brake fluid DODGE DURANGO 2023 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: DURANGO, Model: DODGE DURANGO 2023Pages: 328, PDF Size: 13.82 MB

Page 138 of 328

136STARTING AND OPERATING

VEHICLE LOADING

CERTIFICATION LABEL

As required by National Highway Traffic Safety

Administration regulations, your vehicle has a

certification label affixed to the driver's side door or

pillar.

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear (GAWR).

Total load must be limited so GVWR and front and

rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by

purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has not

been exceeded. The weight on the front and rear of

the vehicle should then be determined separately

to be sure that the load is properly distributed over

the front and rear axle. Weighing the vehicle may

show that the GAWR of either the front or rear axles

has been exceeded but the total load is within the

specified GVWR and maximum Payload. If so,

weight must be shifted from front to rear or rear to

front as appropriate until the specified weight

limitations are met. Store the heavier items down

low and be sure that the weight is distributed

equally. Stow all loose items securely before

driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

23_WD_OM_EN_USC_t.book Page 136

Page 152 of 328

150STARTING AND OPERATING

7. When the N (Neutral) indicator light turns off, release the N (Neutral) button.

8. After the N (Neutral) button has been released, the transfer case will shift to the position

indicated by the selector switch.

9. Shift the transmission into PARK and turn the

engine off.

10. Release the brake pedal.

11. Disconnect vehicle from the tow vehicle.

12. Start the engine.

13. Press and hold the brake pedal.

14. Release the parking brake.

15. Shift the transmission into REVERSE or DRIVE, release the brake pedal, and check that the

vehicle operates normally.

DRIVING TIPS

ON-ROAD DRIVING TIPS

Utility vehicles have higher ground clearance and a

narrower track to make them capable of

performing in a wide variety of off-road

applications. Specific design characteristics give

them a higher center of gravity than conventional

passenger cars. An advantage of the higher ground clearance is a

better view of the road, allowing you to anticipate

problems. They are not designed for cornering at

the same speeds as conventional passenger cars

any more than sports cars are designed to perform

satisfactorily in off-road conditions. Avoid sharp

turns or abrupt maneuvers. As with other vehicles

of this type, failure to operate this vehicle correctly

may result in loss of control or vehicle rollover.

OFF-ROAD DRIVING TIPS

When To Use 4WD Low — If Equipped

When off-road driving, shift to 4WD Low for

additional traction. This range should be limited to

extreme situations such as deep snow, mud, or

sand where additional low speed pulling power is

needed. Vehicle speeds in excess of 25 mph

(40 km/h) should be avoided when in 4WD Low.

Driving Through Water

Although your vehicle is capable of driving through

water, there are a number of precautions that

must be considered before entering the water.

Driving through water more than a few inches/

centimeters deep will require extra caution to

ensure safety and prevent damage to your vehicle.

If you must drive through water, try to determine

the depth and the bottom condition (and location

of any obstacles) prior to entering. Proceed with

caution and maintain a steady controlled speed

less than 5 mph (8 km/h) in deep water to

minimize wave effects.

WARNING!

Do not drive in 4WD Low on dry pavement;

driveline damage may result. 4WD Low locks

front and rear drivelines together and does not

allow for differential action between the front to

rear driveshafts. Driving in 4WD Low on

pavement will cause driveline binding; use only

on wet or slippery surfaces.

CAUTION!

When driving through water, do not exceed

5 mph (8 km/h). Always check water depth

before entering as a precaution, and check all

fluids afterward. Driving through water may

cause damage not covered by the New Vehicle

Limited Warranty.

23_WD_OM_EN_USC_t.book Page 150

Page 153 of 328

STARTING AND OPERATING151

Flowing Water

If the water is swift flowing and rising (as in storm

run-off), avoid crossing until the water level

recedes and/or the flow rate is reduced. If you

must cross flowing water avoid depths in excess of

9 inches (23 cm). The flowing water can erode the

streambed, causing your vehicle to sink into

deeper water. Determine exit point(s) that are

downstream of your entry point to allow for drifting.

Standing Water

Avoid driving in standing water deeper than

20 inches (51 cm), and reduce speed

appropriately to minimize wave effects. Maximum

speed in 20 inches (51 cm) of water is less than

5 mph (8 km/h).

Maintenance

After driving through deep water, inspect your

vehicle fluids and lubricants (engine oil,

transmission oil, axle, transfer case) to ensure the

fluids have not been contaminated. Contaminated

fluid (milky, foamy in appearance) should be

flushed/changed as soon as possible to prevent

component damage.

