tow bar DODGE DURANGO 2023 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: DURANGO, Model: DODGE DURANGO 2023Pages: 328, PDF Size: 13.82 MB

Page 5 of 328

3

EXTERIOR LIGHTS.................................................. 45 Multifunction Lever ..........................................45

Headlight Switch ..............................................45

Daytime Running Lights (DRLs) ......................46

High/Low Beam Switch....................................46

Automatic High Beam — If Equipped ..............47

Flash-To-Pass....................................................47

Automatic Headlights ......................................47

Parking Lights And Panel Lights ......................47

Automatic Headlights With Wipers..................47

Headlight Delay ................................................48

Lights-On Reminder..........................................48

Fog Lights — If Equipped ..................................48

Turn Signals ......................................................48

Lane Change Assist — If Equipped ..................48

Automatic Headlight Leveling — If Equipped ..49

Battery Saver ....................................................49

INTERIOR LIGHTS ................................................. 49

Courtesy Lights .................................................49

Front Map/Reading Lights —If Equipped ........49

Ambient Light — If Equipped ............................50

Dimmer Control ................................................50

Illuminated Entry ..............................................51

WINDSHIELD WIPERS AND WASHERS .............. 51

Windshield Wiper Operation ...........................51

Rain Sensing Wipers — If Equipped ...............52

Rear Window Wiper/Washer ..........................53 CLIMATE CONTROLS..............................................53

Automatic Climate Control Descriptions

And Functions ...................................................53

Automatic Temperature Control (ATC) ............59

Climate Voice Recognition ...............................59

Operating Tips .................................................60

INTERIOR STORAGE AND EQUIPMENT ............... 61

Storage..............................................................61

USB/AUX Control .............................................63

Lighted Cupholders — If Equipped ..................65

Electrical Power Outlets ...................................65

Power Inverter — If Equipped ..........................67

Wireless Charging Pad —If Equipped .............68

WINDOWS ..............................................................68

Power Windows ................................................68

Wind Buffeting .................................................70

POWER SUNROOF — IF EQUIPPED ...................... 70

Opening And Closing The Sunroof...................70

Sunshade Operation ........................................71

Pinch Protect Feature ......................................71

Sunroof Maintenance ......................................71

Ignition Off Operation.......................................71

HOOD .......................................................................71

Opening The Hood............................................71

Closing The Hood .............................................72

LIFTGATE ................................................................. 72

Power Liftgate — If Equipped ...........................72

Cargo Area Features .......................................73

ROOF LUGGAGE RACK — IF EQUIPPED ............... 74

Deploying The Crossbars .................................75

Stowing The Crossbars ....................................76

GETTING TO KNOW YOUR

INSTRUMENT PANEL

INSTRUMENT CLUSTER ........................................ 78Instrument Cluster Descriptions ..................... 79

INSTRUMENT CLUSTER DISPLAY ........................ 79

Location And Controls...................................... 80

Engine Oil Life Reset ....................................... 82

Display And Messages ..................................... 83

Instrument Cluster Display Menu Items ........ 84

Battery Saver On/Battery Saver Mode

Message — Electrical Load Reduction

Actions — If Equipped ..................................... 87

WARNING LIGHTS AND MESSAGES ................... 88

Red Warning Lights ..........................................88

Yellow Warning Lights ...................................... 91

Yellow Indicator Lights ..................................... 94

Green Indicator Lights ..................................... 94

White Indicator Lights ...................................... 95

Blue Indicator Lights ........................................ 95

ONBOARD DIAGNOSTIC SYSTEM — OBD II ....... 96

Onboard Diagnostic System

(OBD II) Cybersecurity ...................................... 96

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS ........................................................... 96

23_WD_OM_EN_USC_t.book Page 3

Page 57 of 328

GETTING TO KNOW YOUR VEHICLE55

Driver And Passenger Temperature

Buttons

These buttons provide the driver and passenger

with independent temperature control.

