brake light DODGE DURANGO 2018 Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2018, Model line: DURANGO, Model: DODGE DURANGO 2018Pages: 592, PDF Size: 6.57 MB

Page 360 of 592

Use the following procedure to prepare your vehicle for

recreational towing.

CAUTION!

It is necessary to follow these steps to be certain that

the transfer case is fully in NEUTRAL (N) before

recreational towing to prevent damage to internal

parts.

1. Bring the vehicle to a complete stop on level ground, with the engine running.

2. Press and hold the brake pedal.

3. Shift the transmission into NEUTRAL.

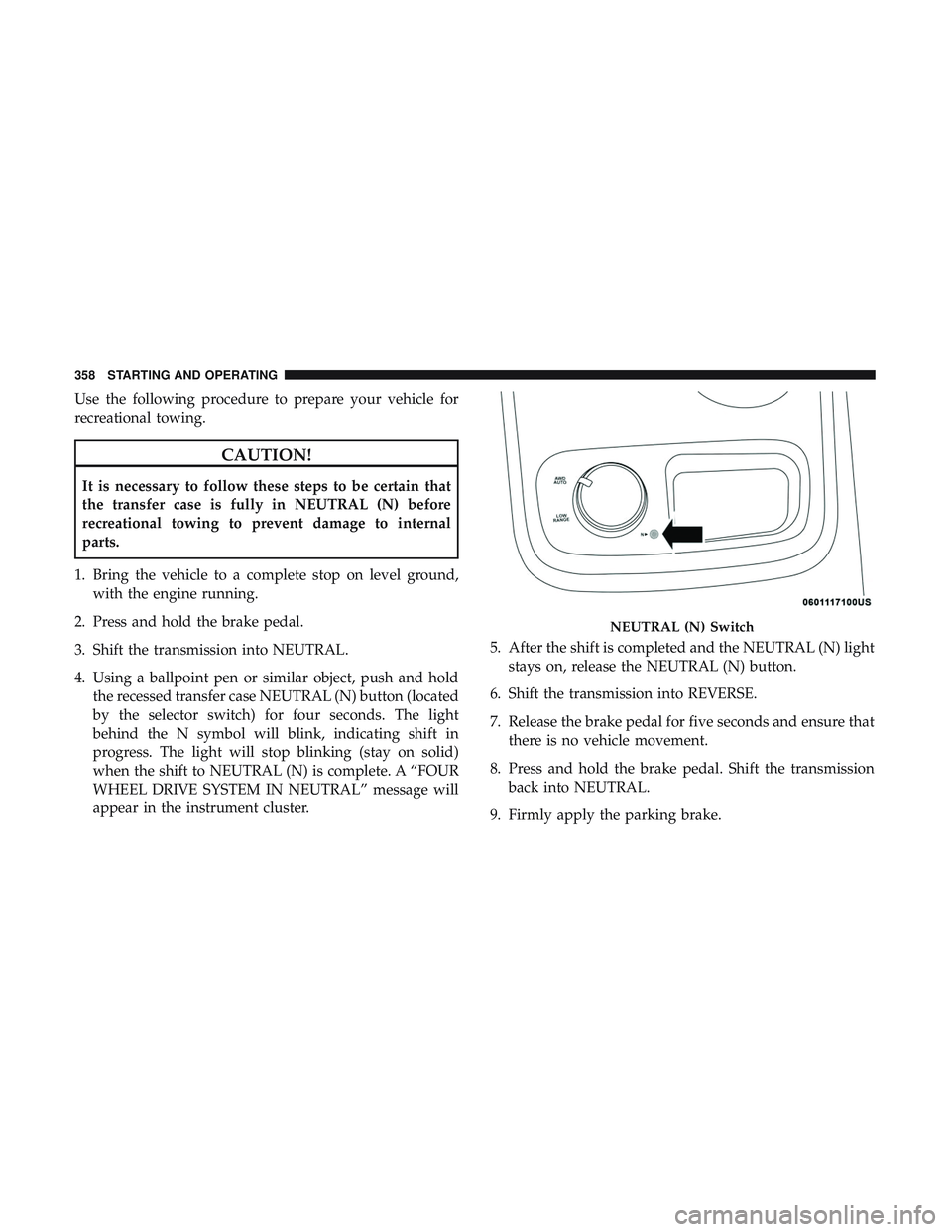

4. Using a ballpoint pen or similar object, push and hold the recessed transfer case NEUTRAL (N) button (located

by the selector switch) for four seconds. The light

behind the N symbol will blink, indicating shift in

progress. The light will stop blinking (stay on solid)

