DODGE DURANGO 2000 1.G Manual PDF

Manufacturer: DODGE, Model Year: 2000, Model line: DURANGO, Model: DODGE DURANGO 2000 1.GPages: 193, PDF Size: 5.65 MB

Page 71 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Remove accessory drive belt refer to Group 7,

Cooling System for procedure.

(3) Remove A/C compressor mouning fasteners and

set aside.(4) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(5) Remove upper radiator hose.

(6) Using Special Tools 6958 Spanner with Adapter

Pins 8346 loosen fan and viscous assembly from

water pump (Fig. 126).

(7) Remove fan and viscous assembly.

(8) Disconnect electrical connector for fan mounted

inside radiator shroud.

(9) Remove radiator shroud attaching fasteners.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

(10) Remove radiator shroud.

(11) Remove crankshaft damper bolt.

(12) Remove damper using Special Tools 8513

Insert and 1026 Three Jaw Puller (Fig. 127).

(13) Using Special Tool 8511, remove crankshaft

front seal (Fig. 128).

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

(1) Using Special Tool 8348 and 8512, install

crankshaft front seal (Fig. 129).

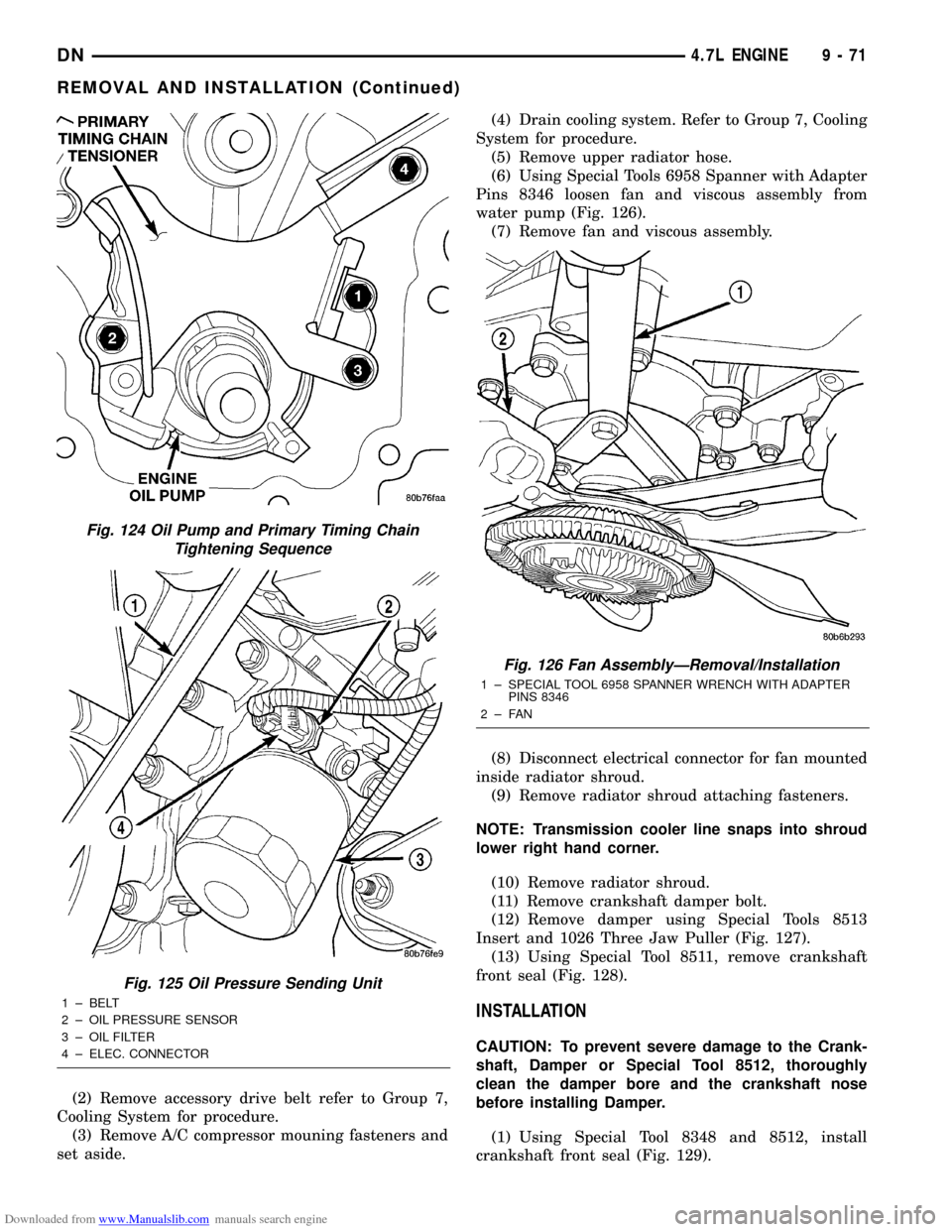

Fig. 124 Oil Pump and Primary Timing Chain

Tightening Sequence

Fig. 125 Oil Pressure Sending Unit

1 ± BELT

2 ± OIL PRESSURE SENSOR

3 ± OIL FILTER

4 ± ELEC. CONNECTOR

Fig. 126 Fan AssemblyÐRemoval/Installation

1 ± SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2±FAN

DN4.7L ENGINE 9 - 71

REMOVAL AND INSTALLATION (Continued)