Push the Up button on the faceplate or

press and slide the temperature bar

towards the red arrow button on the

touchscreen for warmer temperature

settings.

Push the Down button on the faceplate or

press and slide the temperature bar

towards the blue arrow button on the

touchscreen for cooler temperature

settings.

SYNC Button

Press the SYNC button on the

touchscreen to toggle the SYNC feature

on/off. The SYNC indicator illuminates

when SYNC is on. SYNC is used to

synchronize the front passenger temperature and

rear passenger temperature, mode, and blower

settings with the driver temperature, mode, and

blower settings. Changing the front passenger

temperature or rear passenger temperature,

mode, and blower settings while in SYNC will

automatically exit this feature.

NOTE:The SYNC setting is only available on the touch -

screen.

Blower Control

Blower Control is used to regulate the

amount of air forced through the Climate

Control system. There are seven blower

speeds available. Adjusting the blower

will cause automatic mode to switch to manual

operation. The speeds can be selected using either

the blower control knob on the faceplate or the

buttons on the touchscreen.

Faceplate: The blower speed increases as you

turn the blower control knob clockwise from the

lowest blower setting. The blower speed

decreases as you turn the blower control knob

counterclockwise.

Touchscreen: Use the small blower icon to

reduce the blower setting and the large blower

icon to increase the blower setting. Blower

speed can also be selected by pressing the

blower bar area between the icons.

Mode Control

Select Mode by pressing the Mode

button on the faceplate, or one of the

Mode buttons on the touchscreen to

change the airflow distribution mode.

The airflow distribution mode can be adjusted so

air comes from the instrument panel outlets, floor

outlets, defrost outlets and demist outlets.

Panel Mode

Air comes from the outlets in the

instrument panel. Each of these outlets

can be individually adjusted to direct the

flow of air. The air vanes of the center

outlets and outboard outlets can be moved up and

down or side to side to regulate airflow direction.

There is a shut-off wheel located below the air

vanes to shut off or adjust the amount of airflow

from these outlets.

Do not use scrapers, sharp instruments, or

abrasive window cleaners on the interior

surface of the window.

Keep all objects a safe distance from the

window.

CAUTION!

2

23_WD_OM_EN_USC_t.book Page 55

Page 76 of 328

74GETTING TO KNOW YOUR VEHICLE

(Continued)

