lights DODGE DURANGO 2016 3.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2016, Model line: DURANGO, Model: DODGE DURANGO 2016 3.GPages: 739, PDF Size: 5.52 MB

Page 500 of 739

Alternate Procedure

1. Bring the vehicle to complete stop.

2. With the ignition switch in ON/ RUN position andengine running, shift the transmission to Neutral.

3. Rotate the AWD control switch to the desired position.

4. After the desired position indicator light is ON (not flashing), shift the transmission back into gear.

NOTE:

•

If Steps 1 or 2 of either the Preferred or Alternate

Procedure are not satisfied prior to attempting the shift

or if they no longer are being met while the shift attempt

is in process, the desired position indicator light will

flash continuously while the original position indicator

light is ON, until all requirements have been met.

• The ignition switch must be in the RUN position for a

shift to take place and for the position indicator lights to be operable. If the ignition switch is not in the RUN

position, then the shift will not take place and no

position indicator lights will be on or flashing.

NEUTRAL Shift Procedure

1. Bring the vehicle to a complete stop with the engine

running.

2. Press and hold the brake pedal.

3. Shift the transmission into NEUTRAL.

4.

Using a ballpoint pen or similar object, press and hold the

recessed transfer case NEUTRAL (N) button (located by

the selector switch) for four seconds. The light next to the

N symbol will blink, indicating shift in progress. The light

will stop blinking (stay on solid) when the shift to NEU-

TRAL (N) is complete. A “4WD System in Neutral” mes-

sage will display on the Driver Information Display (DID).

Refer to “Driver Information Display (DID)” in “Under-

standing Your Instrument Panel” for further information.

498 STARTING AND OPERATING

Page 585 of 739

actuated brakes. When towing a trailer equipped with

a hydraulic surge actuated brake system, an electronic

brake controller is not required.

• Trailer brakes are recommended for trailers over

1,000 lbs (453 kg) and required for trailers in excess of

2,000 lbs (907 kg).

WARNING!

• Do not connect trailer brakes to your vehicle’s

hydraulic brake lines. It can overload your brake

system and cause it to fail. You might not have

brakes when you need them and could have a

collision.

• Towing any trailer will increase your stopping

distance. When towing you should allow for addi-

tional space between your vehicle and the vehicle

in front of you. Failure to do so could result in a

collision.

CAUTION!

If the trailer weighs more than 1,000 lbs (453 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do this

could lead to accelerated brake lining wear, higher

brake pedal effort, and longer stopping distances.

Towing Requirements — Trailer Lights And Wiring

Whenever you pull a trailer, regardless of the trailer size,

stoplights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four- and seven-

pin wiring harness. Use a factory approved trailer har-

ness and connector.

NOTE: Do not cut or splice wiring into the vehicles

wiring harness.

5

STARTING AND OPERATING 583

Page 595 of 739

NOTE:

•Steps 1 through 3 are requirements that must be met

before pressing the NEUTRAL (N) button, and must

continue to be met until the shift has been completed.

If any of these requirements are not met before push-

ing the NEUTRAL (N) button or are no longer met

during the shift, the NEUTRAL (N) indicator light will

flash continuously until all requirements are met or

until the NEUTRAL (N) button is released.

• The ignition switch must be in the ON/RUN position

for a shift to take place and for the position indicator

lights to be operable. If the ignition switch is not in the

ON/RUN position, the shift will not take place and no

position indicator lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light

indicates that shift requirements have not been met.Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your vehicle for

normal usage.

1. Bring the vehicle to a complete stop, leaving it con- nected to the tow vehicle.

2. Firmly apply the parking brake.

3. Start the engine.

4. Press and hold the brake pedal.

5. Shift the transmission into NEUTRAL.

6. Using a ballpoint pen or similar object, press and hold the recessed transfer case NEUTRAL (N) button (lo-

cated by the selector switch) for one second.

5

STARTING AND OPERATING 593

Page 597 of 739

NOTE:

•Steps 1 through 5 are requirements that must be met

before pressing the NEUTRAL (N) button, and must

continue to be met until the shift has been completed.