when the shift to NEUTRAL (N) is complete. A “FOUR

WHEEL DRIVE SYSTEM IN NEUTRAL” message will

appear in the instrument cluster. 5. After the shift is completed and the NEUTRAL (N) light

stays on, release the NEUTRAL (N) button.

6. Shift the transmission into REVERSE.

7. Release the brake pedal for five seconds and ensure that there is no vehicle movement.

8. Press and hold the brake pedal. Shift the transmission back into NEUTRAL.

9. Firmly apply the parking brake.

NEUTRAL (N) Switch

358 STARTING AND OPERATING

Page 361 of 592

10. With the transmission and transfer case in NEUTRAL,push and hold the ENGINE START/STOP button until

the engine turns off.

11. Place the transmission gear selector in PARK. Release the brake pedal.

12. Push the ENGINE STOP/START button twice (without pressing the brake pedal) to turn the ignition to the

OFF mode.

CAUTION!

Damage to the transmission may occur if the transmis-

sion is shifted into PARK with the transfer case in

NEUTRAL (N) and the engine running. With the

transfer case in NEUTRAL (N) ensure that the engine

is OFF before shifting the transmission into PARK.

13. Attach the vehicle to the tow vehicle using a suitable tow bar.

14. Release the parking brake. NOTE:

•

Steps 1 through 3 are requirements that must be met

before pushing the NEUTRAL (N) button, and must

continue to be met until the shift has been completed. If

any of these requirements are not met before pushing

the NEUTRAL (N) button or are no longer met during

the shift, the NEUTRAL (N) indicator light will flash

continuously until all requirements are met or until the

NEUTRAL (N) button is released.

• The ignition must be in the ON/RUN mode for a shift to

take place and for the position indicator lights to be

operable. If the ignition is not in the ON/RUN mode, the

shift will not take place and no position indicator lights

will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indi-

cates that shift requirements have not been met.

6

STARTING AND OPERATING 359

Page 362 of 592

Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your vehicle for

normal usage.

