tires DODGE DURANGO 2020 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: DURANGO, Model: DODGE DURANGO 2020Pages: 464, PDF Size: 22.14 MB

Page 141 of 464

SAFETY139

(Continued)

This is defined as the tire pressure after the

vehicle has not been driven for at least three

hours, or driven less than 1 mile (1.6 km) after

a three-hour period. Refer to ‚ÄúTires‚ÄĚ in

‚ÄúServicing And Maintenance‚ÄĚ for information on

how to properly inflate the vehicle’s tires. The

tire pressure will also increase as the vehicle is

driven ‚ÄĒ this is normal and there should be no

adjustment for this increased pressure.

The TPMS will warn the driver of a low tire

pressure if the tire pressure falls below the low

pressure warning threshold for any reason,

including low temperature effects, or natural

pressure loss through the tire.

The TPMS will continue to warn the driver of low

tire pressure as long as the condition exists,

and will not turn off until the tire pressure is at

or above recommended cold tire pressure.

Once the low tire pressure warning has been

illuminated, the tire pressure must be increased

to the recommended cold tire pressure in order

for the TPMS Warning Light to be turned off. NOTE:

When filling warm tires, the tire pressure may

need to be increased up to an additional 4 psi

(28 kPa) above the recommended cold placard

pressure in order to turn the TPMS Warning

Light off.

The system will automatically update and the

TPMS Warning Light will extinguish once the

updated tire pressures have been received. The

vehicle may need to be driven for up to

20 minutes above 15 mph (24 km/h) to receive

this information.

For example, your vehicle has a recommended

cold (parked for more than three hours) tire

pressure of 33 psi (227 kPa). If the ambient

temperature is 68¬įF (20¬įC) and the measured

tire pressure is 28 psi (193 kPa), a temperature

drop to 20¬įF (-7¬įC) will decrease the tire

pressure to approximately 24 psi (165 kPa).

This tire pressure is sufficiently low enough to

turn on the TPMS Warning Light. Driving the

vehicle may cause the tire pressure to rise to

approximately 28 psi (193 kPa), but the TPMS

Warning Light will still be on. In this situation,

the TPMS Warning Light will turn off only after

the tires have been inflated to the vehicle’s

recommended cold tire pressure value.CAUTION!

ÔĀ¨The TPMS has been optimized for the orig

-

inal equipment tires and wheels. TPMS

pressures and warnings have been estab -

lished for the tire size equipped on your

vehicle. Undesirable system operation or

sensor damage may result when using

replacement equipment that is not of the

same size, type, and/or style. The TPM

sensor is not designed for use on after -

market wheels and may contribute to a

poor overall system performance or sensor

damage. Customers are encouraged to use

OEM wheels to assure proper TPM feature

operation.

ÔĀ¨Using aftermarket tire sealants may cause

the Tire Pressure Monitoring System

(TPMS) sensor to become inoperable. After

using an aftermarket tire sealant it is

recommended that you take your vehicle to

an authorized dealership to have your

sensor function checked.

4

20_WD_OM_EN_USC_t.book Page 139

Page 142 of 464

140SAFETY

NOTE:

ÔĀ¨The TPMS is not intended to replace normal

tire care and maintenance, or to provide

warning of a tire failure or condition.

ÔĀ¨The TPMS should not be used as a tire pres -

sure gauge while adjusting your tire pressure.

ÔĀ¨Driving on a significantly under-inflated tire

causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces fuel

efficiency and tire tread life, and may affect

the vehicle’s handling and stopping ability.

ÔĀ¨The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsi -

bility to maintain correct tire pressure using

an accurate tire gauge, even if under-infla -

tion has not reached the level to trigger illu -

mination of the TPMS Warning Light.

ÔĀ¨Seasonal temperature changes will affect

tire pressure, and the TPMS will monitor the

actual tire pressure in the tire.

