load capacity DODGE DURANGO 2022 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2022, Model line: DURANGO, Model: DODGE DURANGO 2022Pages: 332, PDF Size: 19.82 MB

Page 78 of 332

76GETTING TO KNOW YOUR VEHICLE

ROOF LUGGAGE RACK — IF EQUIPPED

The crossbars and side rails are designed to carry

weight on vehicles equipped with a luggage rack.

The load must not exceed 150 lb (68 kg), and

should be uniformly distributed over the luggage

rack crossbars.

The crossbars on your vehicle are delivered stowed

within the roof rack side rails. Crossbars should

always be used whenever cargo is placed on the

roof rack. Check the straps frequently to be sure

that the load remains securely attached.

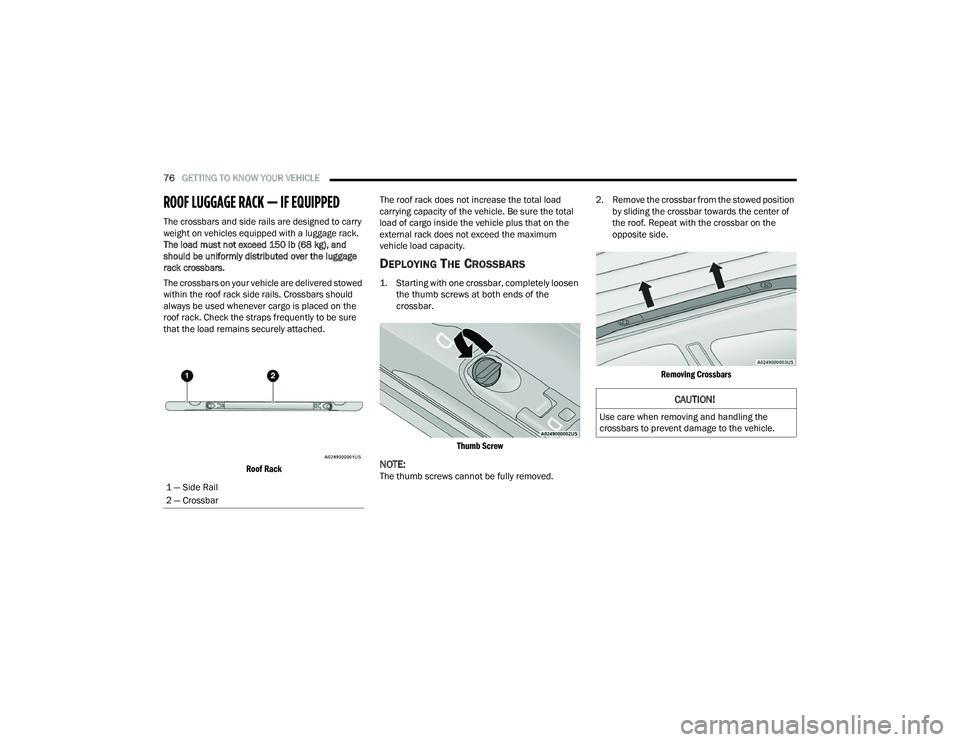

Roof Rack

The roof rack does not increase the total load

carrying capacity of the vehicle. Be sure the total

load of cargo inside the vehicle plus that on the

external rack does not exceed the maximum

vehicle load capacity.

DEPLOYING THE CROSSBARS

1. Starting with one crossbar, completely loosen

the thumb screws at both ends of the

crossbar.

Thumb Screw

NOTE:The thumb screws cannot be fully removed. 2. Remove the crossbar from the stowed position

by sliding the crossbar towards the center of

the roof. Repeat with the crossbar on the

opposite side.

Removing Crossbars

1 — Side Rail

2 — Crossbar

CAUTION!

Use care when removing and handling the

crossbars to prevent damage to the vehicle.

22_WD_OM_EN_USC_t.book Page 76

Page 81 of 332

GETTING TO KNOW YOUR VEHICLE79

(Continued)

(Continued)

CAUTION!

