torque DODGE DURANGO 2020 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: DURANGO, Model: DODGE DURANGO 2020Pages: 464, PDF Size: 22.14 MB

Page 239 of 464

STARTING AND OPERATING237

CHANGING LANESENSE STATUS

The LaneSense system has settings to adjust

the intensity of the torque warning and the

warning zone sensitivity (early/late) that you

can configure through the Uconnect system

screen. Refer to “Uconnect Settings” in

“Multimedia” for further information.

NOTE:

When enabled the system operates above

37 mph (60 km/h) and below 112 mph

(180 km/h).

Use of the turn signal suppresses the

warnings.

The system will not apply torque to the

steering wheel whenever a safety system

engages (Anti-Lock Brakes, Traction Control

System, Electronic Stability Control, Forward

Collision Warning, etc.).

PARKVIEW REAR BACK UP CAMERA

Your vehicle is equipped with the ParkView Rear

Back Up Camera that allows you to see an

on-screen image of the rear surroundings of

your vehicle whenever the gear selector is put

into REVERSE. The image will be displayed on

the Navigation/Multimedia radio display screen

along with a caution note to “check entire

surroundings” across the top of the screen.

After five seconds this note will disappear. The

ParkView camera is located on the rear of the

vehicle above the rear license plate.

When the vehicle is shifted out of REVERSE

(with camera delay turned off), the rear camera

mode is exited and the navigation or audio

screen appears again.

Manual Activation Of The Backup Camera

1. Press the “Controls” button located on the

bottom of the Uconnect display.

2. Press the “Backup Camera” button to turn the Rear View Camera system on. NOTE:

The ParkView Rear Back Up Camera has

programmable modes of operation that may be

selected through the Uconnect System.

Refer to “Uconnect Settings” in “Multimedia”

for further information.

When the vehicle is shifted out of REVERSE

(with camera delay turned off), the rear camera

mode is exited and the previous screen appears

again. When the vehicle is shifted out of

REVERSE (with camera delay turned on), the

camera image will continue to be displayed for

up to ten seconds, unless the vehicle speed

exceeds 8 mph (13 km/h), the vehicle is shifted

into PARK, the vehicle’s ignition is placed in the

OFF position, or the user presses image defeat

“X” to exit out of the camera video display.

When enabled, active guidelines are overlaid on

the image to illustrate the width of the vehicle

and its projected backup path based on the

steering wheel position. A dashed center line

overlay indicates the center of the vehicle to

assist with parking or aligning to a hitch/

receiver. Different colored zones indicate the

distance to the rear of the vehicle.

5

20_WD_OM_EN_USC_t.book Page 237

Page 262 of 464

260STARTING AND OPERATING

After Driving Off-Road

Off-road operation puts more stress on your

vehicle than does most on-road driving. After

going off-road, it is always a good idea to check

for damage. That way you can get any problems

taken care of right away and have your vehicle

ready when you need it.

Completely inspect the underbody of your

vehicle. Check tires, body structure, steering,

suspension, and exhaust system for damage.

Inspect the radiator for mud and debris and

clean as required.

Check threaded fasteners for looseness,

particularly on the chassis, drivetrain compo -

nents, steering, and suspension. Retighten

them, if required, and torque to the values

specified in the Service Manual.

Check for accumulations of plants or brush.

These things could be a fire hazard. They

might hide damage to fuel lines, brake hoses,

axle pinion seals, and propeller shafts.

After extended operation in mud, sand,

water, or similar dirty conditions, have the

radiator, fan, brake rotors, wheels, brake

linings, and axle yokes inspected and

cleaned as soon as possible.

If you experience unusual vibration after

driving in mud, slush or similar conditions,

check the wheels for impacted material.

Impacted material can cause a wheel imbal-

ance and freeing the wheels of it will correct

the situation.

WARNING!

Abrasive material in any part of the brakes

may cause excessive wear or unpredictable

braking. You might not have full braking

power when you need it to prevent a collision.