1. Bring the vehicle to a complete stop, leaving it con-nected to the tow vehicle.

2. Firmly apply the parking brake.

3. Start the engine.

4. Press and hold the brake pedal.

5. Shift the transmission into NEUTRAL.

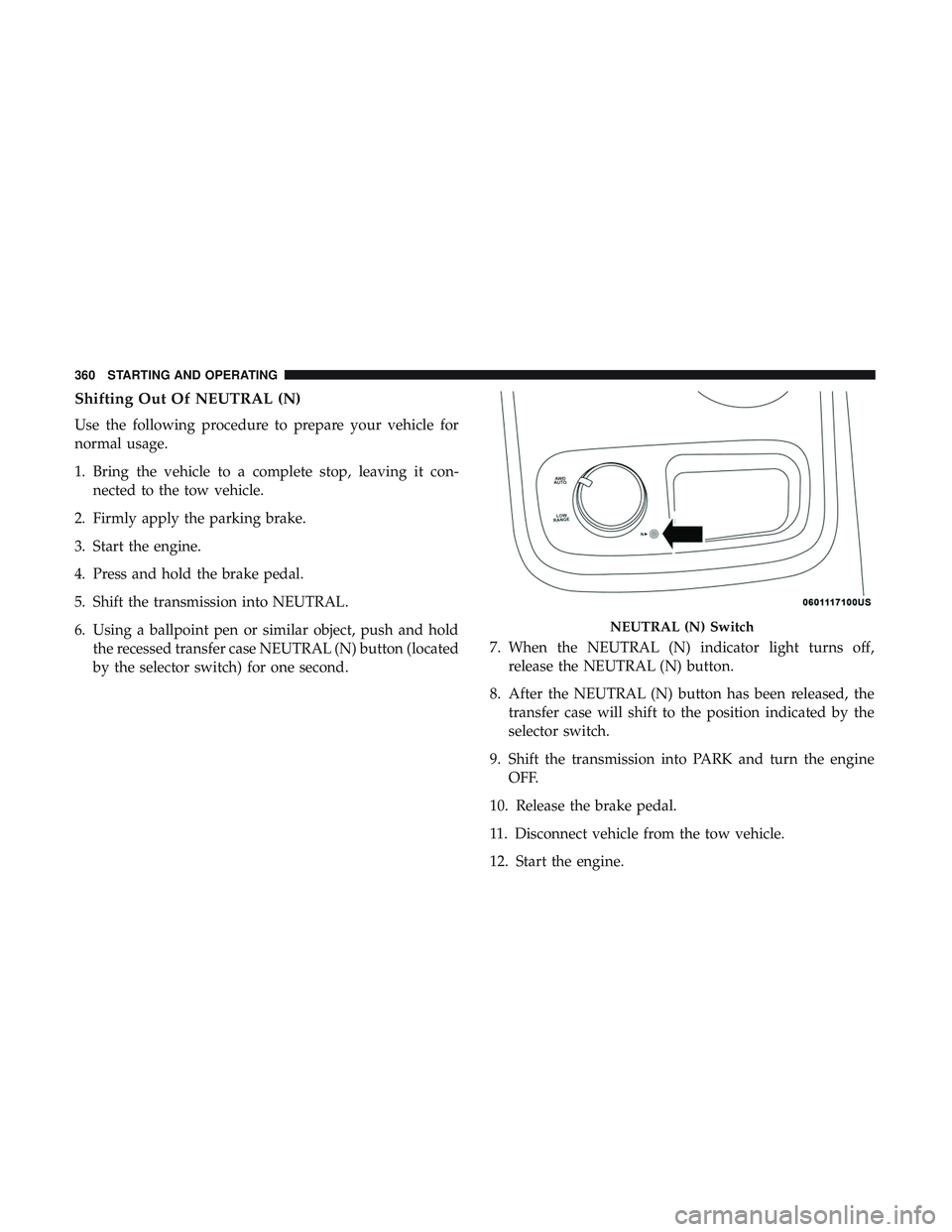

6. Using a ballpoint pen or similar object, push and hold the recessed transfer case NEUTRAL (N) button (located

by the selector switch) for one second. 7. When the NEUTRAL (N) indicator light turns off,

release the NEUTRAL (N) button.

8. After the NEUTRAL (N) button has been released, the transfer case will shift to the position indicated by the

selector switch.

9. Shift the transmission into PARK and turn the engine OFF.

10. Release the brake pedal.

11. Disconnect vehicle from the tow vehicle.

12. Start the engine.

NEUTRAL (N) Switch

360 STARTING AND OPERATING

Page 363 of 592

13. Press and hold the brake pedal.

14. Release the parking brake.

15. Shift the transmission into DRIVE, release the brakepedal, and check that the vehicle operates normally.

NOTE:

• Steps 1 through 5 are requirements that must be met

before pushing the NEUTRAL (N) button, and must

continue to be met until the shift has been completed. If

any of these requirements are not met before pushing

the NEUTRAL (N) button or are no longer met during

the shift, the NEUTRAL (N) indicator light will flash

continuously until all requirements are met or until the

NEUTRAL (N) button is released.

• The ignition must be in the ON/RUN mode for a shift to

take place and for the position indicator lights to be

operable. If the ignition is not in the ON/RUN mode, the

shift will not take place and no position indicator lights

will be on or flashing.

• A flashing NEUTRAL (N) position indicator light indi-

cates that shift requirements have not been met.DRIVING TIPS

On-Road Driving Tips

Utility vehicles have higher ground clearance and a nar-

rower track to make them capable of performing in a wide

variety of off-road applications. Specific design character-

istics give them a higher center of gravity than conven-

tional passenger cars.

