steering DODGE DURANGO 2004 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: DURANGO, Model: DODGE DURANGO 2004 2.GPages: 386, PDF Size: 6.22 MB

Page 238 of 386

WARNING!

²Do not use a tire, wheel size or rating other than that

specified for your vehicle. Some combinations of

unapproved tires and wheels may change suspen-

sion dimensions and performance characteristics,

resulting in changes to steering, handling, and brak-

ing of your vehicle. This can cause unpredictable

handling and stress to steering and suspension com-

ponents. You could lose control and have an accident

resulting in serious injury or death. Use only the tire

and wheel sizes with load ratings approved for your

vehicle.

²Never use a tire with a smaller load index or capacity,

other than what was originally equipped on your

vehicle. Using a tire with a smaller load index could

result in tire overloading and failure. You could lose

control and have an accident.

²Failure to equip your vehicle with tires having

adequate speed capability can result in sudden tire

failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different size

may result in false speedometer and odometer read-

ings.

Alignment And Balance

Poor suspension alignment may result in:

²Fast tire wear.

²Uneven tire wear, such as feathering and one-sided

wear.

²Vehicle pull to right or left.

Tires may also cause the vehicle to pull to the left or right.

Alignment will not correct this condition. See your dealer

for proper diagnosis.

238 STARTING AND OPERATING

Page 241 of 386

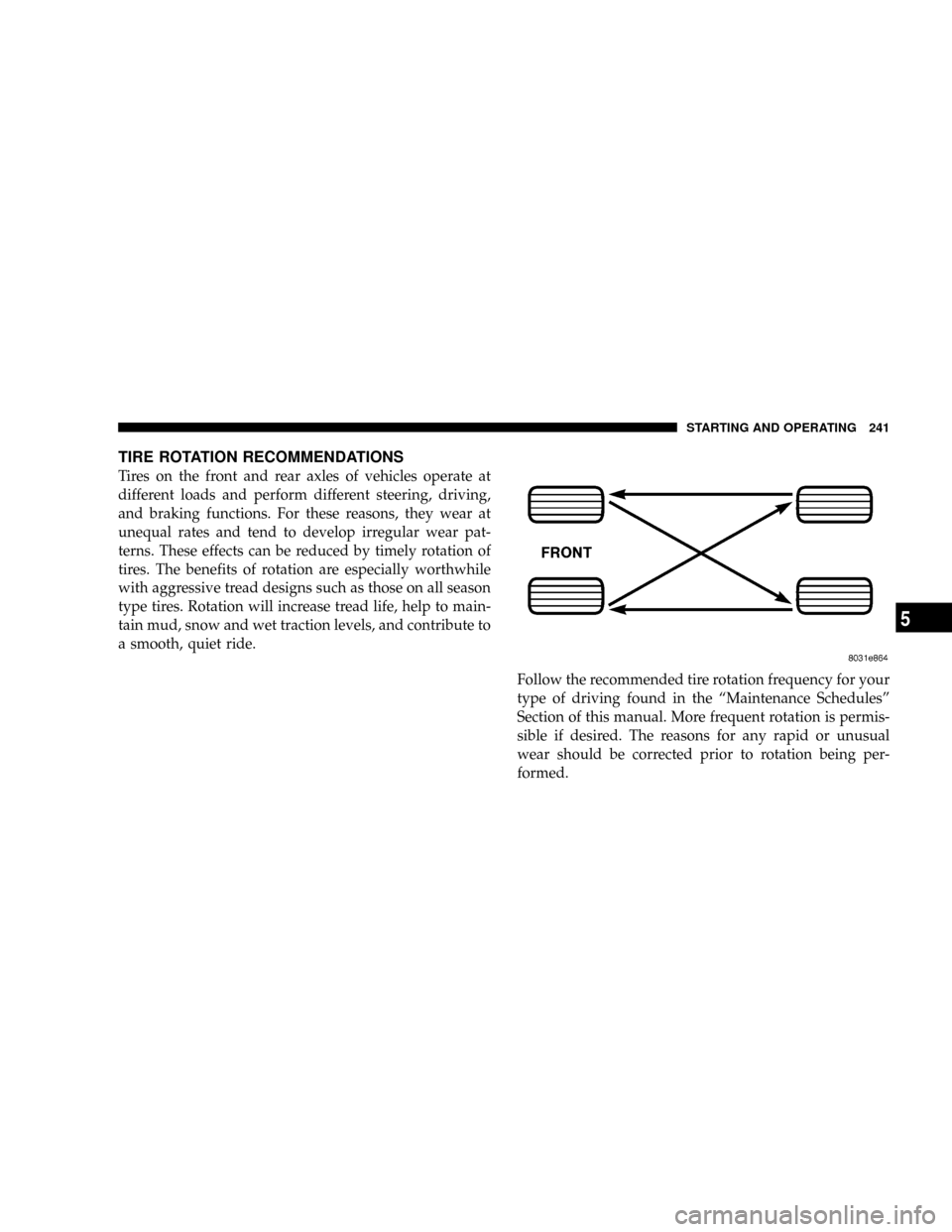

TIRE ROTATION RECOMMENDATIONS

Tires on the front and rear axles of vehicles operate at

different loads and perform different steering, driving,

and braking functions. For these reasons, they wear at

unequal rates and tend to develop irregular wear pat-

terns. These effects can be reduced by timely rotation of

tires. The benefits of rotation are especially worthwhile

