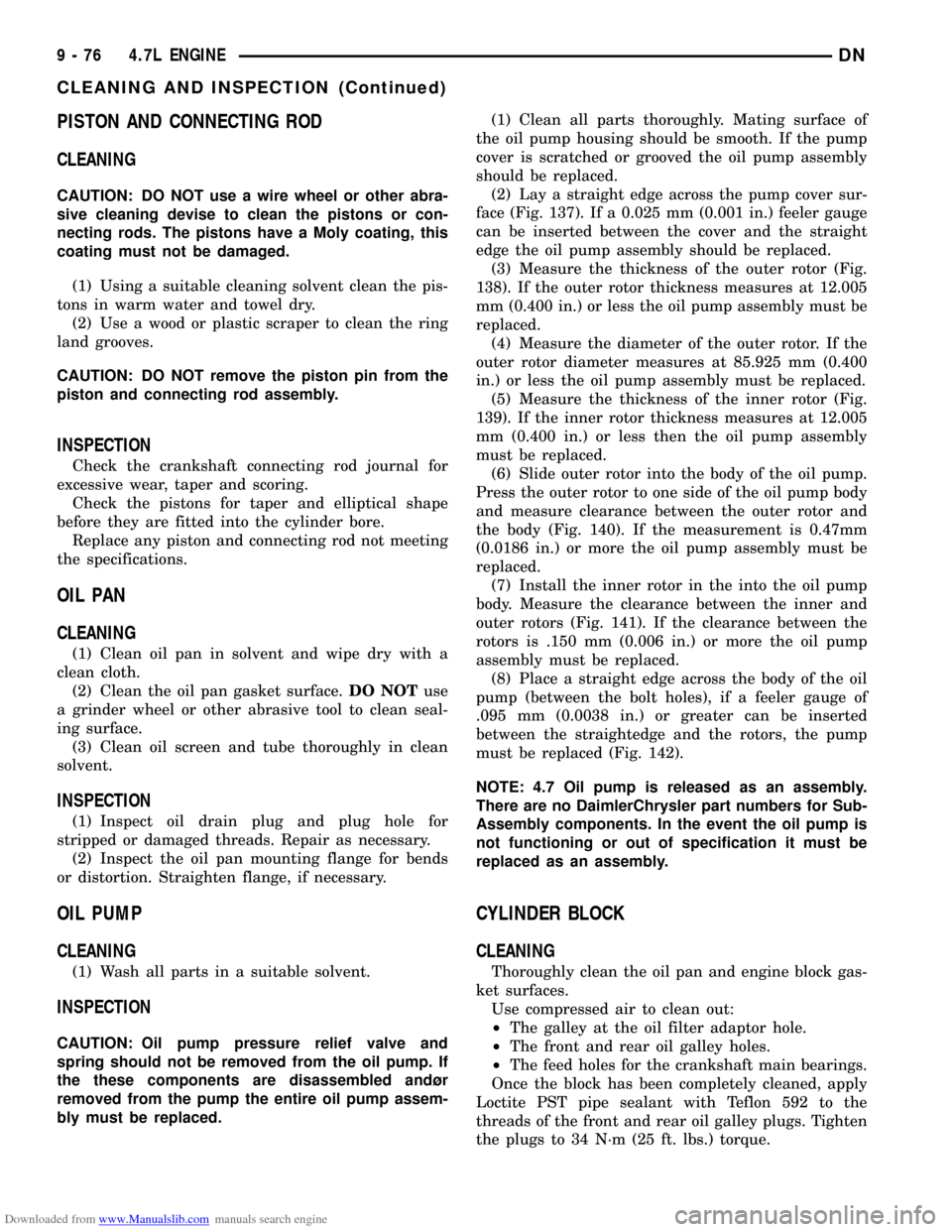

(2) Lay a straight edge across the pump cover sur-

face (Fig. 137). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between the cover and the straight

edge the oil pump assembly should be replaced.

(3) Measure the thickness of the outer rotor (Fig.

138). If the outer rotor thickness measures at 12.005

mm (0.400 in.) or less the oil pump assembly must be

replaced.

(4) Measure the diameter of the outer rotor. If the

outer rotor diameter measures at 85.925 mm (0.400

in.) or less the oil pump assembly must be replaced.

(5) Measure the thickness of the inner rotor (Fig.

139). If the inner rotor thickness measures at 12.005

mm (0.400 in.) or less then the oil pump assembly

must be replaced.

(6) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 140). If the measurement is 0.47mm

(0.0186 in.) or more the oil pump assembly must be

replaced.

(7) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 141). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

(8) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 142).

NOTE: 4.7 Oil pump is released as an assembly.

There are no DaimlerChrysler part numbers for Sub-

Assembly components. In the event the oil pump is

not functioning or out of specification it must be

replaced as an assembly.

CYLINDER BLOCK

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 34 N´m (25 ft. lbs.) torque.