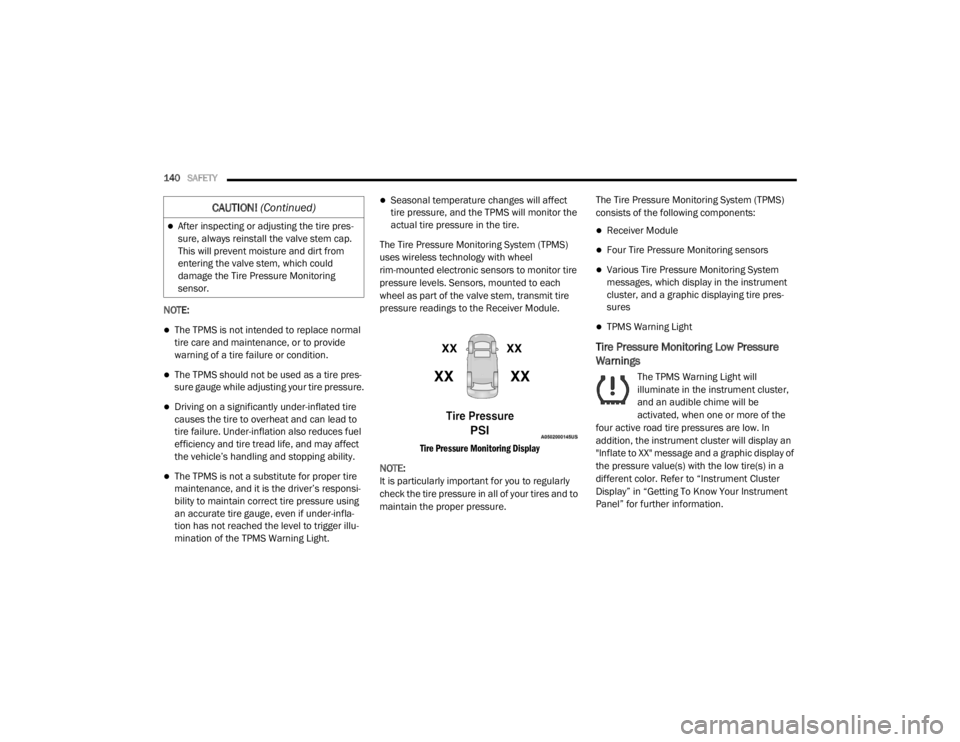

The Tire Pressure Monitoring System (TPMS)

uses wireless technology with wheel

rim-mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire

pressure readings to the Receiver Module.

Tire Pressure Monitoring Display

NOTE:

It is particularly important for you to regularly

check the tire pressure in all of your tires and to

maintain the proper pressure. The Tire Pressure Monitoring System (TPMS)

consists of the following components:

ÔĀ¨Receiver Module

ÔĀ¨Four Tire Pressure Monitoring sensors

ÔĀ¨Various Tire Pressure Monitoring System

messages, which display in the instrument

cluster, and a graphic displaying tire pres

-

sures

ÔĀ¨TPMS Warning Light

Tire Pressure Monitoring Low Pressure

Warnings

The TPMS Warning Light will

illuminate in the instrument cluster,

and an audible chime will be

activated, when one or more of the

four active road tire pressures are low. In

addition, the instrument cluster will display an

"Inflate to XX" message and a graphic display of

the pressure value(s) with the low tire(s) in a

different color. Refer to “Instrument Cluster

Display‚ÄĚ in ‚ÄúGetting To Know Your Instrument

Panel‚ÄĚ for further information.

ÔĀ¨After inspecting or adjusting the tire pres -

sure, always reinstall the valve stem cap.

This will prevent moisture and dirt from

entering the valve stem, which could

damage the Tire Pressure Monitoring

sensor.

CAUTION! (Continued)