An advantage of the higher ground clearance is a better view

of the road, allowing you to anticipate problems. They are not

designed for cornering at the same speeds as conventional

passenger cars any more than low-slung sports cars are

designed to perform satisfactorily in off-road conditions.

Avoid sharp turns or abrupt maneuvers. As with other

vehicles of this type, failure to operate this vehicle correctly

may result in loss of control or vehicle rollover.

Off-Road Driving Tips

When To Use 4WD LOW Range — If Equipped

When off-road driving, shift to 4WD LOW for additional

traction. This range should be limited to extreme situations

such as deep snow, mud, or sand where additional low speed

pulling power is needed. Vehicle speeds in excess of 25 mph

(40 km/h) should be avoided when in 4WD LOW range.

6

STARTING AND OPERATING 361

Page 365 of 592

transfer case) to assure the fluids have not been contami-

nated. Contaminated fluid (milky, foamy in appearance)

should be flushed/changed as soon as possible to prevent

component damage.

Driving In Snow, Mud And Sand

In heavy snow, when pulling a load, or for additional

control at slower speeds, shift the transmission to a low

gear and shift the transfer case to LOW if necessary. Refer

to “All-Wheel Drive Operation” in “Starting And Operat-

ing” for further information. Do not shift to a lower gear

than necessary to maintain forward motion. Over-revving

the engine can spin the wheels and traction will be lost.

Avoid abrupt downshifts on icy or slippery roads, because

engine braking may cause skidding and loss of control.

Hill Climbing

NOTE:Before attempting to climb a hill, determine the

conditions at the crest and/or on the other side.

Before climbing a steep hill, shift the transmission to a

lower gear and shift the transfer case to LOW. Use first gear

and LOW for very steep hills.

If you stall or begin to lose forward motion while climbing

a steep hill, allow your vehicle to come to a stop and immediately apply the brakes. Restart the engine, and shift

into REVERSE. Back slowly down the hill, allowing the

compression braking of the engine to help regulate your

speed. If the brakes are required to control vehicle speed,

apply them lightly and avoid locking or skidding the tires.

WARNING!

If the engine stalls, you lose forward motion, or cannot

make it to the top of a steep hill or grade, never attempt

to turn around. To do so may result in tipping and

rolling the vehicle. Always back carefully straight

down a hill in REVERSE gear. Never back down a hill

in NEUTRAL using only the brake.

Remember, never drive diagonally across a hill; always

drive straight up or down.

If the wheels start to slip as you approach the crest of a hill,

ease off the accelerator and maintain forward motion by

turning the front wheels slowly. This may provide a fresh

“bite” into the surface and will usually provide traction to

complete the climb.