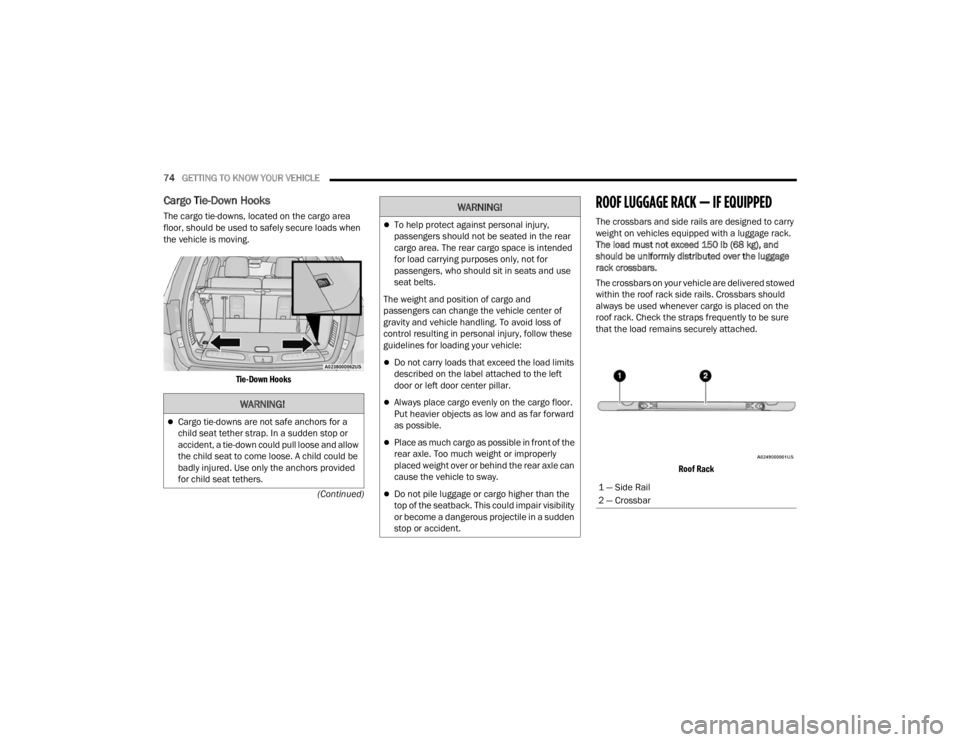

Cargo Tie-Down Hooks

The cargo tie-downs, located on the cargo area

floor, should be used to safely secure loads when

the vehicle is moving.

Tie-Down Hooks

ROOF LUGGAGE RACK — IF EQUIPPED

The crossbars and side rails are designed to carry

weight on vehicles equipped with a luggage rack.

The load must not exceed 150 lb (68 kg), and

should be uniformly distributed over the luggage

rack crossbars.

The crossbars on your vehicle are delivered stowed

within the roof rack side rails. Crossbars should

always be used whenever cargo is placed on the

roof rack. Check the straps frequently to be sure

that the load remains securely attached.

Roof Rack

WARNING!

Cargo tie-downs are not safe anchors for a

child seat tether strap. In a sudden stop or

accident, a tie-down could pull loose and allow

the child seat to come loose. A child could be

badly injured. Use only the anchors provided

for child seat tethers.

To help protect against personal injury,

passengers should not be seated in the rear

cargo area. The rear cargo space is intended

for load carrying purposes only, not for

passengers, who should sit in seats and use

seat belts.

The weight and position of cargo and

passengers can change the vehicle center of

gravity and vehicle handling. To avoid loss of

control resulting in personal injury, follow these

guidelines for loading your vehicle:

Do not carry loads that exceed the load limits

described on the label attached to the left

door or left door center pillar.

Always place cargo evenly on the cargo floor.

Put heavier objects as low and as far forward

as possible.

Place as much cargo as possible in front of the

rear axle. Too much weight or improperly

placed weight over or behind the rear axle can

cause the vehicle to sway.

Do not pile luggage or cargo higher than the

top of the seatback. This could impair visibility

or become a dangerous projectile in a sudden

stop or accident.

WARNING!

1 — Side Rail

2 — Crossbar

23_WD_OM_EN_USC_t.book Page 74

Page 77 of 328

GETTING TO KNOW YOUR VEHICLE75

The roof rack does not increase the total load

carrying capacity of the vehicle. Be sure the total

load of cargo inside the vehicle plus that on the

external rack does not exceed the maximum

vehicle load capacity.