If you have been operating your vehicle in

dirty conditions, get your brakes checked and

cleaned as necessary.

20_WD_OM_EN_USC_t.book Page 260

Page 284 of 464

282IN CASE OF EMERGENCY

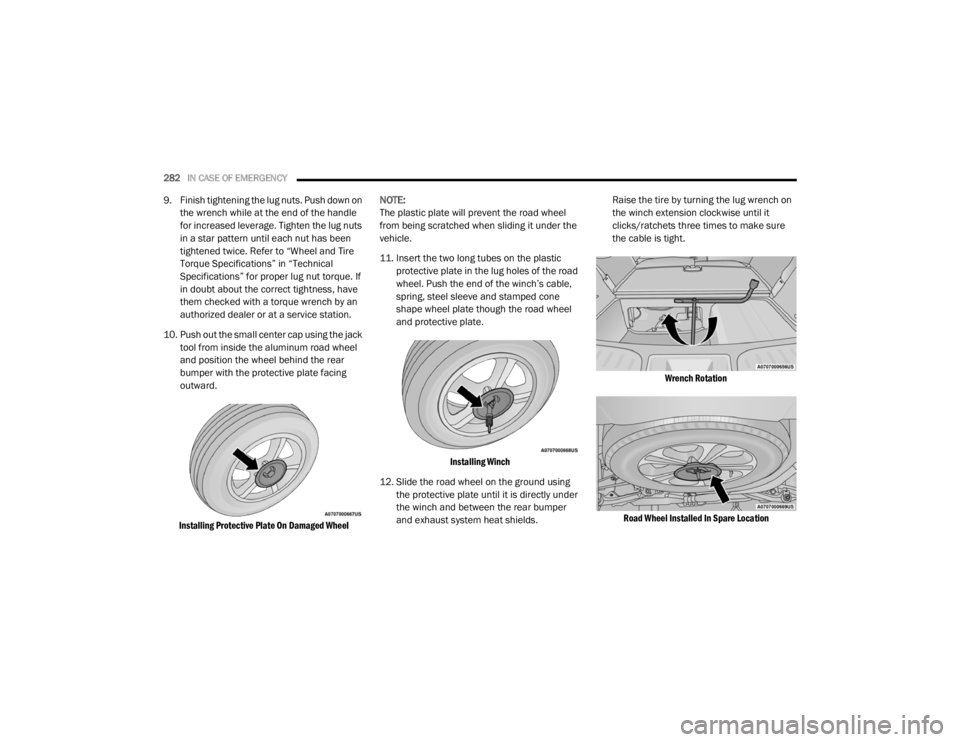

9. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Wheel and Tire

Torque Specifications” in “Technical

Specifications” for proper lug nut torque. If

in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or at a service station.

10. Push out the small center cap using the jack tool from inside the aluminum road wheel

and position the wheel behind the rear

bumper with the protective plate facing

outward.

Installing Protective Plate On Damaged Wheel

NOTE:

The plastic plate will prevent the road wheel

from being scratched when sliding it under the

vehicle.

11. Insert the two long tubes on the plastic

protective plate in the lug holes of the road

wheel. Push the end of the winch’s cable,

spring, steel sleeve and stamped cone

shape wheel plate though the road wheel

and protective plate.

Installing Winch

12. Slide the road wheel on the ground using the protective plate until it is directly under

the winch and between the rear bumper

and exhaust system heat shields. Raise the tire by turning the lug wrench on

the winch extension clockwise until it

clicks/ratchets three times to make sure

the cable is tight.

Wrench Rotation

Road Wheel Installed In Spare Location

20_WD_OM_EN_USC_t.book Page 282

Page 285 of 464

IN CASE OF EMERGENCY283

NOTE:

Double check to ensure the tire is snug against

the underbody of the vehicle. Damage to the

winch cable may result if the vehicle is driven

with the tire loose.