To prevent damage to the roof of your vehicle,

DO NOT carry any loads on the roof rack

without the crossbars deployed. The load

should be secured and placed on top of the

crossbars, not directly on the roof. If it is

necessary to place the load on the roof, place

a blanket or other protective layer between

the load and the roof surface.

To avoid damage to the roof rack and vehicle,

do not exceed the maximum roof rack load

capacity of 150 lb (68 kg). Always distribute

heavy loads as evenly as possible and secure

the load appropriately.

Load should always be secured to crossbars

first, with tie down loops used as additional

securing points if needed. Tie loops are

intended as supplementary tie down points

only. Do not use ratcheting mechanisms with

the tie loops. Check the straps and thumb

wheels frequently to be sure that the load

remains securely attached.

Long loads that extend over the windshield,

such as wood panels or surfboards, or loads

with large frontal area should be secured to

both the front and rear of the vehicle.

CAUTION!

Travel at reduced speeds and turn corners

carefully when carrying large or heavy loads

on the roof rack. Wind forces, due to natural

causes or nearby truck traffic, can add sudden

upward lift to a load. This is especially true on

large flat loads and may result in damage to

the cargo or your vehicle.

CAUTION!

2

22_WD_OM_EN_USC_t.book Page 79

Page 116 of 332

114STARTING AND OPERATING

7. New brake pads installed on old rotors require a burnish. New rotors installed with old brake

pads should be burnished at the track or

driven for 300 miles (485 km) of city driving to

develop an adequate lining transfer layer on

the rotor surface prior to track use.

8. Rotors that pulsate during track use should be replaced.

NOTE:Resurfacing of the rotors is not recommended, as

it removes mass from the rotor, reducing its

thermal capacity. Resurfacing also thins the rotor

cheek, making it less robust and increasing the

likelihood of pulsation in further track use.

FUEL SAVER TECHNOLOGY 5.7L ONLY —

IF EQUIPPED

This feature offers improved fuel economy by

shutting off four of the engine's eight cylinders

during light load and cruise conditions. The system

is automatic with no driver inputs.

NOTE:This system may take some time to return to full

functionality after a battery disconnect.

POWER STEERING

The electric power steering system will provide

increased vehicle response and ease of

maneuverability. The power steering system

adapts to different driving conditions and adjusts

accordingly.

Alternate electric power steering efforts can be

selected through the Uconnect System

Úpage 156.

If the Electric Power Steering warning icon is

displayed and the “SERVICE POWER STEERING” or

the “POWER STEERING ASSIST OFF – SERVICE

SYSTEM” message is displayed within the

instrument cluster display, this indicates the

vehicle needs to be taken to the dealer for service

Ú page 89.

NOTE:

Even if the power steering assistance is no

longer operational, it is still possible to steer the

vehicle. Under these conditions there will be a

substantial increase in steering effort, espe -

cially at low speeds and during parking maneu -

vers.

If the condition persists, see an authorized

dealer for service.

If the Steering icon is displayed and the “POWER

STEERING SYSTEM OVER TEMP” message is

displayed on the instrument cluster screen, this

indicates an over temperature condition in the

power steering system. Once driving conditions are

safe, pull over and let the vehicle idle for a few

moments until the icon and message turn off.

STOP/START SYSTEM — IF EQUIPPED

The Stop/Start function is developed to reduce

fuel consumption. The system will stop the engine

automatically during a vehicle stop if the required

conditions are met. Releasing the brake pedal or

pressing the accelerator pedal will automatically

re-start the engine.

This vehicle has been upgraded with a heavy duty

starter, enhanced battery, and other upgraded

engine parts, to handle the additional engine

starts.

WARNING!

Continued operation with reduced assist could

pose a safety risk to yourself and others. Service

should be obtained as soon as possible.

22_WD_OM_EN_USC_t.book Page 114

Page 140 of 332

138STARTING AND OPERATING

(Continued)

Fuel Filler

3. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is full.