Driving In Snow, Mud And Sand

In heavy snow, when pulling a load, or for

additional control at slower speeds, shift the

transmission to a low gear and shift the transfer

case to AWD Low if necessary Ú page 108. Only

shift into a lower gear to maintain forward motion.

Over-revving the engine can spin the wheels and

traction will be lost.

Avoid abrupt downshifts on icy or slippery roads,

because engine braking may cause skidding and

loss of control.

Hill Climbing

NOTE:Before attempting to climb a hill, determine the

conditions at the crest and/or on the other side.

Before climbing a steep hill, shift the transmission

to a lower gear and shift the transfer case to AWD

Low. Use FIRST gear and AWD Low for very steep

hills. If you stall or begin to lose forward motion while

climbing a steep hill, allow your vehicle to come to

a stop and immediately apply the brakes. Restart

the engine, and shift into REVERSE. Back slowly

down the hill, allowing the compression braking of

the engine to help regulate the speed. If the brakes

are required to control vehicle speed, apply them

lightly and avoid locking or skidding the tires.

WARNING!

If the engine stalls, you lose forward motion, or

cannot make it to the top of a steep hill or grade,

never attempt to turn around. To do so may

result in tipping and rolling the vehicle. Always

back carefully straight down a hill in REVERSE

gear. Never back down a hill in NEUTRAL using

only the brake.4

23_WD_OM_EN_USC_t.book Page 151

Page 230 of 328

228SAFETY

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel or

brake fluid leaks are suspected, the cause should

be located and corrected immediately.

EXHAUST GAS

The best protection against carbon monoxide entry

into the vehicle body is a properly maintained

engine exhaust system.

Whenever a change is noticed in the sound of the

exhaust system, when exhaust fumes can be

detected inside the vehicle, or when the underside

or rear of the vehicle is damaged, have an

authorized dealer inspect the complete exhaust

system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts.

Open seams or loose connections could permit

exhaust fumes to seep into the passenger

compartment. In addition, inspect the exhaust

system each time the vehicle is raised for

lubrication or oil change. Replace as required.CARBON MONOXIDE WARNINGS

WARNING!

Exhaust gases can injure or kill. They contain

carbon monoxide (CO), which is colorless and

odorless. Breathing it can make you

unconscious and can eventually poison you. To

avoid breathing (CO), follow these safety tips:

Do not run the engine in a closed garage or in

confined areas any longer than needed to

move your vehicle in or out of the area.

If you are required to drive with the trunk/lift -

gate/rear doors open, make sure that all

windows are closed and the climate control

BLOWER switch is set at high speed. DO NOT

use the recirculation mode.

If it is necessary to sit in a parked vehicle with

the engine running, adjust your heating or

cooling controls to force outside air into the

vehicle. Set the blower at high speed.

WARNING!

Carbon monoxide (CO) in exhaust gases is

deadly. Follow the precautions below to prevent

carbon monoxide poisoning:

Do not inhale exhaust gases. They contain

carbon monoxide, a colorless and odorless

gas, which can kill. Never run the engine in a

closed area, such as a garage, and never sit in

a parked vehicle with the engine running for

an extended period. If the vehicle is stopped in

an open area with the engine running for more

than a short period, adjust the ventilation

system to force fresh, outside air into the

vehicle.

Guard against carbon monoxide with proper

maintenance. Have the exhaust system

inspected every time the vehicle is raised.

Have any abnormal conditions repaired

promptly. Until repaired, drive with all side

windows fully open.

23_WD_OM_EN_USC_t.book Page 228

Page 251 of 328

249

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, extremely hot or cold ambient

temperatures, and E85 fuel usage will influence

when the “Oil Change Required” message is

displayed. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check the tire pressure and look for unusual