13. Lower the jack to the fully closed position.

Return the tools to the proper positions in

the tool bag. Fold the flap on the tool bag

under the tools and roll the tools in the bag

underneath the others. Use the hook and

loop fasteners to secure the tool bag to the

jack with the lug wrench on the forward side

of the jack. Expand the jack on the bracket

by turning the thumb screw clockwise until

it is tight to prevent rattles.

14. Reinstall the plastic plug into the floor of the cargo area. Roll up and store the Jack, Tool

Kit and Tire Changing Instructions. Reinstall

the cover for the jack in the rear storage bin. 15. Have the aluminum road wheel and tire

repaired as soon as possible and properly

secure the spare tire, jack and tool kit.

ROAD TIRE INSTALLATION

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten the lug nuts. 3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Refer to “Wheel and Tire Torque Specifi -

cations” in “Technical Specifications” for

proper lug nut torque.

5. After 25 miles (40 km), check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so please

follow the procedures in this section carefully.

CAUTION!

The winch mechanism is designed for use

with the jack wrench extension tool only. Use

of air wrench or power tool may damage the

winch.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

6

20_WD_OM_EN_USC_t.book Page 283

Page 328 of 464

326SERVICING AND MAINTENANCE

AUTOMATIC TRANSMISSION

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid.

NOTE:

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the

transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supplemental

additives. Therefore, do not add any fluid

additives to the transmission. Avoid using

transmission sealers as they may adversely

affect seals.

Fluid Level Check

The fluid level is preset at the factory and does

not require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service

tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an

improper fluid level can cause severe

transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not

required. However, change the fluid and filter if

the fluid becomes contaminated (with water,

etc.), or if the transmission is disassembled for

any reason.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An

authorized dealer has the proper tools to

adjust the fluid level accurately.

20_WD_OM_EN_USC_t.book Page 326

Page 329 of 464

SERVICING AND MAINTENANCE327

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks

are not required. When the vehicle is serviced

for other reasons the exterior surfaces of the

axle assembly should be inspected. If gear oil

leakage is suspected inspect the fluid level.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

Front Axle Fluid Level Check

The front axle oil level needs to be no lower than

1/8 inch (3 mm) below the bottom of the fill

hole.

The front axle fill and drain plugs should be

tightened to 22 to 29 ft lbs (30 to 40 N·m).

Rear Axle Fluid Level Check

The rear axle oil level needs to be no lower than

1/8 inch (3 mm) below the bottom of the fill

hole. The rear axle fill and drain plugs should be

tightened to 22 to 29 ft lbs (30 to 40 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

TRANSFER CASE

Fluid Level Check

For normal service, periodic fluid level checks

are not required. When the vehicle is serviced

for other reasons the exterior surfaces of the

transfer case assembly should be inspected. If

oil leakage is suspected inspect the fluid level.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

Adding Fluid

Add fluid at the filler hole, until it runs out of the

hole, when the vehicle is in a level position.

Drain

First remove fill plug, then remove drain plug.

Recommended tightening torque for drain and

fill plugs is 15 to 25 ft lbs (20 to 34 N·m).

Selection Of Lubricant

Use only the manufacturer's recommended

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

CAUTION!

Do not overtighten the plugs as it could

damage them and cause them to leak.

CAUTION!

Do not overtighten the plugs as it could

damage them and cause them to leak.CAUTION!

When installing plugs, do not overtighten. You

could damage them and cause them to leak.