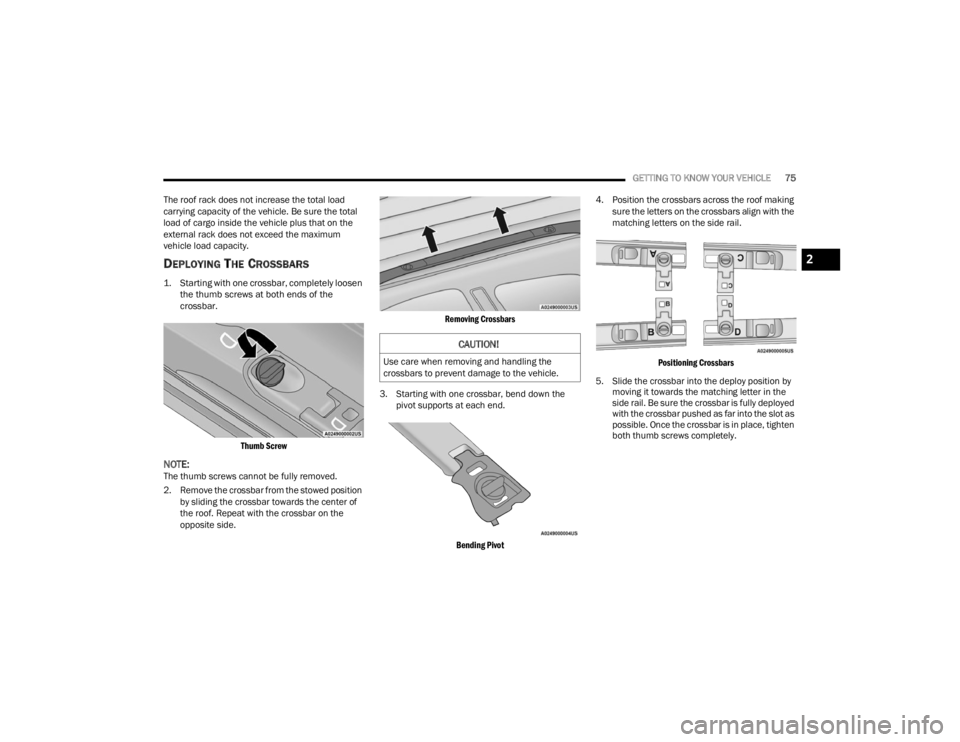

DEPLOYING THE CROSSBARS

1. Starting with one crossbar, completely loosen the thumb screws at both ends of the

crossbar.

Thumb Screw

NOTE:The thumb screws cannot be fully removed.

2. Remove the crossbar from the stowed position by sliding the crossbar towards the center of

the roof. Repeat with the crossbar on the

opposite side.

Removing Crossbars

3. Starting with one crossbar, bend down the pivot supports at each end.

Bending Pivot

4. Position the crossbars across the roof making

sure the letters on the crossbars align with the

matching letters on the side rail.

Positioning Crossbars

5. Slide the crossbar into the deploy position by moving it towards the matching letter in the

side rail. Be sure the crossbar is fully deployed

with the crossbar pushed as far into the slot as

possible. Once the crossbar is in place, tighten

both thumb screws completely.

CAUTION!

Use care when removing and handling the

crossbars to prevent damage to the vehicle.