20_WD_OM_EN_USC_t.book Page 140

Page 143 of 464

SAFETY141

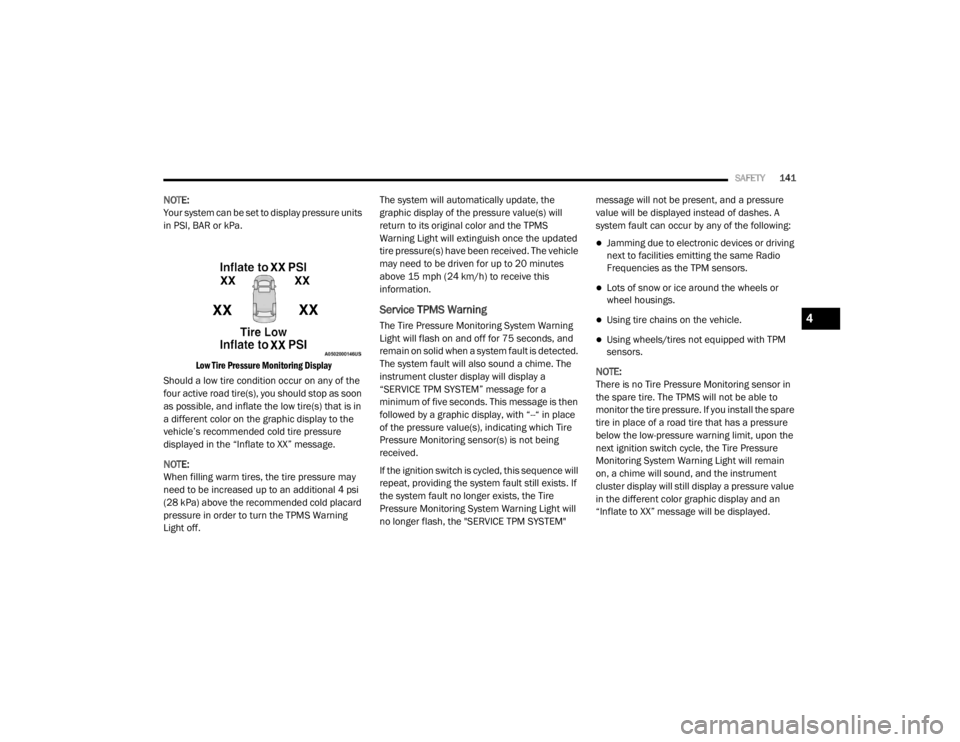

NOTE:

Your system can be set to display pressure units

in PSI, BAR or kPa.

Low Tire Pressure Monitoring Display

Should a low tire condition occur on any of the

four active road tire(s), you should stop as soon

as possible, and inflate the low tire(s) that is in

a different color on the graphic display to the

vehicle’s recommended cold tire pressure

displayed in the ‚ÄúInflate to XX‚ÄĚ message.

NOTE:

When filling warm tires, the tire pressure may

need to be increased up to an additional 4 psi

(28 kPa) above the recommended cold placard

pressure in order to turn the TPMS Warning

Light off. The system will automatically update, the

graphic display of the pressure value(s) will

return to its original color and the TPMS

Warning Light will extinguish once the updated

tire pressure(s) have been received. The vehicle

may need to be driven for up to 20 minutes

above 15 mph (24 km/h) to receive this

information.

Service TPMS Warning

The Tire Pressure Monitoring System Warning

Light will flash on and off for 75 seconds, and

remain on solid when a system fault is detected.

The system fault will also sound a chime. The

instrument cluster display will display a

‚ÄúSERVICE TPM SYSTEM‚ÄĚ message for a

minimum of five seconds. This message is then

followed by a graphic display, with “--“ in place

of the pressure value(s), indicating which Tire

Pressure Monitoring sensor(s) is not being

received.

If the ignition switch is cycled, this sequence will

repeat, providing the system fault still exists. If

the system fault no longer exists, the Tire

Pressure Monitoring System Warning Light will

no longer flash, the "SERVICE TPM SYSTEM"

message will not be present, and a pressure

value will be displayed instead of dashes. A

system fault can occur by any of the following:

ÔĀ¨Jamming due to electronic devices or driving

next to facilities emitting the same Radio

Frequencies as the TPM sensors.

ÔĀ¨Lots of snow or ice around the wheels or

wheel housings.

ÔĀ¨Using tire chains on the vehicle.

ÔĀ¨Using wheels/tires not equipped with TPM

sensors.

NOTE:

There is no Tire Pressure Monitoring sensor in

the spare tire. The TPMS will not be able to

monitor the tire pressure. If you install the spare

tire in place of a road tire that has a pressure

below the low-pressure warning limit, upon the

next ignition switch cycle, the Tire Pressure

Monitoring System Warning Light will remain

on, a chime will sound, and the instrument

cluster display will still display a pressure value

in the different color graphic display and an

‚ÄúInflate to XX‚ÄĚ message will be displayed.

4

20_WD_OM_EN_USC_t.book Page 141

Page 144 of 464

142SAFETY

After driving the vehicle for up to 20 minutes

above 15 mph (24 km/h), the Tire Pressure

Monitoring System Warning Light will flash on

and off for 75 seconds and then remain on

solid. In addition, the instrument cluster display

will display a “SERVICE TPM SYSTEM" message

for five seconds and then display dashes (--) in

place of the pressure value. For each subse -

quent ignition switch cycle, a chime will sound,

the Tire Pressure Monitoring System Warning

Light will flash on and off for 75 seconds and

then remain on solid, and the instrument

cluster display will display a "SERVICE TPM

SYSTEM" message for five seconds and then

display dashes (--) in place of the pressure

value. Once you repair or replace the original

road tire, and reinstall it on the vehicle in place

of the spare tire, the TPMS will update automat -

ically.

In addition, the Tire Pressure Monitoring System

Warning Light will turn off and the graphic in the

instrument cluster display will display a new

pressure value instead of dashes (--), as long as

no tire pressure is below the low-pressure

warning limit in any of the four active road tires.

