recommended oil DODGE DURANGO 2020 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: DURANGO, Model: DODGE DURANGO 2020Pages: 464, PDF Size: 22.14 MB

Page 106 of 464

104GETTING TO KNOW YOUR INSTRUMENT PANEL

Tire Pressure Monitor System

If tire pressure is OK for all tires a vehicle icon

is displayed with tire pressure values in each

corner of the icon.

If one or more tires have low pressure,

“Inflate Tire To XX” is displayed with the

vehicle icon and the tire pressure values in

each corner of the icon with the pressure

value of the low tire are displayed in a

different color than the other tire pressure

value.

If the Tire Pressure system requires service,

“Service Tire Pressure System” is displayed.

Tire Pressure is an information only function,

and cannot be reset.

Refer to “Tire Pressure Monitoring System

(TPMS)” in “Safety” for further information.

Coolant Temperature — If Equipped

Displays the current temperature of the

coolant.

Transmission Temperature

Displays the actual transmission tempera -

ture. Oil Temperature

Displays the actual oil temperature.

Oil Pressure

Displays the actual oil pressure.

Oil Life

Displays the current oil life of the vehicle.

Battery Voltage

Displays the current voltage level of the

battery.

Storage Mode — If Equipped

Through this option, the vehicle can be

placed into Storage Mode.

SRT Performance Features — If Equipped

Push and release the up or down arrow button

until the SRT icon/title is highlighted in the

instrument cluster display. Push and release

the left or right arrow button to scroll through

the performance feature submenus. The Performance Features include the

following:0-60 mph (0-100 km/h) Timer

Best

Last

Recent

Reaction Time — If Selected

WARNING!

Measurement of vehicle statistics with the

Performance Features is intended for

off-highway or track use only and should not

be done on any public roadways. It is

recommended that these features be used in

a controlled environment and within the limits

of the law. The capabilities of the vehicle as

measured by the performance pages must

never be exploited in a reckless or dangerous

manner, which can jeopardize the user’s

safety or the safety of others. Only a safe,

attentive, and skillful driver can prevent

accidents.

20_WD_OM_EN_USC_t.book Page 104

Page 190 of 464

188STARTING AND OPERATING

COLD WEATHER OPERATION (BELOW

–22°F O

R −30°C)

To ensure reliable starting at these

temperatures, use of an externally powered

electric engine block heater (available from an

authorized dealer) is recommended.

AFTER STARTING

The idle speed is controlled automatically, and

it will decrease as the engine warms up.

ENGINE BLOCK HEATER — IF EQUIPPED

The engine block heater warms the engine, and

permits quicker starts in cold weather. Connect

the cord to a standard 110-115 Volt AC

electrical outlet with a grounded, three-wire

extension cord.

The engine block heater must be plugged in at

least one hour to have an adequate warming

effect on the engine. The engine block heater cord is located:

3.6L Engine — Coiled and strapped to the

engine oil dipstick tube.

5.7L Engine — Bundled and fastened to the

injector harness.

ENGINE BREAK-IN RECOMMENDATIONS –

NON-SRT

A long break-in period is not required for the

engine and drivetrain (transmission and axle) in

your vehicle.

Drive moderately during the first 300 miles

(500 km). After the initial 60 miles (100 km),

speeds up to 50 or 55 mph (80 or 90 km/h) are

desirable.

While cruising, brief full-throttle acceleration

within the limits of local traffic laws contributes

to a good break-in.

Wide-open throttle acceleration in low gear can

be detrimental and should be avoided.

The engine oil installed in the engine at the

factory is a high-quality energy conserving type

lubricant. Oil changes should be consistent with

anticipated climate conditions under which

vehicle operations will occur. For the

recommended viscosity and quality grades,

refer to “Dealer Service” in “Servicing And

Maintenance”.

NOTE:

A new engine may consume some oil during its

first few thousand miles (kilometers) of opera

-

tion. This should be considered a normal part of

the break-in and not interpreted as a problem.

Please check your oil level with the engine oil

indicator often during the break-in period. Add

oil as required.

CAUTION!