7

20_WD_OM_EN_USC_t.book Page 327

Page 352 of 464

350

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

VEHICLE IDENTIFICATION NUMBER

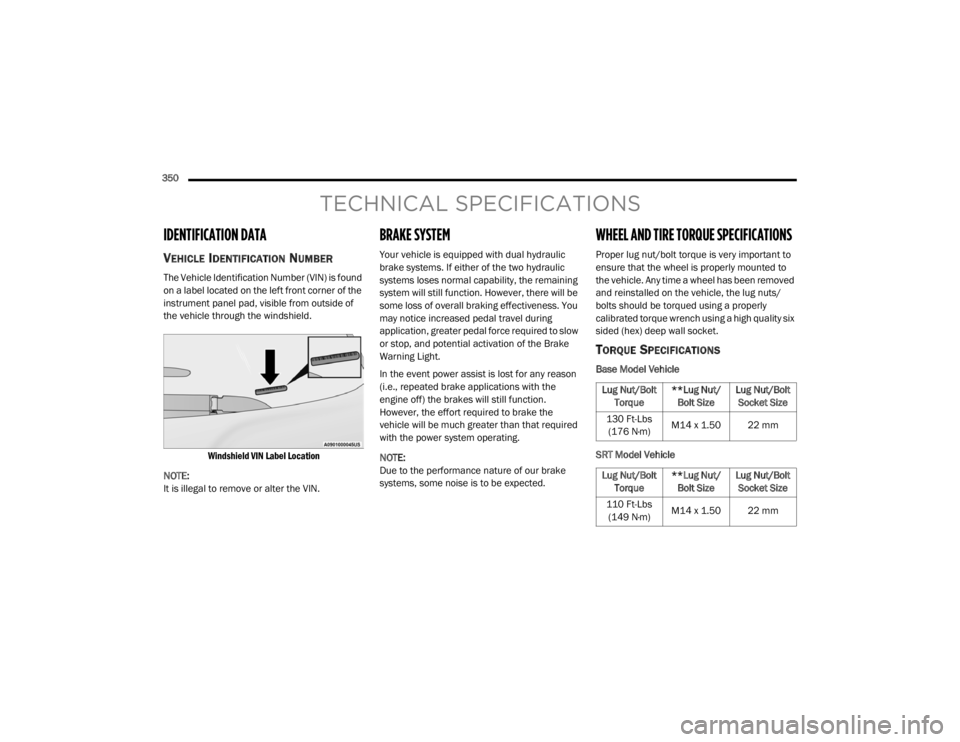

The Vehicle Identification Number (VIN) is found

on a label located on the left front corner of the

instrument panel pad, visible from outside of

the vehicle through the windshield.

Windshield VIN Label Location

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems loses normal capability, the remaining

system will still function. However, there will be

some loss of overall braking effectiveness. You

may notice increased pedal travel during

application, greater pedal force required to slow

or stop, and potential activation of the Brake

Warning Light.

In the event power assist is lost for any reason

(i.e., repeated brake applications with the

engine off) the brakes will still function.

However, the effort required to brake the

vehicle will be much greater than that required

with the power system operating.

NOTE:

Due to the performance nature of our brake

systems, some noise is to be expected.