The vehicle may need to be driven for up to

20 minutes above 15 mph (24 km/h) in order

for the TPMS to receive this information.TPMS Deactivation ‚ÄĒ If Equipped

The Tire Pressure Monitoring System (TPMS)

can be deactivated if replacing all four wheel

and tire assemblies (road tires) with wheel and

tire assemblies that do not have TPMS sensors,

such as when installing winter wheel and tire

assemblies on your vehicle.

To deactivate the TPMS, first, replace all four

wheel and tire assemblies (road tires) with tires

not equipped with Tire Pressure Monitoring

(TPM) sensors. Then, drive the vehicle for

20 minutes above 15 mph (24 km/h). The

TPMS will chime, the TPMS Warning Light will

flash on and off for 75 seconds and then remain

on. The instrument cluster will display the

‚ÄúSERVICE TPM SYSTEM‚ÄĚ message and then

display dashes (--) in place of the pressure

values.

Beginning with the next ignition cycle, the TPMS

will no longer chime or display the “SERVICE

TPM SYSTEM‚ÄĚ message in the instrument

cluster but dashes (--) will remain in place of the

pressure values. To reactivate the TPMS, replace all four wheel

and tire assemblies (road tires) with tires

equipped with TPM sensors. Then, drive the

vehicle for up to 20 minutes above 15 mph

(24 km/h). The TPMS will chime, the TPMS

Warning Light will flash on and off for

75 seconds and then turn off. The instrument

cluster will display the ‚ÄúSERVICE TPM SYSTEM‚ÄĚ

message and then display pressure values in

place of the dashes. On the next ignition cycle

the "SERVICE TPM SYSTEM" message will no

longer be displayed as long as no system fault

exists.

General Information

The following regulatory statement applies to all

Radio Frequency (RF) devices equipped in this

vehicle:

This device complies with Part 15 of the FCC

Rules and with Innovation, Science and

Economic Development Canada license-exempt

RSS standard(s).

20_WD_OM_EN_USC_t.book Page 142

Page 185 of 464

SAFETY183

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones, nails,

glass, or other objects lodged in the tread or

sidewall. Inspect the tread for cuts and cracks.

Inspect sidewalls for cuts, cracks, and bulges.

Check the wheel nuts for tightness. Check the

tires (including spare) for proper cold inflation

pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel, or

brake fluid leaks are suspected, the cause

should be located and corrected immediately.

WARNING!

To prevent SERIOUS INJURY or DEATH when

using ‚ÄúTrack-Use‚ÄĚ parts and equipment:

ÔĀ¨NEVER use any ‚ÄúTrack-Use‚ÄĚ equipment on

public roads. FCA US LLC does not autho -

rize the use of ‚ÄúTrack-Use‚ÄĚ equipment on

public roads.

ÔĀ¨The intended use of ‚ÄúTrack-Use‚ÄĚ parts is for

race vehicles on race tracks. To help

ensure the safety of the race driver, engi -

neers should supervise the installation of

‚ÄúTrack-Use‚ÄĚ parts.

ÔĀ¨FCA US LLC does not authorize the installa -

tion or use of any part noted as ‚ÄúTrack-Use‚ÄĚ

on any new vehicle prior to its first retail

sale.

WARNING!

To prevent SERIOUS INJURY or DEATH:

ÔĀ¨ALWAYS remove any ‚ÄúTrack-Use‚ÄĚ equip -

ment before driving on public roads.

ÔĀ¨ALWAYS properly use your three-point seat

belts when driving on public roads.

ÔĀ¨In a collision, you and your passengers can

suffer much greater injuries if you are not

properly buckled up. You can strike the inte -

rior of your vehicle or other passengers, or

you can be thrown out of the vehicle.

4

20_WD_OM_EN_USC_t.book Page 183

Page 202 of 464

200STARTING AND OPERATING

The LOW RANGE position is designed for loose,

slippery road surfaces only. Driving in the LOW

RANGE position on dry hard surfaced roads may

cause increased tire wear and damage to the

driveline components.

Transfer Case Position Indicator Messages

The Transfer Case Position Indicator messages

(AWD AUTO and LOW RANGE) are located in the

instrument cluster and indicate the current and

desired transfer case selection. Refer to

‚ÄúInstrument Cluster Display‚ÄĚ in ‚ÄúGetting To

Know Your Instrument Panel‚ÄĚ for further

information. When you select a different

transfer case position, the position indicator

lights will do the following:

If All Shift Conditions Are Met:

1. The current position indicator light will turn

off.

2. The selected position indicator light will flash until the transfer case completes the

shift.

3. When the shift is complete, the indicator light for the selected position will stop

flashing and remain on. If shift conditions are not met, one or more of

the following events may occur:

1. The indicator light for the current position

will remain on.