9 - 76 4.7L ENGINEDN

CLEANING AND INSPECTION (Continued)

Page 78 of 193

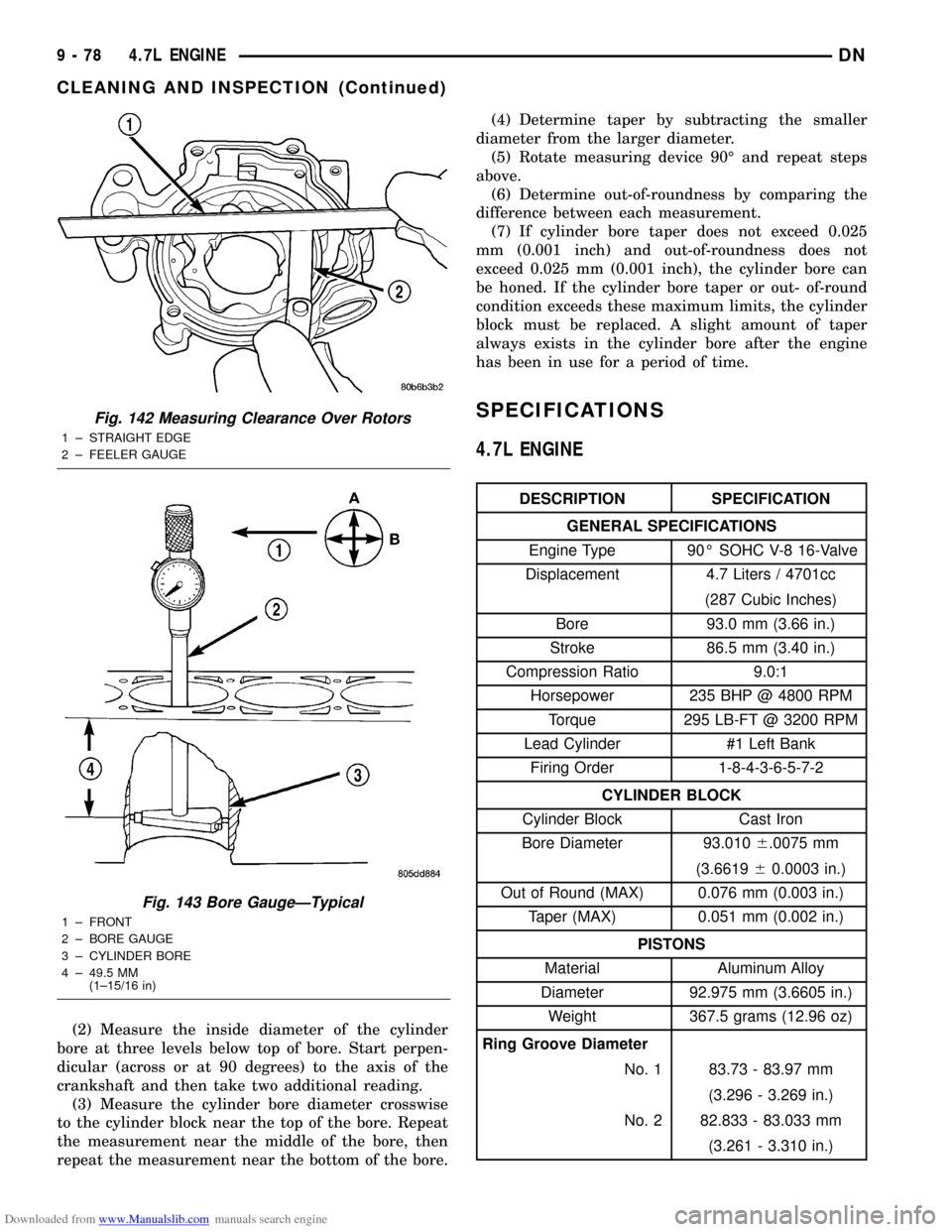

Downloaded from www.Manualslib.com manuals search engine (2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.

SPECIFICATIONS

4.7L ENGINE

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É SOHC V-8 16-Valve

Displacement 4.7 Liters / 4701cc

(287 Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 86.5 mm (3.40 in.)

Compression Ratio 9.0:1

Horsepower 235 BHP @ 4800 RPM

Torque 295 LB-FT @ 3200 RPM

Lead Cylinder #1 Left Bank

Firing Order 1-8-4-3-6-5-7-2

CYLINDER BLOCK

Cylinder Block Cast Iron

Bore Diameter 93.0106.0075 mm

(3.661960.0003 in.)

Out of Round (MAX) 0.076 mm (0.003 in.)

Taper (MAX) 0.051 mm (0.002 in.)

PISTONS

Material Aluminum Alloy

Diameter 92.975 mm (3.6605 in.)

Weight 367.5 grams (12.96 oz)

Ring Groove Diameter

No. 1 83.73 - 83.97 mm

(3.296 - 3.269 in.)

No. 2 82.833 - 83.033 mm

(3.261 - 3.310 in.)

Fig. 142 Measuring Clearance Over Rotors

1 ± STRAIGHT EDGE

2 ± FEELER GAUGE

Fig. 143 Bore GaugeÐTypical

1 ± FRONT

2 ± BORE GAUGE

3 ± CYLINDER BORE

4 ± 49.5 MM

(1±15/16 in)

9 - 78 4.7L ENGINEDN

CLEANING AND INSPECTION (Continued)