If any of these requirements are not met before press-

ing the NEUTRAL (N) button or are no longer met

during the shift, the NEUTRAL (N) indicator light will

flash continuously until all requirements are met or

until the NEUTRAL (N) button is released.

• The ignition switch must be in the ON/RUN position

for a shift to take place and for the position indicator

lights to be operable. If the ignition switch is not in the

ON/RUN position, the shift will not take place and no

position indicator lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator light

indicates that shift requirements have not been met.

5

STARTING AND OPERATING 595

Page 676 of 739

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in

closed areas they may cause respiratory harm.

CAUTION!

Direct contact of air fresheners, insect repellents,

suntan lotions, or hand sanitizers to the plastic,

painted, or decorated surfaces of the interior may

cause permanent damage. Wipe away immediately.

CAUTION!

Damage caused by these type of products may not be

covered by your New Vehicle Limited Warranty.

CAUTION!

Do not use Alcohol and Alcohol-based and/or Keton

based cleaning products to clean leather seats, as

damage to the seat may result.

Cleaning Headlights

Your vehicle is equipped with plastic headlights and fog

lights that are lighter and less susceptible to stone break-

age than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution fol-

lowed by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

674 MAINTAINING YOUR VEHICLE

Page 680 of 739

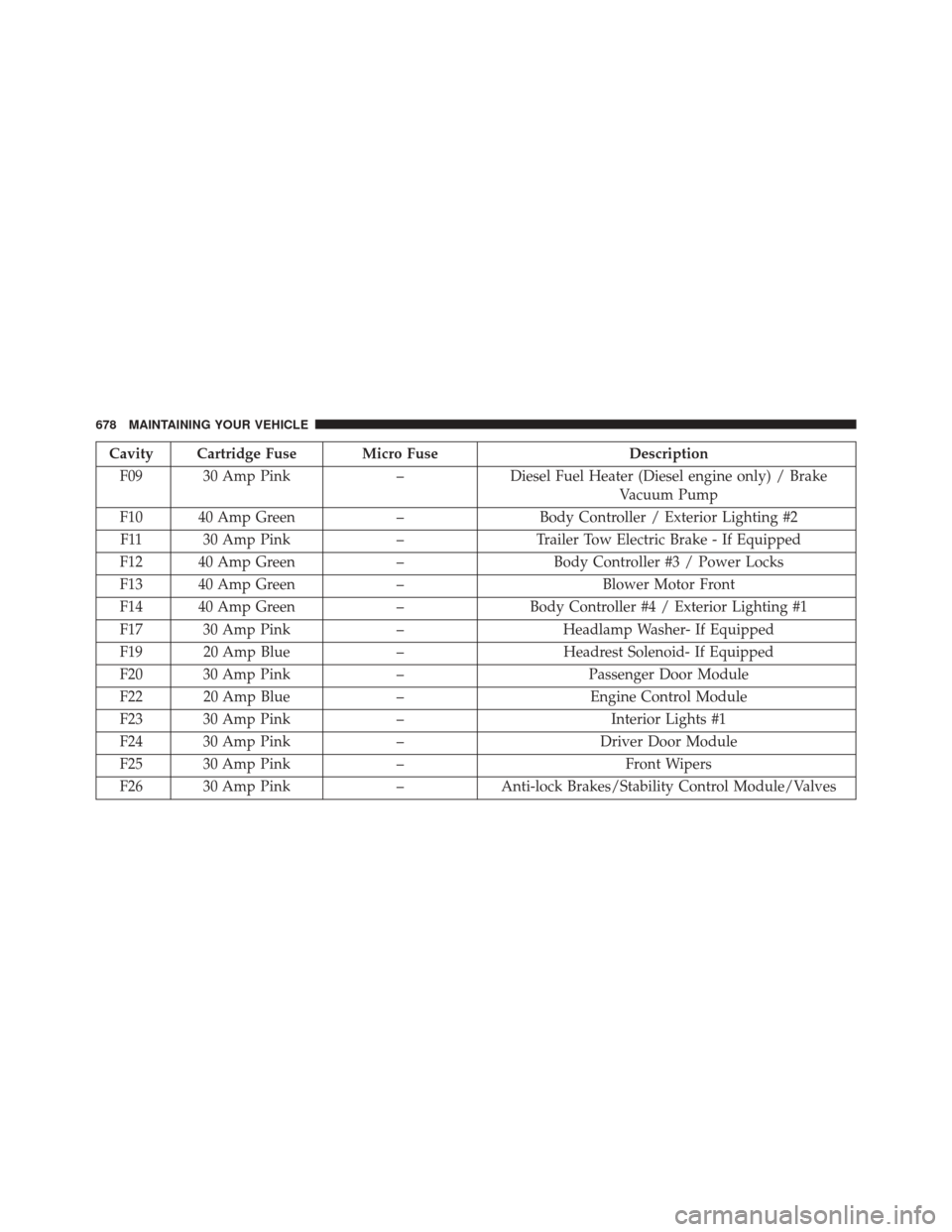

Cavity Cartridge Fuse Micro FuseDescription

F09 30 Amp Pink –Diesel Fuel Heater (Diesel engine only) / Brake

Vacuum Pump

F10 40 Amp Green –Body Controller / Exterior Lighting #2