Traction Downhill

Shift the transmission into a low gear, and the transfer case

into LOW range. Let the vehicle go slowly down the hill

6

STARTING AND OPERATING 363

Page 380 of 592

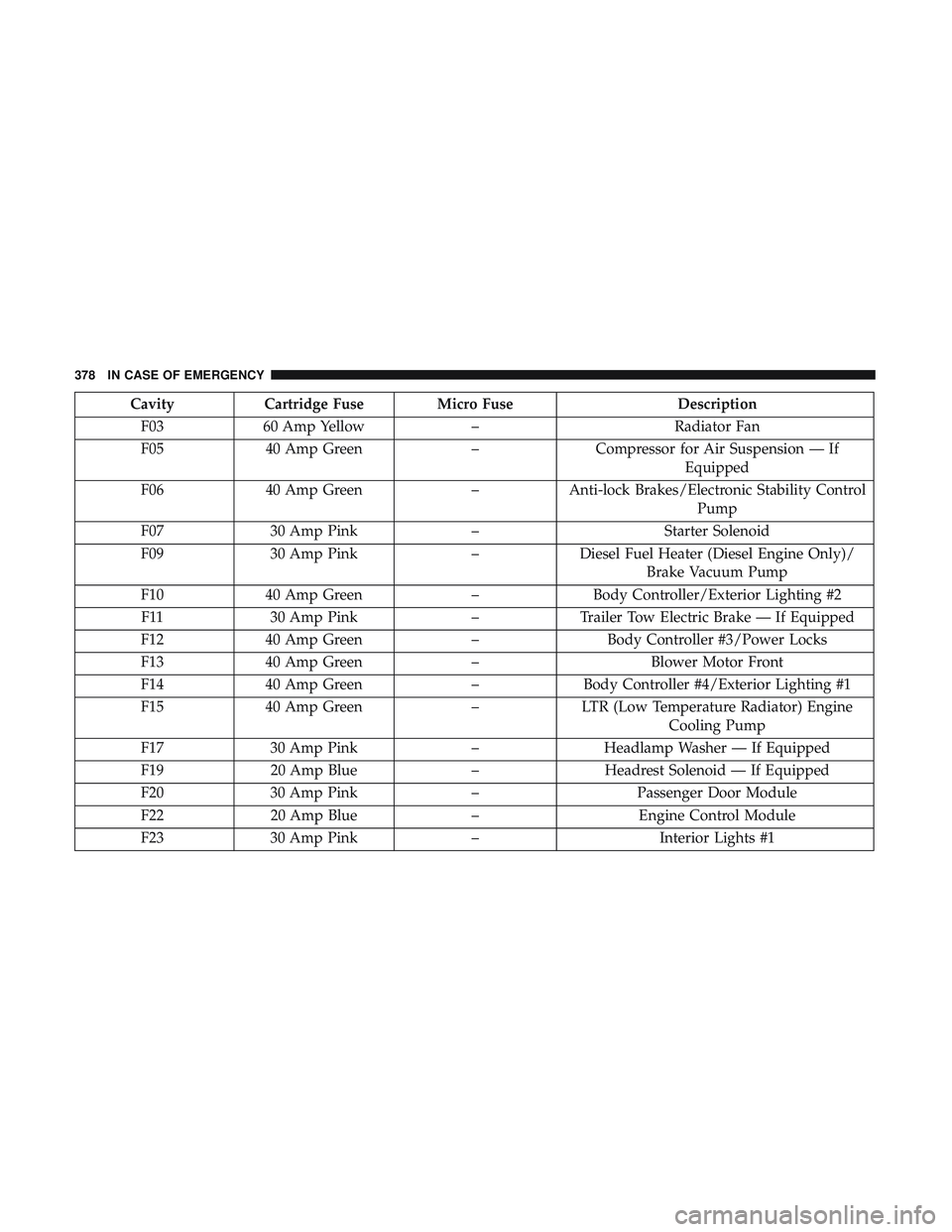

CavityCartridge Fuse Micro Fuse Description

F03 60 Amp Yellow –Radiator Fan

F05 40 Amp Green –Compressor for Air Suspension — If

Equipped

F06 40 Amp Green –Anti-lock Brakes/Electronic Stability Control

Pump

F07 30 Amp Pink –Starter Solenoid

F09 30 Amp Pink –Diesel Fuel Heater (Diesel Engine Only)/

Brake Vacuum Pump

F10 40 Amp Green –Body Controller/Exterior Lighting #2

F11 30 Amp Pink –Trailer Tow Electric Brake — If Equipped

F12 40 Amp Green –Body Controller #3/Power Locks

F13 40 Amp Green –Blower Motor Front