4. Wait five seconds before removing the fuel nozzle to allow fuel to drain from nozzle.

5. Remove the nozzle and push the fuel door all the way in to secure it in place.

VEHICLE LOADING

CERTIFICATION LABEL

As required by National Highway Traffic Safety

Administration regulations, your vehicle has a

certification label affixed to the driver's side door or

pillar.

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear (GAWR).

Total load must be limited so GVWR and front and

rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by

purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

22_WD_OM_EN_USC_t.book Page 138

Page 141 of 332

STARTING AND OPERATING139

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has not

been exceeded. The weight on the front and rear of

the vehicle should then be determined separately

to be sure that the load is properly distributed over

the front and rear axle. Weighing the vehicle may

show that the GAWR of either the front or rear axles

has been exceeded but the total load is within the

specified GVWR and maximum Payload. If so, weight must be shifted from front to rear or rear to

front as appropriate until the specified weight

limitations are met. Store the heavier items down

low and be sure that the weight is distributed

equally. Stow all loose items securely before

driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you can

reasonably do with your vehicle. Before towing a

trailer, carefully review this information to tow your

load as efficiently and safely as possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing related definitions will

assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be limited

so that you do not exceed the GVWR Ú

page 138.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the weight

of all cargo, consumables and equipment

(permanent or temporary) loaded in or on the

trailer in its "loaded and ready for operation"

condition.

The recommended way to measure GTW is to put

your fully loaded trailer on a vehicle scale. The

entire weight of the trailer must be supported by

the scale.

WARNING!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR. If

you do, parts on your vehicle can break, or it can

change the way your vehicle handles. This could

cause you to lose control. Overloading can

shorten the life of your vehicle.

WARNING!

If the gross trailer weight is 5,000 lb (2,267 kg)

or more, it is recommended to use a

weight-distributing hitch to ensure stable

handling of your vehicle. If you use a standard

weight-carrying hitch, you could lose control of

your vehicle and cause a collision.

4

22_WD_OM_EN_USC_t.book Page 139

Page 142 of 332

140STARTING AND OPERATING

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Ú page 138.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link that

can be installed between the hitch receiver and the

trailer tongue that typically provides adjustable

friction associated with the telescoping motion to

dampen any unwanted trailer swaying motions

while traveling.

If equipped, the electronic TSC recognizes a

swaying trailer and automatically applies individual

wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and

the trailer axle(s). When used in accordance with

the manufacturer's directions, it provides for a

more level ride, offering more consistent steering

and brake control thereby enhancing towing

safety. The addition of a friction/hydraulic sway control also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. Trailer Sway Control

(TSC) and a weight distributing (load equalizing)

hitch are recommended for heavier Tongue

Weights (TW) and may be required depending on

vehicle and trailer configuration/loading to comply

with Gross Axle Weight Rating (GAWR)

requirements.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the vehicle

and have a collision.

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability,

braking performance, and could result in a

collision.

Weight-distributing hitch systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

22_WD_OM_EN_USC_t.book Page 140

Page 147 of 332

STARTING AND OPERATING145

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when

towing while using a full size spare tire.

Proper tire inflation pressures are essential to

the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Úpage 286.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system

or vacuum system of your vehicle with that of

the trailer. This could cause inadequate braking

and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer with

electronically actuated brakes. When towing a trailer equipped with a hydraulic surge actuated

brake system, an electronic brake controller is

not required.

Trailer brakes are recommended for trailers

over 1,000 lb (453 kg) and required for trailers

in excess of 2,000 lb (907 kg).

