oil pressure DODGE DURANGO 2008 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: DURANGO, Model: DODGE DURANGO 2008 2.GPages: 481, PDF Size: 7.75 MB

Page 77 of 481

Safety Checks You Should Make Outside The

Vehicle

Tires

Examine tires for tread wear or uneven wear patterns.

Check for stones, nails, glass or other objects lodged in

the tread.

Inspect for tread cuts or sidewall cracks. Check wheel

nuts for tightness and tires for proper pressure.

Lights

Check the operation of all exterior lights. Check turn

signal and high beam indicator lights on the instrument

panel.

Door Latches

Check for positive closing, latching and locking.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

water, oil, or other fluid leaks. Also, if fuel fumes are

detected the cause should be located and corrected.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 77

2

Page 195 of 481

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, see Section 7 of this manual. Follow

the warnings under the Cooling System Pressure Cap

paragraph.

8. Speedometer

Shows the vehicles speed.

9. Voltage Light

This light monitors the electrical system voltage.

The light should turn on momentarily as the

engine is started. If the light stays on or turns on while

driving, it indicates a problem with the charging system.

Immediate service should be obtained.10. Security Light

This light will flash rapidly for approximately 15 seconds

when the vehicle theft alarm is arming. The light will

flash at a slower speed continuously after the alarm is set.

The security light will also come on for about three

seconds when the ignition is first turned on.

11. ABS Warning Light

This light monitors the Anti-Lock Brake System

which is described elsewhere in this manual.

This light will come on when the ignition key is

turned to the ON position and may stay on for

approximately 3 seconds. If this light remains on or

comes on during driving, it indicates that the Anti-Lock

portion of the brake system is not functioning and that

service is required. See your authorized dealer immedi-

ately. With the ABS malfunctioning, the BAS and ESP are

also switched off. Both malfunction indicator lights illu-

minate with the engine running. If the charging voltage

falls below 10 volts, the malfunction indicator light

INSTRUMENT PANEL AND CONTROLS 195

4

Page 196 of 481

illuminates and the ABS is switched off. When the

voltage is above this value again, the malfunction indi-

cator light should go out and the ABS is operational. If

the malfunction indicator light stays illuminated, have

the system checked at your authorized dealer as soon as

possible.

12. Engine Oil Pressure Indicator Light

This light indicates that the engine oil pressure has

become too low. For a bulb check, this light will

come on momentarily when the ignition is turned On. If

the light turns on while driving, stop the vehicle and shut

off the engine as soon as possible. Immediate service

should be obtained.

13. Tachometer

This gauge measures engine revolutions-per-minute

(rpm x 1000).14. Gear Selector

The electronic gear selector display is self-contained

within the instrument cluster. It displays the position of

the automatic transmission shift lever, and the relation of

each position to all other positions. For a good signal the

display will place a box around the selected transmission

range (PRND21). If the PRNDL displays only the char-

acters PRND21 (no boxes) have the system checked by an

authorized dealer.

15. Odometer/Trip Odometer

The odometer shows the total distance the vehicle has

been driven. U.S. federal regulations require that upon

transfer of vehicle ownership, the seller certify to the

purchaser the correct mileage that the vehicle has been

driven. Therefore, if the odometer reading is changed

during repair or replacement, be sure to keep a record of

the reading before and after the service so that the correct

mileage can be determined.

196 INSTRUMENT PANEL AND CONTROLS

Page 271 of 481

mSupplemental Tire Pressure Information Ð If

Equipped............................322

mTire Chains...........................322

mSnow Tires...........................323

mTire Rotation Recommendations............324

mTire Pressure Monitor System (TPMS) Ð If

Equipped............................325

NBase System ± If Equipped...............327

NPremium System ± If Equipped...........329

NGeneral Information...................332

mFuel Requirements......................332

NReformulated Gasoline.................333

NGasoline/Oxygenate Blends..............333

NMMT In Gasoline.....................334NMaterials Added To Fuel................335

NFuel System Cautions..................335

NCarbon Monoxide Warnings..............336

mAdding Fuel..........................336

NFuel Filler Cap (Gas Cap)...............336

NLoose Fuel Filler Cap (Gas Cap) Message....338

mFlexible Fuel Ð If Equipped...............339

NE-85 General Information................339

NEthanol Fuel (E-85)....................340

NFuel Requirements....................340

NSelection Of Engine Oil For Flexible Fuel

Vehicles (E-85) And Gasoline Vehicles.......341

NStarting............................341

STARTING AND OPERATING 271

5

Page 320 of 481

WARNING!