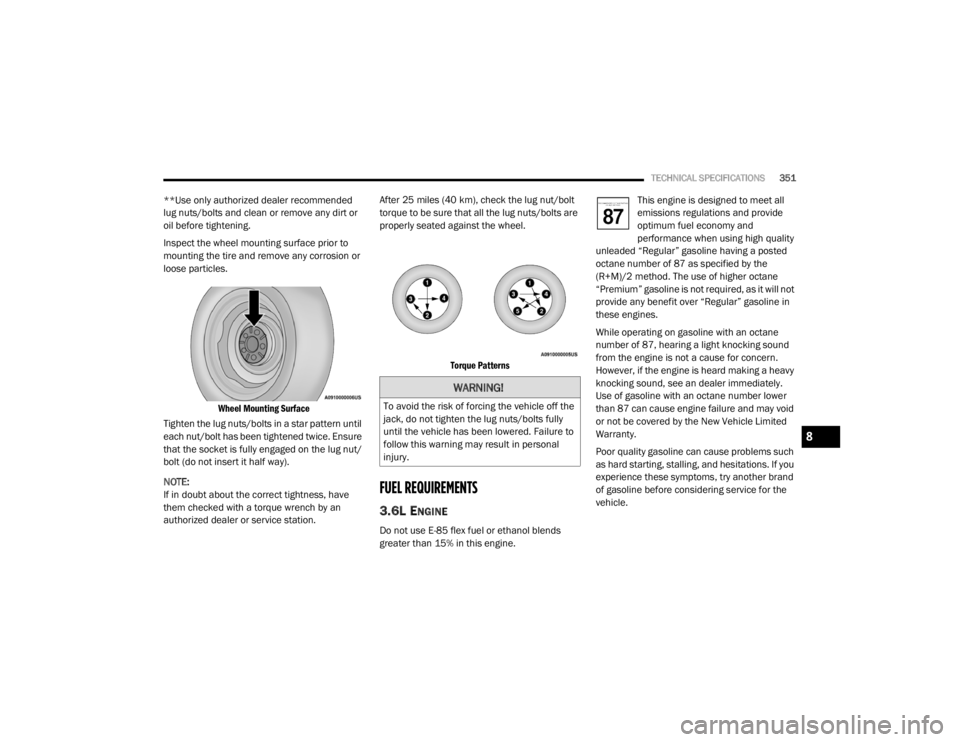

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

TORQUE SPECIFICATIONS

Base Model Vehicle

SRT Model Vehicle

Lug Nut/Bolt Torque **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

130 Ft-Lbs (176 N·m) M14 x 1.50 22 mm

Lug Nut/Bolt Torque **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

110 Ft-Lbs (149 N·m) M14 x 1.50 22 mm

20_WD_OM_EN_USC_t.book Page 350

Page 353 of 464

TECHNICAL SPECIFICATIONS351

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/

bolt (do not insert it half way).

NOTE:

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station. After 25 miles (40 km), check the lug nut/bolt

torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

Torque Patterns

FUEL REQUIREMENTS

3.6L ENGINE

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine. This engine is designed to meet all

emissions regulations and provide

optimum fuel economy and

performance when using high quality

unleaded “Regular” gasoline having a posted

octane number of 87 as specified by the

(R+M)/2 method. The use of higher octane

“Premium” gasoline is not required, as it will not

provide any benefit over “Regular” gasoline in

these engines.

While operating on gasoline with an octane

number of 87, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an dealer immediately.

Use of gasoline with an octane number lower

than 87 can cause engine failure and may void

or not be covered by the New Vehicle Limited

Warranty.

Poor quality gasoline can cause problems such

as hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand

of gasoline before considering service for the

vehicle.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully

until the vehicle has been lowered. Failure to

follow this warning may result in personal

injury.