2. The newly selected position indicator light will continue to flash.

3. The transfer case will not shift.

NOTE:

Before retrying a selection, make certain that all

the necessary requirements for selecting a new

transfer case position have been met. To retry

the selection, turn the control knob back to the

current position, wait five seconds, and retry

selection. To find the shift requirements, refer

to the "Shifting Procedure" for your transfer

case, located in this section.

The ‚ÄúSERV AWD‚ÄĚ Warning Light monitors the

electronic shift all-wheel drive system. If this

light remains on after engine start up or

illuminates during driving, it means that the

all-wheel drive system is not functioning

properly and that service is required. NOTE:

Do not attempt to make a shift while only the

front or rear wheels are spinning. This could

cause damage to driveline components.

When operating your vehicle in LOW RANGE, the

engine speed is approximately three times that

of the AWD AUTO position at a given road speed.

Take care not to overspeed the engine and do

not exceed 25 mph (40 km/h).

Proper operation of all-wheel drive vehicles

depends on tires of equal size, type and

circumference on each wheel. Any difference in

tire size can cause damage to the transfer case.

Because all-wheel drive provides improved

traction, there is a tendency to exceed safe

turning and stopping speeds. Do not go faster

than road conditions permit.

WARNING!

Always engage the parking brake when

powering down the vehicle if the “SERV AWD

Warning Light‚ÄĚ is illuminated. Not engaging

the parking brake may allow the vehicle to roll

which may cause personal injury.

20_WD_OM_EN_USC_t.book Page 200

Page 242 of 464

240STARTING AND OPERATING

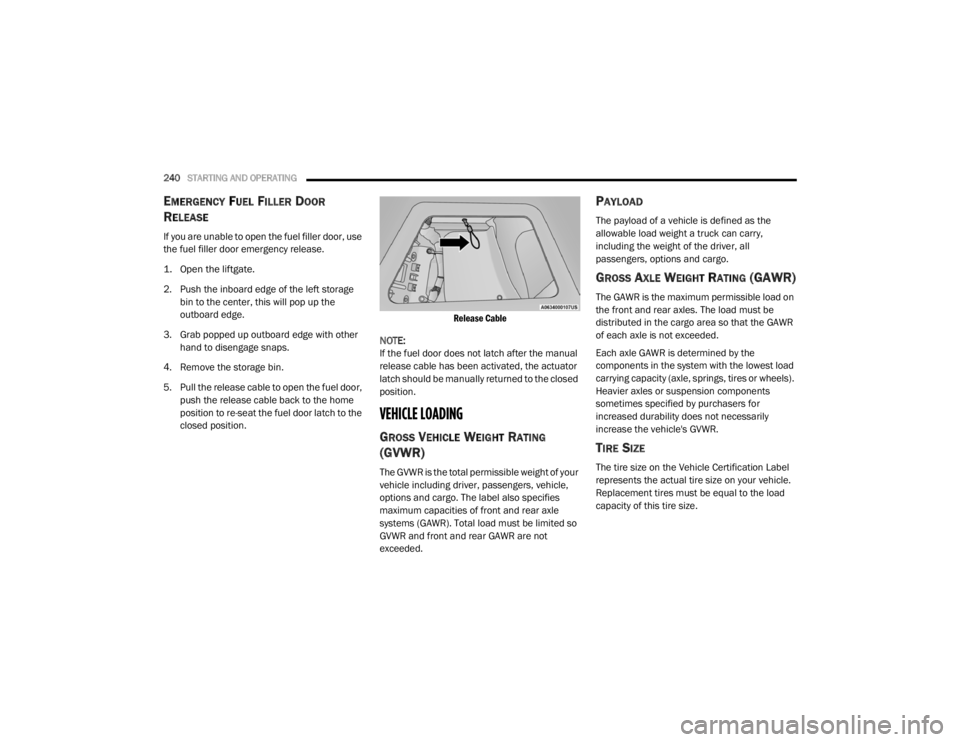

EMERGENCY FUEL FILLER DOOR

R

ELEASE

If you are unable to open the fuel filler door, use

the fuel filler door emergency release.

1. Open the liftgate.

2. Push the inboard edge of the left storage

bin to the center, this will pop up the

outboard edge.

3. Grab popped up outboard edge with other hand to disengage snaps.

4. Remove the storage bin.

5. Pull the release cable to open the fuel door, push the release cable back to the home

position to re-seat the fuel door latch to the

closed position.

Release Cable

NOTE:

If the fuel door does not latch after the manual

release cable has been activated, the actuator

latch should be manually returned to the closed

position.