wear or damage

Check the fluid levels of the coolant reservoir,

brake master cylinder and fill as needed

Check function of all interior and exterior lights

8

23_WD_OM_EN_USC_t.book Page 249

Page 253 of 328

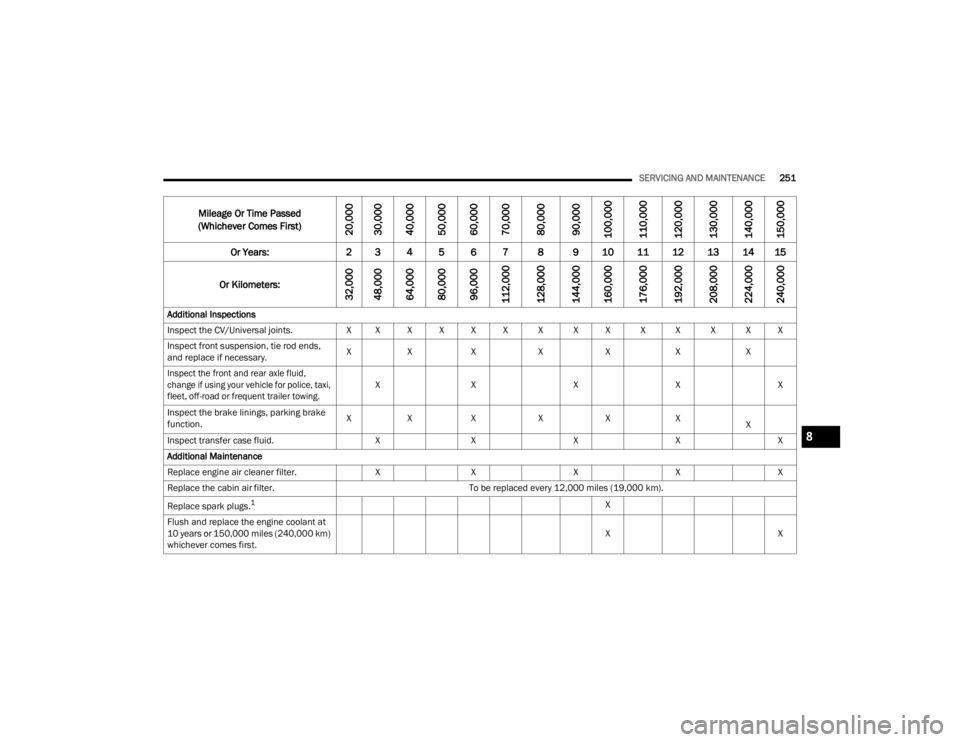

SERVICING AND MAINTENANCE251

Mileage Or Time Passed

(Whichever Comes First)

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

Or Years: 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Or Kilometers:

32,000

48,000

64,000

80,000

96,000

112,000

128,000

144,000

160,000

176,000

192,000

208,000

224,000

240,000

Additional Inspections

Inspect the CV/Universal joints. X X X X X X X X X X X X X X

Inspect front suspension, tie rod ends,

and replace if necessary. X

X X XX XX

Inspect the front and rear axle fluid,

change if using your vehicle for police, taxi,

fleet, off-road or frequent trailer towing.

X

X XXX

Inspect the brake linings, parking brake

function. X

X X XX X

X

Inspect transfer case fluid. XX XXX

Additional Maintenance

Replace engine air cleaner filter. XX XXX

Replace the cabin air filter. To be replaced every 12,000 miles (19,000 km).

Replace spark plugs.

1X

Flush and replace the engine coolant at

10 years or 150,000 miles (240,000 km)