8

20_WD_OM_EN_USC_t.book Page 351

Page 458 of 464

456

T

Telescoping Steering Column

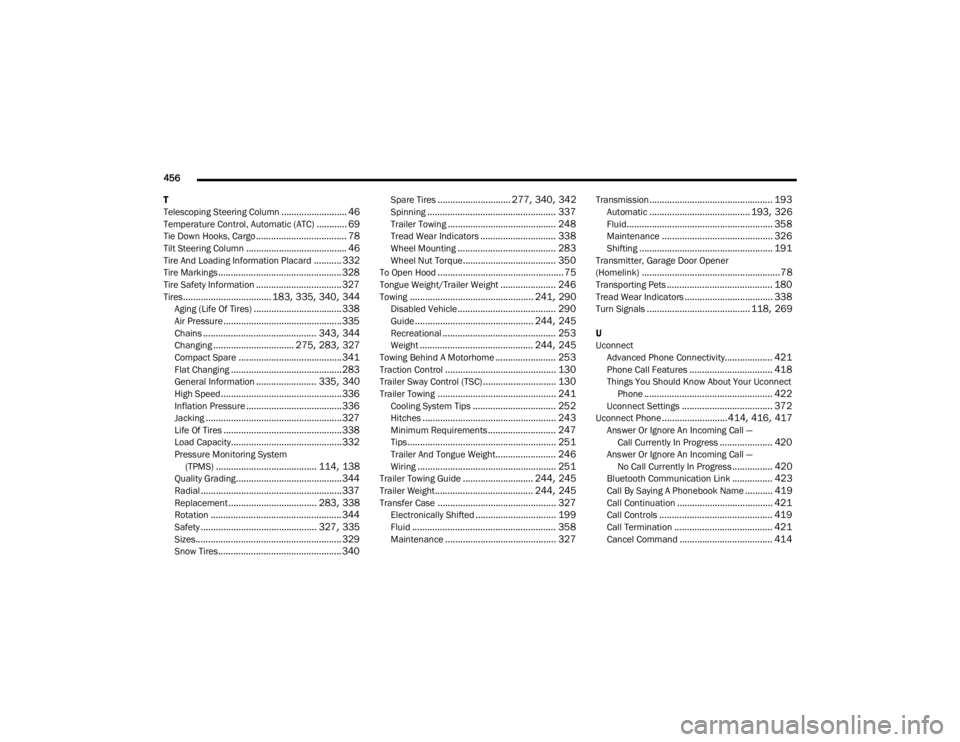

.......................... 46Temperature Control, Automatic (ATC)............ 69Tie Down Hooks, Cargo.................................... 78Tilt Steering Column........................................ 46Tire And Loading Information Placard........... 332Tire Markings................................................. 328Tire Safety Information.................................. 327Tires................................... 183, 335, 340, 344Aging (Life Of Tires)................................... 338Air Pressure............................................... 335Chains............................................. 343, 344Changing................................ 275, 283, 327Compact Spare......................................... 341Flat Changing............................................ 283General Information........................ 335, 340High Speed................................................ 336Inflation Pressure...................................... 336Jacking...................................................... 327Life Of Tires............................................... 338Load Capacity............................................ 332Pressure Monitoring System (TPMS)........................................ 114, 138Quality Grading.......................................... 344Radial........................................................ 337Replacement................................... 283, 338Rotation.................................................... 344Safety.............................................. 327, 335Sizes.......................................................... 329Snow Tires................................................. 340

Spare Tires............................. 277, 340, 342Spinning................................................... 337Trailer Towing........................................... 248Tread Wear Indicators.............................. 338Wheel Mounting....................................... 283Wheel Nut Torque..................................... 350To Open Hood.................................................. 75Tongue Weight/Trailer Weight...................... 246Towing................................................. 241, 290Disabled Vehicle....................................... 290Guide............................................... 244, 245Recreational............................................. 253Weight............................................. 244, 245Towing Behind A Motorhome........................ 253Traction Control............................................ 130Trailer Sway Control (TSC)............................. 130Trailer Towing............................................... 241Cooling System Tips................................. 252Hitches..................................................... 243Minimum Requirements........................... 247Tips........................................................... 251Trailer And Tongue Weight........................ 246Wiring....................................................... 251Trailer Towing Guide............................ 244, 245Trailer Weight....................................... 244, 245Transfer Case............................................... 327Electronically Shifted................................ 199Fluid......................................................... 358Maintenance............................................ 327

Transmission................................................. 193Automatic........................................ 193, 326Fluid.......................................................... 358Maintenance............................................ 326Shifting..................................................... 191Transmitter, Garage Door Opener

(Homelink).......................................................78Transporting Pets.......................................... 180Tread Wear Indicators................................... 338Turn Signals......................................... 118, 269

U

UconnectAdvanced Phone Connectivity

................... 421Phone Call Features................................. 418Things You Should Know About Your Uconnect Phone................................................... 422Uconnect Settings.................................... 372Uconnect Phone..........................414, 416, 417Answer Or Ignore An Incoming Call — Call Currently In Progress..................... 420Answer Or Ignore An Incoming Call — No Call Currently In Progress................ 420Bluetooth Communication Link................ 423Call By Saying A Phonebook Name........... 419Call Continuation...................................... 421Call Controls............................................. 419Call Termination....................................... 421Cancel Command..................................... 414

20_WD_OM_EN_USC_t.book Page 456