Page 72 of 193

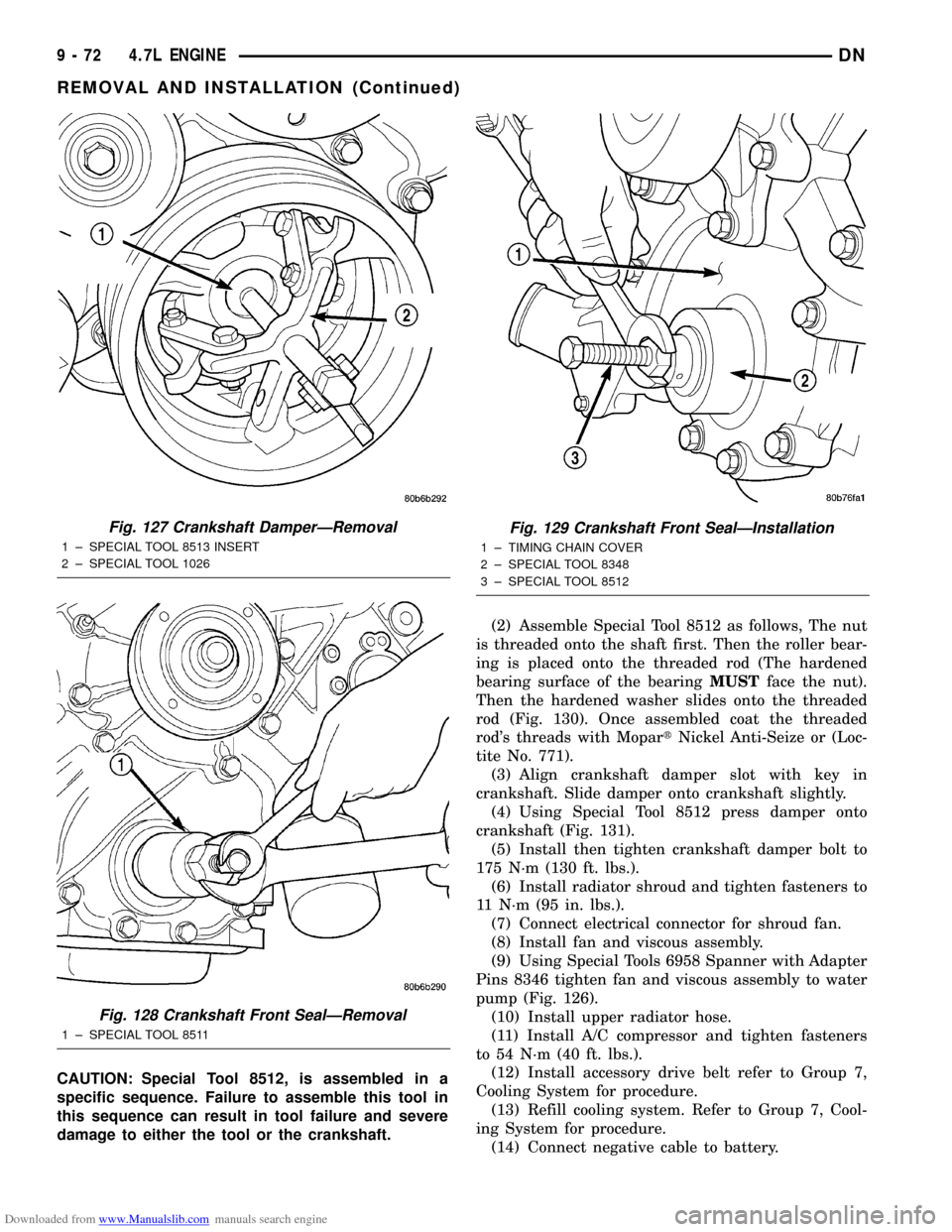

Downloaded from www.Manualslib.com manuals search engine CAUTION: Special Tool 8512, is assembled in a

specific sequence. Failure to assemble this tool in

this sequence can result in tool failure and severe

damage to either the tool or the crankshaft.(2) Assemble Special Tool 8512 as follows, The nut

is threaded onto the shaft first. Then the roller bear-

ing is placed onto the threaded rod (The hardened

bearing surface of the bearingMUSTface the nut).

Then the hardened washer slides onto the threaded

rod (Fig. 130). Once assembled coat the threaded

rod's threads with MopartNickel Anti-Seize or (Loc-

tite No. 771).

(3) Align crankshaft damper slot with key in

crankshaft. Slide damper onto crankshaft slightly.

(4) Using Special Tool 8512 press damper onto

crankshaft (Fig. 131).

(5) Install then tighten crankshaft damper bolt to

175 N´m (130 ft. lbs.).

(6) Install radiator shroud and tighten fasteners to

11 N´m (95 in. lbs.).

(7) Connect electrical connector for shroud fan.

(8) Install fan and viscous assembly.

(9) Using Special Tools 6958 Spanner with Adapter

Pins 8346 tighten fan and viscous assembly to water

pump (Fig. 126).

(10) Install upper radiator hose.

(11) Install A/C compressor and tighten fasteners

to 54 N´m (40 ft. lbs.).

(12) Install accessory drive belt refer to Group 7,

Cooling System for procedure.

(13) Refill cooling system. Refer to Group 7, Cool-

ing System for procedure.

(14) Connect negative cable to battery.

Fig. 127 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 8513 INSERT

2 ± SPECIAL TOOL 1026

Fig. 128 Crankshaft Front SealÐRemoval

1 ± SPECIAL TOOL 8511

Fig. 129 Crankshaft Front SealÐInstallation

1 ± TIMING CHAIN COVER

2 ± SPECIAL TOOL 8348

3 ± SPECIAL TOOL 8512

9 - 72 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 73 of 193

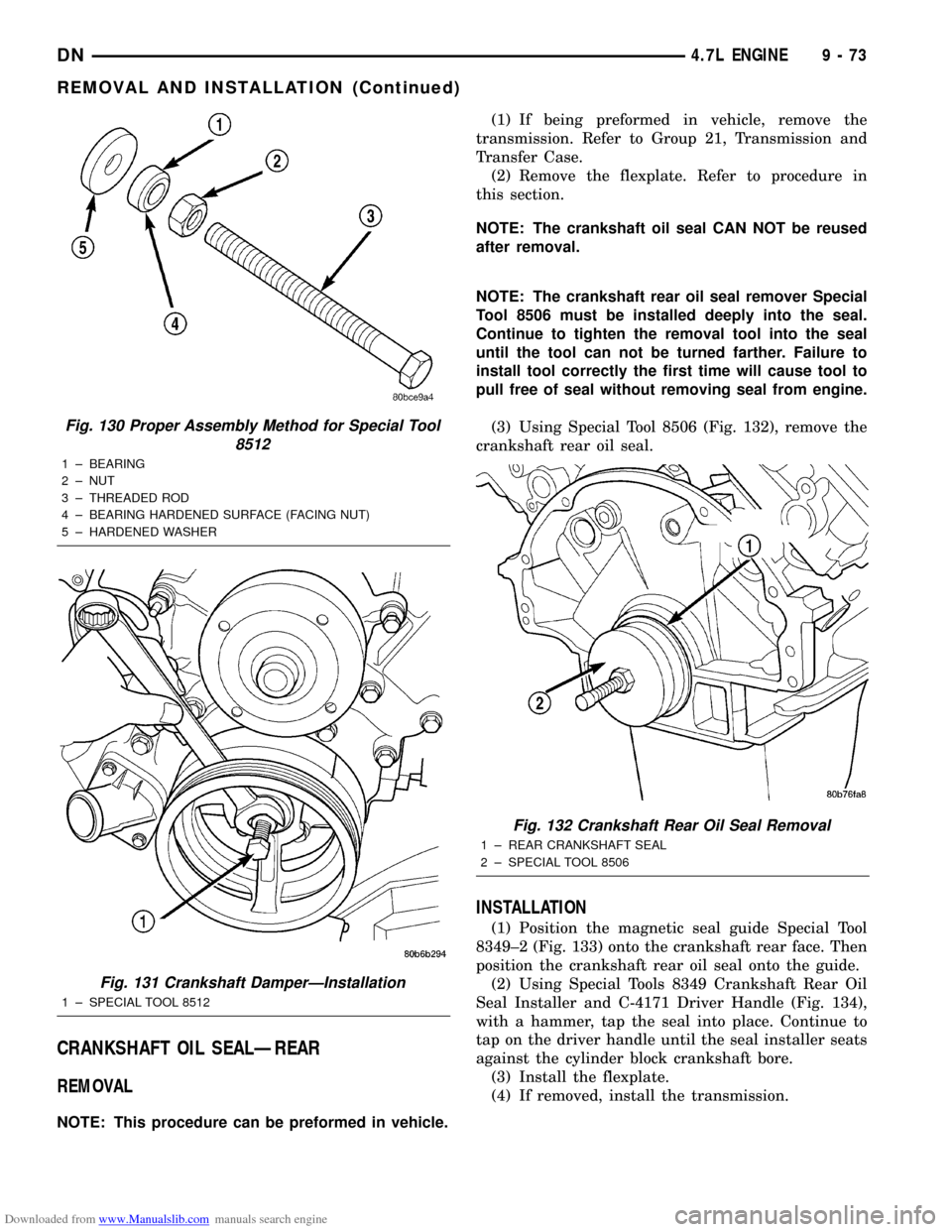

Downloaded from www.Manualslib.com manuals search engine CRANKSHAFT OIL SEALÐREAR

REMOVAL

NOTE: This procedure can be preformed in vehicle.(1) If being preformed in vehicle, remove the

transmission. Refer to Group 21, Transmission and

Transfer Case.