whichever comes first. X

X

8

23_WD_OM_EN_USC_t.book Page 251

Page 255 of 328

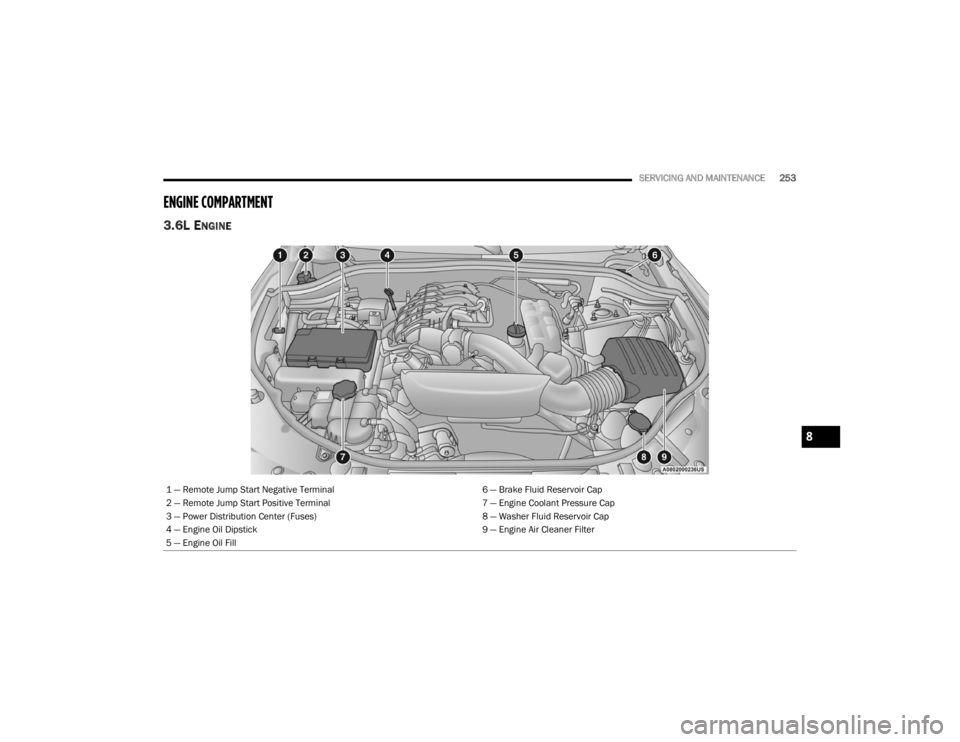

SERVICING AND MAINTENANCE253

ENGINE COMPARTMENT

3.6L ENGINE

1 — Remote Jump Start Negative Terminal 6 — Brake Fluid Reservoir Cap

2 — Remote Jump Start Positive Terminal 7 — Engine Coolant Pressure Cap

3 — Power Distribution Center (Fuses) 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Dipstick 9 — Engine Air Cleaner Filter

5 — Engine Oil Fill

8

23_WD_OM_EN_USC_t.book Page 253

Page 256 of 328

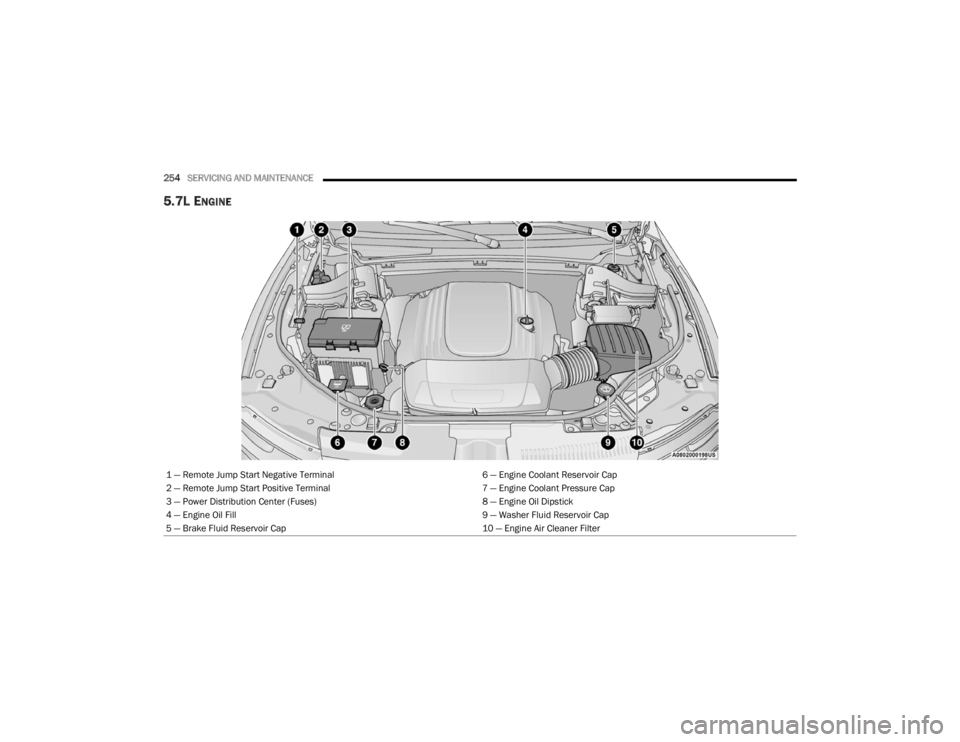

254SERVICING AND MAINTENANCE

5.7L ENGINE

1 — Remote Jump Start Negative Terminal 6 — Engine Coolant Reservoir Cap

2 — Remote Jump Start Positive Terminal 7 — Engine Coolant Pressure Cap

3 — Power Distribution Center (Fuses) 8 — Engine Oil Dipstick

4 — Engine Oil Fill 9 — Washer Fluid Reservoir Cap

5 — Brake Fluid Reservoir Cap 10 — Engine Air Cleaner Filter

23_WD_OM_EN_USC_t.book Page 254

Page 270 of 328

268SERVICING AND MAINTENANCE

(Continued)

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces-

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Ú page 250.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked whenever the vehicle is serviced, or

immediately if the Brake System Warning Light is

on. If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the top

of the master cylinder area before removing cap.