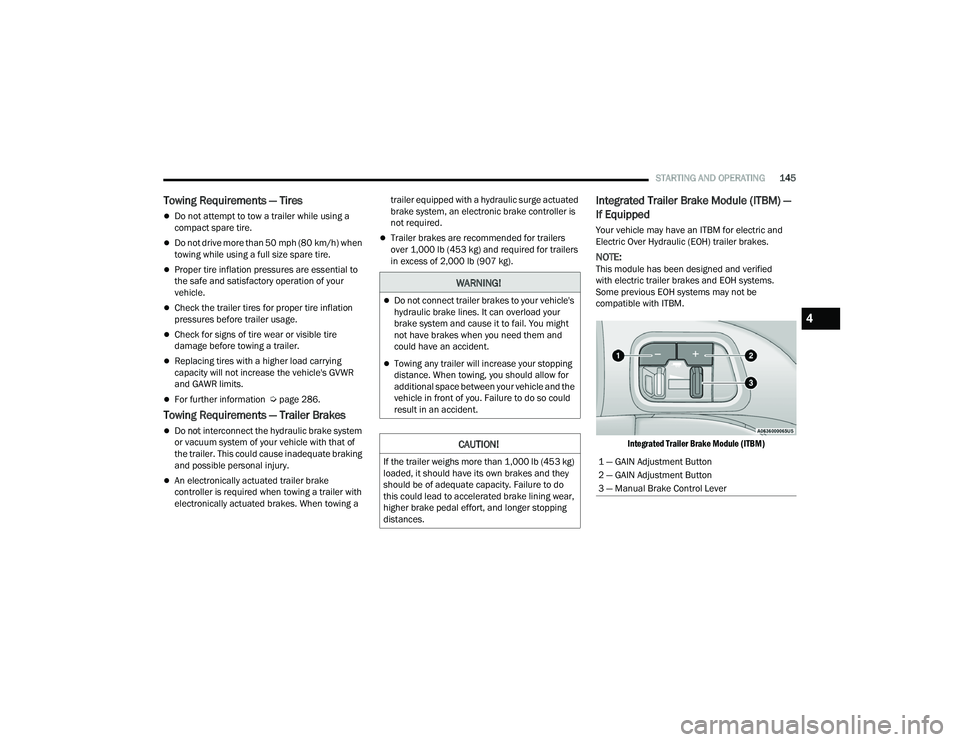

Integrated Trailer Brake Module (ITBM) —

If Equipped

Your vehicle may have an ITBM for electric and

Electric Over Hydraulic (EOH) trailer brakes.

NOTE:This module has been designed and verified

with electric trailer brakes and EOH systems.

Some previous EOH systems may not be

compatible with ITBM.

Integrated Trailer Brake Module (ITBM)

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your

brake system and cause it to fail. You might

not have brakes when you need them and

could have an accident.