(2) Remove the flexplate. Refer to procedure in

this section.

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506 (Fig. 132), remove the

crankshaft rear oil seal.

INSTALLATION

(1) Position the magnetic seal guide Special Tool

8349±2 (Fig. 133) onto the crankshaft rear face. Then

position the crankshaft rear oil seal onto the guide.

(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 134),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) If removed, install the transmission.

Fig. 130 Proper Assembly Method for Special Tool

8512

1 ± BEARING

2 ± NUT

3 ± THREADED ROD

4 ± BEARING HARDENED SURFACE (FACING NUT)

5 ± HARDENED WASHER

Fig. 131 Crankshaft DamperÐInstallation

1 ± SPECIAL TOOL 8512

Fig. 132 Crankshaft Rear Oil Seal Removal

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8506

DN4.7L ENGINE 9 - 73

REMOVAL AND INSTALLATION (Continued)

Page 74 of 193

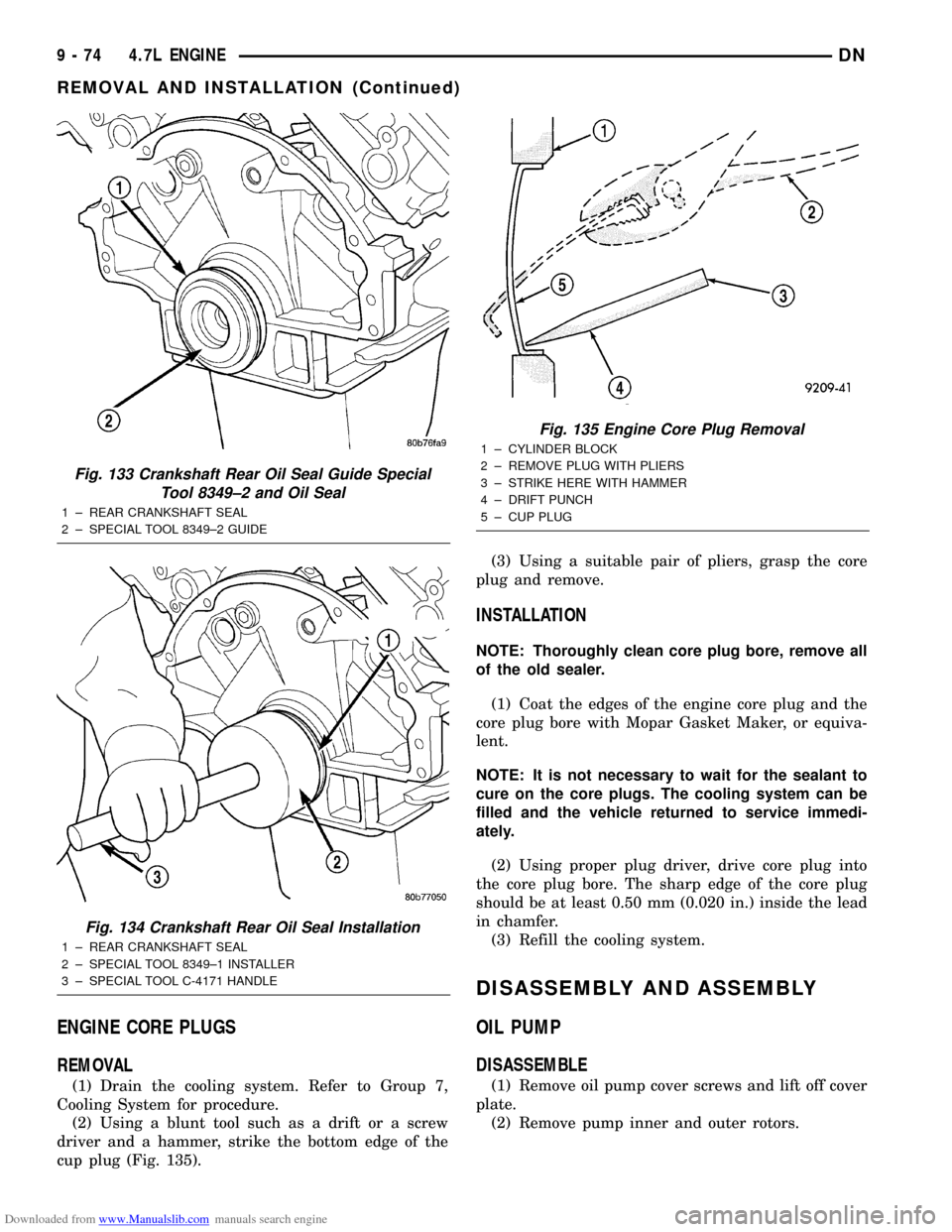

Downloaded from www.Manualslib.com manuals search engine ENGINE CORE PLUGS

REMOVAL

(1) Drain the cooling system. Refer to Group 7,

Cooling System for procedure.

(2) Using a blunt tool such as a drift or a screw

driver and a hammer, strike the bottom edge of the

cup plug (Fig. 135).(3) Using a suitable pair of pliers, grasp the core

plug and remove.

INSTALLATION

NOTE: Thoroughly clean core plug bore, remove all

of the old sealer.

(1) Coat the edges of the engine core plug and the

core plug bore with Mopar Gasket Maker, or equiva-

lent.

NOTE: It is not necessary to wait for the sealant to

cure on the core plugs. The cooling system can be

filled and the vehicle returned to service immedi-

ately.

(2) Using proper plug driver, drive core plug into

the core plug bore. The sharp edge of the core plug

should be at least 0.50 mm (0.020 in.) inside the lead

in chamfer.

(3) Refill the cooling system.

DISASSEMBLY AND ASSEMBLY

OIL PUMP

DISASSEMBLE

(1) Remove oil pump cover screws and lift off cover

plate.

(2) Remove pump inner and outer rotors.