To prevent damage to the starter, do not

continuously crank the engine for more than

25 seconds at a time. Wait 60 seconds

before trying again.

WARNING!

Remember to disconnect the engine block

heater cord before driving. Damage to the

110-115 Volt electrical cord could cause

electrocution.

CAUTION!

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

20_WD_OM_EN_USC_t.book Page 188

Page 191 of 464

STARTING AND OPERATING189

ENGINE BREAK-IN RECOMMENDATIONS –

SRT

The following tips will be helpful in obtaining

optimum performance and maximum durability

for your new SRT Vehicle.

Despite modern technology and World Class

manufacturing methods, the moving parts of

the vehicle still require wear in with one

another. This wearing in occurs mainly during

the first 500 miles (805 km) and continues

through the first oil change interval.

It is recommended that the operator observe

the following driving behaviors during the new

vehicle break-in period:

0 to 100 miles (0 to 161 km):

Do not allow the engine to operate at idle for

an extended period of time.

Depress the accelerator pedal slowly and

not more than halfway to avoid rapid

acceleration.

Avoid aggressive braking.

Drive with the engine speed less than

3,500 RPM.

Maintain vehicle speed below 55 mph

(88 km/h) and observe local speed limits.

100 to 300 miles (161 to 483 km):

Depress the accelerator pedal slowly and not

more than halfway to avoid rapid accelera -

tion in lower gears (FIRST to THIRD gears).

Avoid aggressive braking.

Drive with the engine speed less than

5,000 RPM.

Maintain vehicle speed below 70 mph

(112 km/h) and observe local speed limits. 300 to 500 miles (483 to 805 km):

Exercise the full engine RPM range, shifting

manually (paddles or gear shift) at higher

RPM when possible.

Do not perform sustained operation with the

accelerator pedal at wide open throttle.

Maintain vehicle speed below 85 mph

(136 km/h) and observe local speed limits.

For the first 1,500 miles (2,414 km):

Do not participate in track events, sport

driving schools, or similar activities during

the first 1,500 miles (2,414 km).

NOTE:

Check engine oil with every refueling and add if

necessary. Oil and fuel consumption may be

higher through the first oil change interval.

Running the engine with an oil level below the

add mark can cause severe engine damage.5

20_WD_OM_EN_USC_t.book Page 189

Page 310 of 464

308SERVICING AND MAINTENANCE

PRESSURE WASHING

Cleaning the engine compartment with a high

pressure washer is not recommended.

DEALER SERVICE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed against

you.

ENGINE OIL

Change Engine Oil — Non-SRT (If Equipped)

The oil change indicator system will remind you

that it is time to take your vehicle in for

scheduled maintenance. Refer to the

“Maintenance Plan” for further information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or any

other booster source with an output greater

than 12 Volts. Do not allow cable clamps to

touch each other.

Battery posts, terminals, and related acces -

sories contain lead and lead compounds.

Wash hands after handling.

CAUTION!

It is essential when replacing the cables on

the battery that the positive cable is

attached to the positive post and the nega -

tive cable is attached to the negative post.

Battery posts are marked positive (+) and

negative (-) and are identified on the battery

case. Cable clamps should be tight on the

terminal posts and free of corrosion.

If a “fast charger” is used while the battery

is in the vehicle, disconnect both vehicle

battery cables before connecting the

charger to the battery. Do not use a “fast

charger” to provide starting voltage.

WARNING! (Continued)

CAUTION!

Precautions have been taken to safeguard all

parts and connections however, the

pressures generated by these machines is

such that complete protection against water

ingress cannot be guaranteed.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service work

for which you have the knowledge and the

proper equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.

20_WD_OM_EN_USC_t.book Page 308

Page 311 of 464

SERVICING AND MAINTENANCE309

Change Engine Oil — SRT (If Equipped)

The oil change indicator system will remind you

that it is time to take your vehicle in for

scheduled maintenance. Refer to “Scheduled

Servicing” for further information.

NOTE:

Under no circumstances should oil change

intervals exceed 6,000 miles (10,000 km) or

6 months, whichever occurs first.