With disc brakes, fluid level can be expected to fall

as the brake pads wear. Brake fluid level should be

checked when pads are replaced. If the brake fluid

is abnormally low, check the system for leaks. For

further information Ú page 307.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only the manufacturer’s recommended

brake fluid Úpage 307. Using the wrong type

of brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

23_WD_OM_EN_USC_t.book Page 268

Page 309 of 328

TECHNICAL SPECIFICATIONS307

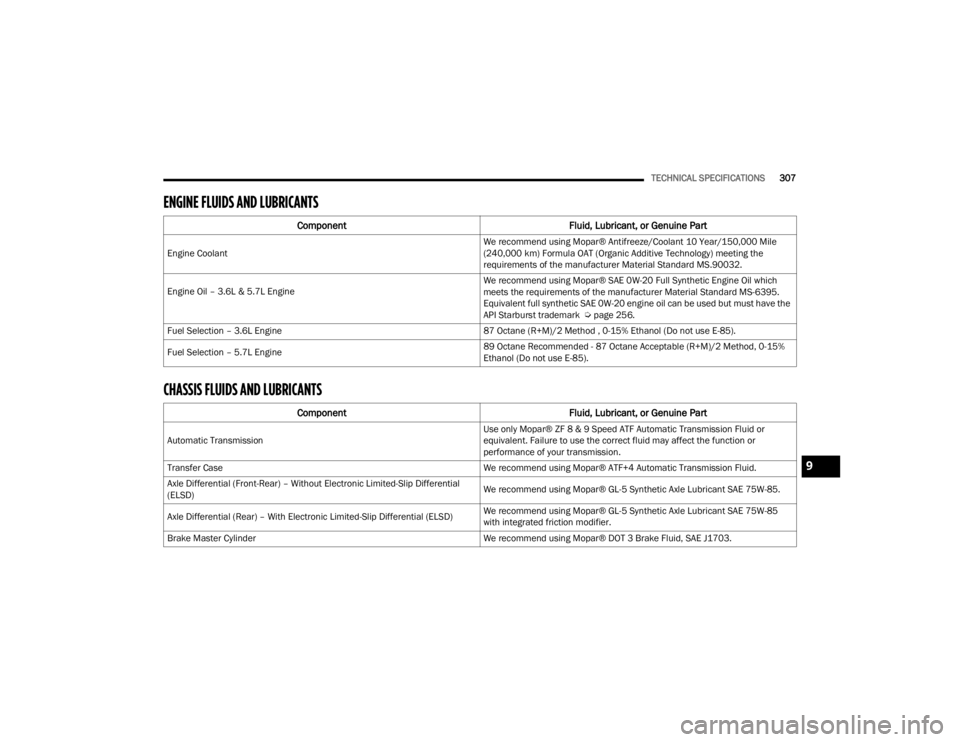

ENGINE FLUIDS AND LUBRICANTS

CHASSIS FLUIDS AND LUBRICANTS

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend using Mopar® Antifreeze/Coolant 10 Year/150,000 Mile

(240,000 km) Formula OAT (Organic Additive Technology) meeting the

requirements of the manufacturer Material Standard MS.90032.

Engine Oil – 3.6L & 5.7L Engine

We recommend using Mopar® SAE 0W-20 Full Synthetic Engine Oil which

meets the requirements of the manufacturer Material Standard MS-6395.

Equivalent full synthetic SAE 0W-20 engine oil can be used but must have the

API Starburst trademark Ú

page 256.

Fuel Selection – 3.6L Engine 87 Octane (R+M)/2 Method , 0-15% Ethanol (Do not use E-85).

Fuel Selection – 5.7L Engine 89 Octane Recommended - 87 Octane Acceptable (R+M)/2 Method, 0-15%

Ethanol (Do not use E-85).

Component

Fluid, Lubricant, or Genuine Part

Automatic Transmission Use only Mopar® ZF 8 & 9 Speed ATF Automatic Transmission Fluid or

equivalent. Failure to use the correct fluid may affect the function or

performance of your transmission.

Transfer Case We recommend using Mopar® ATF+4 Automatic Transmission Fluid.

Axle Differential (Front-Rear) – Without Electronic Limited-Slip Differential

(ELSD) We recommend using Mopar® GL-5 Synthetic Axle Lubricant SAE 75W-85.

Axle Differential (Rear) – With Electronic Limited-Slip Differential (ELSD) We recommend using Mopar® GL-5 Synthetic Axle Lubricant SAE 75W-85

with integrated friction modifier.

Brake Master Cylinder We recommend using Mopar® DOT 3 Brake Fluid, SAE J1703.

9

23_WD_OM_EN_USC_t.book Page 307