Fig. 133 Crankshaft Rear Oil Seal Guide Special

Tool 8349±2 and Oil Seal

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8349±2 GUIDE

Fig. 134 Crankshaft Rear Oil Seal Installation

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8349±1 INSTALLER

3 ± SPECIAL TOOL C-4171 HANDLE

Fig. 135 Engine Core Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

9 - 74 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 75 of 193

Downloaded from www.Manualslib.com manuals search engine NOTE: Once the oil pressure relief valve, cup plug,

and pin are removed, the pump assembly must be

replaced.

(3) If it is necessary to remove the pressure relief

valve, drive the roll pin from pump housing and

remove cup plug, spring and valve.

ASSEMBLE

(1) Wash all parts in a suitable solvent and inspect

carefully for damage or wear.

(2) Install inner and outer rotors

(3) Install oil pump cover plate and install cover

bolts and tighten them to 12 N´m (105 in. lbs.).

(4) Prime oil pump before installation by filling

rotor cavity with engine oil.

(5) If oil pressure is low and pump is within spec-

ifications, inspect for worn engine bearings or other

causes for oil pressure loss.

CLEANING AND INSPECTION

INTAKE MANIFOLD

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.

(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

EXHAUST MANIFOLD

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

CYLINDER HEADS

CLEANING

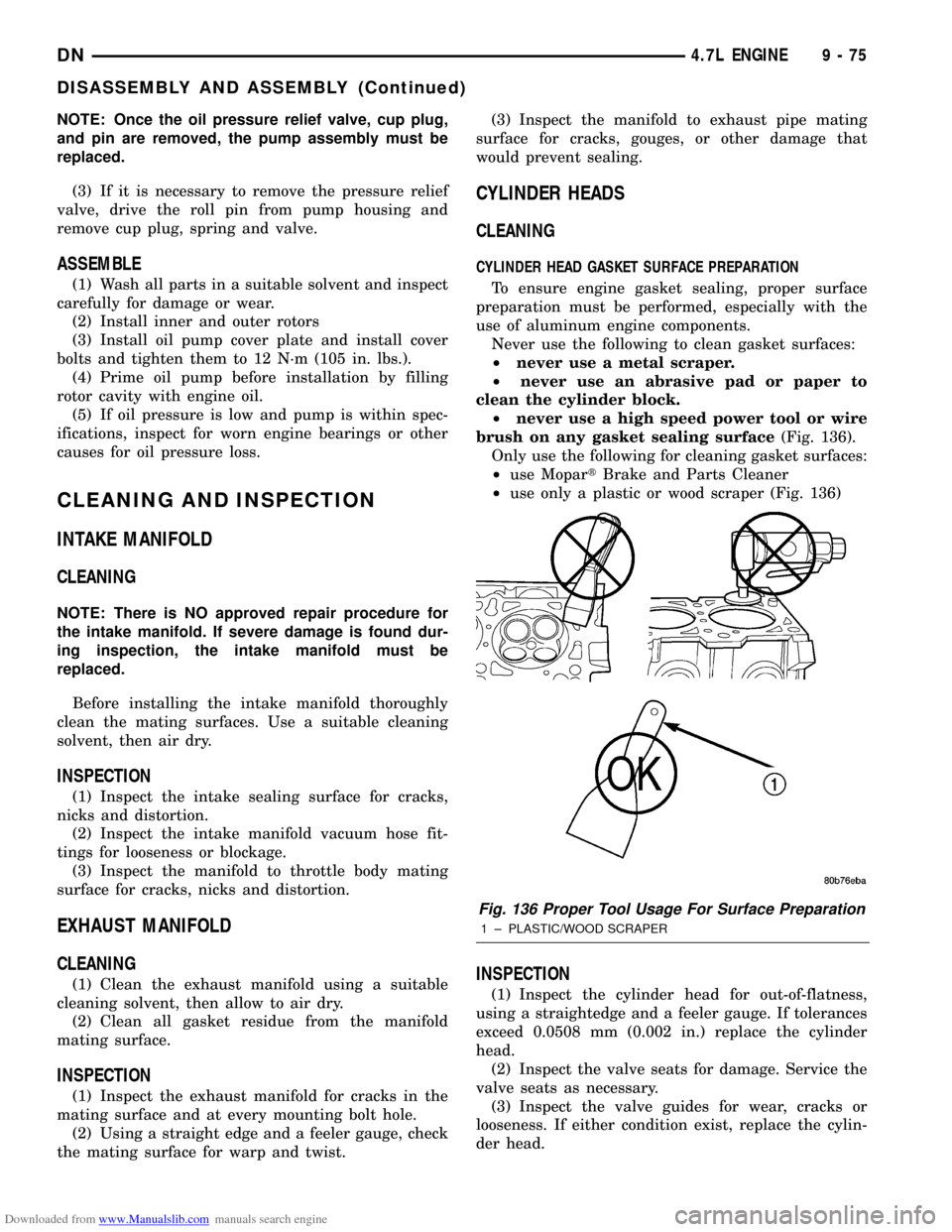

CYLINDER HEAD GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components.

Never use the following to clean gasket surfaces:

²never use a metal scraper.

²never use an abrasive pad or paper to

clean the cylinder block.

²never use a high speed power tool or wire

brush on any gasket sealing surface(Fig. 136).

Only use the following for cleaning gasket surfaces:

²use MopartBrake and Parts Cleaner

²use only a plastic or wood scraper (Fig. 136)

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

Fig. 136 Proper Tool Usage For Surface Preparation

1 ± PLASTIC/WOOD SCRAPER

DN4.7L ENGINE 9 - 75

DISASSEMBLY AND ASSEMBLY (Continued)

Page 76 of 193

Downloaded from www.Manualslib.com manuals search engine PISTON AND CONNECTING ROD

CLEANING

CAUTION: DO NOT use a wire wheel or other abra-

sive cleaning devise to clean the pistons or con-

necting rods. The pistons have a Moly coating, this

coating must not be damaged.

(1) Using a suitable cleaning solvent clean the pis-

tons in warm water and towel dry.

(2) Use a wood or plastic scraper to clean the ring

land grooves.

CAUTION: DO NOT remove the piston pin from the

piston and connecting rod assembly.

INSPECTION

Check the crankshaft connecting rod journal for

excessive wear, taper and scoring.

Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore.

Replace any piston and connecting rod not meeting

the specifications.

OIL PAN

CLEANING

(1) Clean oil pan in solvent and wipe dry with a

clean cloth.

(2) Clean the oil pan gasket surface.DO NOTuse

a grinder wheel or other abrasive tool to clean seal-

ing surface.

(3) Clean oil screen and tube thoroughly in clean

solvent.

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads. Repair as necessary.

(2) Inspect the oil pan mounting flange for bends

or distortion. Straighten flange, if necessary.

OIL PUMP

CLEANING

(1) Wash all parts in a suitable solvent.