2

23_WD_OM_EN_USC_t.book Page 75

Page 78 of 328

76GETTING TO KNOW YOUR VEHICLE

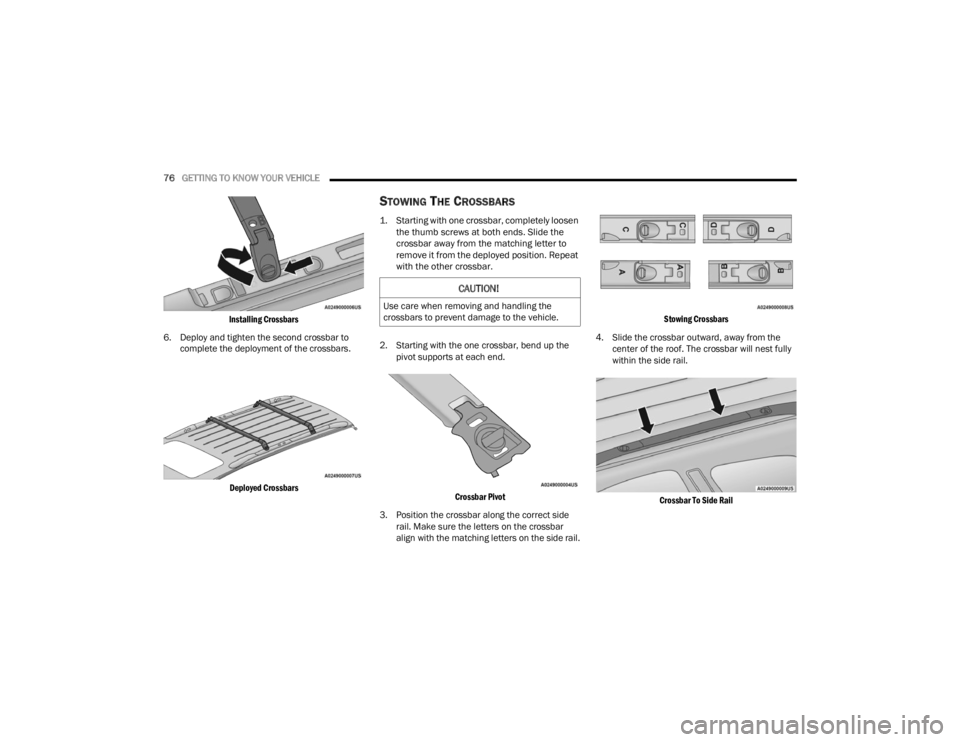

Installing Crossbars

6. Deploy and tighten the second crossbar to complete the deployment of the crossbars.

Deployed Crossbars

STOWING THE CROSSBARS

1. Starting with one crossbar, completely loosen the thumb screws at both ends. Slide the

crossbar away from the matching letter to

remove it from the deployed position. Repeat

with the other crossbar.

2. Starting with the one crossbar, bend up the pivot supports at each end.

Crossbar Pivot

3. Position the crossbar along the correct side rail. Make sure the letters on the crossbar

align with the matching letters on the side rail.

Stowing Crossbars

4. Slide the crossbar outward, away from the center of the roof. The crossbar will nest fully

within the side rail.

Crossbar To Side Rail

CAUTION!

Use care when removing and handling the

crossbars to prevent damage to the vehicle.

23_WD_OM_EN_USC_t.book Page 76

Page 79 of 328

GETTING TO KNOW YOUR VEHICLE77

(Continued)

5. Once the driver’s side crossbar is in place,

tighten the thumb screws completely.

Tightening Crossbar

6. Repeat the procedure to stow the second crossbar on the opposite side.

Stowed Crossbars

NOTE:

To help control wind noise, stow the crossbars in

the side rails when they are not in use.

If any metallic object is placed over the satellite

radio antenna (if equipped), you may experience

interruption of satellite radio reception.

WARNING!

Cargo must be securely tied down before driving

your vehicle. Improperly secured loads can fly off

the vehicle, particularly at high speeds, resulting

in personal injury or property damage. Follow

the roof rack cautions when carrying cargo on

your roof rack.

CAUTION!

To prevent damage to the roof of your vehicle,

DO NOT carry any loads on the roof rack

without the crossbars deployed. The load

should be secured and placed on top of the

crossbars, not directly on the roof. If it is

necessary to place the load on the roof, place

a blanket or other protective layer between

the load and the roof surface.

To avoid damage to the roof rack and vehicle,

do not exceed the maximum roof rack load

capacity of 150 lb (68 kg). Always distribute

heavy loads as evenly as possible and secure

the load appropriately.

Load should always be secured to crossbars

first, with tie down loops used as additional

securing points if needed. Tie loops are

intended as supplementary tie down points

only. Do not use ratcheting mechanisms with

the tie loops. Check the straps and thumb

wheels frequently to be sure that the load

remains securely attached.

Long loads that extend over the windshield,

such as wood panels or surfboards, or loads

with large frontal area should be secured to

both the front and rear of the vehicle.

Travel at reduced speeds and turn corners

carefully when carrying large or heavy loads

on the roof rack. Wind forces, due to natural

causes or nearby truck traffic, can add sudden

upward lift to a load. This is especially true on

large flat loads and may result in damage to

the cargo or your vehicle.

CAUTION!

2

23_WD_OM_EN_USC_t.book Page 77

Page 138 of 328

136STARTING AND OPERATING

VEHICLE LOADING

CERTIFICATION LABEL

As required by National Highway Traffic Safety

Administration regulations, your vehicle has a

certification label affixed to the driver's side door or

pillar.

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear (GAWR).