with aggressive tread designs such as those on all season

type tires. Rotation will increase tread life, help to main-

tain mud, snow and wet traction levels, and contribute to

a smooth, quiet ride.

Follow the recommended tire rotation frequency for your

type of driving found in the ªMaintenance Schedulesº

Section of this manual. More frequent rotation is permis-

sible if desired. The reasons for any rapid or unusual

wear should be corrected prior to rotation being per-

formed.

STARTING AND OPERATING 241

5

Page 256 of 386

²Trailer brakes are recommended for trailers over 1,000

lbs (454 kg) and required for trailers in excess of 2,000

lbs. (907 kg).

²Use an approved trailer harness and connector. If a

hitch is ordered, the proper wiring will be provided.

²When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

²Make certain that the load is secured in the trailer and

will not shift during travel. When trailering cargo that

cannot be fully secured, dynamic load shifts can occur

that may be difficult for the driver to control.

²All trailer hitches should be professionally installed on

your vehicle.

²Safety chains must always be used between your

vehicle and trailer.

²Connect trailer lighting and brakes using factory har-

nesses only. Do not cut or splice any wiring to the

brake circuits.

Trailer and Tongue Weight

Gross Trailer Weight (GTW) means the maximum allow-

able weight of the trailer plus the weight of all cargo and

equipment loaded on the trailer when in actual under-

way towing condition. The recommended way to mea-

sure GTW is to put your fully loaded trailer on a vehicle

scale. The entire weight of the trailer must be supported

by the scale.

Tongue Weight is the weight placed on the vehicle's

trailer hitch by the trailer. Always load a trailer with 60%

to 65% of the weight in the front of the trailer. This places

10% to 15% of the GTW on the tow hitch of your vehicle.