F11 30 Amp Pink –Trailer Tow Electric Brake - If Equipped

F12 40 Amp Green –Body Controller #3 / Power Locks

F13 40 Amp Green –Blower Motor Front

F14 40 Amp Green –Body Controller #4 / Exterior Lighting #1

F17 30 Amp Pink –Headlamp Washer- If Equipped

F19 20 Amp Blue –Headrest Solenoid- If Equipped

F20 30 Amp Pink –Passenger Door Module

F22 20 Amp Blue –Engine Control Module

F23 30 Amp Pink –Interior Lights #1

F24 30 Amp Pink –Driver Door Module

F25 30 Amp Pink –Front Wipers

F26 30 Amp Pink –Anti-lock Brakes/Stability Control Module/Valves

678 MAINTAINING YOUR VEHICLE

Page 681 of 739

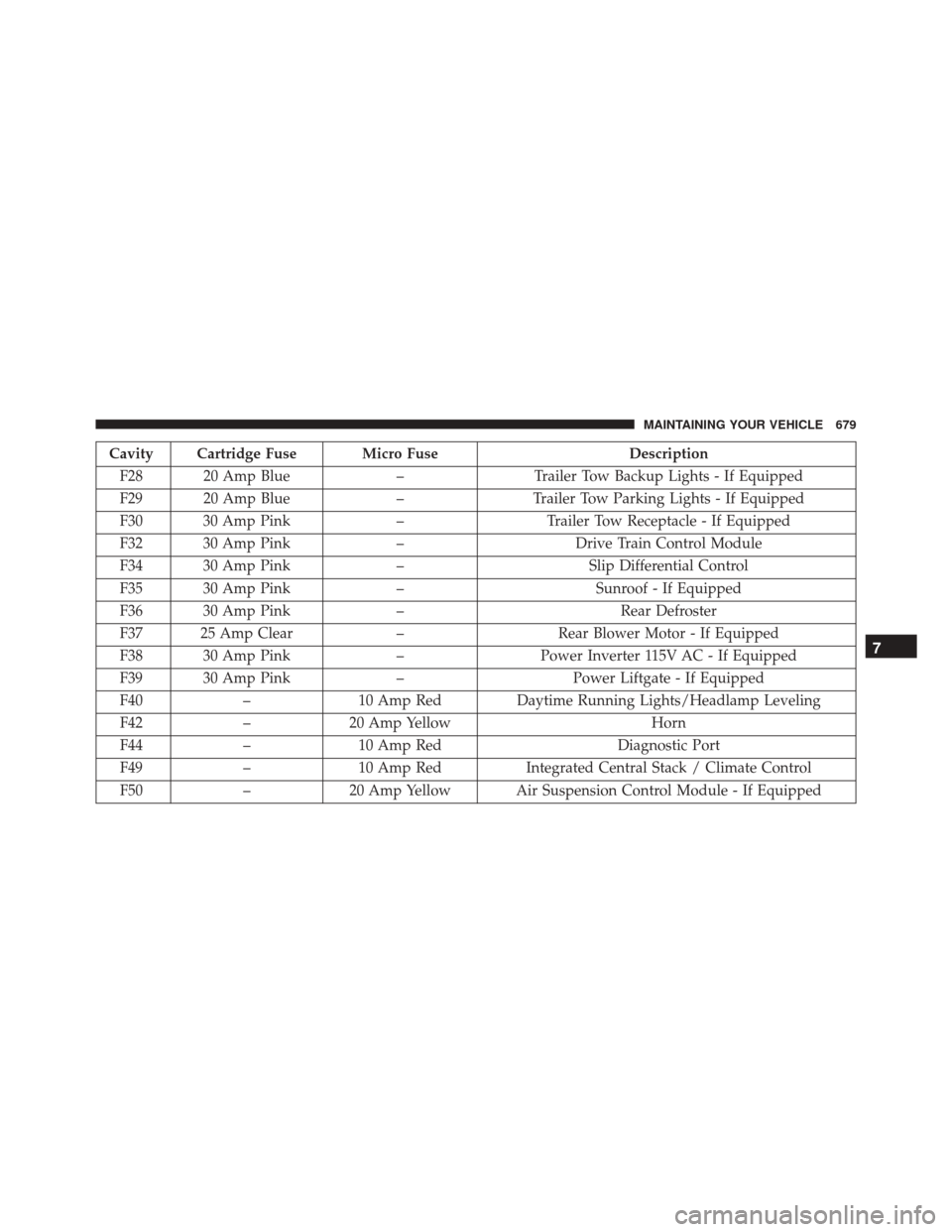

Cavity Cartridge Fuse Micro FuseDescription

F28 20 Amp Blue –Trailer Tow Backup Lights - If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights - If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle - If Equipped