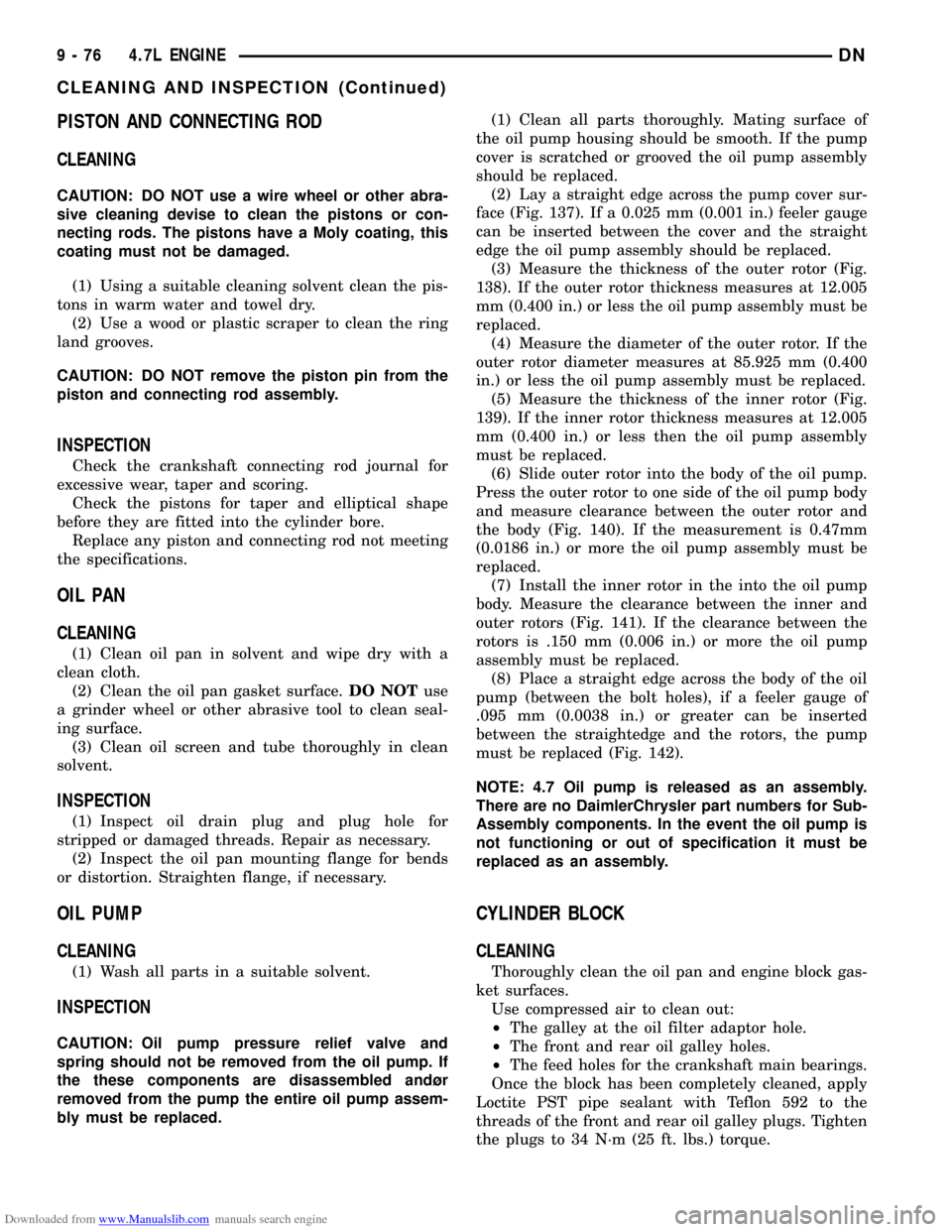

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

the these components are disassembled andùr

removed from the pump the entire oil pump assem-

bly must be replaced.(1) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

(2) Lay a straight edge across the pump cover sur-

face (Fig. 137). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between the cover and the straight

edge the oil pump assembly should be replaced.

(3) Measure the thickness of the outer rotor (Fig.

138). If the outer rotor thickness measures at 12.005

mm (0.400 in.) or less the oil pump assembly must be

replaced.

(4) Measure the diameter of the outer rotor. If the

outer rotor diameter measures at 85.925 mm (0.400

in.) or less the oil pump assembly must be replaced.

(5) Measure the thickness of the inner rotor (Fig.

139). If the inner rotor thickness measures at 12.005

mm (0.400 in.) or less then the oil pump assembly

must be replaced.

(6) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 140). If the measurement is 0.47mm

(0.0186 in.) or more the oil pump assembly must be

replaced.

(7) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 141). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