256 STARTING AND OPERATING

Page 270 of 386

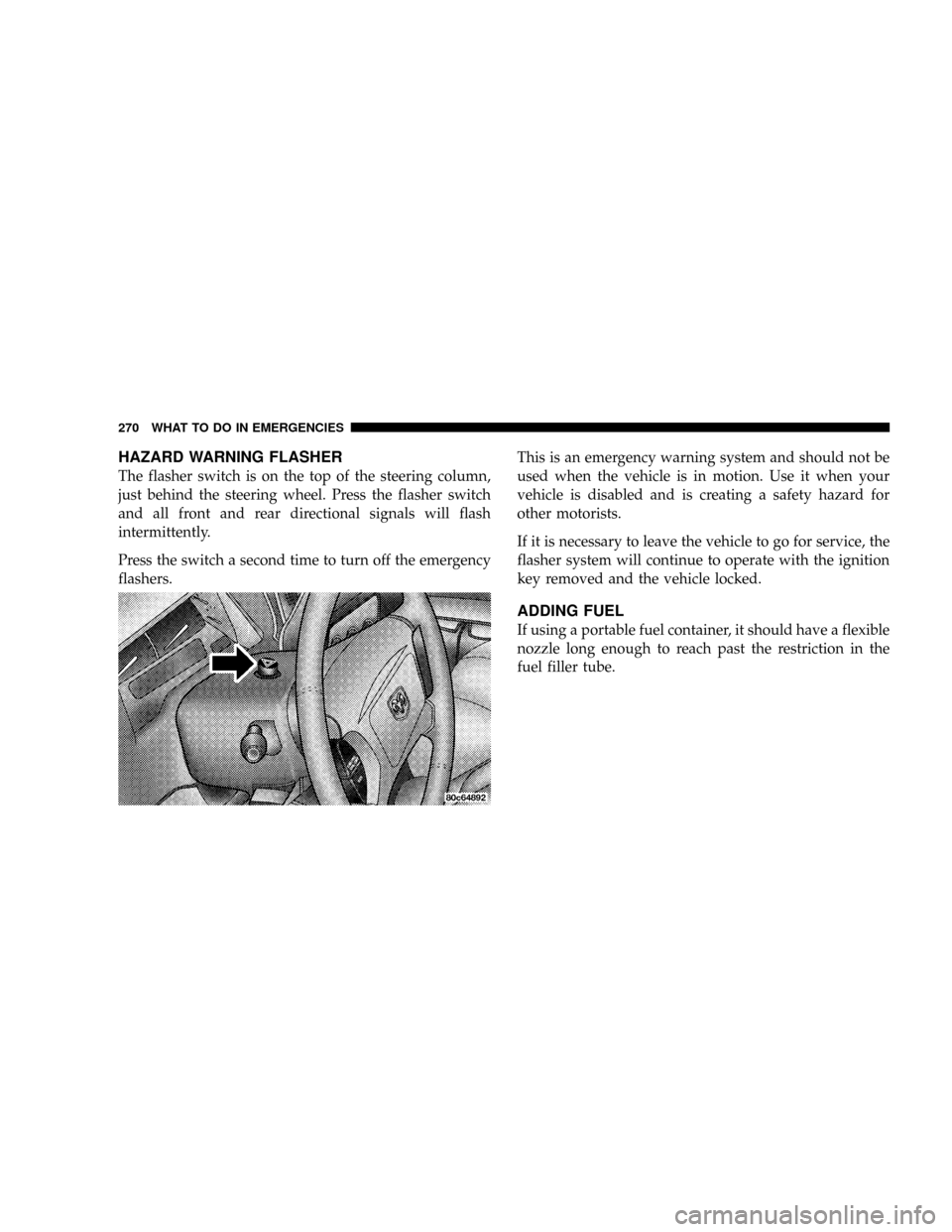

HAZARD WARNING FLASHER

The flasher switch is on the top of the steering column,

just behind the steering wheel. Press the flasher switch

and all front and rear directional signals will flash

intermittently.

Press the switch a second time to turn off the emergency

flashers.This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

If it is necessary to leave the vehicle to go for service, the

flasher system will continue to operate with the ignition

key removed and the vehicle locked.

ADDING FUEL

If using a portable fuel container, it should have a flexible

nozzle long enough to reach past the restriction in the

fuel filler tube.