VEHICLE LOADING

GROSS VEHICLE WEIGHT RATING

(GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear axle

systems (GAWR). Total load must be limited so

GVWR and front and rear GAWR are not

exceeded.

PAYLOAD

The payload of a vehicle is defined as the

allowable load weight a truck can carry,

including the weight of the driver, all

passengers, options and cargo.

GROSS AXLE WEIGHT RATING (GAWR)

The GAWR is the maximum permissible load on

the front and rear axles. The load must be

distributed in the cargo area so that the GAWR

of each axle is not exceeded.

Each axle GAWR is determined by the

components in the system with the lowest load

carrying capacity (axle, springs, tires or wheels).

Heavier axles or suspension components

sometimes specified by purchasers for

increased durability does not necessarily

increase the vehicle's GVWR.

TIRE SIZE

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

20_WD_OM_EN_USC_t.book Page 240

Page 247 of 464

STARTING AND OPERATING245

NOTE:

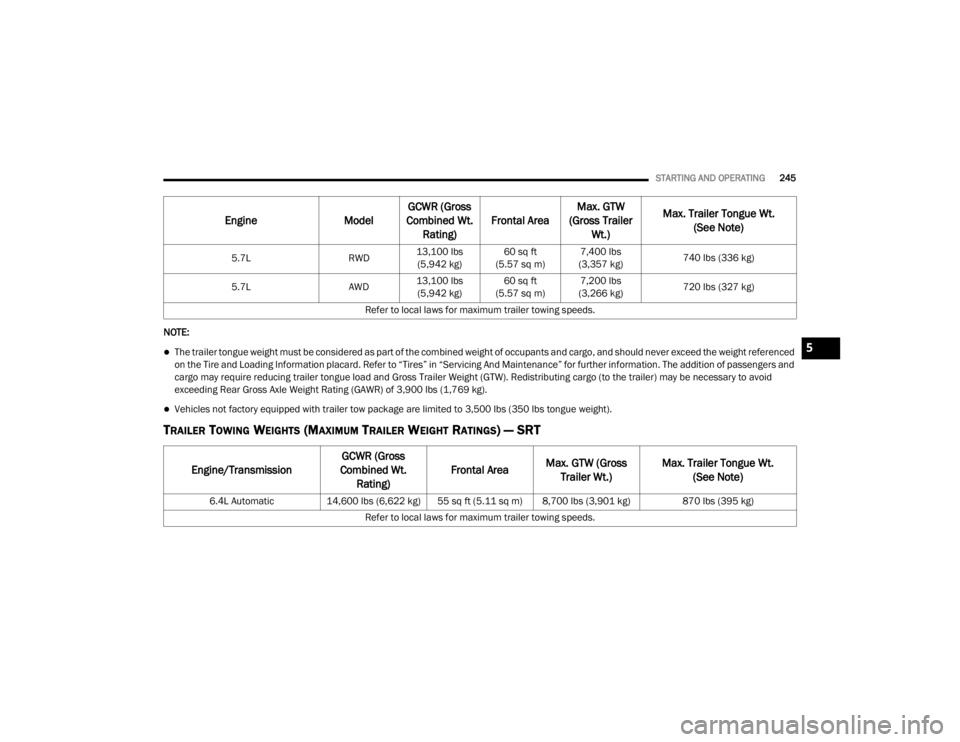

ÔĀ¨The trailer tongue weight must be considered as part of the combined weight of occupants and cargo, and should never exceed the weight referenced

on the Tire and Loading Information placard. Refer to ‚ÄúTires‚ÄĚ in ‚ÄúServicing And Maintenance‚ÄĚ for further information. The addition of passengers and

cargo may require reducing trailer tongue load and Gross Trailer Weight (GTW). Redistributing cargo (to the trailer) may be necessary to avoid

exceeding Rear Gross Axle Weight Rating (GAWR) of 3,900 lbs (1,769 kg).

ÔĀ¨Vehicles not factory equipped with trailer tow package are limited to 3,500 lbs (350 lbs tongue weight).

TRAILER TOWING WEIGHTS (MAXIMUM TRAILER WEIGHT RATINGS) ‚ÄĒ SRT

5.7LRWD13,100 lbs

(5,942 kg) 60 sq ft

(5.57 sq m) 7,400 lbs

(3,357 kg) 740 lbs (336 kg)

5.7L AWD13,100 lbs

(5,942 kg) 60 sq ft

(5.57 sq m) 7,200 lbs

(3,266 kg) 720 lbs (327 kg)

Refer to local laws for maximum trailer towing speeds.

Engine ModelGCWR (Gross

Combined Wt. Rating) Frontal Area Max. GTW

(Gross Trailer Wt.) Max. Trailer Tongue Wt.