Tires and spare tire should be replaced after six years,

regardless of the remaining tread. Failure to follow

this warning can result in sudden tire failure. You

could lose control and have an accident resulting in

serious injury or death.

Keep dismounted tires in a cool, dry place with as little

exposure to light as possible. Protect tires from contact

with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for

wear and correct cold tire inflation pressure. The manu-

facturer strongly recommends that you use tires equiva-

lent to the originals in size, quality and performance

when replacement is needed (refer to the paragraph on

ªTread Wear Indicatorsº). Refer to the ªTire and Loading

Informationº placard for the size designation of your tire.

The service description and load identification will be

found on the original equipment tire. Failure to use

equivalent replacement tires may adversely affect the

safety, handling, and ride of your vehicle. We recommend

that you contact your original equipment or an autho-

rized tire dealer with any questions you may have on tire

specifications or capability.

320 STARTING AND OPERATING

Page 373 of 481

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel. Lightly tighten the nuts. To

avoid risk of forcing the vehicle off the jack, do not fully

tighten the nuts until the vehicle has been lowered.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

6. Using the wheel wrench, finish tightening the nuts in

a crisscross pattern. Correct nut tightness is 135 10 ft.

lbs. (183 14 N´m) dynamic torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your dealer or at a service station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack, tools and the extra tire and wheel

in the places provided.

7. Remove wheel blocks. Do not install chrome or alu-

minum wheel center caps on the spare wheel. This may

result in cap damage.

8. Lower the jack to its fully closed position. Stow the

replaced tire, jack, and tools as previously described.

9. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

WHAT TO DO IN EMERGENCIES 373

6

Page 392 of 481

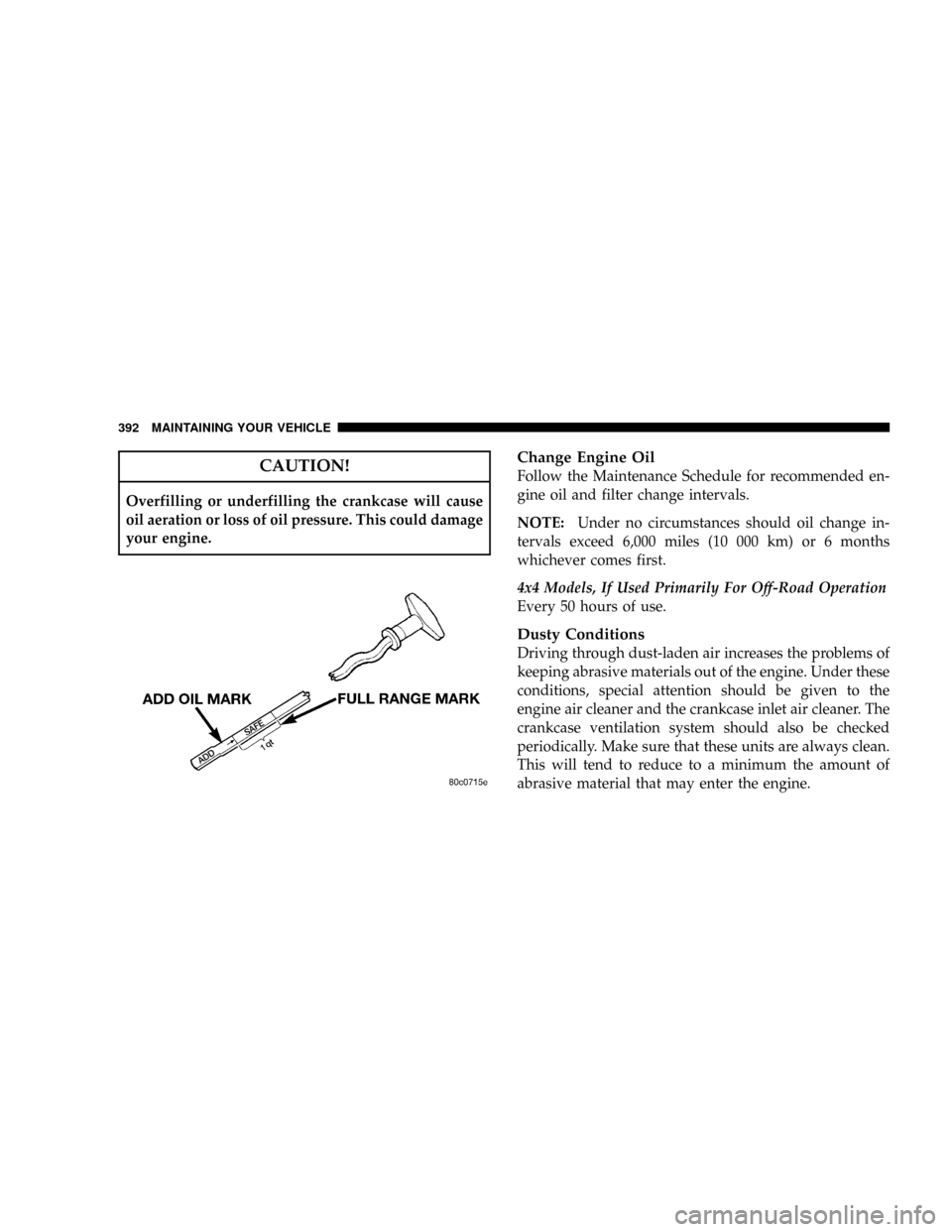

CAUTION!

Overfilling or underfilling the crankcase will cause

oil aeration or loss of oil pressure. This could damage

your engine.

Change Engine Oil

Follow the Maintenance Schedule for recommended en-

gine oil and filter change intervals.

NOTE:Under no circumstances should oil change in-

tervals exceed 6,000 miles (10 000 km) or 6 months

whichever comes first.

4x4 Models, If Used Primarily For Off-Road Operation

Every 50 hours of use.

Dusty Conditions

Driving through dust-laden air increases the problems of

keeping abrasive materials out of the engine. Under these

conditions, special attention should be given to the

engine air cleaner and the crankcase inlet air cleaner. The

crankcase ventilation system should also be checked

periodically. Make sure that these units are always clean.

This will tend to reduce to a minimum the amount of

abrasive material that may enter the engine.

392 MAINTAINING YOUR VEHICLE

Page 400 of 481

WARNING!

²Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi-

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause

the system to fail, requiring costly repairs. Refer to

Section 3 of the Warranty Information book for

further warranty information.

²The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal

injury or damage to the system, adding refrigerant

or any repair requiring lines to be disconnected

should be done by an experienced repairman.NOTE:Use only manufacturer approved A/C System

Sealers, Stop Leak Products, Seal Conditioners, Compres-

sor Oils and Refrigerants.

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

Front Suspension Ball Joints

The ball joints and seals should be inspected whenever

the vehicle is serviced for other reasons. Damaged seals

should be replaced to prevent leakage or contamination

of the grease.

400 MAINTAINING YOUR VEHICLE

Page 403 of 481

damaged, have a competent mechanic inspect the com-

plete exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO) which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing CO, fol-

low the preceding safety tips.

Cooling System

WARNING!

You or others can be badly burned by hot coolant or

steam from your radiator. If you see or hear steam

coming from under the hood, don't open the hood

until the radiator has had time to cool. Never try to

open a cooling system pressure cap when the radiator

is hot.

Engine Coolant Checks

Check the engine coolant (antifreeze) protection every 12

months (before the onset of freezing weather, where

applicable). If coolant is dirty or rusty in appearance, the

system should be drained, flushed and refilled with fresh

coolant. Check the front of the A/C condenser and

radiator for any accumulation of bugs, leaves, etc. If dirty,

MAINTAINING YOUR VEHICLE 403

7

Page 409 of 481

Emission Related Components

Fuel System Hoses And Vapor/Vacuum Harnesses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be given to examining hose surfaces

nearest to high heat sources, such as the exhaust mani-

fold.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily anindication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

You are urged to use only the manufacturer's specified

hoses and clamps, or their equivalent in material and

specification, in any fuel system servicing. It is manda-

tory to replace all clamps that have been loosened or

removed during service. Care should be taken in install-

ing new clamps to insure they are properly torqued.

Positive Crankcase Ventilation (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging because of deposits. Deposits can accumulate in the

PCV valve and passage with increasing mileage. Have

the PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valve ±Do not

MAINTAINING YOUR VEHICLE 409

7