270 WHAT TO DO IN EMERGENCIES

Page 284 of 386

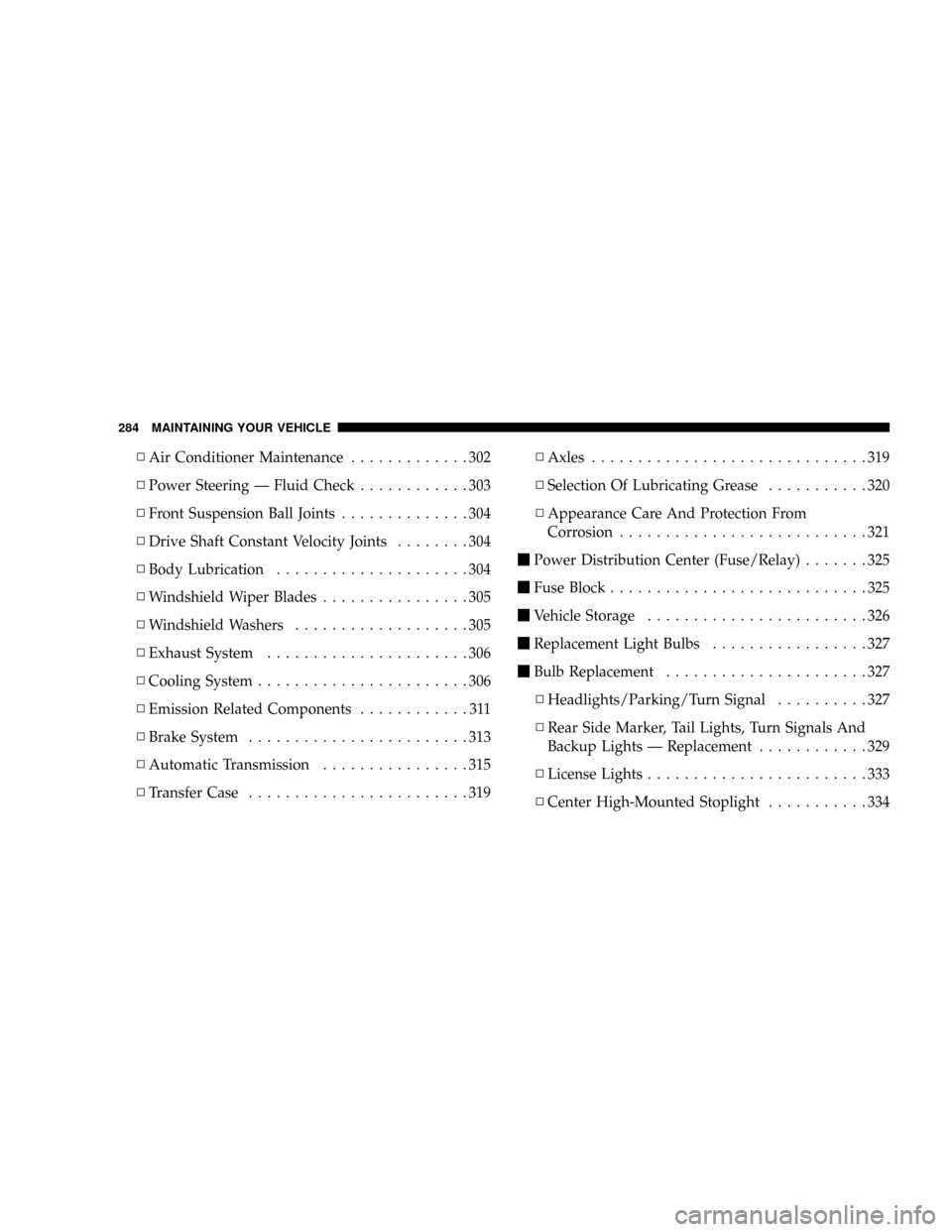

NAir Conditioner Maintenance.............302

NPower Steering Ð Fluid Check............303

NFront Suspension Ball Joints..............304

NDrive Shaft Constant Velocity Joints........304

NBody Lubrication.....................304

NWindshield Wiper Blades................305

NWindshield Washers...................305

NExhaust System......................306

NCooling System.......................306

NEmission Related Components............311

NBrake System........................313

NAutomatic Transmission................315

NTransfer Case........................319NAxles..............................319

NSelection Of Lubricating Grease...........320

NAppearance Care And Protection From

Corrosion...........................321

mPower Distribution Center (Fuse/Relay).......325

mFuse Block............................325

mVehicle Storage........................326

mReplacement Light Bulbs.................327

mBulb Replacement......................327

NHeadlights/Parking/Turn Signal..........327

NRear Side Marker, Tail Lights, Turn Signals And

Backup Lights Ð Replacement............329

NLicense Lights........................333

NCenter High-Mounted Stoplight...........334

284 MAINTAINING YOUR VEHICLE

Page 303 of 386

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

NOTE:Air Conditioning systems found to be contami-

nated with A/C System Sealers, Stop Leak Products, Seal

Conditioners, Compressor Oil, or Refrigerants not ap-

proved by the manufacturer, voids the warranty for the

Air Conditioning system.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises areapparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.9

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Recommended Fluids, Lubricants, and

Genuine Parts for correct fluid type.