(See Note)

Engine/Transmission GCWR (Gross

Combined Wt. Rating) Frontal Area

Max. GTW (Gross

Trailer Wt.) Max. Trailer Tongue Wt.

(See Note)

6.4L Automatic 14,600 lbs (6,622 kg) 55 sq ft (5.11 sq m) 8,700 lbs (3,901 kg) 870 lbs (395 kg)

Refer to local laws for maximum trailer towing speeds.

5

20_WD_OM_EN_USC_t.book Page 245

Page 248 of 464

246STARTING AND OPERATING

NOTE:

ÔĀ¨The trailer tongue weight must be considered

as part of the combined weight of occupants

and cargo, and should never exceed the

weight referenced on the Tire and Loading

Information placard. Refer to ‚ÄúTires‚ÄĚ in

‚ÄúServicing And Maintenance‚ÄĚ for further

information.

ÔĀ¨The manufacturer does not recommend

using the run flat feature while driving a

vehicle loaded at full capacity or towing a

trailer.

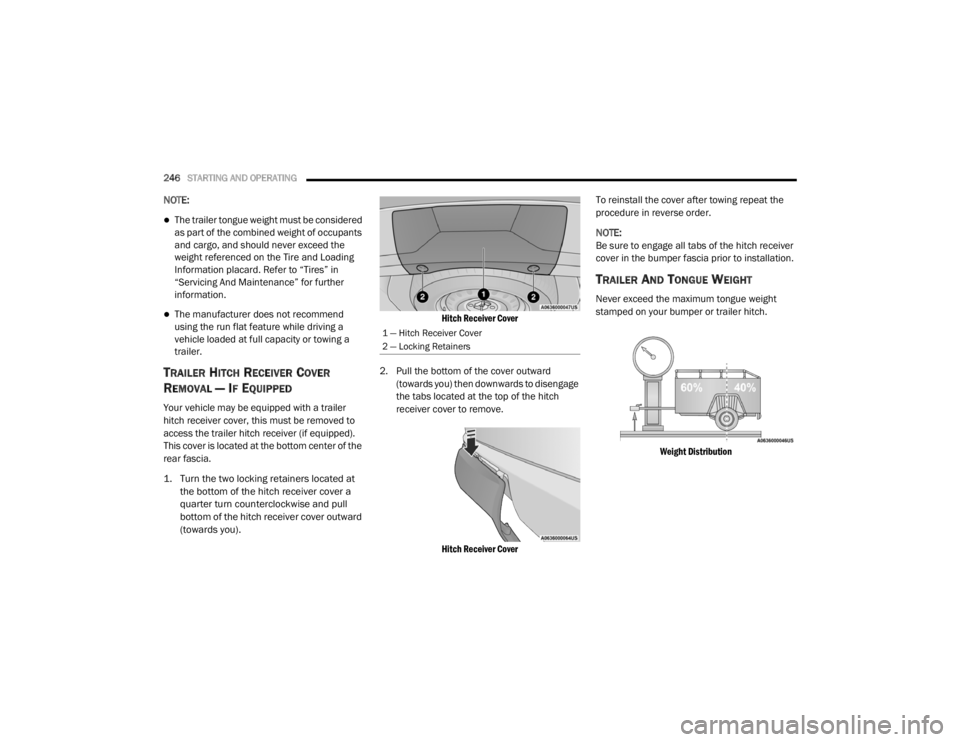

TRAILER HITCH RECEIVER COVER

R

EMOVAL ‚ÄĒ IF EQUIPPED

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This cover is located at the bottom center of the

rear fascia.

1. Turn the two locking retainers located at

the bottom of the hitch receiver cover a

quarter turn counterclockwise and pull

bottom of the hitch receiver cover outward

(towards you).

Hitch Receiver Cover

2. Pull the bottom of the cover outward (towards you) then downwards to disengage

the tabs located at the top of the hitch

receiver cover to remove.

Hitch Receiver Cover

To reinstall the cover after towing repeat the

procedure in reverse order.

NOTE:

Be sure to engage all tabs of the hitch receiver

cover in the bumper fascia prior to installation.