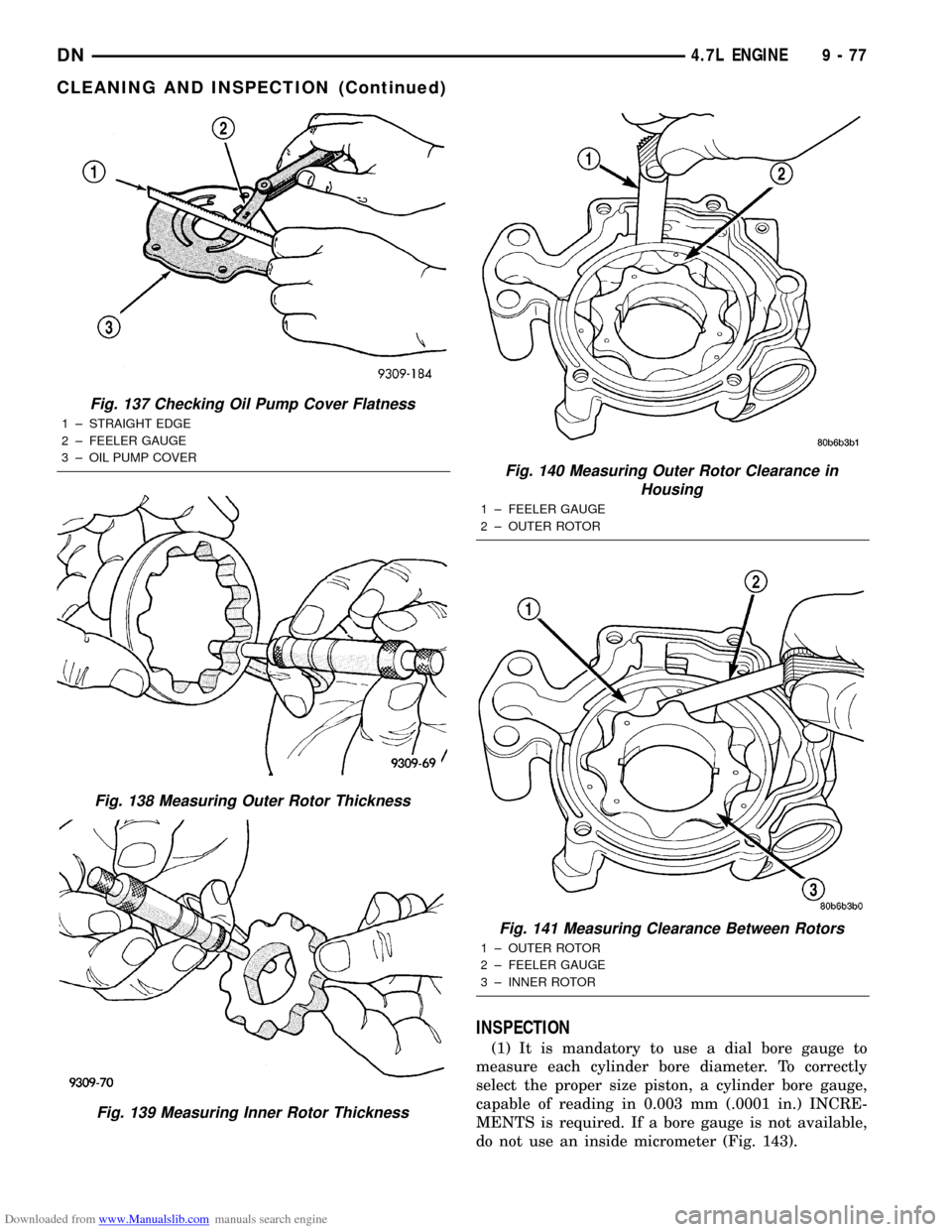

(8) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 142).

NOTE: 4.7 Oil pump is released as an assembly.

There are no DaimlerChrysler part numbers for Sub-

Assembly components. In the event the oil pump is

not functioning or out of specification it must be

replaced as an assembly.

CYLINDER BLOCK

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 34 N´m (25 ft. lbs.) torque.

9 - 76 4.7L ENGINEDN

CLEANING AND INSPECTION (Continued)

Page 77 of 193

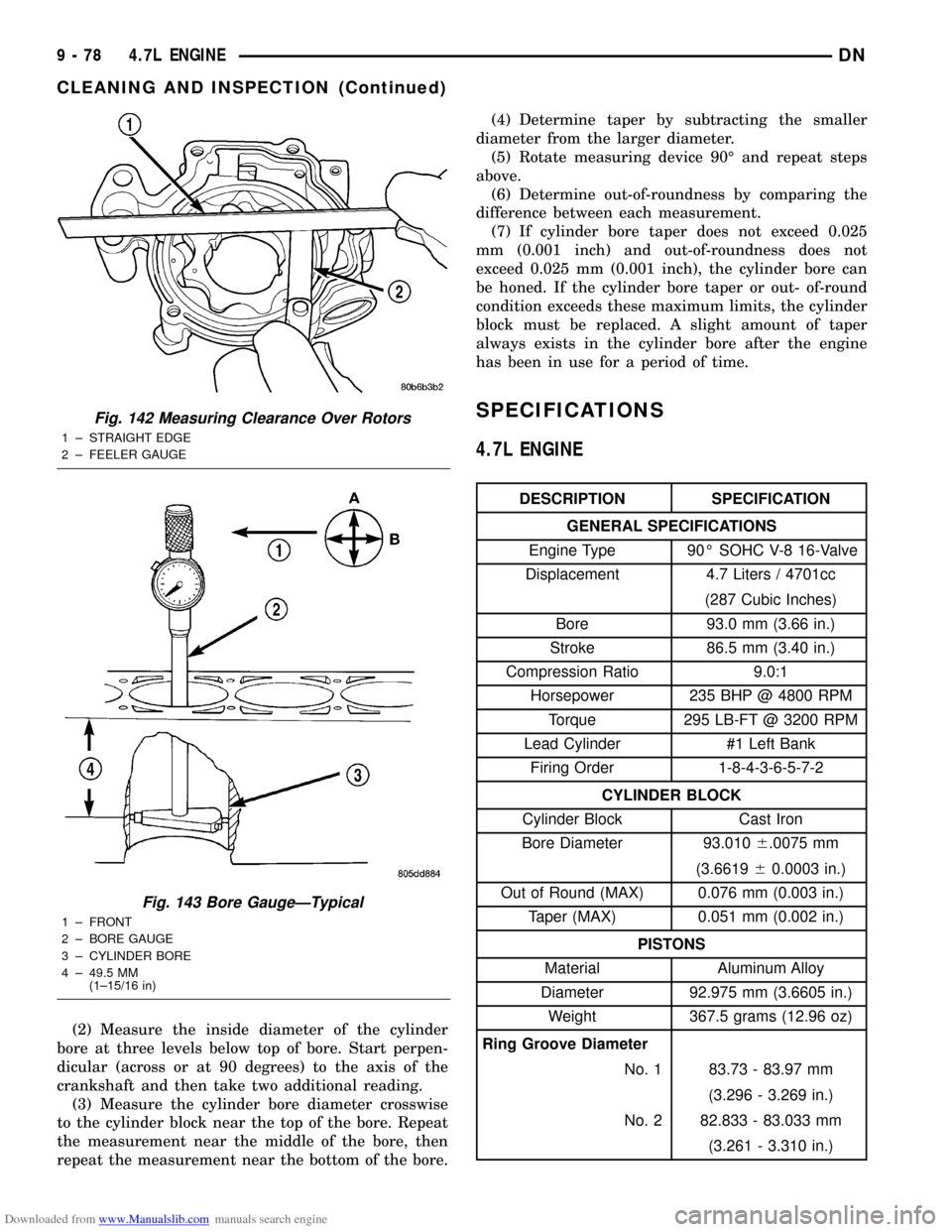

Downloaded from www.Manualslib.com manuals search engine INSPECTION

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore gauge,

capable of reading in 0.003 mm (.0001 in.) INCRE-

MENTS is required. If a bore gauge is not available,

do not use an inside micrometer (Fig. 143).

Fig. 137 Checking Oil Pump Cover Flatness

1 ± STRAIGHT EDGE

2 ± FEELER GAUGE

3 ± OIL PUMP COVER

Fig. 138 Measuring Outer Rotor Thickness

Fig. 139 Measuring Inner Rotor Thickness

Fig. 140 Measuring Outer Rotor Clearance in

Housing

1 ± FEELER GAUGE

2 ± OUTER ROTOR

Fig. 141 Measuring Clearance Between Rotors

1 ± OUTER ROTOR

2 ± FEELER GAUGE

3 ± INNER ROTOR

DN4.7L ENGINE 9 - 77

CLEANING AND INSPECTION (Continued)

Page 78 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.

(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

block must be replaced. A slight amount of taper

always exists in the cylinder bore after the engine

has been in use for a period of time.

SPECIFICATIONS

4.7L ENGINE

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É SOHC V-8 16-Valve

Displacement 4.7 Liters / 4701cc

(287 Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 86.5 mm (3.40 in.)

Compression Ratio 9.0:1

Horsepower 235 BHP @ 4800 RPM

Torque 295 LB-FT @ 3200 RPM

Lead Cylinder #1 Left Bank

Firing Order 1-8-4-3-6-5-7-2

CYLINDER BLOCK

Cylinder Block Cast Iron

Bore Diameter 93.0106.0075 mm

(3.661960.0003 in.)

Out of Round (MAX) 0.076 mm (0.003 in.)

Taper (MAX) 0.051 mm (0.002 in.)