Engine Oil Selection — Non-SRT (If

Equipped)

For best performance and maximum protection

under all types of operating conditions, the

manufacturer only recommends engine oils

that are API Certified and meet the

requirements of FCA Material Standard

MS-6395.

NOTE:

Hemi engines (5.7L) at times can tick right after

startup and then quiet down after approxi -

mately 30 seconds. This is normal and will not

harm the engine. This characteristic can be

caused by short drive cycles. For example, if the

vehicle is started then shut off after driving a

short distance. Upon restarting, you may experience a ticking

sound. Other causes could be if the vehicle is

unused for an extended period of time, incor

-

rect oil, extended oil changes or extended

idling. If the engine continues to tick or if the

Malfunction Indicator Light (MIL) comes on, see

the nearest authorized dealer.

Engine Oil Selection — SRT (If Equipped)

For best performance and maximum protection

under all types of operating conditions, the

manufacturer only recommends full synthetic

engine oils that meet the American Petroleum

Institute (API) categories of SN.

The manufacturer recommends the use of

Pennzoil Ultra 0W-40 engine or equivalent

Mopar oil meeting the FCA Material Standard

MS-12633 for use in all operating

temperatures.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to “Engine Compartment” in this

section for further information. NOTE:

Hemi engines at times can tick right after

startup and then quiet down after approxi

-

mately 30 seconds. This is normal and will not

harm the engine. This characteristic can be

caused by short drive cycles. For example, if the

vehicle is started then shut off after driving a

short distance. Upon restarting, you may experi -

ence a ticking sound. Other causes could be if

the vehicle is unused for an extended period of

time, incorrect oil, extended oil changes or

extended idling. If the engine continues to tick

or if the Malfunction Indicator Light (MIL) comes

on, see the nearest authorized dealer.

CAUTION!

Do not use chemical flushes in your engine oil

as the chemicals can damage your engine.

Such damage is not covered by the New

Vehicle Limited Warranty.7

20_WD_OM_EN_USC_t.book Page 309

Page 312 of 464

310SERVICING AND MAINTENANCE

American Petroleum Institute (API) Engine

Oil Identification Symbol

This symbol means that the oil has

been certified by the American

Petroleum Institute (API). The

manufacturer only recommends API

Certified engine oils.

This symbol certifies 0W-20, 5W-20, 0W-30,

5W-30 and 10W-30 engine oils.

Engine Oil Viscosity (SAE Grade) — 3.6L

Engine

Mopar SAE 0W-20 engine oil approved to FCA

Material Standard MS-6395 such as Pennzoil,

Shell Helix or equivalent is recommended for all

operating temperatures. This engine oil

improves low temperature starting and vehicle

fuel economy. The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to the “Engine Compartment”

illustration in this section.

Lubricants which do not have both the engine

oil certification mark and the correct SAE

viscosity grade number should not be used.

Engine Oil Viscosity (SAE Grade) — 5.7L

Engine

Mopar SAE 5W-20 engine oil approved to FCA

Material Standard MS-6395 such as Pennzoil,

Shell Helix or equivalent is recommended for all

operating temperatures. This engine oil

improves low temperature starting and vehicle

fuel economy.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to the “Engine Compartment”

illustration in this section.

NOTE:

Vehicles equipped with a 5.7L engine must use

SAE 5W-20 oil. Failure to do so may result in

improper operation of the Fuel Saver Tech

-

nology. Refer to “Fuel Saver Technology – If

Equipped” in “Starting And Operating” for

further information.

Lubricants which do not have both the engine

oil certification mark and the correct SAE

viscosity grade number should not be used.Engine Oil Viscosity — 6.4L Engine

Use Pennzoil Ultra Platinum 0W-40 engine or

equivalent Mopar oil meeting the FCA Material

Standard MS-12633 for use in all operating

temperatures.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to “Engine Compartment” in this

section for further information.

CAUTION!

Do not use chemical flushes in your engine oil

as the chemicals can damage your engine.

Such damage is not covered by the New

Vehicle Limited Warranty.