F14 40 Amp Green –Body Controller #4/Exterior Lighting #1

F15 40 Amp Green –LTR (Low Temperature Radiator) Engine

Cooling Pump

F17 30 Amp Pink –Headlamp Washer — If Equipped

F19 20 Amp Blue –Headrest Solenoid — If Equipped

F20 30 Amp Pink –Passenger Door Module

F22 20 Amp Blue –Engine Control Module

F23 30 Amp Pink –Interior Lights #1

378 IN CASE OF EMERGENCY

Page 381 of 592

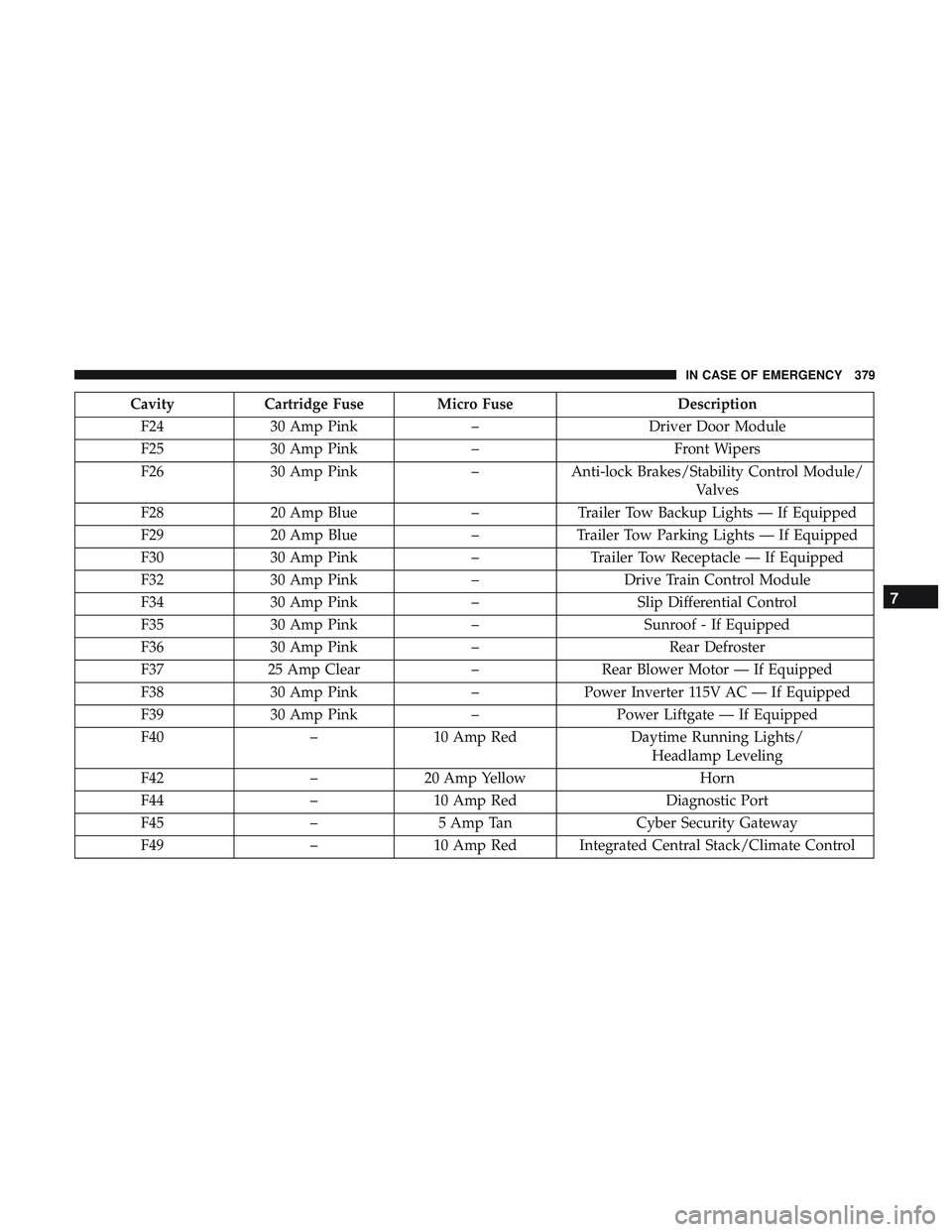

CavityCartridge Fuse Micro Fuse Description

F24 30 Amp Pink –Driver Door Module

F25 30 Amp Pink – Front Wipers

F26 30 Amp Pink –Anti-lock Brakes/Stability Control Module/

Valves

F28 20 Amp Blue –Trailer Tow Backup Lights — If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights — If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle — If Equipped