PISTONS

Material Aluminum Alloy

Diameter 92.975 mm (3.6605 in.)

Weight 367.5 grams (12.96 oz)

Ring Groove Diameter

No. 1 83.73 - 83.97 mm

(3.296 - 3.269 in.)

No. 2 82.833 - 83.033 mm

(3.261 - 3.310 in.)

Fig. 142 Measuring Clearance Over Rotors

1 ± STRAIGHT EDGE

2 ± FEELER GAUGE

Fig. 143 Bore GaugeÐTypical

1 ± FRONT

2 ± BORE GAUGE

3 ± CYLINDER BORE

4 ± 49.5 MM

(1±15/16 in)

9 - 78 4.7L ENGINEDN

CLEANING AND INSPECTION (Continued)

Page 79 of 193

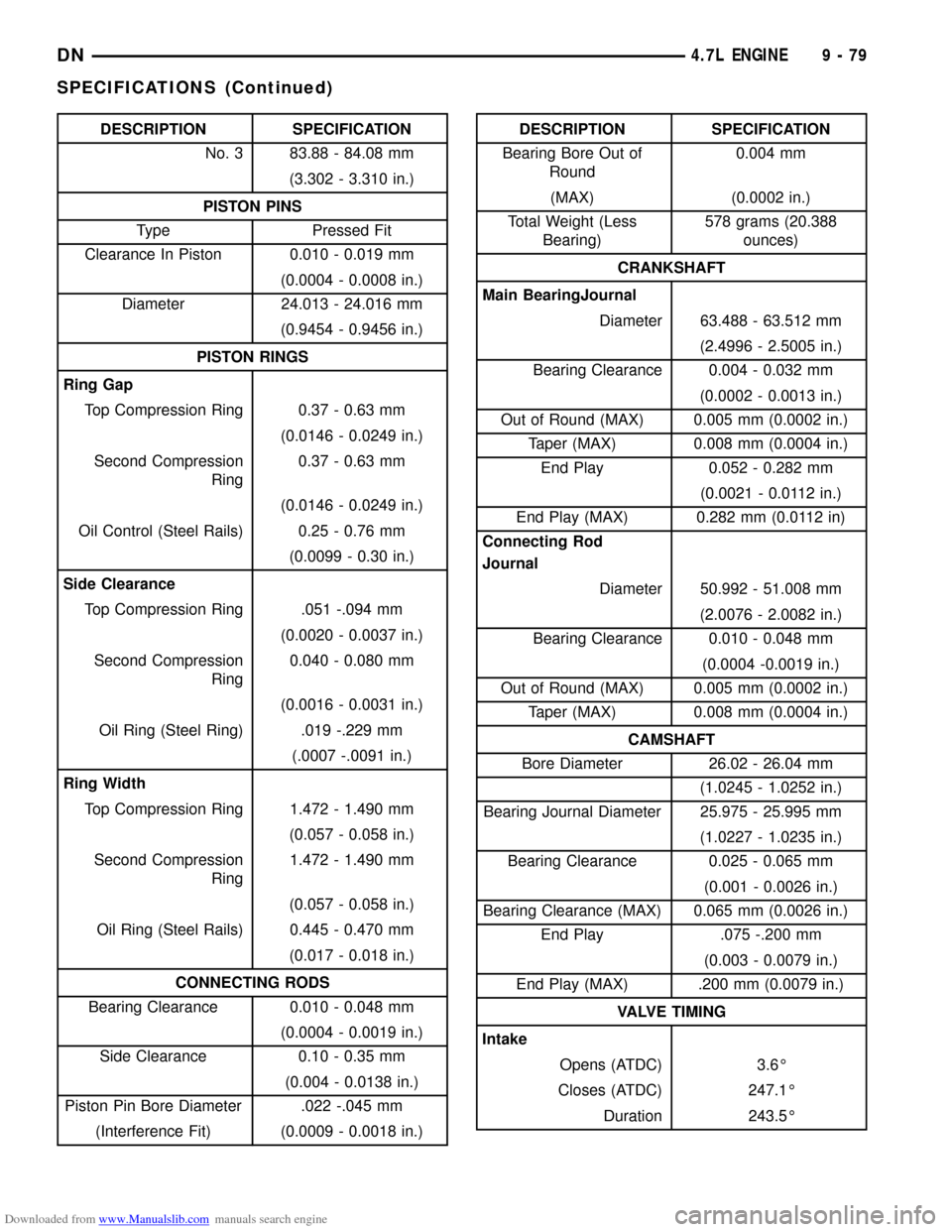

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

No. 3 83.88 - 84.08 mm

(3.302 - 3.310 in.)

PISTON PINS

Type Pressed Fit

Clearance In Piston 0.010 - 0.019 mm

(0.0004 - 0.0008 in.)

Diameter 24.013 - 24.016 mm

(0.9454 - 0.9456 in.)

PISTON RINGS

Ring Gap

Top Compression Ring 0.37 - 0.63 mm

(0.0146 - 0.0249 in.)

Second Compression

Ring0.37 - 0.63 mm

(0.0146 - 0.0249 in.)

Oil Control (Steel Rails) 0.25 - 0.76 mm

(0.0099 - 0.30 in.)

Side Clearance

Top Compression Ring .051 -.094 mm

(0.0020 - 0.0037 in.)

Second Compression

Ring0.040 - 0.080 mm

(0.0016 - 0.0031 in.)

Oil Ring (Steel Ring) .019 -.229 mm

(.0007 -.0091 in.)

Ring Width

Top Compression Ring 1.472 - 1.490 mm

(0.057 - 0.058 in.)

Second Compression

Ring1.472 - 1.490 mm

(0.057 - 0.058 in.)

Oil Ring (Steel Rails) 0.445 - 0.470 mm

(0.017 - 0.018 in.)

CONNECTING RODS

Bearing Clearance 0.010 - 0.048 mm

(0.0004 - 0.0019 in.)

Side Clearance 0.10 - 0.35 mm

(0.004 - 0.0138 in.)

Piston Pin Bore Diameter .022 -.045 mm

(Interference Fit) (0.0009 - 0.0018 in.)DESCRIPTION SPECIFICATION

Bearing Bore Out of

Round0.004 mm

(MAX) (0.0002 in.)

Total Weight (Less

Bearing)578 grams (20.388

ounces)

CRANKSHAFT

Main BearingJournal

Diameter 63.488 - 63.512 mm

(2.4996 - 2.5005 in.)

Bearing Clearance 0.004 - 0.032 mm

(0.0002 - 0.0013 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

End Play 0.052 - 0.282 mm

(0.0021 - 0.0112 in.)

End Play (MAX) 0.282 mm (0.0112 in)

Connecting Rod

Journal

Diameter 50.992 - 51.008 mm

(2.0076 - 2.0082 in.)

Bearing Clearance 0.010 - 0.048 mm

(0.0004 -0.0019 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

CAMSHAFT

Bore Diameter 26.02 - 26.04 mm

(1.0245 - 1.0252 in.)