Total load must be limited so GVWR and front and

rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by

purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has not

been exceeded. The weight on the front and rear of

the vehicle should then be determined separately

to be sure that the load is properly distributed over

the front and rear axle. Weighing the vehicle may

show that the GAWR of either the front or rear axles

has been exceeded but the total load is within the

specified GVWR and maximum Payload. If so,

weight must be shifted from front to rear or rear to

front as appropriate until the specified weight

limitations are met. Store the heavier items down

low and be sure that the weight is distributed

equally. Stow all loose items securely before

driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

23_WD_OM_EN_USC_t.book Page 136

Page 140 of 328

138STARTING AND OPERATING

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and the

trailer axle(s). When used in accordance with the

manufacturer's directions, it provides for a more

level ride, offering more consistent steering and

brake control thereby enhancing towing safety. The

addition of a friction/hydraulic sway control also

dampens sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer

stability. Trailer Sway Control (TSC) and a weight

distributing (load equalizing) hitch are

recommended for heavier Tongue Weights (TW) and

may be required depending on vehicle and trailer

configuration/loading to comply with Gross Axle

Weight Rating (GAWR) requirements.

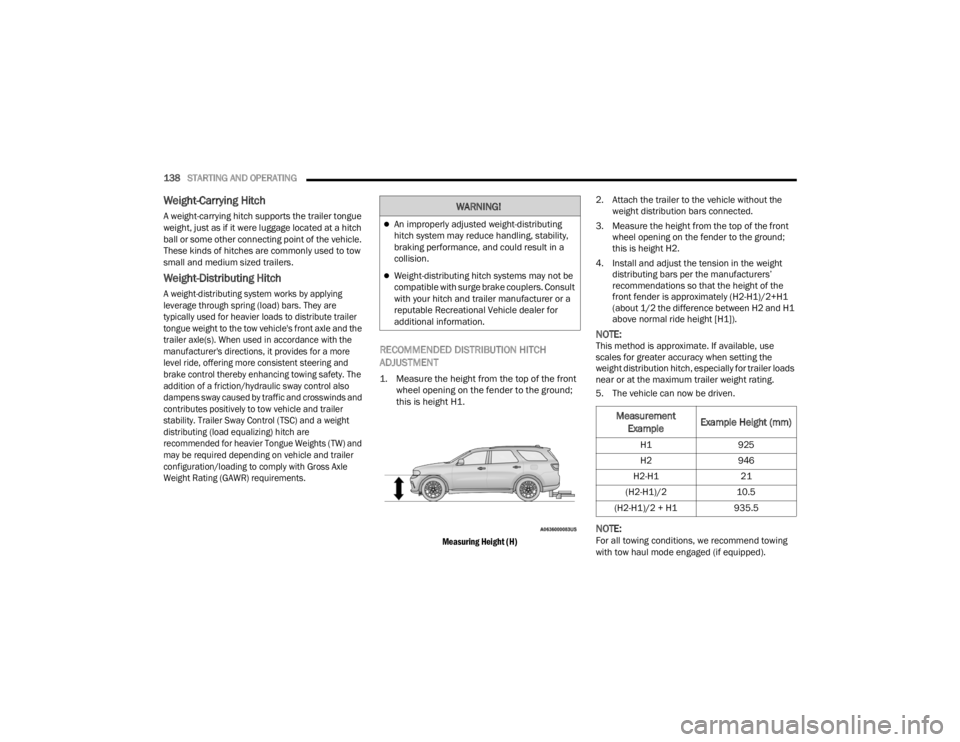

RECOMMENDED DISTRIBUTION HITCH

ADJUSTMENT

1. Measure the height from the top of the front

wheel opening on the fender to the ground;

this is height H1.

Measuring Height (H)

2. Attach the trailer to the vehicle without the

weight distribution bars connected.

3. Measure the height from the top of the front wheel opening on the fender to the ground;

this is height H2.

4. Install and adjust the tension in the weight distributing bars per the manufacturers’

recommendations so that the height of the

front fender is approximately (H2-H1)/2+H1

(about 1/2 the difference between H2 and H1

above normal ride height [H1]).