F32 30 Amp Pink –Drive Train Control Module

F34 30 Amp Pink –Slip Differential Control

F35 30 Amp Pink –Sunroof - If Equipped

F36 30 Amp Pink –Rear Defroster

F37 25 Amp Clear –Rear Blower Motor — If Equipped

F38 30 Amp Pink –Power Inverter 115V AC — If Equipped

F39 30 Amp Pink –Power Liftgate — If Equipped

F40 –10 Amp Red Daytime Running Lights/

Headlamp Leveling

F42 –20 Amp Yellow Horn

F44 –10 Amp Red Diagnostic Port

F45 –5 Amp Tan Cyber Security Gateway

F49 –10 Amp Red Integrated Central Stack/Climate Control

7

IN CASE OF EMERGENCY 379

Page 383 of 592

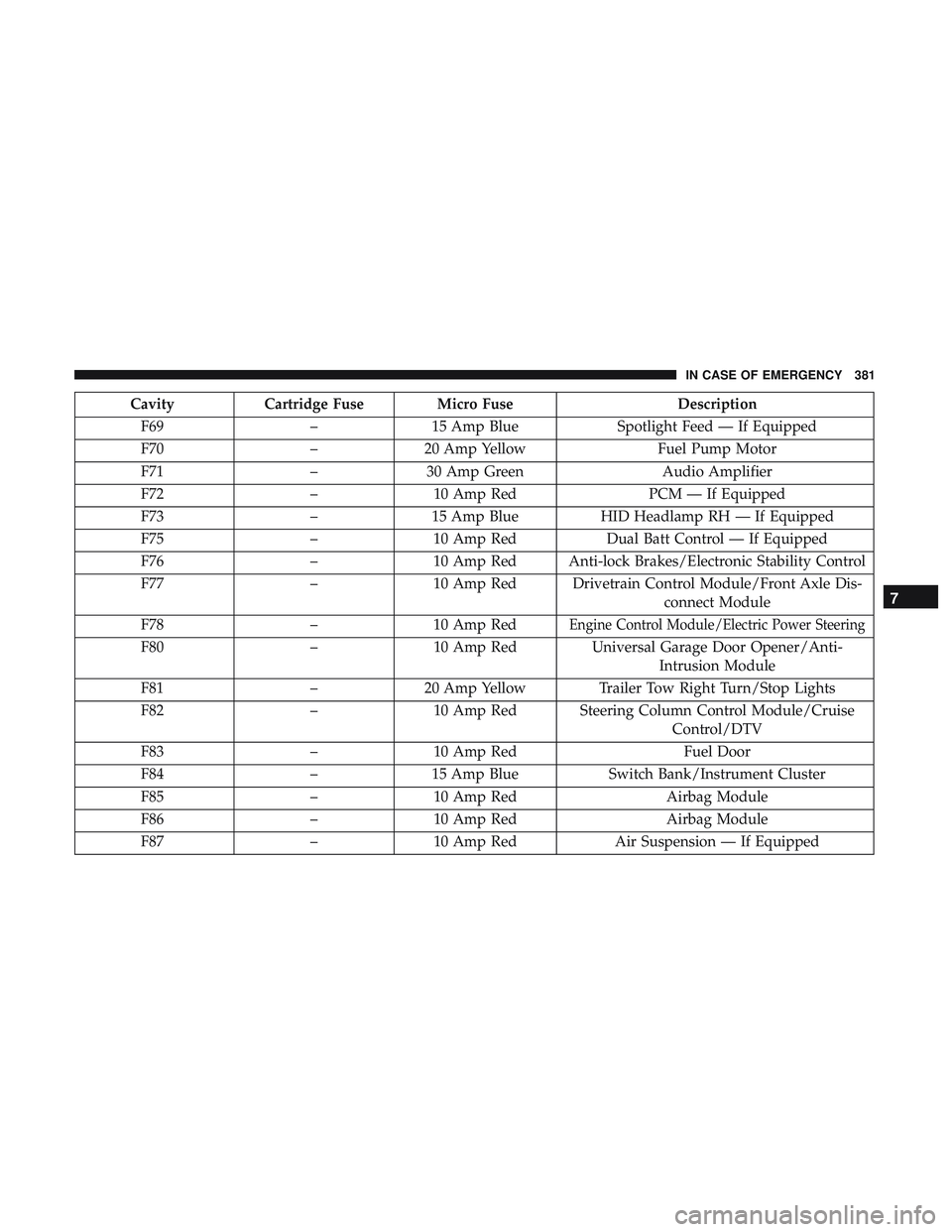

CavityCartridge Fuse Micro Fuse Description

F69 –15 Amp Blue Spotlight Feed — If Equipped

F70 –20 Amp Yellow Fuel Pump Motor

F71 –30 Amp Green Audio Amplifier

F72 –10 Amp Red PCM — If Equipped

F73 –15 Amp Blue HID Headlamp RH — If Equipped

F75 –10 Amp Red Dual Batt Control — If Equipped

F76 –10 Amp Red Anti-lock Brakes/Electronic Stability Control

F77 –10 Amp Red Drivetrain Control Module/Front Axle Dis-

connect Module

F78 –10 Amp Red

Engine Control Module/Electric Power Steering

F80 –10 Amp Red Universal Garage Door Opener/Anti-

Intrusion Module

F81 –20 Amp Yellow Trailer Tow Right Turn/Stop Lights

F82 –10 Amp Red Steering Column Control Module/Cruise

Control/DTV

F83 –10 Amp Red Fuel Door

F84 –15 Amp Blue Switch Bank/Instrument Cluster

F85 –10 Amp Red Airbag Module

F86 –10 Amp Red Airbag Module

F87 –10 Amp Red Air Suspension — If Equipped

7

IN CASE OF EMERGENCY 381

Page 411 of 592

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil change

indicator system. The oil change indicator system will

remind you that it is time to take your vehicle in for

scheduled maintenance.

Based on engine operation conditions, the oil change

indicator message will illuminate. This means that service

is required for your vehicle. Operating conditions such as

frequent short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will influence

when the “Oil Change Required” message is displayed.

Severe Operating Conditions can cause the change oil

message to illuminate as early as 3,500 miles (5,600 km)

since last reset. Have your vehicle serviced as soon as

possible, within the next 500 miles (800 km).

Your authorized dealer will reset the oil change indicator

message after completing the scheduled oil change.

NOTE:Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km), twelve months or 350

hours of engine run time, whichever comes first. The 350