Bearing Journal Diameter 25.975 - 25.995 mm

(1.0227 - 1.0235 in.)

Bearing Clearance 0.025 - 0.065 mm

(0.001 - 0.0026 in.)

Bearing Clearance (MAX) 0.065 mm (0.0026 in.)

End Play .075 -.200 mm

(0.003 - 0.0079 in.)

End Play (MAX) .200 mm (0.0079 in.)

VALVE TIMING

Intake

Opens (ATDC) 3.6É

Closes (ATDC) 247.1É

Duration 243.5É

DN4.7L ENGINE 9 - 79

SPECIFICATIONS (Continued)

Page 80 of 193

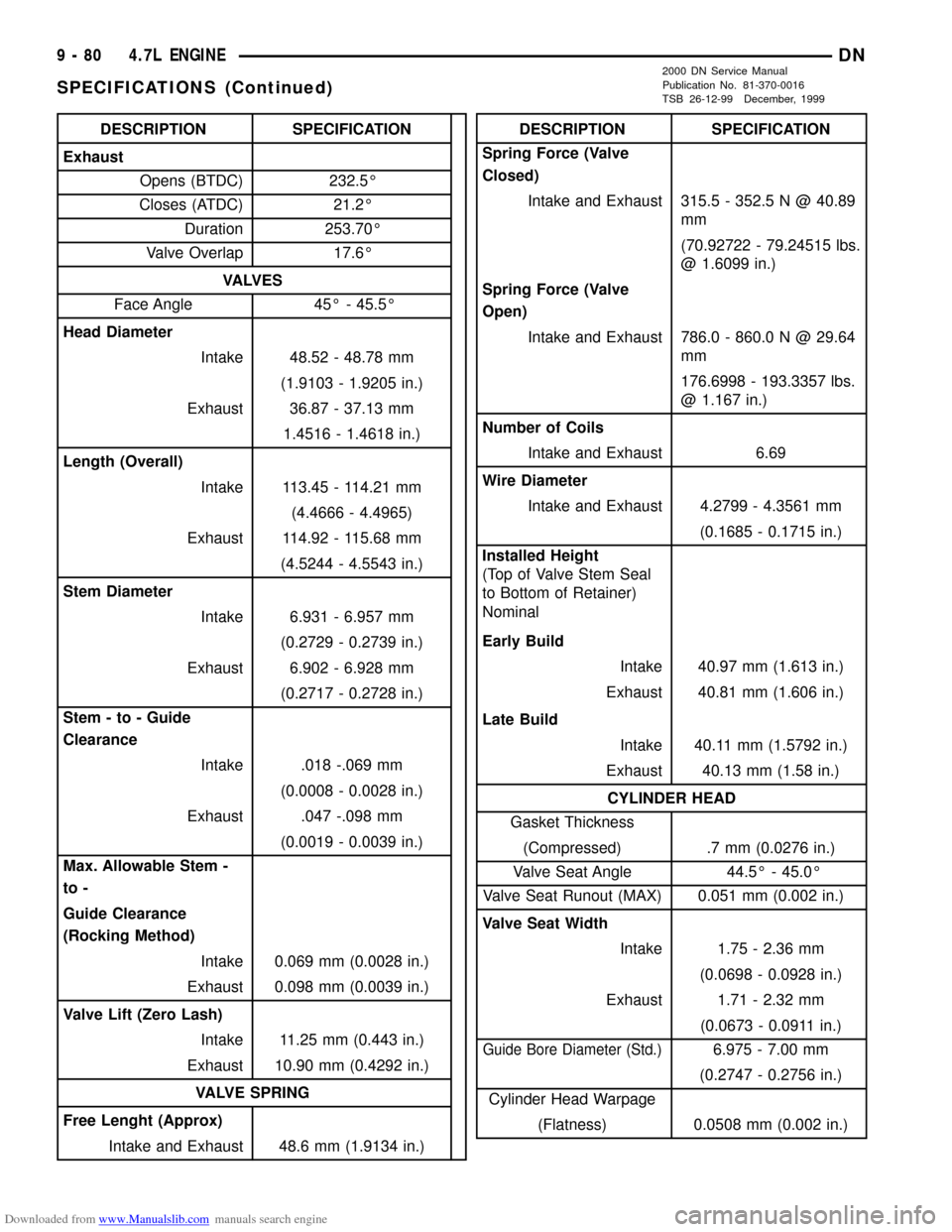

Downloaded from www.Manualslib.com manuals search engine DESCRIPTION SPECIFICATION

Exhaust

Opens (BTDC) 232.5É

Closes (ATDC) 21.2É

Duration 253.70É

Valve Overlap 17.6É

VA LV E S

Face Angle 45É - 45.5É

Head Diameter

Intake 48.52 - 48.78 mm

(1.9103 - 1.9205 in.)

Exhaust 36.87 - 37.13 mm

1.4516 - 1.4618 in.)

Length (Overall)

Intake 113.45 - 114.21 mm

(4.4666 - 4.4965)

Exhaust 114.92 - 115.68 mm

(4.5244 - 4.5543 in.)

Stem Diameter

Intake 6.931 - 6.957 mm

(0.2729 - 0.2739 in.)

Exhaust 6.902 - 6.928 mm

(0.2717 - 0.2728 in.)

Stem - to - Guide

Clearance

Intake .018 -.069 mm

(0.0008 - 0.0028 in.)

Exhaust .047 -.098 mm

(0.0019 - 0.0039 in.)

Max. Allowable Stem -

to -

Guide Clearance

(Rocking Method)

Intake 0.069 mm (0.0028 in.)

Exhaust 0.098 mm (0.0039 in.)

Valve Lift (Zero Lash)

Intake 11.25 mm (0.443 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

Free Lenght (Approx)

Intake and Exhaust 48.6 mm (1.9134 in.)DESCRIPTION SPECIFICATION

Spring Force (Valve

Closed)

Intake and Exhaust 315.5 - 352.5 N @ 40.89

mm

(70.92722 - 79.24515 lbs.

@ 1.6099 in.)

Spring Force (Valve

Open)

Intake and Exhaust 786.0 - 860.0 N @ 29.64

mm

176.6998 - 193.3357 lbs.

@ 1.167 in.)

Number of Coils

Intake and Exhaust 6.69

Wire Diameter

Intake and Exhaust 4.2799 - 4.3561 mm

(0.1685 - 0.1715 in.)

Installed Height

(Top of Valve Stem Seal

to Bottom of Retainer)

Nominal

Early Build

Intake 40.97 mm (1.613 in.)

Exhaust 40.81 mm (1.606 in.)

Late Build

Intake 40.11 mm (1.5792 in.)

Exhaust 40.13 mm (1.58 in.)

CYLINDER HEAD

Gasket Thickness

(Compressed) .7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter (Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)

Cylinder Head Warpage

(Flatness) 0.0508 mm (0.002 in.)

9 - 80 4.7L ENGINEDN

SPECIFICATIONS (Continued)

2000 DN Service Manual

Publication No. 81-370-0016

TSB 26-12-99 December, 1999