NOTE:This method is approximate. If available, use

scales for greater accuracy when setting the

weight distribution hitch, especially for trailer loads

near or at the maximum trailer weight rating.

5. The vehicle can now be driven.

NOTE:For all towing conditions, we recommend towing

with tow haul mode engaged (if equipped).

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability,

braking performance, and could result in a

collision.

Weight-distributing hitch systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

Measurement

Example Example Height (mm)

H1

925

H2 946

H2-H1 21

(H2-H1)/2 10.5

(H2-H1)/2 + H1 935.5

23_WD_OM_EN_USC_t.book Page 138

Page 150 of 328

148STARTING AND OPERATING

Shifting Into N (Neutral)

Use the following procedure to prepare your

vehicle for recreational towing.

1. Bring the vehicle to a complete stop on level

ground, with the engine running.

2. Press and hold the brake pedal.

3. Shift the transmission into NEUTRAL.

NOTE:

Steps 1 through 3 are requirements that

must be met before pushing the N (Neutral)

button, and must continue to be met until

the shift has been completed. If any of

these requirements are not met before

pushing the N (Neutral) button or are no

longer met during the shift, the N (Neutral)

indicator light will flash continuously until all

requirements are met or until the N

(Neutral) button is released.

The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the ignition

is not in the ON/RUN mode, the shift will not

take place and no position indicator lights

will be on or flashing.

A flashing N (Neutral) position indicator light

indicates that shift requirements have not

been met.

4. Using a ballpoint pen or similar object, push and hold the recessed transfer case N

(Neutral) button (located by the selector

switch) for four seconds. The light behind the N

symbol will blink, indicating shift in progress.

The light will stop blinking (stay on solid) when

the shift to N (Neutral) is complete. A “FOUR

WHEEL DRIVE SYSTEM IN NEUTRAL” message

will appear in the instrument cluster.

CAUTION!

DO NOT dolly tow any AWD vehicle. Towing

with only one set of wheels on the ground

(front or rear) will cause severe transmission

and/or transfer case damage. Tow with all

four wheels either ON the ground, or OFF the

ground (using a vehicle trailer).

Tow only in the forward direction. Towing this

vehicle backwards can cause severe damage

to the transfer case.

The transmission must be in PARK for recre -

ational towing.

Before recreational towing, be certain that the

transfer case is fully in N (Neutral)

Ú page 148. Otherwise, internal damage will

result.

Towing this vehicle in violation of the above

requirements can cause severe transmission

and/or transfer case damage. Damage from

improper towing is not covered under the New

Vehicle Limited Warranty.

Do not use a bumper-mounted clamp-on tow

bar on your vehicle. The bumper face bar will

be damaged.

WARNING!

You or others could be injured or killed if you

leave the vehicle unattended with the transfer

case in the N (Neutral) position without first fully

engaging the parking brake. The transfer case N

(Neutral) position disengages both the front and

rear driveshafts from the powertrain and will

allow the vehicle to roll, even if the transmission

is in PARK. The parking brake should always be

applied when the driver is not in the vehicle.

CAUTION!

It is necessary to follow these steps to be certain

that the transfer case is fully in N (Neutral)

before recreational towing to prevent damage to

internal parts.