MAINTAINING YOUR VEHICLE 303

7

Page 312 of 386

swelling suggest deterioration of the rubber. Particular

attention should be given to examining hose surfaces

nearest to high heat sources, such as the exhaust mani-

fold.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

You are urged to use only the manufacturer's specified

hoses and clamps, or their equivalent in material andspecification, in any fuel system servicing. It is manda-

tory to replace all clamps that have been loosened or

removed during service. Care should be taken in install-

ing new clamps to insure they are properly torqued.

Positive Crankcase Ventilation (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging because of deposits. Deposits can accumulate in the

PCV valve and passage with increasing mileage. Have

the PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valve ±Do not

attempt to clean the oil PCV valve!Check ventilating

hose for indication of damage or plugging with deposits.

Replace if necessary.

312 MAINTAINING YOUR VEHICLE

Page 338 of 386

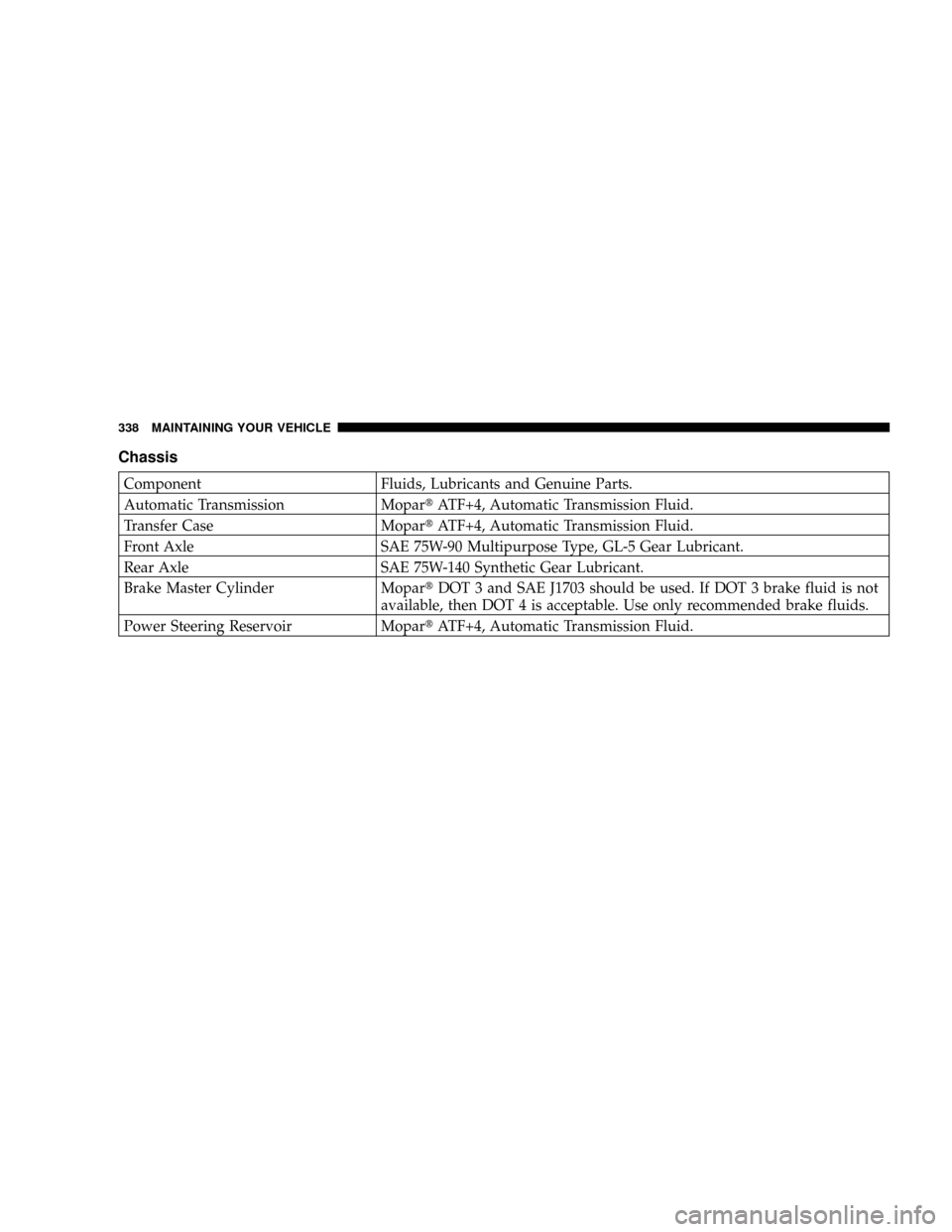

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transmission MopartATF+4, Automatic Transmission Fluid.

Transfer Case MopartATF+4, Automatic Transmission Fluid.

Front Axle SAE 75W-90 Multipurpose Type, GL-5 Gear Lubricant.

Rear Axle SAE 75W-140 Synthetic Gear Lubricant.

Brake Master Cylinder MopartDOT 3 and SAE J1703 should be used. If DOT 3 brake fluid is not

available, then DOT 4 is acceptable. Use only recommended brake fluids.

Power Steering Reservoir MopartATF+4, Automatic Transmission Fluid.

338 MAINTAINING YOUR VEHICLE

Page 371 of 386

Axle Lubrication........................ 319

Ball Joints............................. 304

Battery............................... 300

Charging............................ 280

Emergency Starting..................... 280

Gas Caution.......................... 280

Keyless Transmitter Replacement............ 24

Saving Feature........................ 105

Belts, Drive............................ 297

Belts, Seat.............................. 29

Body Mechanism Lubrication............... 304

B-Pillar Location........................ 226

Brake Fluid............................ 338

Brake System........................218,313

Anti-Lock........................... 218

Disc Brakes.......................... 313

Fluid Check.......................... 313