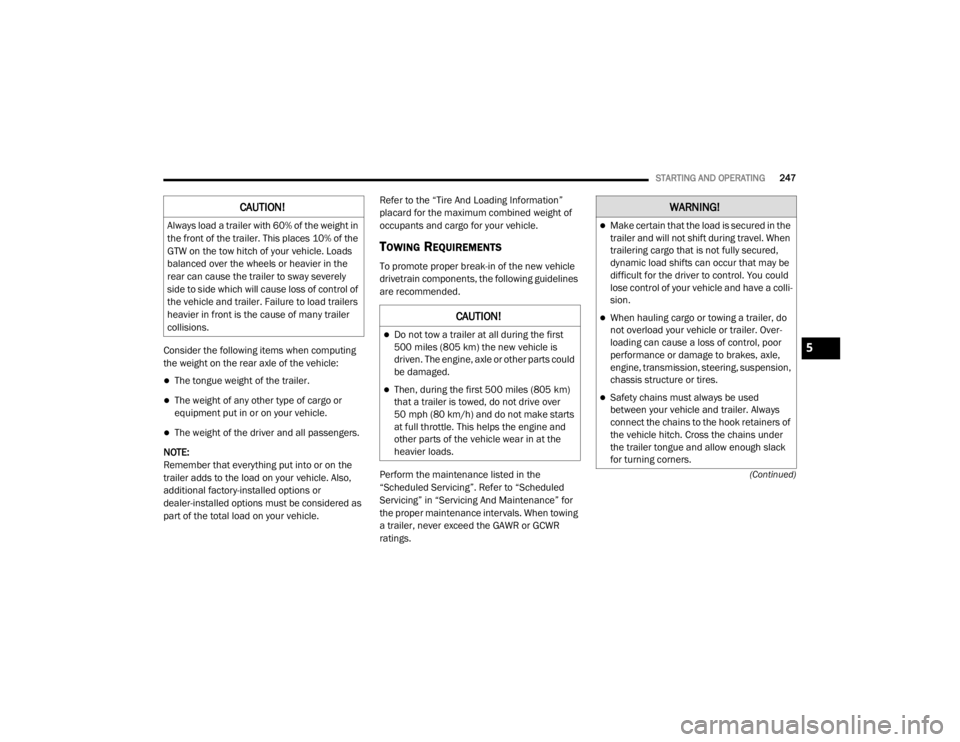

TRAILER AND TONGUE WEIGHT

Never exceed the maximum tongue weight

stamped on your bumper or trailer hitch.

Weight Distribution

1 ‚ÄĒ Hitch Receiver Cover

2 ‚ÄĒ Locking Retainers

20_WD_OM_EN_USC_t.book Page 246

Page 249 of 464

STARTING AND OPERATING247

(Continued)

Consider the following items when computing

the weight on the rear axle of the vehicle:

ÔĀ¨The tongue weight of the trailer.

ÔĀ¨The weight of any other type of cargo or

equipment put in or on your vehicle.

ÔĀ¨The weight of the driver and all passengers.

NOTE:

Remember that everything put into or on the

trailer adds to the load on your vehicle. Also,

additional factory-installed options or

dealer-installed options must be considered as

part of the total load on your vehicle. Refer to the ‚ÄúTire And Loading Information‚ÄĚ

placard for the maximum combined weight of

occupants and cargo for your vehicle.

TOWING REQUIREMENTS

To promote proper break-in of the new vehicle

drivetrain components, the following guidelines

are recommended.

Perform the maintenance listed in the

‚ÄúScheduled Servicing‚ÄĚ. Refer to ‚ÄúScheduled

Servicing‚ÄĚ in ‚ÄúServicing And Maintenance‚ÄĚ for

the proper maintenance intervals. When towing

a trailer, never exceed the GAWR or GCWR

ratings.

CAUTION!

Always load a trailer with 60% of the weight in

the front of the trailer. This places 10% of the

GTW on the tow hitch of your vehicle. Loads

balanced over the wheels or heavier in the

rear can cause the trailer to sway severely

side to side which will cause loss of control of

the vehicle and trailer. Failure to load trailers

heavier in front is the cause of many trailer

collisions.

CAUTION!

ÔĀ¨Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is

driven. The engine, axle or other parts could

be damaged.

ÔĀ¨Then, during the first 500 miles (805 km) that a trailer is towed, do not drive over

50 mph (80 km/h) and do not make starts

at full throttle. This helps the engine and

other parts of the vehicle wear in at the

heavier loads.

WARNING!

ÔĀ¨Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could

lose control of your vehicle and have a colli -

sion.

ÔĀ¨When hauling cargo or towing a trailer, do

not overload your vehicle or trailer. Over -

loading can cause a loss of control, poor

performance or damage to brakes, axle,

engine, transmission, steering, suspension,

chassis structure or tires.

ÔĀ¨Safety chains must always be used

between your vehicle and trailer. Always

connect the chains to the hook retainers of

the vehicle hitch. Cross the chains under

the trailer tongue and allow enough slack

for turning corners.

5

20_WD_OM_EN_USC_t.book Page 247