20_WD_OM_EN_USC_t.book Page 310

Page 313 of 464

SERVICING AND MAINTENANCE311

Synthetic Engine Oils

You may use synthetic engine oils provided the

recommended oil quality requirements are met,

and the recommended maintenance intervals

for oil and filter changes are followed.

Synthetic engine oils which do not have both the

engine oil certification mark and the correct SAE

viscosity grade number should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends

against the addition of any additives (other than

leak detection dyes) to the engine oil. Engine oil

is an engineered product and its performance

may be impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used

engine oil and oil filters from your vehicle. Used

oil and oil filters, indiscriminately discarded, can

present a problem to the environment. Contact

an authorized dealer, service station or

governmental agency for advice on how and

where used oil and oil filters can be safely

discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a

new filter at every engine oil change.

Engine Oil Filter Selection

This manufacturer's engines have a full-flow

type disposable oil filter. Use a filter of this type

for replacement. The quality of replacement

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine oil filters are high quality

oil filters and are recommended.

ENGINE AIR CLEANER FILTER

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

NOTE:

Be sure to follow the “Severe Duty Conditions”

maintenance interval if applicable. Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner

filters varies considerably. Only high quality

filters should be used to ensure most efficient

service. Mopar engine air cleaner filters are a

high quality filter and are recommended.

Engine Air Cleaner Filter Inspection and

Replacement

Inspect engine air cleaner filter for dirt and/or

debris, if you find evidence of either dirt or

debris change the engine air cleaner filter.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in

the case of engine backfire. Do not remove

the air induction system (air cleaner, hoses,

etc.) unless such removal is necessary for

repair or maintenance. Make sure that no

one is near the engine compartment before

starting the vehicle with the air induction

system (air cleaner, hoses, etc.) removed.

Failure to do so can result in serious personal

injury.

7

20_WD_OM_EN_USC_t.book Page 311

Page 327 of 464

SERVICING AND MAINTENANCE325

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked whenever the vehicle is serviced, or

immediately if the brake system warning light is

on. If necessary, add fluid to bring level within

the designated marks on the side of the

reservoir of the brake master cylinder. Be sure

to clean the top of the master cylinder area

before removing cap. With disc brakes, fluid level can be expected to

fall as the brake pads wear. Brake fluid level

should be checked when pads are replaced. If

the brake fluid is abnormally low, check the

system for leaks.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle

is also identified on the original factory

installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

20_WD_OM_EN_USC_t.book Page 325

Page 329 of 464

SERVICING AND MAINTENANCE327

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks

are not required. When the vehicle is serviced

for other reasons the exterior surfaces of the

axle assembly should be inspected. If gear oil

leakage is suspected inspect the fluid level.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

Front Axle Fluid Level Check

The front axle oil level needs to be no lower than

1/8 inch (3 mm) below the bottom of the fill

hole.

The front axle fill and drain plugs should be

tightened to 22 to 29 ft lbs (30 to 40 N·m).

Rear Axle Fluid Level Check

The rear axle oil level needs to be no lower than

1/8 inch (3 mm) below the bottom of the fill

hole. The rear axle fill and drain plugs should be

tightened to 22 to 29 ft lbs (30 to 40 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

TRANSFER CASE

Fluid Level Check

For normal service, periodic fluid level checks

are not required. When the vehicle is serviced

for other reasons the exterior surfaces of the

transfer case assembly should be inspected. If

oil leakage is suspected inspect the fluid level.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

Adding Fluid

Add fluid at the filler hole, until it runs out of the

hole, when the vehicle is in a level position.

Drain

First remove fill plug, then remove drain plug.

Recommended tightening torque for drain and

fill plugs is 15 to 25 ft lbs (20 to 34 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

CAUTION!

Do not overtighten the plugs as it could

damage them and cause them to leak.

CAUTION!

Do not overtighten the plugs as it could

damage them and cause them to leak.CAUTION!

When installing plugs, do not overtighten. You

could damage them and cause them to leak.