Towing any trailer will increase your stopping

distance. When towing, you should allow for

additional space between your vehicle and the

vehicle in front of you. Failure to do so could

result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do

this could lead to accelerated brake lining wear,

higher brake pedal effort, and longer stopping

distances.1 — GAIN Adjustment Button

2 — GAIN Adjustment Button

3 — Manual Brake Control Lever

4

22_WD_OM_EN_USC_t.book Page 145

Page 291 of 332

SERVICING AND MAINTENANCE289

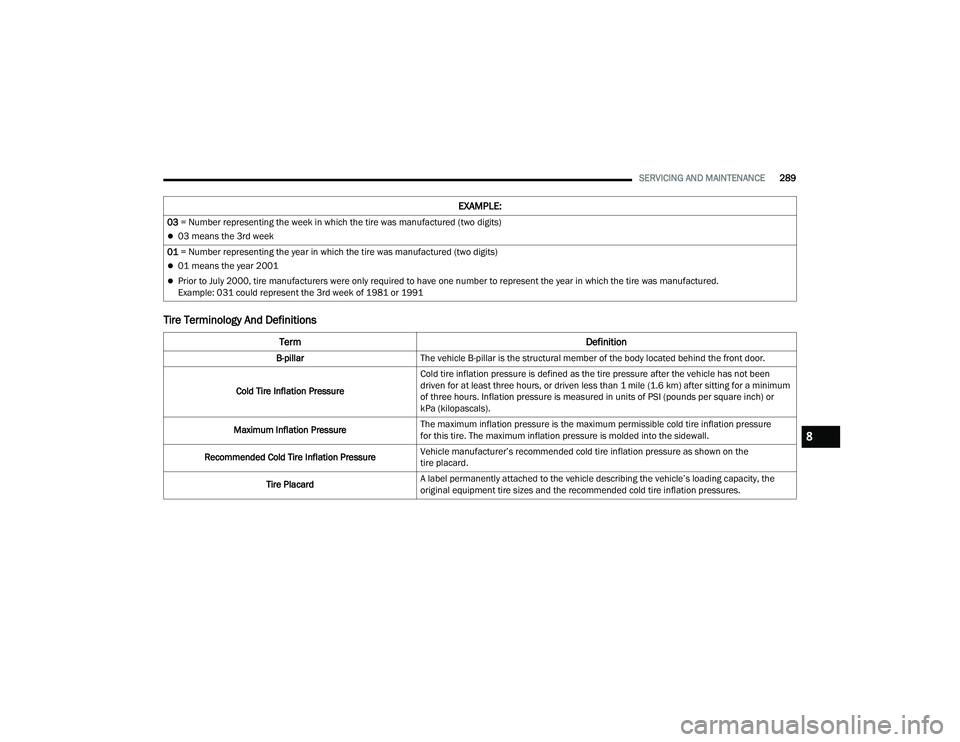

Tire Terminology And Definitions

03 = Number representing the week in which the tire was manufactured (two digits)

03 means the 3rd week

01 = Number representing the year in which the tire was manufactured (two digits)

01 means the year 2001

Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured.

Example: 031 could represent the 3rd week of 1981 or 1991

Term Definition

B-pillarThe vehicle B-pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum

of three hours. Inflation pressure is measured in units of PSI (pounds per square inch) or

kPa (kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire inflation pressure

for this tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation Pressure Vehicle manufacturer’s recommended cold tire inflation pressure as shown on the

tire placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

EXAMPLE:

