oil pressure DODGE DURANGO 2004 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: DURANGO, Model: DODGE DURANGO 2004 2.GPages: 386, PDF Size: 6.22 MB

Page 64 of 386

Safety Checks You Should Make Outside The

Vehicle:

Tires

Examine tires for tread wear or uneven wear patterns.

Check for stones, nails, glass or other objects lodged in

the tread.

Inspect for tread cuts or sidewall cracks. Check wheel

nuts for tightness and tires for proper pressure.

Lights

Have someone observe the operation of exterior lights as

you turn them on. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for positive closing, latching and locking.

Fluid Leaks

Check the area under vehicle after overnight parking for

fuel, water, oil, or other fluid leaks. Also, if gasoline

fumes are detected, the cause should be located and

corrected.

64 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 148 of 386

CAUTION!

Driving with a hot engine cooling system could

damage your vehicle. If the temperature light is on,

safely pull over and stop the vehicle. Idle the vehicle

in neutral with the air conditioner turned off until

the light turns off. If the if the light remains on, turn

the engine off immediately, and call for service.

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, see Section 7 of this manual. Follow

the warnings under the Cooling System Pressure

Cap paragraph.

9. Speedometer

Shows vehicle speed in miles per hour and kilometers

per hour.

10. Voltage Light

This light monitors the electrical system voltage.

The light should turn on momentarily as the

148 INSTRUMENT PANEL AND CONTROLS

Page 149 of 386

engine is started. If the light stays on or turns on while

driving, it indicates a problem with the charging system.

Immediate service should be obtained.

11. Liftgate Open

The Gate Open light will illuminate when the liftgate is

not properly closed and the ignition is ON.

12. Security Light

This light will flash rapidly for approximately 15 seconds

when the vehicle theft alarm is arming. The light will

flash at a slower speed continuously after the alarm is set.

The security light will also come on for about three

seconds when the ignition is first turned on.

13. ABS Warning Light

This light monitors the Anti-Lock Brake System

which is described elsewhere in this manual.

This light will come on when the ignition key is

turned to the ON position and may stay on for

approximately 3 seconds. If this light remains on orcomes on during driving, it indicates that the Anti-Lock

portion of the brake system is not functioning and that

service is required. See your authorized dealer immedi-

ately.

14. Engine Oil Pressure Indicator Light

This light indicates that the engine oil pressure has

become too low. For a bulb check, this light will

come on momentarily when the ignition is turned On. If

the light turns on while driving, stop the vehicle and shut

off the engine as soon as possible. Immediate service

should be obtained.

15. Tachometer

This gage measures engine revolutions-per-minute (rpm

x 1000).

16. Gear Selector

The electronic gear selector display is self-contained

within the instrument cluster. It displays the position of

the automatic transmission shift lever, and the relation of

INSTRUMENT PANEL AND CONTROLS 149

4

Page 278 of 386

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

6. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel. Lightly tighten the nuts. To

avoid risk of forcing the vehicle off the jack, do not fully

tighten the nuts until the vehicle has been lowered.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

7. Using the wheel wrench, finish tightening the nuts in

a crisscross pattern. Correct nut tightness is 85-115 ft. lbs.

(115-155 N´m) torque. If in doubt about the correct

tightness, have them checked with a torque wrench by

your dealer or at a service station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle.

Always stow the jack, tools and the extra tire and

wheel in the places provided.

8. Install wheel center cap and remove wheel blocks. Do

not install chrome or aluminum wheel center caps on the

spare wheel. This may result in cap damage.

9. Lower the jack to its fully closed position. Stow the

replaced tire, jack, and tools as previously described.

10. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

278 WHAT TO DO IN EMERGENCIES

Page 293 of 386

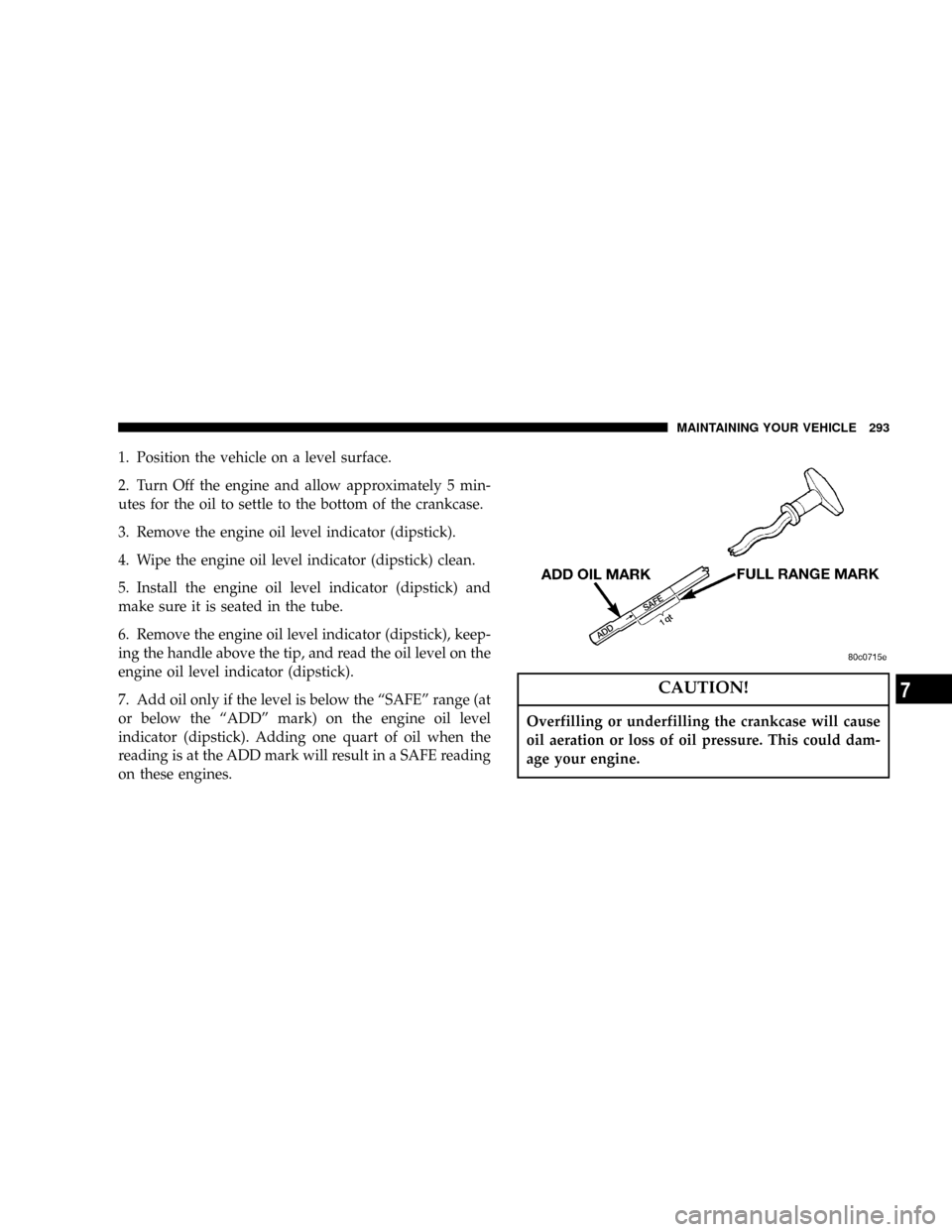

1. Position the vehicle on a level surface.

2. Turn Off the engine and allow approximately 5 min-

utes for the oil to settle to the bottom of the crankcase.

3. Remove the engine oil level indicator (dipstick).

4. Wipe the engine oil level indicator (dipstick) clean.

5. Install the engine oil level indicator (dipstick) and

make sure it is seated in the tube.

6. Remove the engine oil level indicator (dipstick), keep-

ing the handle above the tip, and read the oil level on the

engine oil level indicator (dipstick).

7. Add oil only if the level is below the ªSAFEº range (at

or below the ªADDº mark) on the engine oil level

indicator (dipstick). Adding one quart of oil when the

reading is at the ADD mark will result in a SAFE reading

on these engines.

CAUTION!

Overfilling or underfilling the crankcase will cause

oil aeration or loss of oil pressure. This could dam-

age your engine.

MAINTAINING YOUR VEHICLE 293

7

Page 312 of 386

swelling suggest deterioration of the rubber. Particular

attention should be given to examining hose surfaces

nearest to high heat sources, such as the exhaust mani-

fold.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

You are urged to use only the manufacturer's specified

hoses and clamps, or their equivalent in material andspecification, in any fuel system servicing. It is manda-

tory to replace all clamps that have been loosened or

removed during service. Care should be taken in install-

ing new clamps to insure they are properly torqued.

Positive Crankcase Ventilation (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging because of deposits. Deposits can accumulate in the

PCV valve and passage with increasing mileage. Have

the PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valve ±Do not

attempt to clean the oil PCV valve!Check ventilating

hose for indication of damage or plugging with deposits.

Replace if necessary.

312 MAINTAINING YOUR VEHICLE

Page 342 of 386

CAUTION!

Failure to perform the required maintenance items

may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, and transmission and add as needed.

²Check all lights and all other electrical items for correct

operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints (if equipped) and front suspen-

sion components.

²Check the automatic transmission fluid level.

²Check the coolant level, hoses, and clamps.

342 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S

Page 383 of 386

Emergency (Jump Starting)............... 280

Engine Block Heater.................... 202

Engine Fails to Start.................... 201

Starting Procedures...................... 200

Steering

Column Controls...................... 108

Column Lock.......................... 12

Power...........................220,303

Wheel, Tilt........................... 113

Steering Wheel Mounted Sound System

Controls............................. 177

Storage, Vehicle......................... 326

Stuck, Freeing.......................... 221

Sun Roof.............................. 133

Supplemental Tire Pressure Information........ 239

Synthetic Engine Oil...................... 296

Tachometer............................ 149

Taillights.............................. 329Temperature Gauge, Engine Coolant.......... 146

Tether Anchor, Child Restraint............... 54

Theft System Arming...................... 25

Theft System Disarming.................... 25

Thermostat............................ 311

Tilt Steering Column..................... 113

Tire and Loading Information Placard......226,239

Tire Identification Number (TIN)............. 225

Tire Markings.......................... 221

Tire Safety Information.................... 221

Tires ...............................64,230

Air Pressure.......................... 230

Alignment........................... 238

Chains.............................. 239

Changing............................ 272

Compact Spare........................ 234

General Information.................... 230

High Speed.......................... 233

Inflation Pressures..................... 231

INDEX 383

10