F32 30 Amp Pink –Drive Train Control Module

F34 30 Amp Pink –Slip Differential Control

F35 30 Amp Pink –Sunroof - If Equipped

F36 30 Amp Pink –Rear Defroster

F37 25 Amp Clear –Rear Blower Motor - If Equipped

F38 30 Amp Pink –Power Inverter 115V AC - If Equipped

F39 30 Amp Pink –Power Liftgate - If Equipped

F40 –10 Amp Red Daytime Running Lights/Headlamp Leveling

F42 –20 Amp Yellow Horn

F44 –10 Amp Red Diagnostic Port

F49 –10 Amp Red Integrated Central Stack / Climate Control

F50 –20 Amp Yellow Air Suspension Control Module - If Equipped

7

MAINTAINING YOUR VEHICLE 679

Page 682 of 739

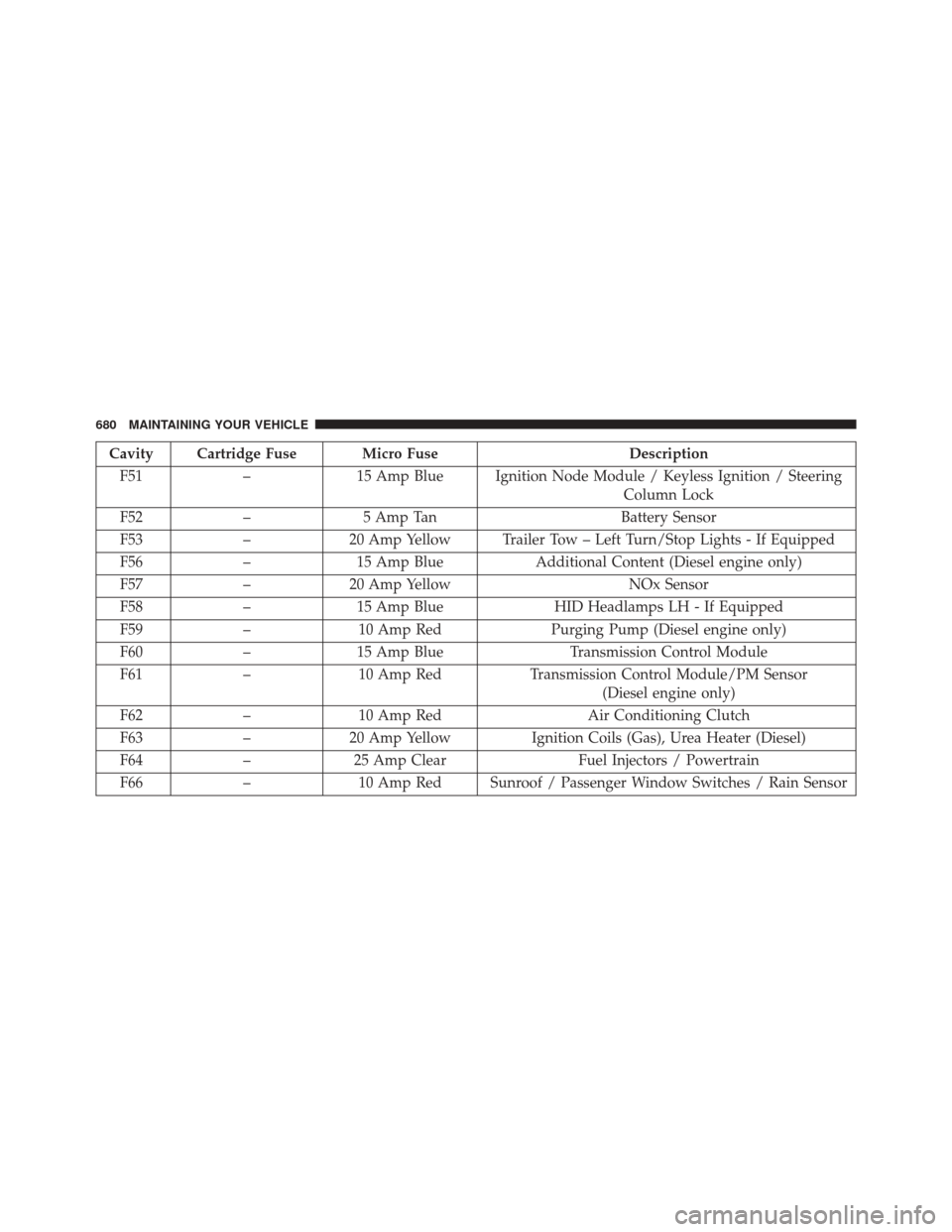

Cavity Cartridge Fuse Micro FuseDescription

F51 –15 Amp Blue Ignition Node Module / Keyless Ignition / Steering

Column Lock

F52 –5 Amp Tan Battery Sensor

F53 –20 Amp Yellow Trailer Tow – Left Turn/Stop Lights - If Equipped

F56 –15 Amp Blue Additional Content (Diesel engine only)

F57 –20 Amp Yellow NOx Sensor

F58 –15 Amp Blue HID Headlamps LH - If Equipped

F59 –10 Amp Red Purging Pump (Diesel engine only)

F60 –15 Amp Blue Transmission Control Module

F61 –10 Amp Red Transmission Control Module/PM Sensor

(Diesel engine only)

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils (Gas), Urea Heater (Diesel)