8

22_WD_OM_EN_USC_t.book Page 289

Page 292 of 332

290SERVICING AND MAINTENANCE

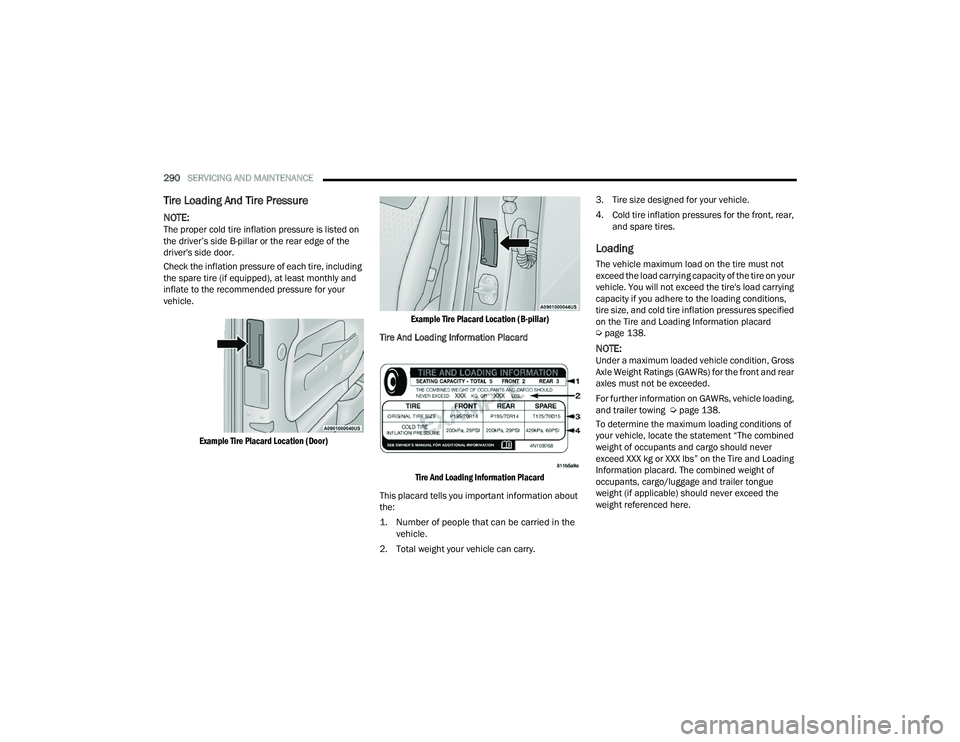

Tire Loading And Tire Pressure

NOTE:The proper cold tire inflation pressure is listed on

the driver’s side B-pillar or the rear edge of the

driver's side door.

Check the inflation pressure of each tire, including

the spare tire (if equipped), at least monthly and

inflate to the recommended pressure for your

vehicle.

Example Tire Placard Location (Door) Example Tire Placard Location (B-pillar)

Tire And Loading Information Placard

Tire And Loading Information Placard

This placard tells you important information about

the:

1. Number of people that can be carried in the vehicle.

2. Total weight your vehicle can carry. 3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear,

and spare tires.

Loading

The vehicle maximum load on the tire must not

exceed the load carrying capacity of the tire on your

vehicle. You will not exceed the tire's load carrying

capacity if you adhere to the loading conditions,

tire size, and cold tire inflation pressures specified

on the Tire and Loading Information placard

Úpage 138.

NOTE:Under a maximum loaded vehicle condition, Gross

Axle Weight Ratings (GAWRs) for the front and rear

axles must not be exceeded.

For further information on GAWRs, vehicle loading,

and trailer towing Ú page 138.

To determine the maximum loading conditions of

your vehicle, locate the statement “The combined

weight of occupants and cargo should never

exceed XXX kg or XXX lbs” on the Tire and Loading

Information placard. The combined weight of

occupants, cargo/luggage and trailer tongue

weight (if applicable) should never exceed the

weight referenced here.

22_WD_OM_EN_USC_t.book Page 290

Page 293 of 332

SERVICING AND MAINTENANCE291

Steps For Determining Correct Load

Limit—

(1) Locate the statement “The combined

weight of occupants and cargo should

never exceed XXX kg or XXX lbs.” on your

vehicle's placard.

(2) Determine the combined weight of

the driver and passengers that will be

riding in your vehicle.

(3) Subtract the combined weight of the

driver and passengers from XXX kg or

XXX lbs.

(4) The resulting figure equals the

available amount of cargo and luggage

load capacity. For example, if “XXX”

amount equals 1400 lbs. and there will

be five 150 lb passengers in your

vehicle, the amount of available cargo

and luggage load capacity is 650 lbs.

(1400-750 (5x150) = 650 lbs.) (5) Determine the combined weight of

luggage and cargo being loaded on the

vehicle. That weight may not safely

exceed the available cargo and luggage

load capacity calculated in Step 4.

(6) If your vehicle will be towing a trailer,

load from your trailer will be transferred

to your vehicle. Consult this manual to

determine how this reduces the

available cargo and luggage load

capacity of your vehicle.Metric Example For Load Limit

For example, if “XXX” amount equals 635 kg and

there will be five 68 kg passengers in your vehicle,

the amount of available cargo and luggage load

capacity is 295 kg (635-340 (5x68) = 295 kg) as

shown in step 4.

NOTE:

If your vehicle will be towing a trailer, load from

your trailer will be transferred to your vehicle.

The following table shows examples on how to

calculate total load, cargo/luggage, and towing

capacities of your vehicle with varying seating

configurations and number and size of occu

-

pants. This table is for illustration purposes only

and may not be accurate for the seating and

load carry capacity of your vehicle.

For the following example, the combined weight

of occupants and cargo should never exceed

865 lbs (392 kg).

8

22_WD_OM_EN_USC_t.book Page 291