23_WD_OM_EN_USC_t.book Page 148

Page 151 of 328

STARTING AND OPERATING149

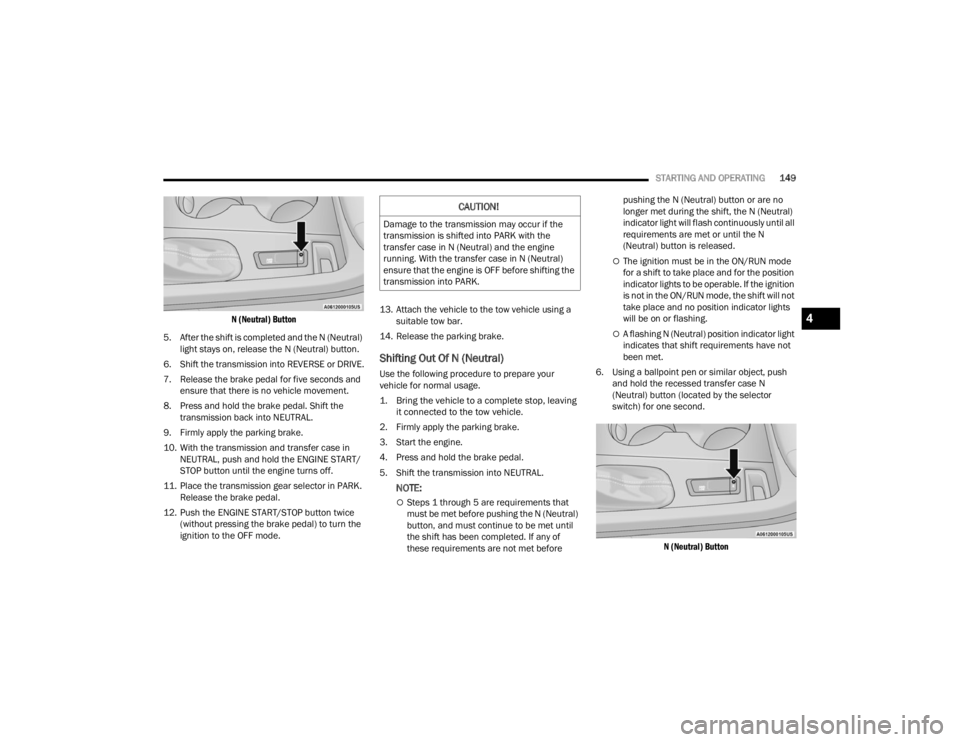

N (Neutral) Button

5. After the shift is completed and the N (Neutral) light stays on, release the N (Neutral) button.

6. Shift the transmission into REVERSE or DRIVE.

7. Release the brake pedal for five seconds and ensure that there is no vehicle movement.

8. Press and hold the brake pedal. Shift the transmission back into NEUTRAL.

9. Firmly apply the parking brake.

10. With the transmission and transfer case in NEUTRAL, push and hold the ENGINE START/

STOP button until the engine turns off.

11. Place the transmission gear selector in PARK. Release the brake pedal.

12. Push the ENGINE START/STOP button twice (without pressing the brake pedal) to turn the

ignition to the OFF mode. 13. Attach the vehicle to the tow vehicle using a

suitable tow bar.

14. Release the parking brake.

Shifting Out Of N (Neutral)

Use the following procedure to prepare your

vehicle for normal usage.

1. Bring the vehicle to a complete stop, leaving it connected to the tow vehicle.

2. Firmly apply the parking brake.

3. Start the engine.

4. Press and hold the brake pedal.

5. Shift the transmission into NEUTRAL.

NOTE:

Steps 1 through 5 are requirements that

must be met before pushing the N (Neutral)

button, and must continue to be met until

the shift has been completed. If any of

these requirements are not met before pushing the N (Neutral) button or are no

longer met during the shift, the N (Neutral)

indicator light will flash continuously until all

requirements are met or until the N

(Neutral) button is released.

The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the ignition

is not in the ON/RUN mode, the shift will not

take place and no position indicator lights

will be on or flashing.

A flashing N (Neutral) position indicator light

indicates that shift requirements have not

been met.

6. Using a ballpoint pen or similar object, push and hold the recessed transfer case N

(Neutral) button (located by the selector

switch) for one second.

N (Neutral) Button

CAUTION!

Damage to the transmission may occur if the

transmission is shifted into PARK with the

transfer case in N (Neutral) and the engine

running. With the transfer case in N (Neutral)

ensure that the engine is OFF before shifting the

transmission into PARK.

4

23_WD_OM_EN_USC_t.book Page 149