Hoses.............................. 314Master Cylinder....................... 313

Parking............................. 217

Warning Light.....................149,151

Brakes............................... 218

Brake/Transmission Interlock............... 203

Break-In Recommendations, New Vehicle........ 62

Bulb Replacement....................... 327

Bulbs, Light............................ 327

Calibration, Compass..................... 124

Capacities, Fluid........................ 335

Caps, Filler

Power Steering........................ 303

Car Washes............................ 321

Carbon Monoxide Warning................. 248

Cargo ................................ 250

Catalytic Converter....................249,299

CD Player..........................155,161

Cellular Phone........................74,179

INDEX 371

10

Page 373 of 386

Daytime Running Lights................... 107

Dealer Service.......................... 291

Defroster, Rear Window................... 195

Defroster, Windshield................63,182,187

Delay Wipers........................... 110

Diagnostic System, Onboard................ 289

Dimmer Switch, Headlight................. 147

Dipsticks

Automatic Transmission................. 316

Oil (Engine).......................... 292

Power Steering........................ 303

Disarming, Theft System................... 25

Disc Brakes............................ 313

Disposal

Used Coolant......................... 308

Door Ajar Light......................... 151

Door Locks............................. 13

Door Opener, Garage..................... 126

Drive Belts............................ 297Drive Shaft Universal Joints................ 304

Electric Remote Mirrors.................... 72

Electrical Power Outlets................... 135

Electronic Speed Control................... 116

Emergency, In Case of

Freeing Vehicle When Stuck............... 221

Jacking............................. 275

Overheating.......................... 310

Towing............................. 282

Emission Control System Maintenance......... 340

Emission Related Components.............. 311

Engine

Air Cleaner.......................... 298

Block Heater......................... 202

Break-In Recommendations................ 62

Compartment......................287,288

Coolant..........................308,337

Cooling............................. 306

INDEX 373

10