F64 –25 Amp Clear Fuel Injectors / Powertrain

F66 –10 Amp Red Sunroof / Passenger Window Switches / Rain Sensor

680 MAINTAINING YOUR VEHICLE

Page 684 of 739

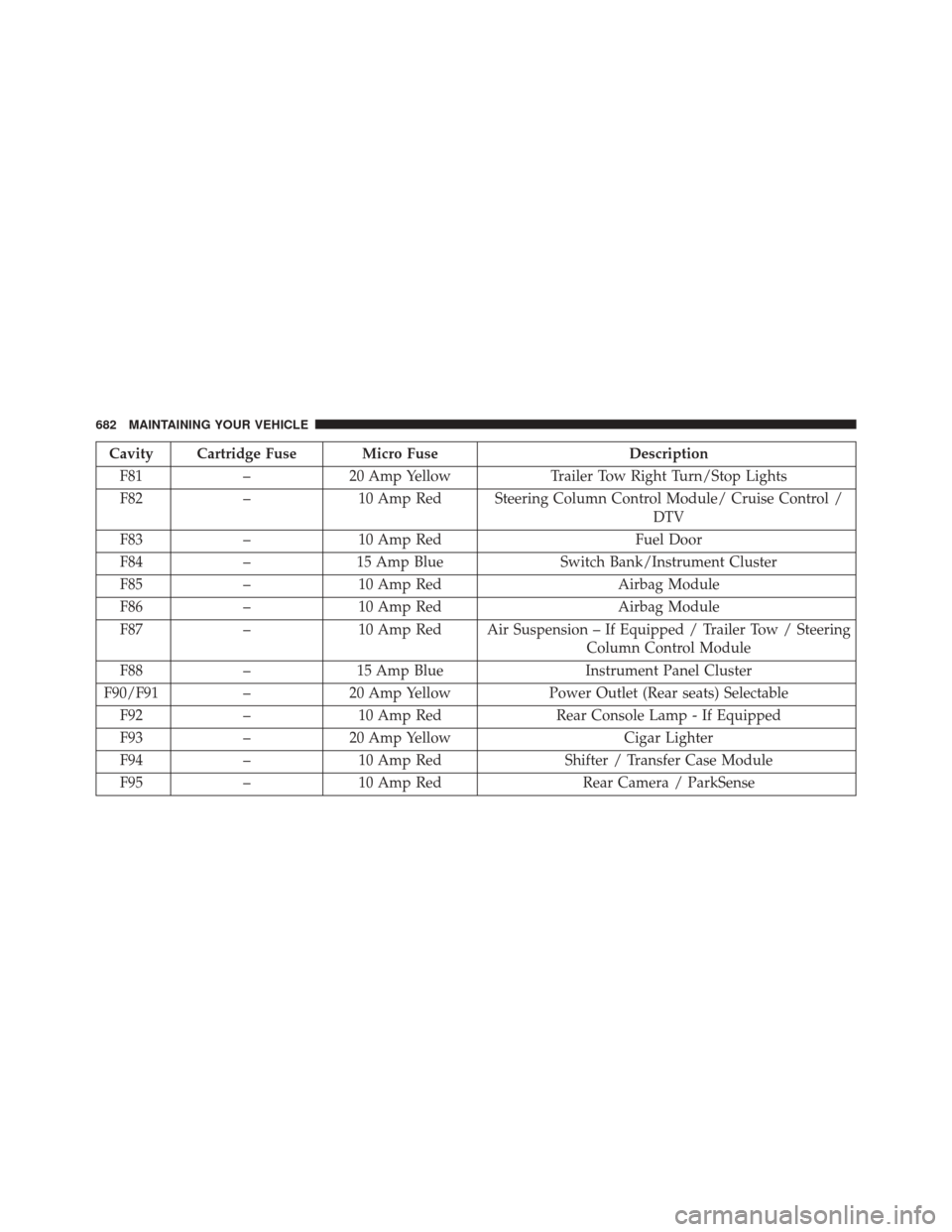

Cavity Cartridge Fuse Micro FuseDescription

F81 –20 Amp Yellow Trailer Tow Right Turn/Stop Lights

F82 –10 Amp Red Steering Column Control Module/ Cruise Control /

DTV

F83 –10 Amp Red Fuel Door

F84 –15 Amp Blue Switch Bank/Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp Red Air Suspension – If Equipped / Trailer Tow / Steering