hours of engine run or idle time is generally only a concern

for fleet customers. Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or 350 hours of

engine run time if the vehicle is operated in a dusty and off

road environment or is operated predominately at idle or

only very low engine RPM’s. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:

•

Check engine oil level

• Check windshield washer fluid level

• Check the tire inflation pressures and look for unusual

wear or damage

• Check the fluid levels of the coolant reservoir, brake

master cylinder and fill as needed.

• Check function of all interior and exterior lights

8

SERVICING AND MAINTENANCE 409

Page 439 of 592

WARNING!

Riding the brakes can lead to brake failure and possi-

bly a collision. Driving with your foot resting or riding

on the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible

brake damage. You would not have your full braking

capacity in an emergency.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be checked

whenever the vehicle is serviced, or immediately if the

brake system warning light is on. If necessary, add fluid to

bring level within the designated marks on the side of the

reservoir of the brake master cylinder. Be sure to clean the

top of the master cylinder area before removing cap. With

disc brakes, fluid level can be expected to fall as the brake

pads wear. Brake fluid level should be checked when pads

are replaced. If the brake fluid is abnormally low, check the

system for leaks.

Refer to “Fluids And Lubricants” in “Technical Specifica-

tions” for further information.

WARNING!

•Use only manufacturer’s recommended brake fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. Using the

wrong type of brake fluid can severely damage your

brake system and/or impair its performance. The

proper type of brake fluid for your vehicle is also

identified on the original factory installed hydraulic

master cylinder reservoir.

• To avoid contamination from foreign matter or mois-

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master cylin-

der reservoir cap secured at all times. Brake fluid in

a open container absorbs moisture from the air

resulting in a lower boiling point. This may cause it

to boil unexpectedly during hard or prolonged brak-

ing, resulting in sudden brake failure. This could

result in a collision.

• Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

(Continued)

8

SERVICING AND MAINTENANCE 437