7

20_WD_OM_EN_USC_t.book Page 327

Page 340 of 464

338SERVICING AND MAINTENANCE

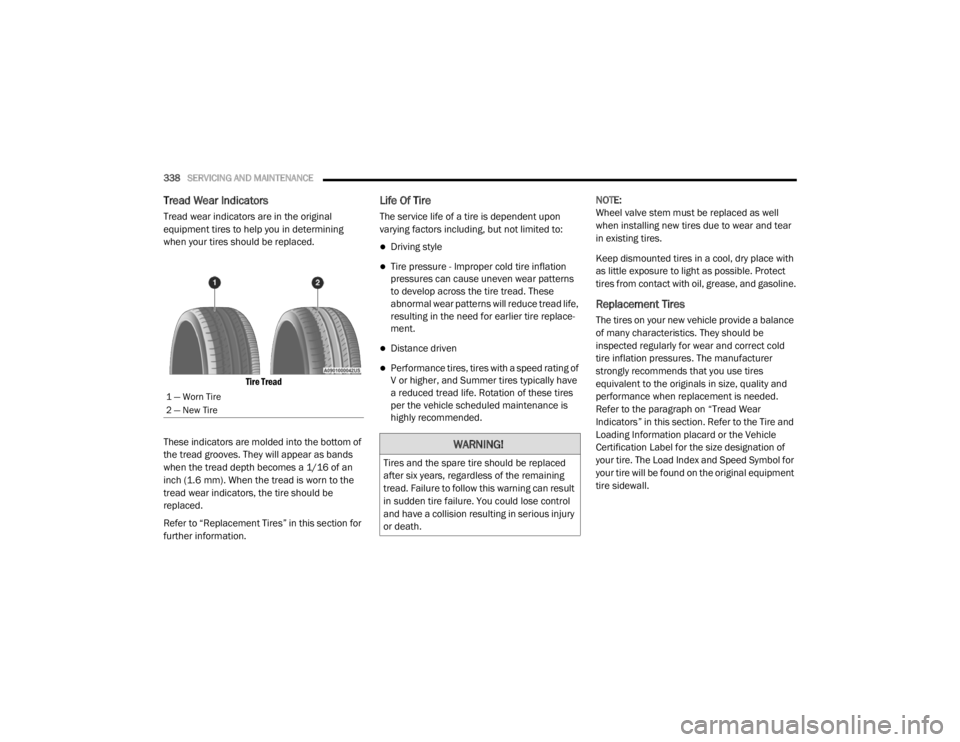

Tread Wear Indicators

Tread wear indicators are in the original

equipment tires to help you in determining

when your tires should be replaced.

Tire Tread

These indicators are molded into the bottom of

the tread grooves. They will appear as bands

when the tread depth becomes a 1/16 of an

inch (1.6 mm). When the tread is worn to the

tread wear indicators, the tire should be

replaced.

Refer to “Replacement Tires” in this section for

further information.

Life Of Tire

The service life of a tire is dependent upon

varying factors including, but not limited to:

Driving style

Tire pressure - Improper cold tire inflation

pressures can cause uneven wear patterns

to develop across the tire tread. These

abnormal wear patterns will reduce tread life,

resulting in the need for earlier tire replace -

ment.

Distance driven

Performance tires, tires with a speed rating of

V or higher, and Summer tires typically have

a reduced tread life. Rotation of these tires

per the vehicle scheduled maintenance is

highly recommended. NOTE:

Wheel valve stem must be replaced as well

when installing new tires due to wear and tear

in existing tires.

Keep dismounted tires in a cool, dry place with

as little exposure to light as possible. Protect

tires from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance

of many characteristics. They should be

inspected regularly for wear and correct cold

tire inflation pressures. The manufacturer

strongly recommends that you use tires

equivalent to the originals in size, quality and

performance when replacement is needed.

Refer to the paragraph on “Tread Wear

Indicators” in this section. Refer to the Tire and

Loading Information placard or the Vehicle

Certification Label for the size designation of

your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

1 — Worn Tire

2 — New Tire

WARNING!

Tires and the spare tire should be replaced

after six years, regardless of the remaining

tread. Failure to follow this warning can result

in sudden tire failure. You could lose control

and have a collision resulting in serious injury

or death.

20_WD_OM_EN_USC_t.book Page 338