Column Control Module

F88 –15 Amp Blue Instrument Panel Cluster

F90/F91 –20 Amp Yellow Power Outlet (Rear seats) Selectable

F92 –10 Amp Red Rear Console Lamp - If Equipped

F93 –20 Amp Yellow Cigar Lighter

F94 –10 Amp Red Shifter / Transfer Case Module

F95 –10 Amp Red Rear Camera / ParkSense

682 MAINTAINING YOUR VEHICLE

Page 701 of 739

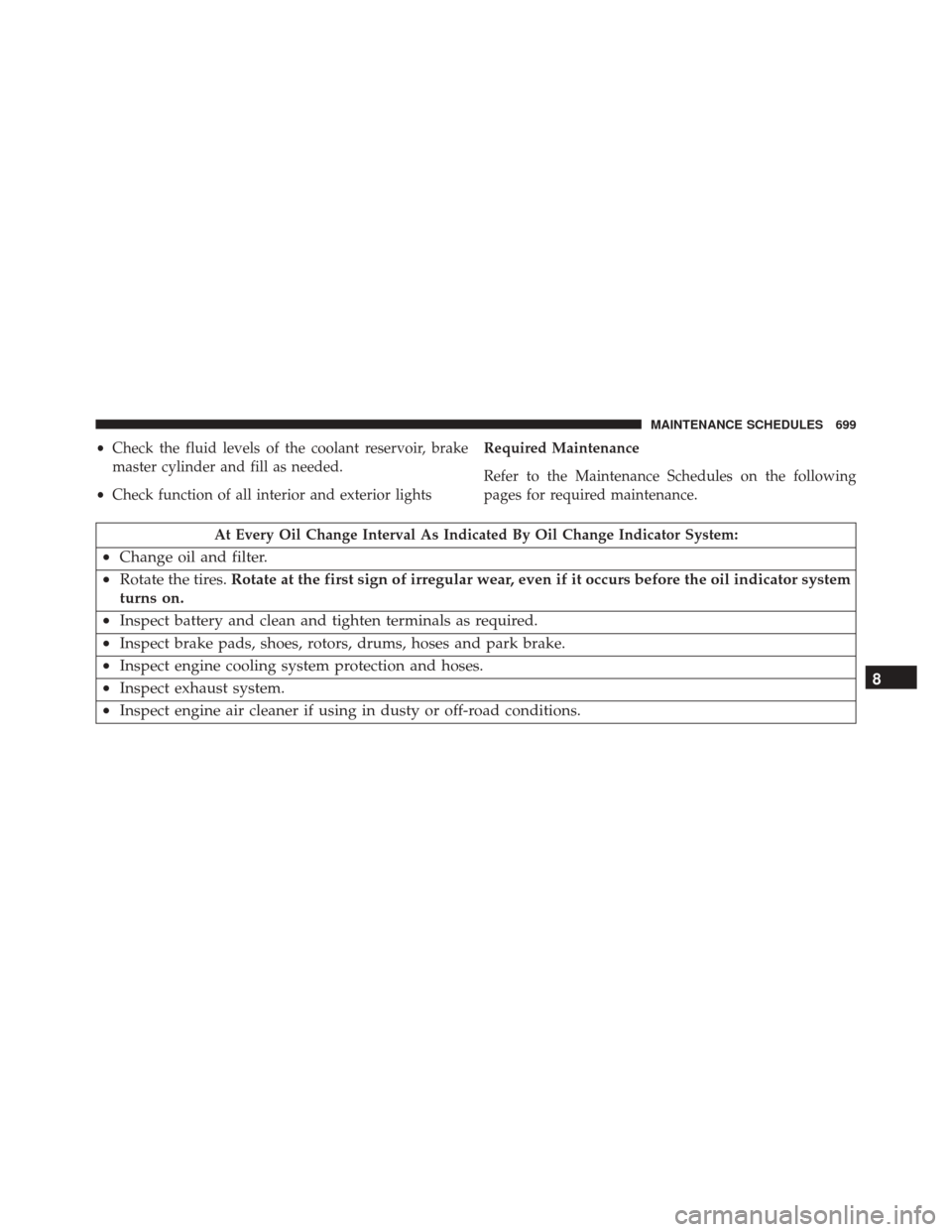

•Check the fluid levels of the coolant reservoir, brake

master cylinder and fill as needed.

• Check function of all interior and exterior lights Required Maintenance

Refer to the Maintenance Schedules on the following

pages for required maintenance.

At Every Oil Change Interval As Indicated By Oil Change Indicator System:

•

Change oil and filter.

• Rotate the tires. Rotate at the first sign of irregular wear, even if it occurs before the oil indicator system

turns on.

• Inspect battery and clean and tighten terminals as required.

• Inspect brake pads, shoes, rotors, drums, hoses and park brake.

• Inspect engine cooling system protection and hoses.

• Inspect exhaust system.

• Inspect engine air cleaner if using in dusty or off-road conditions. 8

MAINTENANCE SCHEDULES 699